EP0476718B2 - Dispositif pour piquer des produits d'imprimerie à plusieurs parties - Google Patents

Dispositif pour piquer des produits d'imprimerie à plusieurs parties Download PDFInfo

- Publication number

- EP0476718B2 EP0476718B2 EP91119133A EP91119133A EP0476718B2 EP 0476718 B2 EP0476718 B2 EP 0476718B2 EP 91119133 A EP91119133 A EP 91119133A EP 91119133 A EP91119133 A EP 91119133A EP 0476718 B2 EP0476718 B2 EP 0476718B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- wire

- heads

- stapler

- supports

- stapling

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000000284 resting effect Effects 0.000 claims description 3

- 210000003128 head Anatomy 0.000 description 97

- 230000006835 compression Effects 0.000 description 18

- 238000007906 compression Methods 0.000 description 18

- 238000005452 bending Methods 0.000 description 12

- 238000003825 pressing Methods 0.000 description 6

- 238000007639 printing Methods 0.000 description 5

- 230000008878 coupling Effects 0.000 description 3

- 238000010168 coupling process Methods 0.000 description 3

- 238000005859 coupling reaction Methods 0.000 description 3

- 230000008719 thickening Effects 0.000 description 3

- 238000012546 transfer Methods 0.000 description 3

- 230000009471 action Effects 0.000 description 2

- 238000013459 approach Methods 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 125000006850 spacer group Chemical group 0.000 description 2

- 238000012549 training Methods 0.000 description 2

- 238000011144 upstream manufacturing Methods 0.000 description 2

- 238000003462 Bender reaction Methods 0.000 description 1

- 206010034016 Paronychia Diseases 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 210000001520 comb Anatomy 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 210000001331 nose Anatomy 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000002123 temporal effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42B—PERMANENTLY ATTACHING TOGETHER SHEETS, QUIRES OR SIGNATURES OR PERMANENTLY ATTACHING OBJECTS THERETO

- B42B4/00—Permanently attaching together sheets, quires or signatures by discontinuous stitching with filamentary material, e.g. wire

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42B—PERMANENTLY ATTACHING TOGETHER SHEETS, QUIRES OR SIGNATURES OR PERMANENTLY ATTACHING OBJECTS THERETO

- B42B4/00—Permanently attaching together sheets, quires or signatures by discontinuous stitching with filamentary material, e.g. wire

- B42B4/02—Rotary type stitching machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42C—BOOKBINDING

- B42C1/00—Collating or gathering sheets combined with processes for permanently attaching together sheets or signatures or for interposing inserts

- B42C1/12—Machines for both collating or gathering and permanently attaching together the sheets or signatures

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H5/00—Feeding articles separated from piles; Feeding articles to machines

- B65H5/32—Saddle-like members over which partially-unfolded sheets or signatures are fed to signature-gathering, stitching, or like machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/43—Gathering; Associating; Assembling

- B65H2301/436—Gathering; Associating; Assembling on saddles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/43—Gathering; Associating; Assembling

- B65H2301/436—Gathering; Associating; Assembling on saddles

- B65H2301/4361—Gathering; Associating; Assembling on saddles on a rotary carrier rotating around an axis parallel to the saddles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/44—Moving, forwarding, guiding material

- B65H2301/447—Moving, forwarding, guiding material transferring material between transport devices

- B65H2301/44795—Saddle conveyor with saddle member extending transversally to transport direction

Definitions

- the present invention relates to a device for Wire stitching of multi-part folded printed matter according to the preamble of claim 1.

- Such a device is known from DE-A-36 16 566.

- the latter are marked by these cushions with their fold line perpendicular to the direction of circulation of the supports conveyed through a stitching area.

- a stapler arranged, which a number of stapling heads for Set the wire clips.

- the stitching heads are in the Distance between the parallel runs on one bracket pivotable about the axis of rotation of the supports arranged.

- the stirrup is swung around by means of a swivel drive moved here, the stitching heads each during the temporal short synchronization with the editions at the same time one Brackets in the resting on the pads Put printed products.

- the structure of the stitching heads itself is in DE-A-36 16 566 on CH-A-549 443 referenced, which can be inferred from each stitching head one wire each is fed, of which by means of a Stapling head arranged separator each Wire section is separated.

- This wire section will by means of a slide-mounted stamp around a die a clamp bent, which can also be pushed by means of a stored plunger pressed out of the stamp into the Printed products used and then through in the Requirements arranged bender is closed.

- the swivel drive designed as a sliding crank gear for Has stapling heads especially at high processing speeds great acceleration and deceleration forces to apply.

- the rotating pads and oscillating stitch heads meet in every work cycle - kinematically-only especially during a short movement path in synchronism, during which the brackets must be placed.

- DE-A-32 03 376 describes a stapling device at of the products to be stapled between each interacting Clamp setting elements and clamp bending elements be passed through.

- the clamp setting elements and the Bracket bending elements are each on an endless, all-round driven chain attached, one strand parallel to the Direction of movement of products and adjacent to Trajectory of the latter runs.

- the clamp setting elements and the latter facing each other during the stapling process Clamp bending elements run synchronously with the stapling Products with.

- This stapling device is relatively complex Construction, three round trips are necessary, namely one for the patrices feeding the straight pieces of wire, one for the cooperating with the latter to form the brackets Clamp setting elements and one for the clamp bending elements.

- the brackets are used along an in Direction of movement of the products set.

- US-A-4,792,077 is now a simplified version of the Device described above, in which only two more chain runs are provided.

- the chains of the Round trips are guided over deflection wheels and lie with each other opposite a section lying between the deflection wheels.

- the chain of a chain run runs on one Wire section dispenser over, with certain chain links straight wire sections are passed that are in Extend the direction of rotation of the chain.

- the ones to be stapled Products are conveyed to the two by means of a feeder Chain runs fed and between the two themselves opposite sections of the two chain circuits introduced.

- the products are then transported further by clamping between the limbs of the two Chain runs, with the products also folded become.

- the chain circuits thus take over Multiple task of folding, setting wire clips and forward transport.

- the present invention is based on the object of a device for wire-stitching multi-part To create printed products that are simple and reliable Allows stapling of the products.

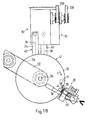

- FIG. 1 shows a collecting drum 10 as described in detail in the subsequently published EP-A-0 341 425 is.

- This collecting drum 10 is arranged around a common rotation axis 12 in Saddle-shaped supports 14 running in the direction of the rotational axis 12 and driven in the rotational direction U on.

- one in the direction of the axis of rotation 12 is and movable carriage 16 with a controllable clamping arrangement 18 for astride the supports 14 stored folded printed sheet 20 provided.

- a stapling station 22 has a stapling head arrangement 24 along a coaxial around the collecting drum 10 around running trajectory 26 stapling heads 28 arranged one behind the other.

- Each edition 14th is assigned a stitching head 28, which is thus arranged essentially at the same mutual distance A. are like the editions 14.

- a wire section dispenser designated 30, is provided, on which the trajectory 26 passes.

- This wire section dispenser 30 has a cutting device 32 by means of which wire sections 38 are separated from a wire 36 drawn off from a supply roll 34 become.

- the cutting device 32 is followed by a cutting device 32 with wire sections 38 fed magazine 40.

- a conveyor wheel 42 driven in the direction of rotation V pulls along with it Circumferentially distributed holding members 44 each from the magazine 40 from a wire section 38 and promotes these to the stitching heads 28.

- the device shown in FIG. 1 operates as follows: seen in the conveying direction of the carriage 16 Upstream of the stapling station 22 are feeding stations for printed sheets in a known manner. These feed stations place a folded printed sheet 20 on each passing in the circumferential direction U at the feed station Edition 14 astride. Before each edition 14 in the lower area of their circular movement path arrives, the relevant clamping arrangement 18 for holding the corresponding Carriage 16 reaching parts of the printed sheets 20 clamped. In the course of going through the lower Half of the path of movement of the supports 14 make the carriage 16 a working stroke in the longitudinal direction of the circumferential axis 12 to the next feed station or stapling station 22.

- the stitching heads 28 are also driven in the direction of rotation U in synchronism with the supports 14.

- a stapling head 28 on the feed wheel 42 takes over a wire section 38 from the feed wheel 42.

- the wire section 38 now held by the stitching head 28 is formed into a clamp, as is shown below still to be described in detail.

- the clip is seen from the radial side of the outside of the stitching heads 28 brought to the inner side facing the supports 14.

- the relevant stitching heads 28 lowered onto the printed sheets 20 placed one above the other on the supports 14 and the clamps inserted in the printed sheets.

- the distance A of the stitching heads 28 corresponds to the distance between the pads 14.

- the collecting drum 10 shown in Figure 2 corresponds to that of Figure 1 and is therefore not described in more detail.

- the path of movement 26 for the stitching heads 28 is kidney-shaped formed and runs in an area D along the orbit of the supports 14 of the collecting drum 10.

- the collecting drum 10 is outside the path of movement 26 and that which is only indicated schematically Wire section dispenser 30 arranged within this.

- the collecting drum 10 runs counterclockwise U um and the stitching heads 28 are in the opposite direction U 'at the same speed as that of Pads 14 driven.

- the distance A of the stitching heads 28 again corresponds when the staples are set the distance between the pads 14, so that in area D for setting the brackets one with each pad corresponding stitching head 28 runs along.

- the embodiment of the device for collecting folded printed sheets shown in FIG. 3 20 has a collecting conveyor 46, as described in the subsequently published EP-A-0 346 578 or the like Structure is described in EP-PS 0 095 603 and the corresponding US-PS 4,489,930.

- This instructs by two spaced apart axes of rotation 48, indicated only with their essentially horizontal axes of rotation Deflection wheels around guided tension element 50, on which at certain intervals one behind the other, Pads 14 running parallel to one another and at right angles to the direction of rotation U are arranged.

- the stapling station 22 has a stapling head arrangement 24 arranged above the collecting conveyor 46 with a elongated movement path 26 for the stitching heads 28.

- the stitching heads 28 are on one, not shown Traction element with the same distances A as the pads 14 arranged in the area D.

- the tension member is driven in the direction U 'at the same speed as the pulling element 50 in the direction U.

- the stitching heads 28 thus run in the area D synchronously with the supports 14 and move in each case from the area D. removed wire section dispenser 30 past.

- the Stapling station 22 along the upper run of the collecting conveyor 46 feeding stations for laying folded Printing sheet 20 upstream of the pads 14.

- the stapling station 22 is a guide station downstream for the stapled printed sheets 20.

- each stapling head 28 takes over each when passing the wire section dispenser 30 of this one wire section.

- the movement path 26 is in the area between the Wire section dispenser 30 and the area D (clip setting area) from the wire section a clip bent and placed on the outside of the stitching heads 28 with respect to the movement path 26.

- the stitching heads 28 come onto the relevant supports 14 or those placed thereon Press sheet 20 to the plant and put the clip in the sheet 20.

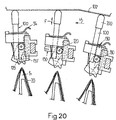

- the in the Figure 4 and 5 shown stapling station 22 has two stapling head arrangements arranged on the same holding arrangement 52 24 on.

- the holding arrangement 52 is annular and coaxially engages around the Revolving axis 12 in the revolving direction U driven collecting drum 10.

- the holding arrangement 52 has two in Holding rings 54 spaced apart from one another in the direction of the circumferential axis 12 and cage-like via grid bars 56 are interconnected.

- the retaining rings 54 are each arranged approximately on three on a frame 58 bearing rollers 60, each equally spaced apart, are freely rotatable.

- Each pad 14 is assigned a stitching head 28 from each stitching head arrangement 24, which is on a common one Support profile 62 are attached spaced apart in the direction of the axis of rotation 12 ( Figure 5).

- a C-shaped mounting part 64 is attached to the support profile 62 at both ends, which with its free end regions 64 'is each guided on a bearing shaft 66 in the radial direction E slidably.

- the stock shaft is 66 arranged on a likewise C-shaped holding part 68 fastened to the respective holding ring 54, the in 5 the end portion 64 'of the mounting part 64 shown above is gripped by the holding part 68.

- a compression spring 70 To the stock 66 around a compression spring 70 is guided, seen in the direction E on the inside of the holding part 68 and supported on the outside of the bearing part 64.

- the compression springs 70 thus hold the stitching heads 28 in one, in the figure 5 rest position, not shown, in which the stitching heads 28 are lifted from the supports 14 and in which the bearing parts 64 are in contact with the holding parts 68.

- the bearing parts 64 each have one in the radial direction over the relevant holding part 68 to the outside protruding arm 72, on each of which a follower roller 74 is freely rotatably mounted.

- the collecting drum 10 is fastened to the frame 58 by a pair of lowering blocks 76 acting on these follow rollers 74.

- each stitching head arrangement 24 is further assigned to the frame 58 Ram slide 78 attached, this in an area in which the stitching heads 28 in their 5 shown, act on plunger 80 of the stitching heads 28.

- driver 82 in the radial direction on each of the holding parts 68 fastened to the holding ring 54 slidably mounted.

- the driver 82 has an essentially at its end facing the support 14 V-shaped driver profile 84 and at its opposite end a freely rotatable follower roller 86 on.

- Another compression spring 88 engages around the driver 82 and is supported in the radial direction seen on the inside on the holding part 68 and on the outside on a ring 90 fastened to the driver 82.

- Means one arranged on the frame 58 and on the follower rollers 86 approximately over the upper half of the movement path 26 of the stapling heads 28 acting driver control link 92 is the respective driver profile 84 from a rest position, not shown in FIG. 5, in which the driver profile 84 on the holding part 68 is present, counter to the force of the further compression spring 88 in a driving position shown in Figure 5 lowerable, in which the V-shaped driver profile 84 engages around the saddle-shaped support 14.

- the pad 14 is shown partially cut away. On the edition 14 are one above the other applied printed sheets 20, being cut open at those located under the stitching heads 28 illustrated printed sheets 20 which are shown in these brackets 104.

- a coupling 106 is parallel to two pivotally mounted on the support 14 pivoting levers 108 running relative to one another in the manner of a parallel crank drive are pivotably mounted.

- the in The swivel lever 108 shown on the left in FIG. 5 is coupled to a control lever 110 which, by means of a Control arrangement, not shown, can be moved back and forth in the longitudinal direction of the support 14. This Aufund Moving the control lever 110 has a back and forth movement of the coupling 106 in the radial direction E. result.

- slots 112 are made in the coupling 106, which only fit one act schematically indicated bending ram 114 in the direction of arrow E.

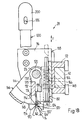

- the stapling heads 28 are first described in more detail below with reference to FIGS. 6 to 8.

- a shaft 120 On the side Flanks 116 of a substantially U-shaped support part 118 is a shaft 120, the one indicated by dash-dotted lines Swivel axis 122 parallel to the longitudinal direction of the support profile 62 (see FIG. 5) and thus parallel to The axis of rotation 12 of the collecting drum 10 runs freely rotatably.

- two spaced sleeves 124 which by means of pins 126 are connected in a rotationally fixed manner to the shaft 120 and on which stamp arms running parallel to one another 128 of a stamp 130 are attached.

- the two punch arms 128 are by means of a lateral web 132 connected with each other. In the free end area, the two punch arms 128 have an opposing, slight thickening 134, in which grooves which run in the radial direction and are open to one another 136 are provided. These grooves 136 are also at the free end of the punch 130 in the radial direction open.

- Each punch arm 128 has at its free end, adjacent to the groove 136, one in the radial direction protruding driver lug 138 and a permanent magnet 140 arranged in the punch arm 128.

- FIGS. 6 and 7 show one of the driver lugs 138 and one of the permanent magnets 140 held wire section 38 shown. In Figures 6 and 7, the stamp 130 is in its rest position and 8 in the clamp setting position 130 '.

- a spacer sleeve 142 sits on each sleeve 124 in the region of the pin 126 and is a pivot lever 144 between the spacer sleeve 142 and the relevant punch arm 128 freely rotatably mounted.

- a pivot lever 144 At the free End regions of the pivot lever 144 is a substantially connecting the two pivot levers 144 to one another Clamp retaining member 146 formed in the form of an annular segment.

- On the clip retaining link 146 are two grooves 148 spaced apart from one another, into which grooves when the stamp is pivoted 130 engage the free end areas of the punch arms 128.

- One swivel lever 144 acts with one counterclockwise force a leaf spring assembly 150 attached to the support member 118 and presses the swivel lever 144 with the stops 152 formed on them against the supporting part 118 the pivot lever 144 protrudes counterclockwise, the clip holding member 146 has a clip guide tab 154 on.

- This clip guide lug 154 is wedge-shaped and has a radial one Seen in the direction towards the wedge surface designated 154 '.

- the plunger 80 is guided on the support part 118 so as to be displaceable in the arrow direction F.

- This direction of displacement F runs parallel to the grooves 136 in the plunger arms 128 when in the clamp-setting position 130 ' Stamp 130.

- the plunger 80 has a plunger head 158 at its lower end region, which in itself Clamp setting position 130 'located punch 130 engages between the two punch arms 128.

- At the Ram head 158 are integrally formed laterally protruding guide wedges 160 which when the ram is moved 80 in the direction F from its rest position shown in FIG. 6 into the ejection position shown in FIG the punch 130 located in the clamp setting position 130 'enter the grooves 136.

- the plunger head 158 has a pushing groove 162 for ejecting it with its lateral arms 104 'into the Grooves 136 performed on bracket 104.

- the plunger 80 also has an open towards the support member 118 groove-shaped recess 164 in which a compression spring 166 is arranged, which is located on the top Tappet 80 and at the bottom on a fastened to the support member 118, which extends into the groove-shaped recess 164 Bolt 168 supports ( Figure 8).

- the compression spring 166 keeps the plunger 80 in place in FIG solid lines and the rest position indicated by dash-dotted lines in FIG. 8.

- the side flanks 116 face at the lower end opposite the one in the clamp setting position 130 ' Stamp 130 protruding pressing tabs 170 through a substantially V-shaped recess 170 'are separated from each other.

- the stitching head 28 is lowered, it comes with the pressing noses 170 on the edition 14 or on the printed sheet 20 on the system.

- the support part 118 is also in a bearing arrangement 172 fastened to the support profile 62 (cf. also FIG. 5) Slidably mounted in the direction of arrow F.

- the support part 118 also has groove-shaped ends Recesses 174 on ( Figures 6 and 7), in each of which a bore 176 with a thread from below 176 'opens. Further bolts 178 are arranged on the bearing arrangement 172, which extend into the groove-shaped recesses 174 engage and on which another compression spring 180 is supported at the top. At the bottom, this compression spring 180 presses against a screw 182 inserted into the thread 176 ' the compression spring 180 thus becomes the supporting part 118 with respect to the bearing arrangement 172 in that shown in FIG.

- a drive arrangement is located on one side flank 116 of the supporting part 118, which is shown at the bottom in FIG 184 attached for pivoting the shaft 120.

- This has a guide member 185 on which the actuating shaft 100 is also mounted displaceably in the direction of arrow F.

- a rack 186 At the lower end is formed on the actuating shaft 100, a rack 186, which with a seat on the shaft 120 rotatably Pinion 190 combs.

- a downwardly open bore 192 in the actuating shaft 100 is another Compression spring 194 arranged on the top of the operating shaft 100 and below on one on the guide member 185 attached pin 196 supports.

- the pin 196 penetrates a slot-shaped passage 198 in the operating shaft 100.

- the upper end region of the operating shaft 100 is of a cap-shaped Sliding shoe 200 covers, which is displaceable in the longitudinal direction with respect to the actuating shaft 100 and by means of a further pin 196 'fastened to the actuating shaft 100, which pin 200 in one also penetrates slot-shaped passage 198 'is held.

- a further compression spring 194' is used, which is on the sliding shoe 200 and supported on the operating shaft 100. If the operating shaft 100 is in its lower, shown in Figure 8 End position and the swivel link 102 approaches the support member 118, takes the Compression spring 194 'this approach.

- the clamping lever 94 is pivotally mounted, which is from the operating shaft 100 is permeated.

- the corresponding hole in the clamping lever 94 has only a slightly larger diameter than the thickness of the operating shaft 100.

- the clamping lever 94 is by means of a compression spring 204 kept biased counterclockwise. Holds in the position of the clamping lever 94 shown in Figure 6 the actuator shaft 100 by tilting by applying a force in the direction of arrow G by means of the release link 96 (cf. FIG. 5) becomes this tilt by pivoting the clamping lever 94 clockwise released and the operating shaft 100 released, this is up by the compression spring 194 postponed.

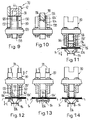

- FIGS. 9 to 14 show parts of the stitching head 28 during various phases of a work cycle.

- the corresponding Parts of the stitching head 28 in these figures are numbered the same as in Figures 6 to 8 and are therefore no longer explained in more detail.

- the bending ram 114 is in the support 14 (FIGS. 11 to 14) guided in the direction of arrow E up and down. Two are pivotally supported on the support 14 stored bender 206 (see also FIG. 5).

- the stamp 130 is in its rest position, which is also shown in FIGS. 6 and 7.

- the plunger 80 with its plunger head 158 is also in the rest position.

- the stapling head 28 moves past the feed wheel 42 of the wire section dispenser 30 (see FIG. 1) and thereby takes over Carrying a wire section 38 by means of the driver lugs 138 from the holding member 44 of the feed wheel 42.

- This wire section 38 is attached to the stamp arms by means of the permanent magnets 140, not shown in this figure 128 held.

- the web connecting the two punch arms 128 to one another is shown at 132.

- the stitching head 28 is located in the area of the die 98 (see FIG. 4), with the stamp 130 is still in its rest position.

- the wire section 38 becomes U-shaped bent into a bracket 104, the side arms 104 'sliding into the grooves 136 of the punch arms 128.

- the actuating shaft 100 brought into its lower end position shown in Figure 8, whereby the punch 130 in the in Figures 8 and 11 clamp setting position 130 'is pivoted.

- the punch arms grip 128 in the area of their thickening 134 in the grooves 148 of the clip holding member 146, whereby the lateral arms 104 'are held in the grooves 136.

- the pivot levers are designated, on which the staple guide member 146 is attached.

- the plunger head 158 of the plunger 80 is in the Clamp setting position 130 'of the stamp 130 also between the two stamp arms 128, but in the area between the shaft 120 and the thickenings 134.

- the tappet link 78 acts on the tappet 80 this is pushed against the support 14 in the direction of arrow F, as shown in FIG. there the guide wedges 160 formed laterally on the tappet head 158 slide into the grooves 136 in FIG Clamp setting position 130 'located punch arms 128.

- the clamp 104 is made from the Stamp 130 ejected, the side arms 104 'at the same time by those placed on the support 14 Printed sheets 20 are pushed.

- the plunger 80 is always through the plunger link 78 still held in the lower end position. After the plunger 80 has run out of the plunger link 78 moves 14 under the force of the compression spring 166 back into the upper rest position, as shown in FIG. 14 is shown. By lowering the bending plunger 114 in the direction of arrow E, the bending machine 206 in swung back to their original position. When the stitching head 28 runs past the release link 96 the actuating shaft 100 released by the clamping lever 94, which causes the stamp 130 to pivot back effected in the rest position.

- FIGS. 15 and 16 are the two stapling head arrangements indicated by the arrow 30 in FIG 24 associated Drant section dispenser 30 shown enlarged.

- Each of these wire section dispensers 30 is constructed in the same way as the wire section dispenser 30 shown in FIG. 1.

- the cutting device 32 is driven by a circumferential toothed belt 208.

- a pair of conveyor rollers 210 conveys the one sandwiched between them Wire 36 gradually in the direction of the arrow H.

- a cutting knife movable up and down in the direction of arrow I.

- the cutting knife 212 is followed by the magazine below the cutting device 32 40 arranged. It has an essentially gap-shaped, approximately in the vertical direction Stacking shaft 214 in which the falling wire sections 38 are substantially horizontal Are stackable one above the other in the direction of the longitudinal extension.

- a pre-stacking device 216 with a tongue 218 is provided at the upper end of the stacking shaft 214, which can be moved into and out of the stacking shaft 214.

- the tongue 218 is moved a number by means of the cutting device 32 wire sections 38 separated from the wire 36 are stacked.

- By briefly withdrawing the Tongue 218 then drops these stacked wire sections 38 together into the stacking shaft 214. This prevents this an erection and tilting of the wire sections 38 during the free fall and guarantees a clean Stacking of the wire sections 38 in the stacking shaft 214.

- the two conveyor wheels 42 arranged below the magazines 40 are seated in a rotationally fixed manner on a common, on a pair of support levers 222 rotatably mounted bearing shaft 224.

- a drive belt 226 on the bearing shaft 224 acting drive device 228 are the two feed wheels 42 in the direction of arrow V. driven revolving.

- Each feed wheel 42 has two spaced-apart parallel disks 230, between which in At certain intervals, the holding members 44 are arranged along the circumference.

- the holding links are U-shaped formed and have at their radially outward free ends on the periphery of the disks 230 slightly protruding driver flanks 232.

- a permanent magnet arrangement on the holding members 44 provided in order to pass the magazine 40 by means of the driver flanks 232 from the To hold stack shaft 214 detached wire sections 38.

- the stitching heads 28 are spaced further apart than the holding members 44 Circumferential speed of the feed wheels 42 is lower than the rotational speed of the stitching heads 28, so that the next stitching head 28 meets the next holding member 44.

- the stitching head 28 thus runs past the holding member 44 and pulls with the driver lugs 138 arranged on the punch arms 128 from Holding member 44 from the relevant wire section 38 and holds it by means of permanent magnets 140 Stamp 130 fixed.

- the holding members 44 are displaceable in the radial direction in a generally known manner and spring-loaded, in order to be able to accept tolerances and to ensure that the To ensure wire sections 38 from the stacking shaft 214 and transfer to the stitching heads 28.

- the initial region of the driver link 92 is shown in FIG.

- the follower rollers 86 of the drivers 82 run on the driver link 92 , which has the consequence that the driver 82, which is guided on the holding part 68 so as to be displaceable in the radial direction the relevant pads 14 of the collecting drum 10 are lowered.

- the V-shaped driver profiles grip around 84 the supports 14. This has the consequence that the arranged on the support profile 62 in FIG Stapling heads 28, not shown, with respect to the assigned support 14 or the printed sheets placed thereon 20 are precisely aligned.

- the holding arrangement 52 is driven exclusively by entrainment by the catches 82 which are in engagement with the supports 14.

- the catches 82 are only in the upper one Area of the orbit of the collecting drum 10 lowered to the pads 14, so in the lower area of the Orbit the printed sheets 20 stapled by the stapling station 22 in the direction of the axis of rotation 12 the supports 14 and driver profiles 84, which are now spaced apart, can be conveyed away, or that the printed sheets 20 to be stapled can be brought into the area of the stapling station 22.

- a stitching head 28 is now in the course of one revolution of the holding arrangement 52 Starting wire segment dispenser 30, tracked.

- the stitching heads 28 pass the wire section dispenser they are in their outer rest position, seen in the radial direction, in which they are from the supports 14 are spaced.

- the stamp 130 are pivoted back into the rest position, so that the free ends of the punch arms 128 are directed towards the outside when viewed in the radial direction.

- walking past of the stapling head 28 on the relevant holding member 44 of the feed wheel 42 becomes that of the holding member 44 supplied wire section 38 detached from the driver lugs 138 and taken away (Fig. 18).

- the support member 118 comes with its pressing tabs 170 on the Pads 14 astride printed sheets 20 to the system. It should be noted that the pressing lugs 170 the printed sheets 20, seen in the direction of the support 14, in front of and behind the bracket 104 and on both Hold sides of this, which leads to a particularly clean stitch. It should also be noted that the support part 118 with respect to the bearing arrangement 172 fixed to the support profile 62 as a function of the thickness the printed sheet 20 is shifted. This ensures a clean stapling of sheets of different thickness 20 guaranteed without having to readjust the device (see FIG. 21).

- the ram 80 slides beneath the effect of the compression spring 166 and the distance increasing in the end region of the slide link 78 back to the support member 118 in its radial position seen in the radial direction.

- the stitching heads 28 are now ready again, from the wire section dispenser 30 to take on a new wire.

- the stapled are now Printing sheet 20 in the direction of the axis of rotation 12 from the area of the stapling station 22 of an exit station, not shown promoted.

- the wire section dispenser 30 can be in which the clamps 104 are placed in the printed sheets 20 are removed. As a consequence, that there is sufficient time for the preparation of the brackets 104 in the area between the wire section dispenser 30 and the bracket setting area is available.

- the processing of the clamps 104 takes place in a different position from the clamp setting position 130 ', which means that the different functions of the stitching heads 28 are spatially separated from each other; this in turn has the consequence that the stitching heads 28 are simple in construction with small dimensions.

- the die can be used to bend the wire section 38 into a bracket 104 on each Stapling head 28 itself may be provided. This has an eccentric shape to the shaft, so that in the In the course of the pivoting movement of the stamp 130 from its rest position into the clamp setting position 130 ', the clamp 104 is formed.

- Such a die could in particular be used as an extension of the clip holding member 146 be formed clockwise on this.

- the drivers it is of course also possible for the drivers to be arranged on the stitching heads. That's the way it is quite conceivable that the pressing lugs 170 serve as drivers. A separate drive for the stapling station 22 is no longer necessary and synchronization problems between the rotation of the collecting drum 10 and the stitching head assemblies 24 are eliminated.

- the traction element or the holding arrangement 52 can be operated by means of its own drive motor be driven all round. It is also conceivable for the wire section dispenser to be an exchangeable magazine or that the wire sections are fed directly from the cutting device to the stitching heads.

- the stamp 130 is in a position of rest for the wire transfer different wire transfer position can be.

- the wire takeover position corresponds but not the clamp setting position 130 '.

- the wire sections 38 run essentially parallel to Swivel axis 122.

- the stapling stations 22 of the devices according to FIGS. 2 and 3 are constructed similarly, like the stapling station 22 described above in connection with the device according to FIG. 1.

- Stapling heads which are particularly suitable for devices according to the invention for wire stitching of printed matter are described in EP-A-0 399 322.

- a stapling head in which a stapling head is permanently assigned to each edition, allow also the mutual displacement of the stitching heads of a stitching head arrangement in the longitudinal direction of the supports. So for example, every second stitching head can be arranged with respect to the other stitching heads arranged in one plane be slightly offset. The two groups of stitching heads then advantageously each run on their own Wire section dispenser over. When stapling the stapled sheets, not all staples come on top of each other to lie.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Mechanical Engineering (AREA)

- Folding Of Thin Sheet-Like Materials, Special Discharging Devices, And Others (AREA)

- Sewing Machines And Sewing (AREA)

- Pile Receivers (AREA)

- Collation Of Sheets And Webs (AREA)

- Insulated Conductors (AREA)

- Dovetailed Work, And Nailing Machines And Stapling Machines For Wood (AREA)

Claims (10)

- Dispositif pour le brochage de produits imprimés pliés (20) en plusieurs éléments, comprenant un agencement d'amenée (10, 14) pour amener les produits à brocher (20) pliés, dont la ligne de pliage s'étend sensiblement à angle droit par rapport à la direction de transport (U), le long d'une voie de déplacement, passant à travers une zone de brochage (D), formée au moyen d'appuis en forme de selle (14), circulant le long d'une voie de circulation fermée, sur lesquels les produits imprimés (20) sont susceptibles d'être déposés à califourchon et qui sont parallèles entre eux et s'étendent sensiblement à angle droit par rapport à leur direction de circulation (U), au moins un agencement (24) de têtes de brochage se composant d'une série de têtes de brochage (28), qui sont destinées à poser des agrafes en fil (104) le long des lignes de pliage, qui, pendant la pose des agrafes en fil (104), circulent sensiblement à la vitesse de déplacement des produits (20), conjointement avec ceux-ci et dans la direction de circulation (U'), disposées l'une derrière l'autre à un distance (A), la voie de circulation (26) des têtes de brochage (28) étant, le long d'une de ses parties, d'un tracé sensiblement parallèle à la voie de déplacement des produits (20) dans la zone de brochage (D), des moyens, pour former les agrafes en fil (104), à partir de parties de fils (38) sensiblement droites, maintenues par les têtes de brochage (28), au moins un agencement de fermeture (114, 206) d'agrafes se composant d'une série d'éléments de repli (206) qui sont destinés à coopérer dans la zone de brochage (D) avec les têtes de brochage (28) et disposés dans les appuis (14), de manière à fermer les agrafes en fil (104) posées qui circulent à la vitesse des produits (20) reposant sur les appuis (14), le long d'une voie de circulation fermée des appuis (14), dont le tracé dans la zone de brochage (D) est sensiblement parallèle, le long d'une de ses parties, à la voie de circulation (26) des têtes de brochage (28) et à la voie de circulation des produits (20), caractérisé en ce que les têtes de brochage (28) circulent également à la vitesse de déplacement des produits (20), le long d'une voie de circulation (26) fermée, dans une direction de circulation (U), et, dans la zone de brochage (D), se déplacent, avec les produits (20), le long d'une partie allongée de sa voie de circulation (26), et en ce que sur la voie de circulation (26) des têtes de brochage (28) est disposée une unité distributrice de parties de fil (30), disposée de facon stationnaire, qui distribue chaque fois une partie de fil (38) aux têtes de brochage (28) passant devant elle et s'étend sensiblement à angle droit par rapport à la direction de circulation (U') des têtes de brochage (28).

- Dispositif selon la revendication 1, caractérisé en ce que l'unité distributrice (30) de parties de fil est disposée en dehors de la zone de brochage (D).

- Dispositif selon la revendication 1, caractérisé en ce que l'agencement de tête de brochage (24) est séparé de l'agencement de transport (10, 14).

- Dispositif selon la revendication 1, caractérisé en ce que les appuis (14) circulent autour d'un axe commun de circulation (12) de tracé sensiblement conforme à la direction horizontale.

- Dispositif selon la revendication 4, caractérisé en ce que le tracé de la voie de circulation (26) des têtes de brochage (28) entoure la voie de circulation des appuis (14).

- Dispositif selon la revendication 1, caractérisé en ce que la voie de circulation (26) des têtes de brochage (28) et la voie de circulation des appuis (14) sont sensiblement rectilignes dans la zone de brochage (D) .

- Dispositif selon la revendication 6, caractérisé en ce que l'unité distributrice (30) de parties de fil est disposée sur le côté intérieur de la voie de circulation fermée (26) des têtes de brochage (28).

- Dispositif selon la revendication 1, caractérisé par un deuxième agencement de têtes de brochage (24) pourvu d'un deuxième agencement (114, 206) de fermeture d'agrafes associé, les têtes de brochage (28) des deux agencements (24) de têtes de brochage se déplaçant le long de voies de déplacement (26) parallèles entre elles.

- Dispositif selon la revendication 8, caractérisé en ce qu'une unité distributrice (30) de parties de fil est associée à chaque agencement de têtes de brochage (24).

- Dispositif selon la revendication 1, caractérisé en ce que l'unité distributrice (30) de parties de fil distribue des parties de fil droites (38) aux têtes de brochage (28), et en ce que ces parties de fil droites (38) sont repliées en forme de U pendant leur transport vers la zone de brochage (D).

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH196489 | 1989-05-25 | ||

| CH196489 | 1989-05-25 | ||

| CH1964/89 | 1989-05-25 | ||

| EP90108961A EP0399317B1 (fr) | 1989-05-25 | 1990-05-12 | Appareil pour grouper et coudre des feuilles imprimées et pliées |

Related Parent Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90108961A Division EP0399317B1 (fr) | 1989-05-25 | 1990-05-12 | Appareil pour grouper et coudre des feuilles imprimées et pliées |

| EP90108961A Division-Into EP0399317B1 (fr) | 1989-05-25 | 1990-05-12 | Appareil pour grouper et coudre des feuilles imprimées et pliées |

| EP90108961.5 Division | 1990-05-12 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0476718A1 EP0476718A1 (fr) | 1992-03-25 |

| EP0476718B1 EP0476718B1 (fr) | 1994-01-05 |

| EP0476718B2 true EP0476718B2 (fr) | 2001-05-09 |

Family

ID=4222731

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91119133A Expired - Lifetime EP0476718B2 (fr) | 1989-05-25 | 1990-05-12 | Dispositif pour piquer des produits d'imprimerie à plusieurs parties |

| EP93107489A Expired - Lifetime EP0569887B1 (fr) | 1989-05-25 | 1990-05-12 | Dispositif pour assembler et brocher des produits imprimés pliés |

| EP90108961A Expired - Lifetime EP0399317B1 (fr) | 1989-05-25 | 1990-05-12 | Appareil pour grouper et coudre des feuilles imprimées et pliées |

Family Applications After (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93107489A Expired - Lifetime EP0569887B1 (fr) | 1989-05-25 | 1990-05-12 | Dispositif pour assembler et brocher des produits imprimés pliés |

| EP90108961A Expired - Lifetime EP0399317B1 (fr) | 1989-05-25 | 1990-05-12 | Appareil pour grouper et coudre des feuilles imprimées et pliées |

Country Status (10)

| Country | Link |

|---|---|

| EP (3) | EP0476718B2 (fr) |

| JP (2) | JP2652077B2 (fr) |

| AT (1) | ATE126130T1 (fr) |

| AU (1) | AU622556B2 (fr) |

| CA (1) | CA2017443C (fr) |

| DD (1) | DD294677A5 (fr) |

| DE (3) | DE59004157D1 (fr) |

| ES (2) | ES2047193T3 (fr) |

| FI (1) | FI98352C (fr) |

| RU (2) | RU2057029C1 (fr) |

Families Citing this family (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DK0399322T3 (da) * | 1989-05-25 | 1993-08-30 | Ferag Ag | Hæfteapparat |

| DE59106663D1 (de) * | 1990-08-06 | 1995-11-16 | Ferag Ag | Vorrichtung zum Drahtheften von mehrteiligen Druckereierzeugnissen. |

| ATE128076T1 (de) * | 1991-12-13 | 1995-10-15 | Ferag Ag | Vorrichtung zum drahtheften von mehrteiligen druckereierzeugnissen. |

| JP3415645B2 (ja) * | 1992-04-14 | 2003-06-09 | グラプハ−ホルディング・アクチエンゲゼルシヤフト | 折り目をつけられたシート状印刷物を集めて綴じるための装置 |

| CH686078A5 (de) * | 1992-11-30 | 1995-12-29 | Grapha Holding Ag | Vorrichtung zum Heften von auf sich folgenden Auflagen einer umlaufenden Fordereinrichtung rittlings ubereinander abgelegten, bogenartigen Druckprodukten. |

| DK0606555T3 (da) * | 1993-01-11 | 1997-10-13 | Ferag Ag | Samlehæftemaskine til trykprodukter,der består af foldede trykarkkark |

| SE506108C2 (sv) * | 1993-02-18 | 1997-11-10 | Tolerans Ingol Sweden Ab | Anordning för att applicera häftklammer till ett material |

| US5570832A (en) * | 1993-06-21 | 1996-11-05 | Grafa-Holding Ag | Apparatus for stapling sequential printed sheets positioned straddled one above the other |

| DE59405899D1 (de) * | 1993-12-21 | 1998-06-10 | Grapha Holding Ag | Verfahren zur Beschickung von zu Druckprodukten gesammelten, mehrblättrigen Druckbogen mit Beilagen |

| ES2103533T3 (es) * | 1994-01-10 | 1997-09-16 | Ferag Ag | Dispositivo para encuadernar articulos impresos. |

| ES2115991T3 (es) * | 1994-03-25 | 1998-07-01 | Ferag Ag | Instalacion para la union por encolado de productos de imprenta. |

| ES2105813T3 (es) | 1994-07-06 | 1997-10-16 | Ferag Ag | Dispositivo para coser con grapas productos impresos. |

| DE59602637D1 (de) * | 1995-05-20 | 1999-09-09 | Koenig & Bauer Ag | Heftvorrichtung |

| RU2185290C2 (ru) | 1997-05-07 | 2002-07-20 | Фераг Аг | Устройство для сшивания в продольном направлении состоящих из многих частей типографских изделий |

| PT1245406E (pt) * | 2001-03-29 | 2008-07-17 | Grapha Holding Ag | Dispositivo para a encadernação de lombadas, com agrafos, de produtos impressos constituídos por folhas de impressão dobradas |

| EP1270479B1 (fr) * | 2001-06-28 | 2006-08-09 | Grapha-Holding AG | Méthode pour fabriquer un produit imprimé relié constitué de plusieurs produits imprimés et dispositif pour la mise en oeuvre de cette méthode |

| US7033123B2 (en) * | 2002-02-28 | 2006-04-25 | Hewlett-Packard Development Company, L.P. | Booklet maker |

| US6969342B2 (en) * | 2002-02-28 | 2005-11-29 | Hewlett-Packard Development Company, L.P. | System for handling folded sheet material |

| US6981830B2 (en) * | 2002-02-28 | 2006-01-03 | Hewlett-Packard Development Company, L.P. | Pivotable collecting device |

| US7581724B2 (en) | 2002-11-09 | 2009-09-01 | Ferag Ag | Device for collecting and processing folded printed products |

| CA2573175A1 (fr) * | 2006-01-13 | 2007-07-13 | Ferag Ag | Methode et installation pour le traitement de produits imprimes en cours de transport |

| CN116373302B (zh) * | 2021-06-28 | 2024-10-01 | 上海轮廓科技有限公司 | 材料馈送机构、多料单元及3d打印系统 |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB740079A (en) * | 1952-01-08 | 1955-11-09 | Crabtree & Sons Ltd R | Improvements in stapling mechanism |

| US2966681A (en) * | 1957-10-09 | 1961-01-03 | Lee R Campbell | Feeding mechanism for fastener driving devices |

| CH459145A (de) * | 1968-01-23 | 1968-07-15 | Leipziger Buchbindereimaschine | Sammeldrahtheftmaschine |

| JPS565680B2 (fr) * | 1972-05-04 | 1981-02-06 | ||

| DD138525A1 (de) * | 1978-09-04 | 1979-11-07 | Winfried Boettcher | Einrichtung zum einstechen von fadenklammern in falzbogen |

| US4315588A (en) * | 1980-01-21 | 1982-02-16 | Faltin Hans G | High speed on-line stitcher for signatures and webs |

| DE3362515D1 (en) * | 1982-06-01 | 1986-04-17 | Ferag Ag | Device for collecting folded printing sheets |

| US4478398A (en) * | 1982-07-16 | 1984-10-23 | Stobb, Inc. | System for routing a signature for stitching using a lift finger |

| JPS60240497A (ja) * | 1984-05-16 | 1985-11-29 | 凸版印刷株式会社 | 製本針金綴不良検査装置 |

| CH667621A5 (de) * | 1985-06-04 | 1988-10-31 | Grapha Holding Ag | Sammelhefter. |

| IT1185103B (it) * | 1985-06-14 | 1987-11-04 | Cerutti Spa Off Mec | Cucitrice perfezionata per seganture |

| US4792077A (en) * | 1987-04-27 | 1988-12-20 | Custom-Bilt Machinery, Inc. | Apparatus for stapling and creasing paper articles in transit |

| DK0399322T3 (da) * | 1989-05-25 | 1993-08-30 | Ferag Ag | Hæfteapparat |

-

1990

- 1990-05-12 ES ES90108961T patent/ES2047193T3/es not_active Expired - Lifetime

- 1990-05-12 AT AT93107489T patent/ATE126130T1/de not_active IP Right Cessation

- 1990-05-12 ES ES93107489T patent/ES2076816T3/es not_active Expired - Lifetime

- 1990-05-12 DE DE91119133T patent/DE59004157D1/de not_active Expired - Fee Related

- 1990-05-12 DE DE90108961T patent/DE59003842D1/de not_active Expired - Fee Related

- 1990-05-12 EP EP91119133A patent/EP0476718B2/fr not_active Expired - Lifetime

- 1990-05-12 EP EP93107489A patent/EP0569887B1/fr not_active Expired - Lifetime

- 1990-05-12 EP EP90108961A patent/EP0399317B1/fr not_active Expired - Lifetime

- 1990-05-12 DE DE59009519T patent/DE59009519D1/de not_active Expired - Fee Related

- 1990-05-23 DD DD90340955A patent/DD294677A5/de not_active IP Right Cessation

- 1990-05-24 AU AU55907/90A patent/AU622556B2/en not_active Ceased

- 1990-05-24 CA CA002017443A patent/CA2017443C/fr not_active Expired - Fee Related

- 1990-05-24 FI FI902605A patent/FI98352C/fi not_active IP Right Cessation

- 1990-05-25 RU SU904830293A patent/RU2057029C1/ru not_active IP Right Cessation

- 1990-05-25 JP JP2136951A patent/JP2652077B2/ja not_active Expired - Fee Related

-

1992

- 1992-01-23 RU SU925010649A patent/RU2071919C1/ru not_active IP Right Cessation

-

1994

- 1994-05-11 JP JP6121978A patent/JP2646191B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| FI902605A0 (fi) | 1990-05-24 |

| EP0399317B1 (fr) | 1993-12-15 |

| EP0569887B1 (fr) | 1995-08-09 |

| JP2652077B2 (ja) | 1997-09-10 |

| ES2047193T3 (es) | 1994-02-16 |

| FI98352C (fi) | 1997-06-10 |

| ATE126130T1 (de) | 1995-08-15 |

| RU2057029C1 (ru) | 1996-03-27 |

| DE59003842D1 (de) | 1994-01-27 |

| EP0476718A1 (fr) | 1992-03-25 |

| CA2017443A1 (fr) | 1990-11-25 |

| EP0569887A1 (fr) | 1993-11-18 |

| CA2017443C (fr) | 2000-08-22 |

| ES2076816T3 (es) | 1995-11-01 |

| JP2646191B2 (ja) | 1997-08-25 |

| EP0399317A1 (fr) | 1990-11-28 |

| FI98352B (fi) | 1997-02-28 |

| EP0476718B1 (fr) | 1994-01-05 |

| AU622556B2 (en) | 1992-04-09 |

| DD294677A5 (de) | 1991-10-10 |

| DE59004157D1 (de) | 1994-02-17 |

| RU2071919C1 (ru) | 1997-01-20 |

| AU5590790A (en) | 1990-11-29 |

| JPH0321497A (ja) | 1991-01-30 |

| DE59009519D1 (de) | 1995-09-14 |

| JPH0752578A (ja) | 1995-02-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0476718B2 (fr) | Dispositif pour piquer des produits d'imprimerie à plusieurs parties | |

| EP0341425B1 (fr) | Dispositif pour collationner des produits imprimés pliés | |

| EP0399322B1 (fr) | Appareil de brochage | |

| EP0675005B1 (fr) | Dispositif pour la reliure adhésive de produits imprimés | |

| EP0623542A1 (fr) | Dispositif pour empiler un chant de feuilles imprimées | |

| EP0473902B1 (fr) | Dispositif d'agrafage de produits imprimés composés | |

| EP0366038B1 (fr) | Dispositif pour plier en zigzag et empiler une bande de matériau | |

| EP0510525B1 (fr) | Procédé et dispositif pour traiter des produits imprimés | |

| EP0336062B1 (fr) | Machine à insérer | |

| EP1943173B1 (fr) | Procede et dispositif pour transferer des produits plats d'une pile de produits a une bande transporteuse | |

| EP0712736B1 (fr) | Méthode pour la fabrication de livres, brochures ou similaires reliés par adhésif | |

| EP0418529A2 (fr) | Appareil pour limiter des feuilles imprimées à trois côtés | |

| EP0872443B1 (fr) | Dispositif pour former une pile partielle s'étandant perpendiculèrement aux feuilles imprimées rangées sur la tranche et une à côté de l'autre | |

| EP1957287B1 (fr) | Brocheuse collectrice | |

| DE1561141B2 (de) | Vorrichtung zum einfuehren von beilagen in gefaltete druckerzeugnisse | |

| EP0586926A2 (fr) | Dispositif pour couper et agrafer des produits imprimés à plusieurs couches dans des appareils de pliage | |

| DE2434360A1 (de) | Vorrichtung zum stapeln loser papierboegen | |

| EP0699611B1 (fr) | Dispositif de transport pour l'alimentation des produits imprimés plats à une machine de traitement | |

| DE3205463A1 (de) | Einrichtung und verfahren zur durchlaufhandhabung von blattfoermigen gegenstaenden | |

| EP0662440A1 (fr) | Dispositif pour l'agrafage par adhésif de produits imprimés | |

| EP1274639B1 (fr) | Dispositif permettant d'acheminer des objets plats | |

| EP1348571B1 (fr) | Dispositif pour relier des éléments plats empilés | |

| EP0301244A1 (fr) | Dispositif pour insérer au moins un supplément dans des imprimés | |

| EP0810174A2 (fr) | Dispositif pour l'empilage vertical de produits imprimés | |

| DE1561141C3 (de) | Vorrichtung zum Einführen von Beilagen in gefaltete Druckerzeugnisse |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 399317 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE GB IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19920206 |

|

| 17Q | First examination report despatched |

Effective date: 19920824 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 399317 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE GB IT LI SE |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19940119 |

|

| REF | Corresponds to: |

Ref document number: 59004157 Country of ref document: DE Date of ref document: 19940217 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| ITF | It: translation for a ep patent filed | ||

| 26 | Opposition filed |

Opponent name: GRAPHA-HOLDING AG Effective date: 19940321 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 91119133.6 |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| APAE | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOS REFNO |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20010509 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): CH DE GB IT LI SE |

|

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN Free format text: AUFRECHTERHALTUNG DES PATENTES IN GEAENDERTER FORM |

|

| GBTA | Gb: translation of amended ep patent filed (gb section 77(6)(b)/1977) | ||

| EN | Fr: translation not filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: FERAG AG Free format text: FERAG AG#ZUERICHSTRASSE 74#8340 HINWIL (CH) -TRANSFER TO- FERAG AG#PATENTABTEILUNG Z. H. MARKUS FELIX ZUERICHSTRASSE 74#8340 HINWIL (CH) |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20080521 Year of fee payment: 19 Ref country code: DE Payment date: 20080523 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20080513 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080527 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080522 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090512 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090531 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090512 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090512 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090513 |