EP0342384A1 - Procédé et dispositif pour le contrôle d'emballages en carton - Google Patents

Procédé et dispositif pour le contrôle d'emballages en carton Download PDFInfo

- Publication number

- EP0342384A1 EP0342384A1 EP89107242A EP89107242A EP0342384A1 EP 0342384 A1 EP0342384 A1 EP 0342384A1 EP 89107242 A EP89107242 A EP 89107242A EP 89107242 A EP89107242 A EP 89107242A EP 0342384 A1 EP0342384 A1 EP 0342384A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- packs

- folding

- carton

- walls

- tabs

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 title claims description 12

- 239000000853 adhesive Substances 0.000 claims abstract description 21

- 230000001070 adhesive effect Effects 0.000 claims abstract description 21

- 230000002950 deficient Effects 0.000 claims abstract description 8

- 238000004026 adhesive bonding Methods 0.000 claims description 9

- 230000004888 barrier function Effects 0.000 claims description 6

- 230000015572 biosynthetic process Effects 0.000 claims description 6

- 238000012545 processing Methods 0.000 claims description 6

- 210000000056 organ Anatomy 0.000 claims description 2

- 238000010276 construction Methods 0.000 abstract 1

- 238000000926 separation method Methods 0.000 abstract 1

- 238000012360 testing method Methods 0.000 description 9

- 235000019504 cigarettes Nutrition 0.000 description 4

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 238000012937 correction Methods 0.000 description 3

- 239000003292 glue Substances 0.000 description 3

- 230000000295 complement effect Effects 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000012856 packing Methods 0.000 description 2

- 238000013461 design Methods 0.000 description 1

- 239000012943 hotmelt Substances 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B57/00—Automatic control, checking, warning, or safety devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07C—POSTAL SORTING; SORTING INDIVIDUAL ARTICLES, OR BULK MATERIAL FIT TO BE SORTED PIECE-MEAL, e.g. BY PICKING

- B07C5/00—Sorting according to a characteristic or feature of the articles or material being sorted, e.g. by control effected by devices which detect or measure such characteristic or feature; Sorting by manually actuated devices, e.g. switches

- B07C5/34—Sorting according to other particular properties

- B07C5/3404—Sorting according to other particular properties according to properties of containers or receptacles, e.g. rigidity, leaks, fill-level

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B7/00—Closing containers or receptacles after filling

- B65B7/16—Closing semi-rigid or rigid containers or receptacles not deformed by, or not taking-up shape of, contents, e.g. boxes or cartons

- B65B7/20—Closing semi-rigid or rigid containers or receptacles not deformed by, or not taking-up shape of, contents, e.g. boxes or cartons by folding-down preformed flaps

Definitions

- the invention relates to a method for checking cardboard packs with regard to the correct formation of (bottom and / or top) walls formed from folding tabs and fixed by adhesive and / or adhesive strips. Furthermore, the invention relates to a device for performing the method.

- the cardboard packs mentioned here are primarily large-volume packs made of corrugated cardboard or the like. They are mainly used to hold smaller packs. For example, small containers of cigarette packs - so-called cigarette sticks with e.g. ten or twenty cigarette packs - packed in such cardboard packs.

- Cuts for the production of carton packs are common Ch folded first so that a rectangular or square "tube” surrounding the package is formed, which is open on two opposite sides. These open sides are then closed by partially overlapping folding tabs, namely two opposite and complementary inner tabs and two mutually opposite and complementary outer tabs.

- the folding flaps create the bottom wall and top wall.

- the folding tabs are connected to each other by gluing.

- glue surfaces are applied to the inner lobes and / or to the inside of the outer lobes.

- the carton pack can be closed by an adhesive strip applied on the outside.

- the invention is concerned with the testing of the closure of such or similar carton packs.

- the object on which the invention is based is to reliably determine any errors in the area of the closure, namely in the area of the walls formed from the folding tabs.

- the method according to the invention is characterized in that, immediately after completion of the walls, pressure is exerted on them in the region of adjacent cardboard edges by folding the folding tabs in such a way that the folding tabs are moved out of the wall plane by incorrectly formed walls.

- the pressure treatment according to the invention of the folding tabs glued or connected to one another ensures that faulty carton packs are also identified in which the connection of the Folding flap to the outside is apparently correct.

- the pressure load in the plane of the walls formed by the folding tabs ensures that inadequate (adhesive) connections lead to the opening of the folding tabs and thus to the incorrect packing being determined.

- the device according to the invention for testing cardboard packs is equipped, following a gluing and folding station, with a test station in which the cardboard packs are acted upon by pressure members which generate pressure in the plane of the walls formed by the folding tabs. Cardboard packs with intact walls withstand the pressure.

- any incorrect packs are identified in the area of a test station and sorted out in terms of conveyor technology.

- light barriers extend in a plane parallel to the walls formed from folding tabs, in particular in a vertical plane. In this way, folding tabs that protrude to the side or adhesive strips - if the adhesive strips are incorrectly attached - are recognized.

- the adhesive strip is expediently applied by a corresponding application element following the test station, but in the conveying direction in front of the control station tion. In the area of the control station, possibly incorrectly applied or insufficiently adhesive adhesive strips are identified.

- the embodiment shown in the drawings is concerned with the production of cardboard packs 10 for holding, for example, cigarette sticks.

- the Carton packs 10 are transported on a feed conveyor 11 (in cycles).

- the feed conveyor 11 here consists of two spaced apart support rods 12, 13, on which the carton pack 10 rests and is slid on.

- the transport is carried out by drivers 14 of a (chain) conveyor acting on the rear.

- the carton pack 10 consists of a blank, e.g. made of corrugated cardboard that surrounds the contents of the pack.

- the carton pack 10 is initially open on both sides - upright side surfaces parallel to the conveying direction.

- the blank has folding flaps which can be folded onto one another, namely inner flaps 15, 16 and outer flaps 17, 18.

- the aforementioned folding flaps 15. 18 are folded over one another to form, for example, bottom wall 19 and top wall 20.

- the inner tabs 15, 16 proceed from mutually opposite vertical edges 21, 22, while the outer tabs 17, 18 merge into upper walls of the cardboard pack 10 via upper and lower horizontal edges 23, 24.

- the outer tabs 17, 18 in the present example of a carton pack 10 are dimensioned such that they completely cover the bottom wall 19 or the top wall 20 and abut one another in the region of a parting line 25. This is arranged in the middle.

- the carton packs 10 are filled outside the aggregates shown here and partially folded in the area of the bottom wall 19 and the top wall 20, namely with respect to the inner tabs 15, 16. These are already folded into the end position when the carton Pack 10 reaches the area of a gluing station 26.

- the outer tabs 17, 18 are pre-folded here so that they are in an inclined position (Fig. 5). With this relative position of the outer tabs 17, 18, the carton pack 10 can glue members 27, 28 arranged on both sides of the feed conveyor 11 are moved past such that appropriately designed nozzle heads 29 extend adjacent to the inside of the oblique outer tabs 17, 18 (FIG. 5). In this position, glue strips 30, 31 (hot-melt) can be sprayed onto the inner tabs 15, 16 in two successive spray cycles.

- a folding station 32 follows the gluing station 26 in the conveying direction. Two measures are carried out in this in the area of the folding tabs. Firstly, the outer tabs 17, 18 are pressed against the inner tabs 15, 16, that is to say folded in the end position. On the other hand, the outer tabs 17, 18 are corrected or aligned with respect to the relative position after this folding step in such a way that the outer tabs 17, 18 abut each other in the region of the parting line 25.

- folding elements are arranged laterally next to the feed conveyor, which can be moved in the transverse direction against the carton pack 10.

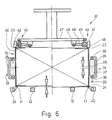

- these are roller folders 33, 34 on both sides of the feed path 11.

- Each roller folder 33, 34 consists of a U-shaped support frame 35 with horizontally directed flanges 36. Inside the support frame 35, namely between the upper and lower Flanges 36, a larger number of freely rotatable pressure rollers 37 is arranged with an upright axis of rotation.

- the roller folders 33, 34 formed in this way are moved from a retracted position (FIG. 5) to a folded position (FIG. 6, left), bearing against the outer tabs 17, 18 pressed against the inner tabs 15, 16.

- the roller folder 33, 34 can remain in this folding or pressing position if the carton pack 10 is conveyed further out of the folding station 32 after the measures provided have been carried out.

- the pressure rollers 42 can be moved against the load of a compression spring 45 or dodge.

- the pressure rollers 42 of a counter-holder 43 are arranged on an elongated carrier 46 which is pivotably mounted on a crossbar 47 which extends above the movement path of the carton packs 10.

- the carrier 46 is provided with a shoulder 48 which is attached to the crossbar 47 with a joint 49.

- the compression springs 45 are supported with the upper end also from the appropriately dimensioned crossbar 47.

- the fully folded cardboard packs 10 arrive in the area of a tape station 50 by further transport on the feed conveyor 11.

- an adhesive strip 51 is applied to the side surfaces, that is to say to the bottom wall 19 and / or top wall 20.

- the adhesive strip 51 is attached so that the parting line 25 between the two outer tabs 17, 18 is covered.

- the adhesive strip 51 is applied by means of tape units 52, 53 of conventional design arranged on both sides of the feed conveyor track.

- a tape 55 provided with an adhesive is pulled off a bobbin 54, transferred to the cardboard pack 10, pressed against it and cut to a suitable length.

- the cardboard pack 10 completed by attaching the adhesive strip 51 arrives at a control station 56 on the feed conveyor 11.

- the cardboard pack 10 is checked for correct formation in the region of the bottom wall 19 and the top wall 20.

- the cardboard pack 10 is raised, namely by (three) pressure strips 57, 58, 59, which grip the latter in the region of the lower horizontal edges 23, 24 and in the middle of the cardboard pack 10.

- the pressure bars 57, 58, 59 are connected via upright webs 60 to a transverse support beam 61 which can be moved up and down by lifting rods 62.

- the carton pack 10 is located (in the control station 56) on a cross conveyor 63, in the area of which the control station 56 is formed following the feed conveyor 11.

- the cross conveyor 63 is designed as a roller conveyor with two conveyor sections 64 and 65. Correctly designed carton packs 10 leave the control station 56 via the conveyor section 64, that is to the left in FIG. 1. Incorrect packs are separated out via the conveyor section 65 to the right.

- drive rollers 66 of the two conveying sections 64, 65 can be rotated in both directions by a common drive.

- the drive rollers 66 each equipped with gear wheels 67, are connected to one another by a common chain drive 68.

- each of the drive rollers 66 is provided with a sprocket 69 for a common drive chain 70 which includes all drive rollers 66.

- a common drive 71 which has a reversible drive motor 72, is installed on the machine frame below the plane of the drive rollers 66.

- the drive motor 71 connected to one of the drive rollers 66 causes the drive rollers to rotate in one direction or the other, depending on whether an intact carton pack 10 is to the left on the conveying section 64 or a defective carton pack 10 is to the right on the conveying section 65 in a processing tion station 73 is to be promoted.

- the control station 56 is formed in the area of the cross conveyor 63 following the feed conveyor 11. To carry out the test, the carton packs 10 are lifted in the control station 56 by the pressure bars 57, 58, 59 from the drive rollers 66 of the cross conveyor 63 and brought to bear against elastic pressure members arranged above the carton pack 10. These are also arranged in the region of the (upper) horizontal edges 23.

- the relatively narrow pressure bars 57..59 are each arranged between adjacent drive rollers 66 and can be lowered below the level of the cross conveyor 63.

- the lifting rod 62 can be actuated by a lifting gear 74, which essentially consists of a crank mechanism 75.

- the middle pressure bar 58 serves as an additional support member for the carton pack 10.

- the counterpressure member which is mounted in a stationary manner above the carton packs 10, here consists of two lateral pressure beams 76, 77. These are supported on a part of the machine frame by means of support rods with compression springs 79, namely on a support plate 80 Pressure bar 76, 77 raised while increasing the contact pressure. As a result, pressure is exerted on the sideward walls (bottom wall 19, top wall 20) formed from the folding tabs, which leads to the opening of improperly bonded folding tabs.

- Cardboard packs 10 which are formed incorrectly are identified in the control station 56 by optoelectric sensors.

- photo sensors namely a transmitter 81

- the vertical light barrier formed between them is formed closely, namely with a small distance, next to the sideways-facing walls (bottom wall 19, top wall 20) of the carton pack 10. Any protruding parts of these walls, in particular folding tabs and / or adhesive strips 51, are found. They lead to a sorting out of the relevant carton pack 10 into the processing station 73 by correspondingly driving the drive rollers 66.

- the defective carton pack 10 rests on freely rotatable, but not driven, support rollers 83.

- the defect in the carton pack 10 is eliminated manually here.

- the corrected carton pack 10 is then returned in the conveying flow, namely in the event of a gap in the supply of correct carton packs 10 with a corresponding drive direction of the drive rollers 66.

- the exact time of introduction of the repaired carton pack 10 into the conveying flow is determined by a stop 84 which holds the carton pack 10 resting on the drive rollers 66 in the raised position until the path for the carton pack 10 is clear is. the stop 84 is lowered by a pivot lever 85 so that the carton pack 10 can then be removed automatically.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Making Paper Articles (AREA)

- Closing Of Containers (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3816856 | 1988-05-18 | ||

| DE3816856A DE3816856A1 (de) | 1988-05-18 | 1988-05-18 | Verfahren und vorrichtung zum pruefen von karton-packungen |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0342384A1 true EP0342384A1 (fr) | 1989-11-23 |

| EP0342384B1 EP0342384B1 (fr) | 1993-11-03 |

Family

ID=6354591

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89107242A Expired - Lifetime EP0342384B1 (fr) | 1988-05-18 | 1989-04-21 | Procédé et dispositif pour le contrôle d'emballages en carton |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US4984409A (fr) |

| EP (1) | EP0342384B1 (fr) |

| JP (1) | JP2581799B2 (fr) |

| AU (1) | AU614838B2 (fr) |

| BR (1) | BR8902305A (fr) |

| CA (1) | CA1330715C (fr) |

| DE (2) | DE3816856A1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0509270A3 (en) * | 1991-04-15 | 1993-07-07 | Focke & Co. (Gmbh & Co.) | Method and apparatus for the elctro-optical scanning of (cigarette) packs |

| CN103043241A (zh) * | 2012-12-28 | 2013-04-17 | 四川烟草工业有限责任公司成都分厂 | 一种用于gdx2包装机上识别小盒短边粘贴不牢的装置 |

Families Citing this family (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2719556B1 (fr) * | 1994-05-09 | 1996-07-19 | Probag Sa | Machine de suremballage de bagages. |

| US5533315A (en) * | 1995-09-01 | 1996-07-09 | Blueprint Automation, Inc. | Closure checking apparatus for bagged goods |

| IT1279620B1 (it) * | 1995-09-08 | 1997-12-16 | Azionaria Costruzioni Acma Spa | Dispositivo e metodo per il controllo dell'integrita' di confezioni di prodotti in macchine confezionatrici |

| DE19607215A1 (de) * | 1996-02-26 | 1997-08-28 | Focke & Co | Verfahren und Vorrichtung zum Herstellen von insbesondere Klappschachteln für Zigaretten |

| DE19707685A1 (de) * | 1997-02-26 | 1998-08-27 | Focke & Co | Vorrichtung zum Handhaben oder Herstellen von Packungen |

| DE19754328A1 (de) * | 1997-12-08 | 1999-06-10 | Focke & Co | Klappschachtel für Zigaretten sowie Verfahren und Vorrichtung zum Beleimen von Verpackungsmaterial |

| US6088995A (en) * | 1998-06-17 | 2000-07-18 | The Mead Corporation | System for automatic inspection and ejection of cartons in a packaging machine |

| DE19917457A1 (de) * | 1999-04-17 | 2000-10-19 | Topack Verpacktech Gmbh | Vorrichtung zum linearen Transport von hinsichtlich der Verklebungsqualität geprüften quaderförmigen Zigarettenpackungen |

| DE19931946A1 (de) | 1999-07-09 | 2001-01-11 | Focke & Co | Verfahren und Vorrichtung zum Herstellen von (Falt-)Kartons |

| US6599227B1 (en) * | 2000-07-06 | 2003-07-29 | Reynolds Consumer Products, Inc. | Method and apparatus for positioning applied slider |

| DE10050297A1 (de) * | 2000-10-10 | 2002-04-11 | Focke & Co | Verfahren und Vorrichtung zum Prüfen von insbesondere Zigarettenpackungen |

| JP4004918B2 (ja) * | 2002-10-22 | 2007-11-07 | 日本テトラパック株式会社 | 検体作成装置 |

| US20050067333A1 (en) * | 2003-09-29 | 2005-03-31 | Unitech, Inc. | Method and apparatus for detecting a cracked or broken case |

| US7886503B2 (en) * | 2003-12-16 | 2011-02-15 | R.A. Pearson Company | Packaging case closing and tape sealing machine and processes |

| US20060249436A1 (en) * | 2005-05-04 | 2006-11-09 | Hardman James L Jr | Pallet defect inspection systems and methods |

| ITBO20080242A1 (it) * | 2008-04-18 | 2009-10-19 | Gd Spa | Macchina cartonatrice |

| CN102514770A (zh) * | 2012-01-06 | 2012-06-27 | 上海兰宝传感科技股份有限公司 | 卷烟包装机缺盒检测剔除装置 |

| CN103434667B (zh) * | 2013-08-23 | 2015-08-19 | 中山市恒鑫聚诚工业设备有限公司 | 一种用于包装箱底部自动折盒机 |

| EP2878544B2 (fr) | 2013-12-02 | 2023-01-11 | Krones Aktiengesellschaft | Procédé et dispositif de contrôle des collages entre des articles d'une gerbe |

| WO2016118959A1 (fr) * | 2015-01-25 | 2016-07-28 | Ten Media, Llc Dba Ten Ag Tech Co. | Procédé et système d'application d'informations sur un emballage de produit alimentaire |

| US10597179B2 (en) | 2016-02-29 | 2020-03-24 | Signode Industrial Group Llc | Automatic random box sealer and method of sealing boxes of different sizes |

| CN105966691B (zh) * | 2016-05-18 | 2017-12-29 | 成都九芝堂金鼎药业有限公司 | 一种自动化药盒包装线 |

| EP3538442A1 (fr) * | 2016-11-08 | 2019-09-18 | Adel Kalemcilik Ticaret Ve Sanayi A. S. | Appareil et procédé de mise en boîte de crayons |

| US11242169B2 (en) | 2018-03-19 | 2022-02-08 | Signode Industrial Group Llc | Random case sealer |

| US11273939B2 (en) | 2018-08-03 | 2022-03-15 | Signode Industrial Group Llc | Case former with case-squaring assembly |

| US11492163B2 (en) | 2019-07-12 | 2022-11-08 | Signode Industrial Group Llc | Random case sealer |

| CN110508498B (zh) * | 2019-08-28 | 2021-11-26 | 贵州大学 | 一种用于爆珠香烟过滤嘴中爆珠质量检测剔废装置 |

| US11952159B2 (en) | 2020-03-25 | 2024-04-09 | Signode Industrial Group Llc | Random case sealer |

| CN111751222B (zh) * | 2020-07-10 | 2023-07-07 | 华北水利水电大学 | 一种抗外压质量检测装置及其操作方法 |

| CN113023230A (zh) * | 2021-03-02 | 2021-06-25 | 宁波锋速物流有限公司 | 一种检测仓储纸箱强度的装置 |

| CN118817696B (zh) * | 2024-07-29 | 2025-02-25 | 张家港市嘉洋精密科技有限公司 | 一种纸箱的封箱缺陷视觉检测方法及系统 |

| CN120515715B (zh) * | 2025-07-24 | 2025-10-28 | 兴化格林生物制品有限公司 | 一种食品添加剂堆垛装置 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1934390A1 (de) * | 1968-07-08 | 1970-01-15 | Skoda Np | Vorrichtung zur Kontrolle der Verschliessung von Zigarettenschachteln oder anderer Pakete durch einen Absperrklebezettel mit nachfolgender Ausscheidung fehlerhafter Zigarettenschachteln |

| DE1561424B1 (de) * | 1966-03-03 | 1971-03-25 | Silver Stanley Milton | Verfahren zum Verschliessen von rechteckigen Kartons |

| US3939063A (en) * | 1974-10-10 | 1976-02-17 | Gerber Products Company | Loose flap detector and case ejector system for wrap-around paperboard cartons |

| GB2010768A (en) * | 1977-12-22 | 1979-07-04 | Focke & Co | Apparatus for folding carton flaps |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7318466U (de) * | 1973-09-06 | Enzinger Union Werke Ag | Vorrichtung zum Prüfen von Kartons auf ordnungsgemäßen Verschluß ihrer Bodenklappen | |

| US2518959A (en) * | 1948-07-21 | 1950-08-15 | Perkins & Son Inc B F | Apparatus for testing the crush strength of paper |

| US3052072A (en) * | 1959-05-07 | 1962-09-04 | Gen Corrugated Machinery Compa | Carton sealing mechanism |

| US3041873A (en) * | 1960-01-25 | 1962-07-03 | Ametek Inc | Load testing apparatus |

| GB1173966A (en) * | 1967-03-20 | 1969-12-10 | British American Tobacco Co | Improvements in Packing Machinery |

| US3464260A (en) * | 1967-04-17 | 1969-09-02 | Maryland Cup Corp | Crushability tester |

| US3714759A (en) * | 1971-01-04 | 1973-02-06 | Schlitz Brewing Co J | Open flap detector for filled cartons |

| SU896517A1 (ru) * | 1980-04-11 | 1982-01-07 | Предприятие П/Я В-2962 | Устройство дл определени прочности сцеплени образцов клеевого соединени |

| US4349998A (en) * | 1980-07-16 | 1982-09-21 | Garvey Corporation | Carton inspecting and conveying apparatus |

| US4643027A (en) * | 1984-07-14 | 1987-02-17 | Hauni-Werke Korber & Co. Kg. | Apparatus for testing cigarette packs and the like |

-

1988

- 1988-05-18 DE DE3816856A patent/DE3816856A1/de not_active Withdrawn

-

1989

- 1989-04-21 DE DE89107242T patent/DE58906072D1/de not_active Expired - Fee Related

- 1989-04-21 EP EP89107242A patent/EP0342384B1/fr not_active Expired - Lifetime

- 1989-04-26 CA CA000597864A patent/CA1330715C/fr not_active Expired - Fee Related

- 1989-05-10 AU AU34656/89A patent/AU614838B2/en not_active Ceased

- 1989-05-17 BR BR898902305A patent/BR8902305A/pt not_active IP Right Cessation

- 1989-05-18 JP JP1125468A patent/JP2581799B2/ja not_active Expired - Fee Related

-

1990

- 1990-08-16 US US07/569,253 patent/US4984409A/en not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1561424B1 (de) * | 1966-03-03 | 1971-03-25 | Silver Stanley Milton | Verfahren zum Verschliessen von rechteckigen Kartons |

| DE1934390A1 (de) * | 1968-07-08 | 1970-01-15 | Skoda Np | Vorrichtung zur Kontrolle der Verschliessung von Zigarettenschachteln oder anderer Pakete durch einen Absperrklebezettel mit nachfolgender Ausscheidung fehlerhafter Zigarettenschachteln |

| US3939063A (en) * | 1974-10-10 | 1976-02-17 | Gerber Products Company | Loose flap detector and case ejector system for wrap-around paperboard cartons |

| GB2010768A (en) * | 1977-12-22 | 1979-07-04 | Focke & Co | Apparatus for folding carton flaps |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0509270A3 (en) * | 1991-04-15 | 1993-07-07 | Focke & Co. (Gmbh & Co.) | Method and apparatus for the elctro-optical scanning of (cigarette) packs |

| US5240117A (en) * | 1991-04-15 | 1993-08-31 | Focke & Co. (Gmbh & Co.) | Method and apparatus for electro-optically scanning (cigarette) packs |

| CN103043241A (zh) * | 2012-12-28 | 2013-04-17 | 四川烟草工业有限责任公司成都分厂 | 一种用于gdx2包装机上识别小盒短边粘贴不牢的装置 |

| CN103043241B (zh) * | 2012-12-28 | 2014-06-18 | 四川烟草工业有限责任公司成都分厂 | 一种用于gdx2包装机上识别小盒短边粘贴不牢的装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0342384B1 (fr) | 1993-11-03 |

| AU3465689A (en) | 1989-11-23 |

| BR8902305A (pt) | 1990-01-09 |

| DE58906072D1 (de) | 1993-12-09 |

| CA1330715C (fr) | 1994-07-19 |

| JP2581799B2 (ja) | 1997-02-12 |

| US4984409A (en) | 1991-01-15 |

| JPH0232932A (ja) | 1990-02-02 |

| DE3816856A1 (de) | 1989-11-30 |

| AU614838B2 (en) | 1991-09-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0342384B1 (fr) | Procédé et dispositif pour le contrôle d'emballages en carton | |

| EP2922758B1 (fr) | Méthode et appareil pour le remplissage de produits dans un conteneur | |

| EP0562349B2 (fr) | Procédé et appareil pour sortir des emballages défectueux d'une machine d'emballage | |

| EP0113899B1 (fr) | Procédé et dispositif pour la fermeture de cartons | |

| DE3429761A1 (de) | Vorrichtung zum aufrichten von faltkartons | |

| EP3299159B1 (fr) | Procédé et dispositif de fabrication de cartons avec rabat de fermeture | |

| EP2197745A1 (fr) | Procédé et dispositif de manutention de particules de tabac en morceaux ou en grains, en particulier de tabac à chiquer ou de substitut de tabac à chiquer (snus) | |

| DE60009209T2 (de) | Verpackungsvorrichtung und Verfahren zum Einwickeln von flachen Gegenständen, wie Büchern | |

| DE3421261A1 (de) | Vorrichtung zum falten und verschliessen der stirnwaende von tray-kartons | |

| EP1067050B1 (fr) | Procédé et dispositif pour la fabrication de boîtes (pliantes) | |

| EP0338255B1 (fr) | Machine d'emballage en carton et procédé d'empaquetage des produits dans des cartons | |

| DE3320459A1 (de) | Verfahren und vorrichtung zum entleeren von tabak-kartons | |

| EP3738896B1 (fr) | Dispositif d'emballage pour groupes d'articles et procédé d'application d'un flan de carton sur un groupe d'articles | |

| DE202021100952U1 (de) | Vorrichtung zum Befüllen eines flexiblen Behältnisses, insbesondere eine Ventilsackabfüllvorrichtung | |

| DE20214693U1 (de) | Vorrichtung zum Verpacken von Packgut, insbesondere Weichpackungen | |

| DE3815019C2 (de) | Vorrichtung zur Überführung und Aufbringung von Verschlußbanderolen | |

| EP1320456A1 (fr) | Dispositif de montage et/ou de controle de recipients pliables et son procede d'exploitation | |

| DE4100783A1 (de) | Verfahren und vorrichtung zum aufrichten einer verpackung und zuschnitt zum herstellen dieser verpackung | |

| EP0697339B1 (fr) | Procédé et dispositif de fabrication d'un emballage de présentation et l'emballage de présentation ainsi fabriqué | |

| DE102018102515A1 (de) | Verfahren und Vorrichtung zum Verpacken von mehreren Gegenständen | |

| DE102018102514A1 (de) | Verfahren und Vorrichtung zur Bereitstellung einer Umverpackung | |

| DE102023107947A1 (de) | Verfahren und Vorrichtung zum Handhaben von Packungen für Produkte der Zigarettenindustrie | |

| DE3537690A1 (de) | Verfahren und vorrichtung zum befuellen von verpackungsbehaeltern | |

| EP0254908A2 (fr) | Procédé et dispositif pour dresser et fermer une boîte pliante | |

| EP4429961A1 (fr) | Procédé et système de mesure destinés au contrôle qualité d'unités d'emballage |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19900317 |

|

| 17Q | First examination report despatched |

Effective date: 19920320 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19931109 |

|

| REF | Corresponds to: |

Ref document number: 58906072 Country of ref document: DE Date of ref document: 19931209 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19960410 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971231 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20050420 Year of fee payment: 17 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060421 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20060421 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060430 Year of fee payment: 18 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20060421 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070421 |