EP0308904A2 - Carte d'identité imprimable à plusieurs couches et procédé pour sa réalisation - Google Patents

Carte d'identité imprimable à plusieurs couches et procédé pour sa réalisation Download PDFInfo

- Publication number

- EP0308904A2 EP0308904A2 EP88115505A EP88115505A EP0308904A2 EP 0308904 A2 EP0308904 A2 EP 0308904A2 EP 88115505 A EP88115505 A EP 88115505A EP 88115505 A EP88115505 A EP 88115505A EP 0308904 A2 EP0308904 A2 EP 0308904A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- card

- characters

- plateaus

- plateau

- laser

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 title claims description 42

- 238000004519 manufacturing process Methods 0.000 title claims description 12

- 239000000463 material Substances 0.000 claims abstract description 30

- 239000004033 plastic Substances 0.000 claims abstract description 25

- 229920003023 plastic Polymers 0.000 claims abstract description 25

- 230000015572 biosynthetic process Effects 0.000 claims abstract description 18

- 238000007639 printing Methods 0.000 claims abstract description 12

- 238000004049 embossing Methods 0.000 claims description 33

- 239000013039 cover film Substances 0.000 claims description 20

- 230000005684 electric field Effects 0.000 claims description 5

- 230000000007 visual effect Effects 0.000 claims description 4

- 238000010521 absorption reaction Methods 0.000 claims description 2

- 230000005855 radiation Effects 0.000 claims 1

- 230000000630 rising effect Effects 0.000 claims 1

- 230000003595 spectral effect Effects 0.000 claims 1

- 239000004417 polycarbonate Substances 0.000 abstract description 2

- 229920000515 polycarbonate Polymers 0.000 abstract description 2

- 239000010410 layer Substances 0.000 description 24

- 239000010408 film Substances 0.000 description 14

- 230000000694 effects Effects 0.000 description 6

- 239000004604 Blowing Agent Substances 0.000 description 5

- 238000002845 discoloration Methods 0.000 description 5

- 238000004040 coloring Methods 0.000 description 4

- 239000012792 core layer Substances 0.000 description 4

- 238000005187 foaming Methods 0.000 description 4

- 238000010330 laser marking Methods 0.000 description 4

- 238000002372 labelling Methods 0.000 description 3

- 238000010030 laminating Methods 0.000 description 3

- 239000011159 matrix material Substances 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 2

- 235000010678 Paulownia tomentosa Nutrition 0.000 description 2

- 240000002834 Paulownia tomentosa Species 0.000 description 2

- 229910052799 carbon Inorganic materials 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 230000002427 irreversible effect Effects 0.000 description 2

- 239000003380 propellant Substances 0.000 description 2

- 239000011265 semifinished product Substances 0.000 description 2

- 239000002904 solvent Substances 0.000 description 2

- 238000005299 abrasion Methods 0.000 description 1

- 230000002745 absorbent Effects 0.000 description 1

- 239000002250 absorbent Substances 0.000 description 1

- 230000003213 activating effect Effects 0.000 description 1

- 238000013475 authorization Methods 0.000 description 1

- 230000009172 bursting Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000005672 electromagnetic field Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 238000005562 fading Methods 0.000 description 1

- 238000003475 lamination Methods 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 239000000256 polyoxyethylene sorbitan monolaurate Substances 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000010076 replication Effects 0.000 description 1

- 229920001169 thermoplastic Polymers 0.000 description 1

- 239000004416 thermosoftening plastic Substances 0.000 description 1

- 239000012780 transparent material Substances 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/40—Manufacture

- B42D25/405—Marking

- B42D25/41—Marking using electromagnetic radiation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/40—Manufacture

- B42D25/405—Marking

- B42D25/425—Marking by deformation, e.g. embossing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/20—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof characterised by a particular use or purpose

- B42D25/23—Identity cards

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/40—Manufacture

- B42D25/405—Marking

- B42D25/43—Marking by removal of material

- B42D25/435—Marking by removal of material using electromagnetic radiation, e.g. laser

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M5/00—Duplicating or marking methods; Sheet materials for use therein

- B41M5/26—Thermography ; Marking by high energetic means, e.g. laser otherwise than by burning, and characterised by the material used

- B41M5/267—Marking of plastic artifacts, e.g. with laser

-

- B42D2033/08—

-

- B42D2035/50—

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/324—Reliefs

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S283/00—Printed matter

- Y10S283/904—Credit card

Definitions

- the invention relates to a multilayer identification card with at least one card surface made of plastic, which in some areas has characters or symbols in a relief structure that can be used as a printing block, and to a method for producing such identification cards.

- ID cards in the form of credit cards, bank cards, cash payment cards, authorization cards or the like are used in a wide variety of areas, such as. B. include cashless payments, access control systems and a wide variety of service systems. These ID cards generally have data related to the cardholder, which are applied in the so-called personalization process. A common form of the possible representation of these characters is the embossing, in which the user-related data are embossed in relief from the back of the ID card to the front of the card. To make the individual characters more visible, they are additionally colored in their apex areas.

- this form of personalization is used more widely, particularly in the case of credit cards, since the character set which can be used as a printing block allows the data to be transferred easily from the card to the current payment slip. So-called imprinters are used, in which the card and the payment slip are inserted.

- the user data is transferred to the payment document via a mechanical embossing process using carbon or carbon paper (DE-PS 20 18 927).

- An internationally defined standard determines, among other things, the location of the embossed data on the ID card, its shape and its relief height (ISO standards 7811/1 and 7811/3).

- the embossed data appear only on a card surface.

- the personalization data are embossed in metal plates and transferred to the card surface when the ID card is laminated.

- the card material softens and flows into the depressions in the metal plate without leaving a negative relief on the back. This creates an embossing in which the characters can no longer be embossed.

- this method is much more complex than the usual embossing method, since a metal plate with the correspondingly engraved personalization data must be produced for each card and this personalization process is a process step that cannot be separated from the card production.

- DE-OS 32 13 315 Only through DE-OS 32 13 315 was an identification card and a method for producing the same presented, with which identification cards can not only be provided in a simple form with characters that can be used as a printing block, but in which these characters are also available in a particularly forgery-proof form .

- a laser beam is preferably used for this purpose, which generates the heat necessary for triggering the foaming process or activating the blowing agents in this foamable plastic material.

- this foaming process can be carried out in a targeted manner in order to produce the characters in accordance with the standards with regard to their dimensions and their relief height.

- this foaming can be associated with discoloration of the plastic material, so that the previously necessary coloring process is unnecessary. Since the discoloration takes place in the plastic material itself and is also irreversible, it is forgery-proof and resistant to abrasion.

- the invention is therefore based on the object, while maintaining the simple, but particularly forgery-proof, individual labeling option given by the laser method, to provide an identification card which can be equipped with a standard embossed character set even without the use of special foamable foils.

- the invention is based on the idea of using the "natural foamability" of plastic materials generally used in identity cards, such as PVC and polycarbonate, which can be caused by laser action, in order to achieve a relief height sufficient for a clear imprint of the characters and the total height of the embossing characters required according to the standard to be realized above the rest of the card surface by an additional deformation of the card body in the area of the embossed character.

- plastic material such as. B. PVC

- this increase in volume caused by the gas bubbles is now used in a targeted manner to generate characters which are not only apparent in color but also in their relief height in relation to the surroundings.

- plastic material such as. B. PVC

- Appropriate optimization of the material and process parameters can therefore be used to generate characters in a relief height sufficient for an impression, the surface in the character area being influenced only imperceptibly and, in particular, still being completely self-contained is.

- the last-mentioned characteristic is of particular importance for the quality of the later reprint of the data. Only at very high intensities does the formation of the gas bubbles lead to bursting in the cover film, as is known from the aforementioned DE-PS.

- the effective maximum height of the sign in relation to its immediate surroundings does not necessarily have to be the 0.46 mm specified by the standard.

- a relief height of approximately 100 ⁇ is already sufficient for a mechanical impression of relief signs.

- This relief height is now achieved according to the invention with the abovementioned laser inscription, preferably by means of a corresponding increase in volume in the transparent cover film of the identification card, while the relief height (360 über) above the card surface required to meet the standard is generated by deforming the card to form plateaus becomes.

- a double-layer transparent cover film is preferably used for the identification card according to the invention, a plastic material being used for the outer layer, which is somewhat less sensitive to the laser effect. This ensures that the outer film softens, but the formation of bubbles is somewhat less than in the more sensitive inner film. The outer film can then evade the inner pressure resulting from the formation of bubbles, itself also contributes to the increase in volume, but is subjected to a somewhat less thermal load in view of a good surface quality.

- the plateaus on which these characters are formed by means of laser can certainly cover a larger area, e.g. B. the area of one or more lines of characters or they can also be composed of a plurality of smaller plateaus, each of which can only accommodate one character.

- plateau formation e.g. B. a mechanical embossing, thermal embossing or embossing the card material while softening the material by means of a high-frequency alternating electromagnetic field.

- the latter method has the advantage that, by appropriately designing the electrodes which simultaneously form the embossing stamp, the card only has to be thermally stressed in the areas which are actually to be deformed. As will be shown later, this fact can also be used to be able to carry out the plateau formation after the laser marking.

- An important advantage of the present invention is that the usual materials known from card production can be used for the construction of the card, only the layer thicknesses required to achieve a sufficient relief height being observed.

- the card manufacturing and personalization processes are also two completely independent process stages. Personalization can thus represent the last step in the production of ID cards.

- the main advantages of this circumstance include: B. that in the card manufacturing "scrap cards" can be discarded before the personalization process or already personalized cards are no longer endangered by subsequent manufacturing steps.

- the relief structures achieved by the natural "foamability" of the plastic material also have sufficient strength, which is necessary for the frequent later use in the above-mentioned imprinters for printing the user-related data.

- the proposed card structure with the transparent double-layer cover film also allows other authenticity features, such as. B. the "laser tilt image” known from DE-OS 36 34 865 or the “parallax image” known from DE-OS 36 34 857 by laser.

- a font without a relief structure can also be generated, the intensity and the scanning speed of the laser beam having to be controlled accordingly in a manner to be explained later.

- a font with a relief structure would have a negative impact on the readability of the magnetic data, since transport rollers arranged in this area impair the smooth card transport.

- an identity card 1 and 2 show an identity card 1, such as. B. a credit card with the information content typical for them. This is e.g. B. the specification of the issuing credit institution 2, the z. B. be applied by printing to the card ticker. Furthermore, the card has an authenticity feature 3, such as. B. a hologram embedded or glued into the cover film.

- the areas 4a and 4b of the card are reserved according to the international standard for the embossed characters 5, which are usually introduced in the area 4b in three or four lines (for the sake of simplicity, only one line is shown in the drawing). These characters are created after the card has been made. H. after welding the individual card layers, stamped in a corresponding embossing press. For better visual visibility, the characters are then displayed in their raised areas, i.e. in the crown areas 6, colored.

- FIG. 2 shows the map in a sectional view with a two-layer structure shown here by way of example.

- An opaque card core 7 carries z. B. one or both sides of a printed image 8 and in the back of a magnetic strip 9 is embedded.

- an electrical circuit (not shown in the figure) can be embedded in a cutout in the card core.

- the embossed characters 5 were introduced by pressing them in from the back and correspondingly deforming the card body, the card being deformed to such an extent that the apex regions 6 reach a height H of approximately 0.45 mm above the card surface.

- the identification card is also embossed, but in this embossing it is not the characters themselves that are introduced, but rather only partial areas 21a, b, into which the embossed characters are to be introduced, raised by a uniform 1/4 0.35 mm above the card surface.

- Areas marked 21a and 21b are hereinafter referred to as plateaus. You can e.g. B. have the size of a line or a multi-line field. These plateaus now serve to achieve the effective relief height of the embossed characters of 0.46 mm as required by the standard.

- Fig. 4 shows the semi-finished product 20 of the identity card in the sectional view.

- the card according to the invention has a three-layer structure. These three layers 22-24 are the opaque core layer 22 and a two-layer transparent cover layer 23, 24.

- the core layer can, as already mentioned above, be provided on one or both sides with printed images 25, 26 and also carry other security features, such as, for. B. a security thread, watermark-like effects or other features that serve to protect against forgery of the card structure.

- This opaque core layer 22 is covered on one side by a one-layer, but preferably two-layer transparent cover film which is matched to the laser inscription in terms of the choice of material.

- the two-layer cover film consists of two transparent PVC layers 23, 24, which have an improved absorption compared to the laser beam to have ability. Such films are such. B. from the previously mentioned documents DE-PS 31 51 407 and DE-OS 36 34 857 known.

- a film is selected which is more sensitive to the laser beam than the outer cover film 24.

- This card can be completely finished, ie printed, laminated and embossed, so that the necessary data only have to be added as a last step in the context of personalization.

- the back of the card can also be covered with a transparent cover film, equipped with a magnetic strip and / or an integrated circuit.

- the data which can be introduced by means of a laser are introduced into the card, the embossing marks 28 being recorded in the plateau region 21 (FIGS. 5, 6).

- the laser beam 29 is guided correspondingly over these plateaus 21a, b of the card 19 to form the characters, the recording parameters such as intensity, scanning speed, pulse frequency etc. being selected such that the greatest possible formation of bubbles 30 results with simultaneous softening of the film, without causing sharp bursts and pronounced crater formation in the surface area.

- a so-called gray wedge can be recorded in a trial run, on the basis of which the optimal laser parameters can then be determined empirically.

- a layer thickness of 100 to 150 150 is preferably selected for the inner cover film 23 and a thickness of 150 to 200 ⁇ for the outer cover film 24.

- This in total Together with 250 to 350 ⁇ thick transparent cover film can be expanded to a thickness of 350 or 450 ⁇ by appropriate laser exposure. Because of the local limitation of the "foaming" area, an increase in volume of approximately 30% is reflected directly in a corresponding change in thickness.

- This expansion (a) of approx. 100 ⁇ achieved by the laser effect together with the plateau formation (1 ⁇ 4 0.36 mm) created by the mechanical embossing results in the height H of 0.46 mm above the remaining card surface required for the standard. Attempts to use this card as a printing block in common imprinter devices showed excellent print quality.

- the relief formation can be additionally optimized by means of an appropriate laser beam guidance.

- the laser operated in pulse mode is guided over the card surface in such a way that the successive pulses overlap locally.

- the effect of the laser beam on the material is thus increased with the intensity remaining the same, since the following pulse strikes partially blackened and thus more absorbent material.

- the same card structure also allows the identification card to be labeled without simultaneously creating a relief. It is important to ensure that the intensity of the laser beam is reduced in such a way that the recording is preferably carried out without overlapping the individual laser pulses, that - as is known from DE-OS 36 34 857 - only a blackening in the more sensitive inner cover layer and essentially there are no visible bubbles.

- This labeling method is particularly suitable for labeling the area of the card in which the magnetic stripe is located on the back, since here a surface that is smooth on both sides is necessary for scanning the magnetic stripe. Usually concerns this is the information provided by the institute 31.

- the data is preferably recorded by scanning the card surface in accordance with a dot or line matrix, in which the laser beam is guided line by line over the card and the character is generated by correspondingly fading the laser beam on and off at the corresponding matrix points.

- a dot or line matrix in which the laser beam is guided line by line over the card and the character is generated by correspondingly fading the laser beam on and off at the corresponding matrix points.

- the card 19 shown in FIG. 5 also has a visually verifiable authenticity feature 27, which is also generated with a laser and whose appearance can change depending on the viewing angle.

- authenticity features are known from the documents, DE-PS 36 34 865 and DE-OS 36 34 857, the disclosure of which reference is made here. It is precisely here that the versatility of laser marking can be seen, which allows data with both the same relief and relief and corresponding visual authenticity features to be created with the same card structure by simply changing the laser control or intensity, possibly combined with a partial embossing (plateau, lens grid) Insert card.

- Fig. 7 shows a further embodiment, in which the plateau 21 each has only the size of a character 28 and a plurality of plateaus placed next to each other are embossed on the card. If technically justifiable, the number of individual fields can also be adapted to the respective number of characters required for the card-specific lettering.

- the individual plateaus or the large-area plateaus shown in the aforementioned examples can be achieved in a variety of ways.

- An embossing method is preferred in which the plastic material of the card 41 (FIG. 8) is softened by the action of a high-frequency electrical field and is deformed by appropriate embossing molds.

- the embossing molds can be electrodes 40a, b for the alternating electrical field.

- the processing of PVC with the help of high-frequency alternating electrical fields is e.g. B. known from the general literature.

- This deformation technique has the advantage that the card is only thermally stressed in the areas to be effectively deformed. Furthermore, this deformation is difficult to recover, since, in contrast to the mechanical cold deformation, this is a deformation "without memory”.

- the HF deformation also allows the plateaus to be formed even after the laser marking has been formed.

- the embossing stamp 40a has a cutout 42 in the card area which carries the already lasered relief data 43, so that the mechanical effect of the embossing stamps is concentrated only on the edge regions of the plateau to be formed.

- the lasered relief data therefore remain undamaged during the embossing process and this allows the embossing to be carried out even after the laser inscription.

- This solution thus has the further advantage that in the case of laser marking, in which the cards are automatically separated, transported and stacked, it is possible to work with flat cards.

- the embossing dies used in the above-mentioned deformation techniques can additionally have a relief in their surface, whereby an embossing pattern (32, FIG. 5) is embossed into the card surface at the same time as the plateau is formed.

- This embossing pattern can e.g. B. represent a micro relief, texturing, a sequence of characters, logos or similar symbols.

- the map thus contains a further feature that makes replication or change considerably more difficult, especially if a self-contained pattern runs over the entire plateau area and is only interrupted by the lasered relief symbols.

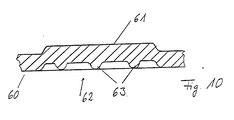

- the multilayer card body 50 is provided with an additional film piece 51 in order to form the plateaus in the embossed area.

- This embedded between core and cover sheet 53 or 54 piece of film 51 can, for. B. be a film of the same transparent material as the inner cover film layer of the embodiment shown in Fig. 4 or 6. This increases the thickness of the map by about 0.3 to 0.4 mm in the required range.

- the characters with the relief structure are then formed by means of, as already described above a laser beam, the volume being increased by the formation of bubbles combined with a simultaneous discoloration in these transparent layers.

- This additional piece of film 51 can, however, also be glued to the outer surface of the finished card or welded onto the card.

- the two-layer cover film structure shown in FIG. 4 is recommended as the material for this additional film.

- the intensity of the laser beam can be controlled in such a way that the card core is at least blackened in its surface and the user data can also be recognized on the card core layer.

- the plateau formation by means of an additional piece of film has the advantage that the back of the card remains completely flat and thus a printed image on the back of the card is not disturbed by impressions. In addition, the plateaus gain stability due to this flat back of the card.

- the support surface for the card in the imprinter devices could be provided with support elements which engage in the cavities on the back of the card and the plateaus during printing support the process.

- the embossing dies or laminating plates in the plateau area on the back of the card are additionally provided with depressions in the form of bores, channels, etc., into which the softened card material can flow during the formation of the plateau.

- FIG. 10 schematically shows such a card 60 with a plateau-like elevation 61 on the front of the card, which is supported on the back by a support profile 62 in the form of support rails 63 which run through the negative structure.

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Electromagnetism (AREA)

- General Health & Medical Sciences (AREA)

- Toxicology (AREA)

- Optics & Photonics (AREA)

- Credit Cards Or The Like (AREA)

- Medicines Containing Plant Substances (AREA)

- Saccharide Compounds (AREA)

- Battery Electrode And Active Subsutance (AREA)

- Diaphragms For Electromechanical Transducers (AREA)

- Shaping Of Tube Ends By Bending Or Straightening (AREA)

- Detergent Compositions (AREA)

- Laminated Bodies (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT88115505T ATE77068T1 (de) | 1987-09-22 | 1988-09-21 | Mehrschichtige als druckstock verwendbare ausweiskarte und verfahren zu deren herstellung. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3731853 | 1987-09-22 | ||

| DE19873731853 DE3731853A1 (de) | 1987-09-22 | 1987-09-22 | Mehrschichtige als druckstock verwendbare ausweiskarte und verfahren zu deren herstellung |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0308904A2 true EP0308904A2 (fr) | 1989-03-29 |

| EP0308904A3 EP0308904A3 (en) | 1989-10-18 |

| EP0308904B1 EP0308904B1 (fr) | 1992-06-10 |

Family

ID=6336572

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88115505A Expired - Lifetime EP0308904B1 (fr) | 1987-09-22 | 1988-09-21 | Carte d'identité imprimable à plusieurs couches et procédé pour sa réalisation |

Country Status (9)

| Country | Link |

|---|---|

| US (2) | US5005872A (fr) |

| EP (1) | EP0308904B1 (fr) |

| JP (1) | JP2731918B2 (fr) |

| AT (1) | ATE77068T1 (fr) |

| DE (2) | DE3731853A1 (fr) |

| DK (1) | DK166999B1 (fr) |

| ES (1) | ES2032512T3 (fr) |

| FI (1) | FI89252C (fr) |

| NO (1) | NO175416C (fr) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5005872A (en) * | 1987-09-22 | 1991-04-09 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Multilayer identity card usable as a printing block and a method of producing it |

| US5083850A (en) * | 1989-08-29 | 1992-01-28 | American Bank Note Holographics, Inc. | Technique of forming a separate information bearing printed pattern on replicas of a hologram or other surface relief diffraction pattern |

| WO2007118654A2 (fr) | 2006-04-13 | 2007-10-25 | Giesecke & Devrient Gmbh | Carte d'identité ayant une structure en relief profilée et procédé de réalisation correspondant |

| WO2010103499A1 (fr) | 2009-03-13 | 2010-09-16 | Arjowiggins Security | Substrat marquable au laser et procede de fabrication associe |

| WO2014076428A1 (fr) * | 2012-11-16 | 2014-05-22 | Oberthur Technologies | Procédé de réalisation d'un motif en relief dans une carte plastique mince |

| EP2956311A4 (fr) * | 2013-02-13 | 2016-11-02 | Entrust Datacard Corp | Document d'identification et son procédé de fabrication |

| WO2017140421A1 (fr) * | 2016-02-17 | 2017-08-24 | Giesecke & Devrient Gmbh | Support de données portatif pourvu d'un bosselage |

Families Citing this family (46)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0389971A (ja) * | 1989-08-31 | 1991-04-15 | Mitsubishi Materials Corp | 貴金属薄板への絵文字記入方法 |

| DE3932505C2 (de) | 1989-09-28 | 2001-03-15 | Gao Ges Automation Org | Datenträger mit einem optisch variablen Element |

| US5131686A (en) * | 1990-09-20 | 1992-07-21 | Carlson Thomas S | Method for producing identification cards |

| US5261987A (en) * | 1992-06-05 | 1993-11-16 | Eastman Kodak Company | Method of making an identification card |

| US6176522B1 (en) * | 1993-06-08 | 2001-01-23 | Securency Pty Ltd | Embossing of bank notes or the like with security devices |

| ES2167366T3 (es) * | 1993-06-08 | 2002-05-16 | Securency Pty Ltd | Estampacion en relieve de billetes de banco o similares, con elementos de seguridad. |

| JP3703860B2 (ja) * | 1994-02-28 | 2005-10-05 | 大日本印刷株式会社 | 印刷物の製造方法 |

| DE4410431A1 (de) * | 1994-03-25 | 1995-09-28 | Giesecke & Devrient Gmbh | Vor unerlaubter Reproduktion mit einem Kopiergerät geschützte Ausweiskarte |

| DE19537177C2 (de) * | 1995-10-06 | 1998-07-23 | Orga Kartensysteme Gmbh | Verfahren zur Herstellung einer Kunststoffkarte in Form einer Ausweiskarte, Telefonkarte, Kreditkarte, Krankenversichertenkarte o. dgl. |

| US6086707A (en) * | 1996-02-29 | 2000-07-11 | Raytheon Company | Method for making an identification document |

| DE19646331C2 (de) * | 1996-11-09 | 2000-08-10 | Fraunhofer Ges Forschung | Verfahren zur lokalen plastischen Verformung durch einen Laser |

| AUPO523997A0 (en) | 1997-02-20 | 1997-04-11 | Securency Pty Ltd | Laser marking of articles |

| US6919162B1 (en) * | 1998-08-28 | 2005-07-19 | Agilent Technologies, Inc. | Method for producing high-structure area texturing of a substrate, substrates prepared thereby and masks for use therein |

| AUPQ119999A0 (en) * | 1999-06-25 | 1999-07-22 | Note Printing Australia Limited | Improved security documents |

| DE19934434B4 (de) * | 1999-07-22 | 2006-10-05 | Bundesdruckerei Gmbh | Wert- und Sicherheitserzeugnis mit Mikrokanälen |

| US6628808B1 (en) * | 1999-07-28 | 2003-09-30 | Datacard Corporation | Apparatus and method for verifying a scanned image |

| ITMI20011889A1 (it) * | 2001-09-10 | 2003-03-10 | Elmiva S A S Di Walter Mantega | Procedimento contro la falsificazione e la contraffazione di documenti di valore in particolare banconote |

| US6701605B2 (en) | 2001-10-09 | 2004-03-09 | Sonoco Development, Inc. | Conductive electrical element and antenna with ink additive technology |

| US7131380B2 (en) * | 2001-11-07 | 2006-11-07 | Sonoco Development, Inc. | EB pattern profile printing |

| US20030107639A1 (en) * | 2001-12-11 | 2003-06-12 | Gary Field | Process for printing a fluorescent security feature on identification cards and cards produced therefrom |

| US6929413B2 (en) * | 2001-12-11 | 2005-08-16 | Zebra Atlantek, Inc. | Printer driver log security verification for identification cards |

| US6734887B2 (en) * | 2001-12-11 | 2004-05-11 | Zih Corp. | Process for printing a metallic security feature on identification cards and cards produced therefrom |

| US6988665B2 (en) * | 2001-12-11 | 2006-01-24 | Zebra Atlantek, Inc. | Grayscale security microprinting for identification cards |

| EP1467834A4 (fr) * | 2001-12-24 | 2005-04-06 | Digimarc Id Systems Llc | Elements de securite grave au laser destines a des documents d'identification et procedes de fabrication de ces elements |

| CN1316421C (zh) * | 2001-12-24 | 2007-05-16 | 数字Id系统有限公司 | 激光刻印方法和组合物以及上面有激光刻印的制品 |

| EP1459239B1 (fr) | 2001-12-24 | 2012-04-04 | L-1 Secure Credentialing, Inc. | Documents d identification comprenant des informations invis ibles variables et leurs procedes de production |

| US7728048B2 (en) * | 2002-12-20 | 2010-06-01 | L-1 Secure Credentialing, Inc. | Increasing thermal conductivity of host polymer used with laser engraving methods and compositions |

| US7793846B2 (en) | 2001-12-24 | 2010-09-14 | L-1 Secure Credentialing, Inc. | Systems, compositions, and methods for full color laser engraving of ID documents |

| US7694887B2 (en) | 2001-12-24 | 2010-04-13 | L-1 Secure Credentialing, Inc. | Optically variable personalized indicia for identification documents |

| WO2003088144A2 (fr) | 2002-04-09 | 2003-10-23 | Digimarc Id Systems, Llc | Techniques de traitement d'images pour imprimer des cartes et des documents d'identification |

| US7824029B2 (en) | 2002-05-10 | 2010-11-02 | L-1 Secure Credentialing, Inc. | Identification card printer-assembler for over the counter card issuing |

| JP4269644B2 (ja) * | 2002-10-29 | 2009-05-27 | 富士ゼロックス株式会社 | 画像形成装置 |

| AU2003298731A1 (en) | 2002-11-26 | 2004-06-18 | Digimarc Id Systems | Systems and methods for managing and detecting fraud in image databases used with identification documents |

| US7763179B2 (en) * | 2003-03-21 | 2010-07-27 | Digimarc Corporation | Color laser engraving and digital watermarking |

| CA2522551C (fr) | 2003-04-16 | 2009-12-22 | Digimarc Corporation | Stockage de donnees en trois dimensions |

| CA2565479C (fr) * | 2004-05-05 | 2013-11-12 | Giesecke & Devrient Gmbh | Document de valeur |

| US7383999B2 (en) | 2004-12-28 | 2008-06-10 | Digimarc Corporation | ID document structure with pattern coating providing variable security features |

| DE102005025095A1 (de) * | 2005-06-01 | 2006-12-07 | Giesecke & Devrient Gmbh | Datenträger und Verfahren zu seiner Herstellung |

| GB201005895D0 (en) | 2010-04-08 | 2010-05-26 | Rue De Int Ltd | Security articles comprising security features and methods of manufacture therof |

| GB201117530D0 (en) * | 2011-10-11 | 2011-11-23 | Rue De Int Ltd | Security devices |

| JP6044087B2 (ja) * | 2012-03-14 | 2016-12-14 | 大日本印刷株式会社 | カード、カードの製造方法 |

| EP3357706A4 (fr) * | 2015-10-02 | 2018-10-03 | Toppan Printing Co., Ltd. | Structure anti-contrefaçon |

| GB2583210A (en) * | 2017-11-03 | 2020-10-21 | Vladimirovna Orlova Alexandra | Plastic card having 3D multi-level raised embossed impression |

| PL440023A1 (pl) | 2021-12-29 | 2023-07-03 | Polska Wytwórnia Papierów Wartościowych Spółka Akcyjna | Sposób wytwarzania podłoża polimerowego ulegającego karbonizacji opatrzonego wyczuwalnym w dotyku oznakowaniem w postaci reliefu z efektem płaskorzeźby, oraz wytworzone tym sposobem zabezpieczone podłoże polimerowe |

| DE102022001564A1 (de) | 2022-05-04 | 2023-11-09 | Giesecke+Devrient ePayments GmbH | Sicheres Element, insbesondere Ausweiskarte mit einem Personalisierungselement und Verfahren zu dessen Herstellung |

| DE102022117017A1 (de) | 2022-07-07 | 2024-01-18 | Bundesdruckerei Gmbh | Wert- oder Sicherheitsprodukt und Verfahren zu dessen Herstellung |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2223290A1 (de) * | 1971-05-14 | 1973-04-05 | Gen Binding Corp | Aus einem stueck bestehende ausweiskreditkarte und verfahren zu ihrer herstellung |

| DE2907004C2 (de) * | 1979-02-22 | 1981-06-25 | GAO Gesellschaft für Automation und Organisation mbH, 8000 München | Ausweiskarte und Verfahren zu ihrer Herstellung |

| DE3213315A1 (de) * | 1982-04-08 | 1983-10-13 | GAO Gesellschaft für Automation und Organisation mbH, 8000 München | Mehrschichtige ausweiskarte und verfahren zu ihrer herstellung |

| DE3248784C1 (de) * | 1982-12-31 | 1984-04-12 | GAO Gesellschaft für Automation und Organisation mbH, 8000 München | Ausweiskarte und Verfahren zu ihrer Herstellung |

| DE3314327C1 (de) * | 1983-04-20 | 1984-07-26 | GAO Gesellschaft für Automation und Organisation mbH, 8000 München | Ausweiskarte und Verfahren zur Herstellung derselben |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1477203A (en) * | 1974-02-11 | 1977-06-22 | Whiley Ltd G | Manufacture of image-bearing cards and other documents |

| US4006060A (en) * | 1974-11-25 | 1977-02-01 | Merck & Co., Inc. | Thienamycin production |

| DE3048736C2 (de) * | 1980-12-23 | 1982-09-30 | GAO Gesellschaft für Automation und Organisation mbH, 8000 München | Ausweiskarte und Verfahren zu deren Herstellung |

| DE3151407C1 (de) * | 1981-12-24 | 1983-10-13 | GAO Gesellschaft für Automation und Organisation mbH, 8000 München | Ausweiskarte und Verfahren zu deren Herstellung |

| US4557963A (en) * | 1983-04-04 | 1985-12-10 | American Hoechst Corporation | Tamper-resistant polyester credit cards |

| US4544183A (en) * | 1983-08-05 | 1985-10-01 | Computer Identification Systems | Identification card with a radiant energy reactive coating |

| JPS61248228A (ja) * | 1985-04-26 | 1986-11-05 | Tokyo Jiki Insatsu Kk | 磁気エンボス用磁気媒体及びそれを使用した磁気カ−ド |

| EP0219011B1 (fr) * | 1985-10-15 | 1992-01-08 | GAO Gesellschaft für Automation und Organisation mbH | Carte d'identité pourvue d'une marque d'authenticité décelable visuellement et son procédé de réalisation |

| DE3687560D1 (de) * | 1985-10-15 | 1993-03-04 | Gao Ges Automation Org | Datentraeger mit einem optischen echtheitsmerkmal sowie verfahren zur herstellung und pruefung des datentraegers. |

| DE3731853A1 (de) * | 1987-09-22 | 1989-03-30 | Gao Ges Automation Org | Mehrschichtige als druckstock verwendbare ausweiskarte und verfahren zu deren herstellung |

-

1987

- 1987-09-22 DE DE19873731853 patent/DE3731853A1/de not_active Withdrawn

-

1988

- 1988-09-16 NO NO884115A patent/NO175416C/no unknown

- 1988-09-20 US US07/246,638 patent/US5005872A/en not_active Expired - Lifetime

- 1988-09-21 EP EP88115505A patent/EP0308904B1/fr not_active Expired - Lifetime

- 1988-09-21 DE DE8888115505T patent/DE3871884D1/de not_active Expired - Fee Related

- 1988-09-21 ES ES198888115505T patent/ES2032512T3/es not_active Expired - Lifetime

- 1988-09-21 DK DK525388A patent/DK166999B1/da not_active IP Right Cessation

- 1988-09-21 FI FI884342A patent/FI89252C/fi active IP Right Grant

- 1988-09-21 AT AT88115505T patent/ATE77068T1/de not_active IP Right Cessation

- 1988-09-22 JP JP63238652A patent/JP2731918B2/ja not_active Expired - Fee Related

-

1991

- 1991-01-18 US US07/642,886 patent/US5122813A/en not_active Expired - Lifetime

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2223290A1 (de) * | 1971-05-14 | 1973-04-05 | Gen Binding Corp | Aus einem stueck bestehende ausweiskreditkarte und verfahren zu ihrer herstellung |

| DE2907004C2 (de) * | 1979-02-22 | 1981-06-25 | GAO Gesellschaft für Automation und Organisation mbH, 8000 München | Ausweiskarte und Verfahren zu ihrer Herstellung |

| DE3213315A1 (de) * | 1982-04-08 | 1983-10-13 | GAO Gesellschaft für Automation und Organisation mbH, 8000 München | Mehrschichtige ausweiskarte und verfahren zu ihrer herstellung |

| GB2118898A (en) * | 1982-04-08 | 1983-11-09 | Gao Ges Automation Org | A multilayer identification card and a method of producing it |

| DE3248784C1 (de) * | 1982-12-31 | 1984-04-12 | GAO Gesellschaft für Automation und Organisation mbH, 8000 München | Ausweiskarte und Verfahren zu ihrer Herstellung |

| DE3314327C1 (de) * | 1983-04-20 | 1984-07-26 | GAO Gesellschaft für Automation und Organisation mbH, 8000 München | Ausweiskarte und Verfahren zur Herstellung derselben |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5005872A (en) * | 1987-09-22 | 1991-04-09 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Multilayer identity card usable as a printing block and a method of producing it |

| US5122813A (en) * | 1987-09-22 | 1992-06-16 | Gao Gesellschaft Fur Automation Und Organisation Mbh. | Method of making a multilayer identification card usable as a printing block |

| US5083850A (en) * | 1989-08-29 | 1992-01-28 | American Bank Note Holographics, Inc. | Technique of forming a separate information bearing printed pattern on replicas of a hologram or other surface relief diffraction pattern |

| WO2007118654A2 (fr) | 2006-04-13 | 2007-10-25 | Giesecke & Devrient Gmbh | Carte d'identité ayant une structure en relief profilée et procédé de réalisation correspondant |

| WO2007118654A3 (fr) * | 2006-04-13 | 2008-01-17 | Giesecke & Devrient Gmbh | Carte d'identité ayant une structure en relief profilée et procédé de réalisation correspondant |

| WO2010103499A1 (fr) | 2009-03-13 | 2010-09-16 | Arjowiggins Security | Substrat marquable au laser et procede de fabrication associe |

| WO2014076428A1 (fr) * | 2012-11-16 | 2014-05-22 | Oberthur Technologies | Procédé de réalisation d'un motif en relief dans une carte plastique mince |

| FR2998208A1 (fr) * | 2012-11-16 | 2014-05-23 | Oberthur Technologies | Procede de realisation d'un motif en relief dans une carte plastique mince |

| US9600753B2 (en) | 2012-11-16 | 2017-03-21 | Oberthur Technologies | Method for producing a pattern in relief in a thin plastic card |

| EP2956311A4 (fr) * | 2013-02-13 | 2016-11-02 | Entrust Datacard Corp | Document d'identification et son procédé de fabrication |

| WO2017140421A1 (fr) * | 2016-02-17 | 2017-08-24 | Giesecke & Devrient Gmbh | Support de données portatif pourvu d'un bosselage |

| US10572782B2 (en) | 2016-02-17 | 2020-02-25 | Giesecke+Devrient Mobile Security Gmbh | Portable data carrier comprising a relief structure |

Also Published As

| Publication number | Publication date |

|---|---|

| FI884342A (fi) | 1989-03-23 |

| DE3731853A1 (de) | 1989-03-30 |

| NO175416C (no) | 1994-10-12 |

| EP0308904B1 (fr) | 1992-06-10 |

| FI89252C (fi) | 1993-09-10 |

| NO175416B (no) | 1994-07-04 |

| JPH01141095A (ja) | 1989-06-02 |

| EP0308904A3 (en) | 1989-10-18 |

| NO884115D0 (no) | 1988-09-16 |

| ES2032512T3 (es) | 1993-02-16 |

| DK525388D0 (da) | 1988-09-21 |

| US5122813A (en) | 1992-06-16 |

| DK166999B1 (da) | 1993-08-16 |

| DK525388A (da) | 1989-03-23 |

| ATE77068T1 (de) | 1992-06-15 |

| DE3871884D1 (de) | 1992-07-16 |

| JP2731918B2 (ja) | 1998-03-25 |

| FI884342A0 (fi) | 1988-09-21 |

| US5005872A (en) | 1991-04-09 |

| FI89252B (fi) | 1993-05-31 |

| NO884115L (no) | 1989-03-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0308904B1 (fr) | Carte d'identité imprimable à plusieurs couches et procédé pour sa réalisation | |

| EP0219011B1 (fr) | Carte d'identité pourvue d'une marque d'authenticité décelable visuellement et son procédé de réalisation | |

| AT391656B (de) | Ausweiskarte und verfahren zu deren herstellung | |

| DE2907004C2 (de) | Ausweiskarte und Verfahren zu ihrer Herstellung | |

| DE3248784C1 (de) | Ausweiskarte und Verfahren zu ihrer Herstellung | |

| DE3048733C2 (de) | "Ausweiskarte und Verfahren zur Herstellung derselben" | |

| DE3314327C1 (de) | Ausweiskarte und Verfahren zur Herstellung derselben | |

| WO2017097430A1 (fr) | Élément de sécurité muni d'une image lenticulaire | |

| DE102007025866B4 (de) | Datenträger mit Sicherheitskennzeichnung | |

| EP3215371B1 (fr) | Support de données comprenant un élément de sécurité transparent | |

| DE102008028705B4 (de) | Verfahren zum Herstellen eines Wert- und/oder Sicherheitsdokuments sowie Wert- und/oder Sicherheitsdokument mit einer demetallisierten Struktur | |

| DE19537177C2 (de) | Verfahren zur Herstellung einer Kunststoffkarte in Form einer Ausweiskarte, Telefonkarte, Kreditkarte, Krankenversichertenkarte o. dgl. | |

| EP0365018B1 (fr) | Carte d'identité et sa méthode d'assemblage | |

| DE4131617C2 (fr) | ||

| EP3484715B1 (fr) | Procédé de fabrication d'un produit de valeur ou de sécurité | |

| DE3314244A1 (de) | Ausweiskarte und verfahren zur herstellung derselben | |

| AT394975B (de) | Verfahren zum aufbringen von individuellen, visuell erkennbaren informationen auf eine ausweiskarte | |

| DE19949881A1 (de) | Wert- und Sicherheitserzeugnis mit Sicherheitsmerkmalen als variable Elemente und Verfahren zum Aufbringen dieser Sicherheitsmerkmale | |

| EP4384401A1 (fr) | Procédé de production d'un élément de sécurité, élément de sécurité pour un support de données, support de données et feuille de stratification | |

| DE102022002471A1 (de) | Verfahren zur Herstellung eines Sicherheitsmerkmals, Sicherheitsmerkmal für einen Datenträger, Datenträger und Laminierblech | |

| EP4368409A1 (fr) | Élément de sécurité, document de sécurité et procédé de fabrication d'un document de sécurité | |

| EP2965918B1 (fr) | Support de donnees ayant une structure a relief tactile | |

| EP0189501A1 (fr) | Procédé de fabrication de supports en matière plastique reproduisant des informations lisibles | |

| DE8237278U1 (de) | Vorrichtung zur Beschriftung von Ausweiskarten |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19900315 |

|

| 17Q | First examination report despatched |

Effective date: 19911024 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 77068 Country of ref document: AT Date of ref document: 19920615 Kind code of ref document: T |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 3871884 Country of ref document: DE Date of ref document: 19920716 |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2032512 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| EPTA | Lu: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 88115505.5 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20050913 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20050919 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20050920 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20050922 Year of fee payment: 18 Ref country code: BE Payment date: 20050922 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20050923 Year of fee payment: 18 Ref country code: LU Payment date: 20050923 Year of fee payment: 18 Ref country code: SE Payment date: 20050923 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20050927 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20051125 Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060921 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060922 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060930 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060930 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060930 Year of fee payment: 19 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070403 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EUG | Se: european patent has lapsed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20060921 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20070401 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060921 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20060922 |

|

| BERE | Be: lapsed |

Owner name: G.- FUR AUTOMATION UND ORGANISATION M.B.H. *GAO Effective date: 20060930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060922 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060921 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070921 |