EP0214145B1 - Dispergierverfahren und rührwerksmühle zu seiner durchführung - Google Patents

Dispergierverfahren und rührwerksmühle zu seiner durchführung Download PDFInfo

- Publication number

- EP0214145B1 EP0214145B1 EP85904973A EP85904973A EP0214145B1 EP 0214145 B1 EP0214145 B1 EP 0214145B1 EP 85904973 A EP85904973 A EP 85904973A EP 85904973 A EP85904973 A EP 85904973A EP 0214145 B1 EP0214145 B1 EP 0214145B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- grinding medium

- container

- stirred ball

- mill

- mill base

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000000034 method Methods 0.000 title claims abstract description 29

- 239000006185 dispersion Substances 0.000 title abstract description 12

- 238000003756 stirring Methods 0.000 title 1

- 239000007787 solid Substances 0.000 claims abstract description 6

- 239000007791 liquid phase Substances 0.000 claims abstract description 5

- 230000002093 peripheral effect Effects 0.000 claims description 2

- 230000004323 axial length Effects 0.000 claims 2

- 239000007788 liquid Substances 0.000 claims 1

- 230000000717 retained effect Effects 0.000 claims 1

- 239000000463 material Substances 0.000 abstract description 12

- 238000000926 separation method Methods 0.000 abstract description 3

- 238000009825 accumulation Methods 0.000 abstract 3

- 239000000725 suspension Substances 0.000 description 4

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000000654 additive Substances 0.000 description 2

- 239000000498 cooling water Substances 0.000 description 2

- 238000007654 immersion Methods 0.000 description 2

- 239000004576 sand Substances 0.000 description 2

- 230000000996 additive effect Effects 0.000 description 1

- 229920000180 alkyd Polymers 0.000 description 1

- 239000003849 aromatic solvent Substances 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012544 monitoring process Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 239000000049 pigment Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000004408 titanium dioxide Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C17/00—Disintegrating by tumbling mills, i.e. mills having a container charged with the material to be disintegrated with or without special disintegrating members such as pebbles or balls

- B02C17/16—Mills in which a fixed container houses stirring means tumbling the charge

Definitions

- the invention relates to a dispersion method according to the preamble of claim 1 (see Chem. Techn., 24th vol., Volume 1, January 1972, pages 22 to 26).

- agitator mills contain grinding media, e.g. Sand, and the energy is supplied by the movement of rotors arranged in the agitator mill.

- the grinding chamber of the agitator mill is filled to 70 to 90% by volume with sand.

- the regrind flows through the grinding chamber in the axial direction.

- the throughput of the material to be ground through the grinding pot is generally selected so that the prescribed nominal fineness is achieved after one or more passages. This procedure is often called one-pass or multiple-pass procedure.

- the production output achievable with this procedure can be increased significantly if the procedure described in DE-PS 2 230 766 or DE-OS 1 902 152 is used.

- this circular mode of operation high mill throughputs flow through the mill, and after leaving the mill, the mill material flows back into a container from which it is pumped back into the mill.

- the regrind flows in the so-called pendulum mode from a container with high throughputs through the agitator mill into a second container. This process is repeated until the desired fineness is reached.

- the invention therefore relates to a dispersion method according to claim 1.

- this object can be achieved by reducing the degree of filling of the grinding container on grinding media and by selecting the speed of the rotors such that the grinding media filling forms a rotating hollow cylinder in the agitator mill due to the centrifugal force.

- the path of the ground material through the bed of grinding media is shorter than in the working method according to the prior art. This is compensated for by the fact that the regrind has to pass through the grinding media more frequently. The drag forces acting radially from the outside inward cause the grinding media to swirl in the centrifugal field. Overall, it is advantageous to choose a high radial flow rate. Despite this high flow rate, a very effective dispersion is surprisingly achieved, the circular mode or the pendulum mode reducing the total dispersion time and the effort for monitoring the process. With this procedure, the dispersion of temperature-sensitive goods can also be carried out without any problems, since only a slight increase in the temperature of the ground material can be detected per passage through the agitator mill. This heat can easily be extracted from the regrind in an external cooler. With this procedure, a significant reduction in the dispersing energy used is additionally achieved compared to the passage mode.

- fine grinding media can be used at high throughputs through the mill, the use of which in state-of-the-art machines is not possible because they are washed onto the separating screen at high throughputs.

- the invention also relates to an agitator mill for carrying out the dispersion process.

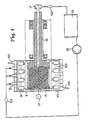

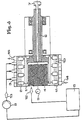

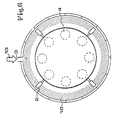

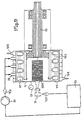

- 1 denotes a grinding container in which rotors 2 designed as paddles are arranged.

- the ground material is fed in at 3, and at 4 a sieve is shown. 5 with a reservoir is designated.

- the rotors 2 are driven via a hollow shaft 6, which can simultaneously serve to discharge the ground material.

- a turret seal is shown and 8 is the required pump.

- 9 denotes a manometer and 10 denotes the grinding media bed inside the grinding container 1.

- the ratio of length to diameter of the grinding container 1 is 0.5: 1 to 1.5: 1.

- a drain sieve for residual products is shown and the grist outlet is indicated by arrow 12, while the grist inlet is indicated by arrow 13.

- the cooling water inlet is shown at 14 and the cooling water outlet is shown at 15.

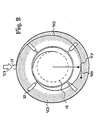

- FIG. 2 an idealized millbase path is shown at 16, while the arrows 17 and 18 indicate the radial speed of the millbase or the peripheral speed of the millbase.

- grinding media fillings in agitator mills are subject to wear and tear, the resulting grinding media shrinkage has to be supplemented from time to time for optimal operation, the setting of the amount of grinding media to be supplemented is best determined via the power consumption of the rotating agitator mill rotor, but this is only possible with today's agitator mills Very complex refill devices are possible, which is surprisingly solved by the idea of the invention in a simple manner that, while the rotor is running, the required grinding media refill quantities can be metered freely into the grinding media-free center via a feed tube until a specified setpoint value for the power consumption of the rotor is reached.

- the ordinate shows the fineness curve Xmax Hegman of a suspension as a function of time.

- Curve 19 shows that the suspension has reached a fineness according to Hegman of 35 ⁇ m after a passage corresponding to 400 min and has reached the fineness 19 m after two passages corresponding to 780 min.

- Curve 20 shows that this result can be achieved in a significantly shorter time with a circulatory procedure.

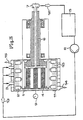

- FIG. 4 shows, as in FIG. 1, a cross section through an agitator mill according to the invention, but now with a fixed cylindrical separating sieve 4.

- Fig. 7 shows, in a representation corresponding to Fig. 5, screens 4 arranged on a pitch circle, but this time fixed, i.e. are not designed to rotate.

- FIG. 8 shows a stationary immersion tube 21 as grinding media separating device, which projects into the grinding media-free space. A sieve is not provided.

- FIG. 9 shows, as grinding media separating device, a screen 22 rotating in the grinding media-free space, the speed of which is independent of the speed of the rotor drive.

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Crushing And Grinding (AREA)

- Mixers Of The Rotary Stirring Type (AREA)

- Disintegrating Or Milling (AREA)

- Combined Means For Separation Of Solids (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT85904973T ATE40056T1 (de) | 1984-10-16 | 1985-10-09 | Dispergierverfahren und ruehrwerksmuehle zu seiner durchfuehrung. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19843437866 DE3437866A1 (de) | 1984-10-16 | 1984-10-16 | Dispergierverfahren und ruehrwerksmuehle zu seiner durchfuehrung |

| DE3437866 | 1984-10-16 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0214145A1 EP0214145A1 (de) | 1987-03-18 |

| EP0214145B1 true EP0214145B1 (de) | 1989-01-18 |

Family

ID=6247996

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85904973A Expired EP0214145B1 (de) | 1984-10-16 | 1985-10-09 | Dispergierverfahren und rührwerksmühle zu seiner durchführung |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US5011089A (enExample) |

| EP (1) | EP0214145B1 (enExample) |

| JP (2) | JPS62500503A (enExample) |

| BR (1) | BR8507233A (enExample) |

| CA (1) | CA1272174A (enExample) |

| DE (2) | DE3437866A1 (enExample) |

| ES (1) | ES8703296A1 (enExample) |

| WO (1) | WO1986002286A1 (enExample) |

| ZA (1) | ZA857434B (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4128074A1 (de) * | 1991-08-23 | 1993-02-25 | Omya Gmbh | Ruehrwerkskugelmuehle |

Families Citing this family (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3727863C1 (de) * | 1987-08-20 | 1989-03-02 | Netzsch Erich Holding | Ruehrwerksmuehle mit Zufuehrrohr fuer Mahlkoerper |

| NZ226551A (en) * | 1987-10-20 | 1990-03-27 | Ici Australia Operations | Fine grinding of ceramic particles in attrition mill |

| JP2579984B2 (ja) * | 1988-01-28 | 1997-02-12 | 株式会社クボタ | 粒状体の製造方法及びその製造装置 |

| DE4007768A1 (de) * | 1990-03-12 | 1991-09-19 | Basf Ag | Dispergierverfahren und ruehrwerksmuehle zu seiner durchfuehrung |

| DE4009092C1 (enExample) * | 1990-03-21 | 1991-05-23 | Erich Netzsch Gmbh & Co Holding Kg, 8672 Selb, De | |

| JPH04166246A (ja) * | 1990-10-31 | 1992-06-12 | Matsushita Electric Ind Co Ltd | 媒体撹拌ミル及び粉砕方法 |

| DE4216939C2 (de) * | 1992-05-22 | 1995-01-26 | Kneisl Wendelin Dipl Ing Th | Rührwerksmühle mit dynamischer Mahlkörperabtrennung |

| US5269234A (en) * | 1992-10-20 | 1993-12-14 | Continental Cement Company | Method for processing solid, Hazardous waste material for use as a fuel |

| US5333804A (en) * | 1993-08-20 | 1994-08-02 | Premier Mill Corp. | Agitator mill |

| US5746916A (en) * | 1994-01-26 | 1998-05-05 | Mitsubishi Rayon Co., Ltd. | Microporous membrane made of non-crystalline polymers and method of producing the same |

| DE4432154A1 (de) * | 1994-09-09 | 1996-03-14 | Evv Vermoegensverwaltungs Gmbh | Verfahren und Vorrichtung zum kontinuierlichen Aufschließen von organischen Bestandteilen eines fließfähigen Behandlungsguts |

| DE4432153A1 (de) * | 1994-09-09 | 1996-03-14 | Evv Vermoegensverwaltungs Gmbh | Verfahren und Vorrichtung zum kontinuierlichen autogenen Mahlen eines fließfähigen Behandlungsguts |

| PL192081B1 (pl) | 1997-08-29 | 2006-08-31 | Lowan Man Pty Ltd | Sposób mielenia rozdrobnionego materiału i młyn do rozdrobnionego materiału |

| AU732830B2 (en) * | 1997-08-29 | 2001-05-03 | Lowan (Management) Pty Limited | Grinding mill |

| DE19819967B4 (de) * | 1998-05-05 | 2007-04-26 | BüHLER GMBH | Rührwerksmühle |

| US6450428B1 (en) | 1999-05-05 | 2002-09-17 | Lowan (Management) Pty Limited | Feed arrangement for grinding mill incorporating fluid feed |

| AU2003902661A0 (en) * | 2003-05-29 | 2003-06-12 | Hicom International Pty Ltd | Centrifugal grinding mills |

| JP4785355B2 (ja) * | 2004-06-28 | 2011-10-05 | 関西ペイント株式会社 | アニュラー型ビーズミル、該ビーズミルを備える顔料分散システム、及び該顔料分散システムを用いた顔料分散方法 |

| EP1943022B1 (de) * | 2005-10-11 | 2010-03-31 | Bühler AG | Rührwerksmühle |

| CN107309054A (zh) * | 2017-06-29 | 2017-11-03 | 马鞍山市恒达轻质墙体材料有限公司 | 一种加气砖中粉料的生产装置 |

| CN107970856B (zh) * | 2017-12-13 | 2024-01-23 | 北方奥钛纳米技术有限公司 | 高效分散装置 |

| DE102021101527B4 (de) | 2021-01-25 | 2023-05-17 | Wilhelm Niemann Gmbh & Co. | Rührwerksmühle |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE707525C (de) * | 1936-04-21 | 1941-06-25 | August Schaich Dr Ing | Wirbelmuehle |

| US2592994A (en) * | 1942-05-28 | 1952-04-15 | Smidth & Co As F L | Method and apparatus for grinding by the use of grinding bodies subjected to centrifugal force |

| US3251578A (en) * | 1961-06-15 | 1966-05-17 | Socony Mobil Oil Co Inc | Dispersing and grinding apparatus and method of dispersing and grinding paste |

| CH477229A (de) * | 1967-03-21 | 1969-08-31 | Vyzk Ustav Organ Syntez | Vorrichtung zum Dispergieren von Suspensionen fester Teilchen auf kolloidale Feinheit |

| CH477916A (de) * | 1967-07-01 | 1969-09-15 | Vyzk Ustav Organickych Synthes | Einrichtung zum Vermahlen fester Teilchen in trockenem Zustand |

| US3550915A (en) * | 1968-04-10 | 1970-12-29 | Vyzk Ustav Organ Syntez | Agitating apparatus |

| DE1902152A1 (de) * | 1969-01-17 | 1970-07-30 | Draiswerke Gmbh | Verfahren und Vorrichtung zum diskontinuierlichen Zerkleinern von in Fluessigkeit suspendierten Teilchen |

| DE2110336A1 (de) * | 1971-03-04 | 1972-09-07 | Draiswerke Gmbh | Ruehrwerksmuehle |

| DE2230766C3 (de) * | 1971-07-27 | 1980-03-06 | Union Process International Inc., Akron, Ohio (V.St.A.) | Verfahren und Vorrichtung zum Zerkleinern von in einer Flüssigkeit suspendierten Feststoffen |

| US3799455A (en) * | 1972-06-19 | 1974-03-26 | A Szegvari | Method for reacting materials |

| US4044957A (en) * | 1976-02-13 | 1977-08-30 | Schold George R | Apparatus for dispersing finely divided solid particles in a liquid vehicle |

| ES449975A1 (es) * | 1976-07-20 | 1977-07-01 | Oliver & Battle Sa | Mejoras en los molinos de eje horizontal refrigerados, para productos predispersados de solidos en liquidos. |

| AT367657B (de) * | 1978-08-24 | 1982-07-26 | Buehler Ag Geb | Ruehrwerkskugelmuehle-regelung |

| JPS5892468A (ja) * | 1981-11-27 | 1983-06-01 | 株式会社三井三池製作所 | 竪型メデイヤ撹拌乾式粉砕機 |

| DE3345680A1 (de) * | 1983-12-16 | 1985-06-20 | Gebrüder Netzsch, Maschinenfabrik GmbH & Co, 8672 Selb | Ruehrwerksmuehle |

| US4742966A (en) * | 1985-06-21 | 1988-05-10 | Morehouse Industries, Inc. | Media mill screen assembly |

-

1984

- 1984-10-16 DE DE19843437866 patent/DE3437866A1/de not_active Withdrawn

-

1985

- 1985-09-26 ZA ZA857434A patent/ZA857434B/xx unknown

- 1985-10-09 EP EP85904973A patent/EP0214145B1/de not_active Expired

- 1985-10-09 WO PCT/EP1985/000526 patent/WO1986002286A1/de not_active Ceased

- 1985-10-09 JP JP60504487A patent/JPS62500503A/ja active Granted

- 1985-10-09 DE DE8585904973T patent/DE3567584D1/de not_active Expired

- 1985-10-09 CA CA000492555A patent/CA1272174A/en not_active Expired - Lifetime

- 1985-10-09 BR BR8507233A patent/BR8507233A/pt not_active IP Right Cessation

- 1985-10-16 ES ES547946A patent/ES8703296A1/es not_active Expired

-

1990

- 1990-02-05 JP JP2024575A patent/JPH089017B2/ja not_active Expired - Lifetime

- 1990-05-04 US US07/518,273 patent/US5011089A/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4128074A1 (de) * | 1991-08-23 | 1993-02-25 | Omya Gmbh | Ruehrwerkskugelmuehle |

Also Published As

| Publication number | Publication date |

|---|---|

| JPH089017B2 (ja) | 1996-01-31 |

| WO1986002286A1 (fr) | 1986-04-24 |

| JPS62500503A (ja) | 1987-03-05 |

| ES547946A0 (es) | 1987-02-16 |

| DE3567584D1 (en) | 1989-02-23 |

| ES8703296A1 (es) | 1987-02-16 |

| ZA857434B (en) | 1986-05-28 |

| EP0214145A1 (de) | 1987-03-18 |

| US5011089A (en) | 1991-04-30 |

| DE3437866A1 (de) | 1986-04-17 |

| BR8507233A (pt) | 1987-10-27 |

| JPH0342052A (ja) | 1991-02-22 |

| CA1272174A (en) | 1990-07-31 |

| JPH0261298B2 (enExample) | 1990-12-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0214145B1 (de) | Dispergierverfahren und rührwerksmühle zu seiner durchführung | |

| EP0799643B1 (de) | Vorrichtung zur Behandlung von Suspensionen | |

| DE2848479A1 (de) | Ruehrwerkskugelmuehle | |

| EP0058886B1 (de) | Rührwerksmühle | |

| CH647422A5 (de) | Ruehrwerksmuehle zum zermahlen einer prozessmischung. | |

| EP0700722A1 (de) | Rührwerksmühle | |

| EP0019834A1 (de) | Verfahren zum Entlüften von viskosem Mahlgut | |

| DE4128074A1 (de) | Ruehrwerkskugelmuehle | |

| DE69506094T2 (de) | Verfahren und Vorrichtung zum Rühren von Behandlungsflüssigkeit | |

| DE1248440B (de) | Ruehrwerksmuehle | |

| DE1237415B (de) | Verfahren zum Entagglomerieren und Dispergieren von Feststoffteilchen in Fluessigkeiten | |

| DE2020649A1 (de) | Vorrichtung zum Deagglomerieren und zum Dispergieren von in agglomerierter Form in einem fluessigen Traeger vorliegenden Festkoerperteilchen | |

| DE2428359A1 (de) | Verfahren und vorrichtung zum dispergieren von suspensionen | |

| EP0271012A2 (de) | Rührwerksmühle zum Mahlen von Pigmenten | |

| EP0700724B2 (de) | Verfahren und Vorrichtung zum kontinuierlichen autogenen Mahlen eines fliessfähigen Behandlungsguts | |

| EP1510256A1 (de) | Rührwerksmühle mit Tauchrohr zur Absaugung und Trennung von Mahlgut und Mahlhilfskörpern | |

| DE2423376A1 (de) | Verfahren und vorrichtung zum mahlen von in einer fluessigkeit suspendierten feststoffteilchen | |

| EP1027161A1 (de) | Verfahren und vorrichtung zum nassmahlen und dispergieren von feststoffpartikeln in flüssigkeiten | |

| DE112017002963B4 (de) | Medien-Umwälzungsmühle | |

| DE4216939C2 (de) | Rührwerksmühle mit dynamischer Mahlkörperabtrennung | |

| DE2546146A1 (de) | Verfahren zum kontinuierlichen feinmahlen und dispergieren und ruehrwerksmuehle zur durchfuehrung des verfahrens | |

| DE1223236B (de) | Ruehrwerkmuehle | |

| CH132086A (de) | Verfahren und Dispersionsmühle zur Herstellung von Dispersionen kolloidaler oder annähernd kolloidaler Feinheit durch Vermahlen. | |

| DE1184188B (de) | Ruehrwerksmuehle zur Herstellung von Feststoffdispersionen | |

| DD227339B5 (de) | Ruehrwerksmuehle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19861120 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: WARNKE, KLAUS Inventor name: KISSAU, GERD, DR. Inventor name: VOCK, FRIEDRICH |

|

| 17Q | First examination report despatched |

Effective date: 19880210 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 40056 Country of ref document: AT Date of ref document: 19890215 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3567584 Country of ref document: DE Date of ref document: 19890223 |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| EPTA | Lu: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 85904973.6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20000925 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20001017 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20001019 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20001020 Year of fee payment: 16 Ref country code: BE Payment date: 20001020 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20001023 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20001030 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20001106 Year of fee payment: 16 Ref country code: DE Payment date: 20001106 Year of fee payment: 16 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011009 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011009 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011010 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011031 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011031 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011031 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| BERE | Be: lapsed |

Owner name: BASF LACKE + FARBEN A.G. Effective date: 20011031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020501 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20011009 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 85904973.6 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020628 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20020501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020702 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |