CN105983788B - 激光开孔加工条件的设定方法以及激光加工机 - Google Patents

激光开孔加工条件的设定方法以及激光加工机 Download PDFInfo

- Publication number

- CN105983788B CN105983788B CN201610148662.2A CN201610148662A CN105983788B CN 105983788 B CN105983788 B CN 105983788B CN 201610148662 A CN201610148662 A CN 201610148662A CN 105983788 B CN105983788 B CN 105983788B

- Authority

- CN

- China

- Prior art keywords

- hole

- conditions

- laser

- aforementioned

- scanner

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000012545 processing Methods 0.000 title claims abstract description 91

- 238000005553 drilling Methods 0.000 title claims abstract description 60

- 238000000034 method Methods 0.000 title claims abstract description 38

- 238000003754 machining Methods 0.000 claims description 29

- 238000005259 measurement Methods 0.000 claims 4

- 238000012360 testing method Methods 0.000 abstract description 69

- 239000000758 substrate Substances 0.000 abstract description 12

- 238000010586 diagram Methods 0.000 description 12

- 238000007796 conventional method Methods 0.000 description 5

- 238000000605 extraction Methods 0.000 description 4

- 238000011156 evaluation Methods 0.000 description 3

- 230000007423 decrease Effects 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 238000011179 visual inspection Methods 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 238000009713 electroplating Methods 0.000 description 1

- 239000000284 extract Substances 0.000 description 1

- 238000003384 imaging method Methods 0.000 description 1

- 239000011229 interlayer Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/36—Electric or electronic devices

- B23K2101/42—Printed circuits

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Plasma & Fusion (AREA)

- Mechanical Engineering (AREA)

- Laser Beam Processing (AREA)

- Manufacturing & Machinery (AREA)

- Microelectronics & Electronic Packaging (AREA)

Applications Claiming Priority (4)

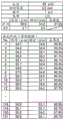

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015-052041 | 2015-03-16 | ||

| JP2015052041 | 2015-03-16 | ||

| JP2015164599A JP6570921B2 (ja) | 2015-03-16 | 2015-08-24 | レーザ穴あけ加工条件の設定方法及びレーザ加工機 |

| JP2015-164599 | 2015-08-24 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN105983788A CN105983788A (zh) | 2016-10-05 |

| CN105983788B true CN105983788B (zh) | 2020-03-17 |

Family

ID=57008490

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201610148662.2A Active CN105983788B (zh) | 2015-03-16 | 2016-03-16 | 激光开孔加工条件的设定方法以及激光加工机 |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP6570921B2 (enExample) |

| KR (1) | KR102381358B1 (enExample) |

| CN (1) | CN105983788B (enExample) |

| TW (1) | TWI689366B (enExample) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7066368B2 (ja) * | 2017-10-24 | 2022-05-13 | 住友重機械工業株式会社 | レーザ加工機の制御装置、レーザ加工方法、及びレーザ加工機 |

| CN110455233B (zh) * | 2019-08-08 | 2024-06-04 | 广州广合科技股份有限公司 | 一种pcb激光钻孔精度测试装置及方法 |

| JP7305273B2 (ja) * | 2019-09-19 | 2023-07-10 | 株式会社ディスコ | レーザー加工方法及びレーザー加工装置 |

| US20230201958A1 (en) * | 2020-05-29 | 2023-06-29 | Mitsubishi Electric Corporation | Laser processing apparatus and laser processing method |

| CN115704678A (zh) * | 2021-08-13 | 2023-02-17 | 深圳市大族数控科技股份有限公司 | 钻孔均匀性的检测方法、检测装置及存储介质 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1772428A (zh) * | 2004-11-12 | 2006-05-17 | 日立比亚机械股份有限公司 | 激光加工机和激光加工方法 |

| CN101112735A (zh) * | 2006-07-27 | 2008-01-30 | 株式会社其恩斯 | 激光加工装置、激光加工条件设定装置、方法、及程序 |

| CN101683703A (zh) * | 2008-09-26 | 2010-03-31 | 日立比亚机械股份有限公司 | 激光加工机 |

| CN102056705A (zh) * | 2008-06-13 | 2011-05-11 | 伊雷克托科学工业股份有限公司 | 用于激光加工工件的自动参数管理 |

| CN103042310A (zh) * | 2011-10-12 | 2013-04-17 | 深圳市大族激光科技股份有限公司 | 一种磨砂玻璃的制造方法 |

| CN103737178A (zh) * | 2013-12-19 | 2014-04-23 | 武汉法利莱切割系统工程有限责任公司 | 一种用于商务车顶盖的在线多层搭接激光填丝熔焊方法 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10258375A (ja) * | 1997-03-14 | 1998-09-29 | Amada Co Ltd | レーザ加工機およびその加工機を用いた真円度測定方法並びに駆動系検査方法 |

| JP3614680B2 (ja) | 1998-09-01 | 2005-01-26 | 松下電器産業株式会社 | レーザ加工方法及び装置 |

| JP2002137074A (ja) * | 2000-10-31 | 2002-05-14 | Hitachi Via Mechanics Ltd | レーザ加工方法およびレーザ加工機 |

| JP2004223561A (ja) * | 2003-01-22 | 2004-08-12 | Sumitomo Heavy Ind Ltd | レーザ加工方法及び装置 |

| JP5336054B2 (ja) * | 2007-07-18 | 2013-11-06 | 浜松ホトニクス株式会社 | 加工情報供給装置を備える加工情報供給システム |

| US8440933B2 (en) * | 2009-04-17 | 2013-05-14 | University Of Connecticut | Systems and methods for enhanced control of laser drilling processes |

| JP2012148308A (ja) * | 2011-01-19 | 2012-08-09 | Keyence Corp | 印字品質評価システム、レーザマーキング装置、印字条件設定装置、印字品質評価装置、印字条件設定プログラム、印字品質評価プログラム、コンピュータで読み取り可能な記録媒体 |

-

2015

- 2015-08-24 JP JP2015164599A patent/JP6570921B2/ja active Active

- 2015-12-28 KR KR1020150187406A patent/KR102381358B1/ko active Active

-

2016

- 2016-01-07 TW TW105100376A patent/TWI689366B/zh active

- 2016-03-16 CN CN201610148662.2A patent/CN105983788B/zh active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1772428A (zh) * | 2004-11-12 | 2006-05-17 | 日立比亚机械股份有限公司 | 激光加工机和激光加工方法 |

| CN101112735A (zh) * | 2006-07-27 | 2008-01-30 | 株式会社其恩斯 | 激光加工装置、激光加工条件设定装置、方法、及程序 |

| CN102056705A (zh) * | 2008-06-13 | 2011-05-11 | 伊雷克托科学工业股份有限公司 | 用于激光加工工件的自动参数管理 |

| CN101683703A (zh) * | 2008-09-26 | 2010-03-31 | 日立比亚机械股份有限公司 | 激光加工机 |

| CN103042310A (zh) * | 2011-10-12 | 2013-04-17 | 深圳市大族激光科技股份有限公司 | 一种磨砂玻璃的制造方法 |

| CN103737178A (zh) * | 2013-12-19 | 2014-04-23 | 武汉法利莱切割系统工程有限责任公司 | 一种用于商务车顶盖的在线多层搭接激光填丝熔焊方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR102381358B1 (ko) | 2022-03-30 |

| TW201634166A (zh) | 2016-10-01 |

| CN105983788A (zh) | 2016-10-05 |

| KR20160111321A (ko) | 2016-09-26 |

| JP6570921B2 (ja) | 2019-09-04 |

| TWI689366B (zh) | 2020-04-01 |

| JP2016172282A (ja) | 2016-09-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN105983788B (zh) | 激光开孔加工条件的设定方法以及激光加工机 | |

| JP5597056B2 (ja) | 画像測定装置、画像測定方法及び画像測定装置用のプログラム | |

| JP7167453B2 (ja) | 外観検査システム、設定装置、画像処理装置、設定方法およびプログラム | |

| JP5525421B2 (ja) | 画像撮像装置および画像撮像方法 | |

| TWI474363B (zh) | Pattern evaluation device and pattern evaluation method | |

| JP5164598B2 (ja) | レビュー方法、およびレビュー装置 | |

| JP6594545B2 (ja) | 基板計測装置およびレーザ加工システム | |

| JP2015025758A (ja) | 基板検査方法、基板製造方法および基板検査装置 | |

| CN110238520B (zh) | 一种基于ccd视觉检测的自动精密激光焊接方法 | |

| TW201132962A (en) | Inspection device and method | |

| JP2012122765A (ja) | 欠陥検査装置 | |

| JP2010127748A (ja) | 欠陥レビュー装置及び欠陥レビュー方法 | |

| KR20150003783A (ko) | X선 검사 방법 및 x선 검사 장치 | |

| JP2015078852A (ja) | アライメント方法 | |

| KR20080003718A (ko) | 결함 수정 장치 | |

| JP5286337B2 (ja) | 半導体製造装置の管理装置、及びコンピュータプログラム | |

| JP2015025759A (ja) | 基板検査方法、基板製造方法および基板検査装置 | |

| JP4617970B2 (ja) | 欠陥検査装置及び欠陥検査方法 | |

| JP2000081324A (ja) | 欠陥検査方法およびその装置 | |

| JP4598492B2 (ja) | 荷電粒子ビーム装置での加工位置決め方法及びそれに用いる赤外顕微鏡 | |

| KR101653861B1 (ko) | 묘화 데이터 생성 방법, 묘화 방법, 묘화 데이터 생성 장치, 및 묘화 장치 | |

| JP7152972B2 (ja) | 検査条件作成支援装置、検査条件作成支援方法、検査条件作成支援プログラムおよび記録媒体 | |

| WO2015094818A1 (en) | A method for measuring positions of structures on a mask and thereby determining mask manufacturing errors | |

| JP6169330B2 (ja) | パターン描画装置およびパターン描画方法 | |

| JP7152973B2 (ja) | 検査条件作成支援装置、検査条件作成支援方法、検査条件作成支援プログラムおよび記録媒体 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |