CN102844151A - 同时双面晶片研磨机中的流体静力垫压力调控 - Google Patents

同时双面晶片研磨机中的流体静力垫压力调控 Download PDFInfo

- Publication number

- CN102844151A CN102844151A CN201180016139XA CN201180016139A CN102844151A CN 102844151 A CN102844151 A CN 102844151A CN 201180016139X A CN201180016139X A CN 201180016139XA CN 201180016139 A CN201180016139 A CN 201180016139A CN 102844151 A CN102844151 A CN 102844151A

- Authority

- CN

- China

- Prior art keywords

- wafer

- abrasive wheel

- pad

- hydrostatic

- grinder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 230000002706 hydrostatic effect Effects 0.000 title claims abstract description 201

- 238000000227 grinding Methods 0.000 claims abstract description 100

- 238000000034 method Methods 0.000 claims abstract description 65

- 230000008859 change Effects 0.000 claims abstract description 22

- 235000012431 wafers Nutrition 0.000 claims description 434

- 238000005259 measurement Methods 0.000 claims description 28

- 239000004065 semiconductor Substances 0.000 claims description 25

- 239000012530 fluid Substances 0.000 claims description 24

- 230000008569 process Effects 0.000 claims description 24

- 238000012545 processing Methods 0.000 claims description 13

- 230000003068 static effect Effects 0.000 claims description 11

- 230000002829 reductive effect Effects 0.000 claims description 10

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 8

- 238000001514 detection method Methods 0.000 claims description 3

- 230000004044 response Effects 0.000 claims description 2

- 238000004458 analytical method Methods 0.000 description 25

- 238000005498 polishing Methods 0.000 description 17

- 230000002950 deficient Effects 0.000 description 16

- 239000000463 material Substances 0.000 description 13

- 238000012916 structural analysis Methods 0.000 description 10

- 238000005452 bending Methods 0.000 description 9

- 238000010586 diagram Methods 0.000 description 9

- 230000033001 locomotion Effects 0.000 description 9

- 230000015572 biosynthetic process Effects 0.000 description 8

- 238000005516 engineering process Methods 0.000 description 7

- 238000012423 maintenance Methods 0.000 description 7

- 238000004364 calculation method Methods 0.000 description 6

- 238000006073 displacement reaction Methods 0.000 description 6

- 238000001914 filtration Methods 0.000 description 6

- 238000003801 milling Methods 0.000 description 6

- 230000000246 remedial effect Effects 0.000 description 6

- 230000009471 action Effects 0.000 description 4

- 230000006866 deterioration Effects 0.000 description 4

- 230000003993 interaction Effects 0.000 description 4

- 241001269238 Data Species 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 230000007547 defect Effects 0.000 description 3

- 230000006870 function Effects 0.000 description 3

- 230000003321 amplification Effects 0.000 description 2

- 230000004888 barrier function Effects 0.000 description 2

- 238000004891 communication Methods 0.000 description 2

- 150000001875 compounds Chemical class 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000002349 favourable effect Effects 0.000 description 2

- 230000000670 limiting effect Effects 0.000 description 2

- 238000003199 nucleic acid amplification method Methods 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 230000001105 regulatory effect Effects 0.000 description 2

- 230000002441 reversible effect Effects 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 206010021703 Indifference Diseases 0.000 description 1

- 239000004990 Smectic liquid crystal Substances 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 230000006399 behavior Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000033228 biological regulation Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 230000002301 combined effect Effects 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 238000011049 filling Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000006386 neutralization reaction Methods 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 230000001737 promoting effect Effects 0.000 description 1

- 238000003908 quality control method Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000004439 roughness measurement Methods 0.000 description 1

- 230000011664 signaling Effects 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 230000002459 sustained effect Effects 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 238000013519 translation Methods 0.000 description 1

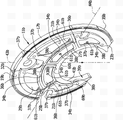

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/04—Lapping machines or devices; Accessories designed for working plane surfaces

- B24B37/042—Lapping machines or devices; Accessories designed for working plane surfaces operating processes therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B1/00—Processes of grinding or polishing; Use of auxiliary equipment in connection with such processes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/04—Lapping machines or devices; Accessories designed for working plane surfaces

- B24B37/07—Lapping machines or devices; Accessories designed for working plane surfaces characterised by the movement of the work or lapping tool

- B24B37/08—Lapping machines or devices; Accessories designed for working plane surfaces characterised by the movement of the work or lapping tool for double side lapping

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/27—Work carriers

- B24B37/28—Work carriers for double side lapping of plane surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B49/00—Measuring or gauging equipment for controlling the feed movement of the grinding tool or work; Arrangements of indicating or measuring equipment, e.g. for indicating the start of the grinding operation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B7/00—Machines or devices designed for grinding plane surfaces on work, including polishing plane glass surfaces; Accessories therefor

- B24B7/10—Single-purpose machines or devices

- B24B7/16—Single-purpose machines or devices for grinding end-faces, e.g. of gauges, rollers, nuts, piston rings

- B24B7/17—Single-purpose machines or devices for grinding end-faces, e.g. of gauges, rollers, nuts, piston rings for simultaneously grinding opposite and parallel end faces, e.g. double disc grinders

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B9/00—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor

- B24B9/02—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor characterised by a special design with respect to properties of materials specific to articles to be ground

- B24B9/06—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor characterised by a special design with respect to properties of materials specific to articles to be ground of non-metallic inorganic material, e.g. stone, ceramics, porcelain

- B24B9/08—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor characterised by a special design with respect to properties of materials specific to articles to be ground of non-metallic inorganic material, e.g. stone, ceramics, porcelain of glass

- B24B9/14—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor characterised by a special design with respect to properties of materials specific to articles to be ground of non-metallic inorganic material, e.g. stone, ceramics, porcelain of glass of optical work, e.g. lenses, prisms

- B24B9/148—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor characterised by a special design with respect to properties of materials specific to articles to be ground of non-metallic inorganic material, e.g. stone, ceramics, porcelain of glass of optical work, e.g. lenses, prisms electrically, e.g. numerically, controlled

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/304—Mechanical treatment, e.g. grinding, polishing, cutting

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/34—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies not provided for in groups H01L21/18, H10D48/04 and H10D48/07, with or without impurities, e.g. doping materials

- H01L21/46—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/428

- H01L21/461—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/428 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/77—Manufacture or treatment of devices consisting of a plurality of solid state components or integrated circuits formed in, or on, a common substrate

- H01L21/78—Manufacture or treatment of devices consisting of a plurality of solid state components or integrated circuits formed in, or on, a common substrate with subsequent division of the substrate into plural individual devices

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Computer Hardware Design (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Physics & Mathematics (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Ceramic Engineering (AREA)

- Inorganic Chemistry (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Grinding Of Cylindrical And Plane Surfaces (AREA)

- Constituent Portions Of Griding Lathes, Driving, Sensing And Control (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US31791910P | 2010-03-26 | 2010-03-26 | |

| US61/317,919 | 2010-03-26 | ||

| PCT/IB2011/051152 WO2011117792A1 (en) | 2010-03-26 | 2011-03-18 | Hydrostatic pad pressure modulation in a simultaneous double side wafer grinder |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN102844151A true CN102844151A (zh) | 2012-12-26 |

Family

ID=44657008

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201180016139XA Pending CN102844151A (zh) | 2010-03-26 | 2011-03-18 | 同时双面晶片研磨机中的流体静力垫压力调控 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US8712575B2 (enExample) |

| EP (1) | EP2552644A4 (enExample) |

| JP (1) | JP6013317B2 (enExample) |

| KR (1) | KR101694574B1 (enExample) |

| CN (1) | CN102844151A (enExample) |

| SG (1) | SG184014A1 (enExample) |

| TW (1) | TWI520202B (enExample) |

| WO (1) | WO2011117792A1 (enExample) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105881213A (zh) * | 2014-09-01 | 2016-08-24 | 曾庆明 | 一种精密双面研磨机的控制器 |

| CN105881195A (zh) * | 2015-02-17 | 2016-08-24 | 光洋机械工业株式会社 | 双头平面研磨装置 |

| CN108127560A (zh) * | 2017-12-08 | 2018-06-08 | 中国兵器科学研究院宁波分院 | 用于方形光学元件双面快速抛光的控制系统 |

| CN108475627A (zh) * | 2015-11-26 | 2018-08-31 | 胜高股份有限公司 | 晶圆抛光方法 |

| CN112930248A (zh) * | 2019-04-01 | 2021-06-08 | 株式会社村田制作所 | 研磨剂供给装置、研磨装置以及研磨剂供给方法 |

| CN113396030A (zh) * | 2018-12-27 | 2021-09-14 | 胜高股份有限公司 | 两头磨削方法 |

| CN114227524A (zh) * | 2021-12-30 | 2022-03-25 | 西安奕斯伟材料科技有限公司 | 双面研磨装置和双面研磨方法 |

| CN115070604A (zh) * | 2022-06-09 | 2022-09-20 | 西安奕斯伟材料科技有限公司 | 双面研磨装置和双面研磨方法 |

| CN115723035A (zh) * | 2022-09-08 | 2023-03-03 | 西安奕斯伟材料科技有限公司 | 用于监控研磨装置的加工状态的系统、方法及双面研磨装置 |

| CN120038618A (zh) * | 2025-04-18 | 2025-05-27 | 浙江求是半导体设备有限公司 | 一种晶圆双面减薄方法和系统 |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9960088B2 (en) * | 2011-11-07 | 2018-05-01 | Taiwan Semiconductor Manufacturing Company, Ltd. | End point detection in grinding |

| US9358660B2 (en) | 2011-11-07 | 2016-06-07 | Taiwan Semiconductor Manufacturing Company, Ltd. | Grinding wheel design with elongated teeth arrangement |

| JP6197580B2 (ja) * | 2013-10-29 | 2017-09-20 | 株式会社Sumco | キャリアプレート及びワークの両面研磨装置 |

| JP6513174B2 (ja) * | 2017-12-25 | 2019-05-15 | 信越半導体株式会社 | ウェーハ保持用キャリアの設計方法 |

| US11415971B2 (en) | 2020-02-10 | 2022-08-16 | Globalwafers Co., Ltd. | Systems and methods for enhanced wafer manufacturing |

| CN116601575A (zh) * | 2020-11-10 | 2023-08-15 | 环球晶圆股份有限公司 | 使用阶层式预测及复合阈值增强机器学习的系统及方法 |

| US12386340B2 (en) | 2022-02-25 | 2025-08-12 | Globalwafers Co., Ltd. | Systems and methods for generating post-polishing topography for enhanced wafer manufacturing |

| CN115383616B (zh) * | 2022-09-22 | 2024-05-31 | 西安奕斯伟材料科技股份有限公司 | 研磨装置、研磨方法及硅片 |

| CN116475934B (zh) * | 2023-03-31 | 2025-03-28 | 西安奕斯伟材料科技股份有限公司 | 静压垫、研磨设备及硅片 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050260922A1 (en) * | 2004-05-21 | 2005-11-24 | Mosel Vitelic, Inc. | Torque-based end point detection methods for chemical mechanical polishing tool which uses ceria-based CMP slurry to polish to protective pad layer |

| US20060009125A1 (en) * | 2002-10-09 | 2006-01-12 | Kenji Okura | Both side grinding method and both side grinder of thin disc-like work |

| CN1933940A (zh) * | 2004-03-19 | 2007-03-21 | Memc电子材料有限公司 | 用于双面研磨机的晶片夹持装置 |

| JP2007096015A (ja) * | 2005-09-29 | 2007-04-12 | Shin Etsu Handotai Co Ltd | 半導体ウェーハの両頭研削装置、静圧パッドおよびこれを用いた両頭研削方法 |

| US20070179660A1 (en) * | 2006-01-30 | 2007-08-02 | Memc Electronic Materials, Inc. | Double side wafer grinder and methods for assessing workpiece nanotopology |

Family Cites Families (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1177497A (ja) * | 1997-09-01 | 1999-03-23 | Waida Seisakusho:Kk | 半導体ウエハの両面研削方法及び両面研削装置 |

| JPH11154655A (ja) * | 1997-11-21 | 1999-06-08 | Komatsu Electron Metals Co Ltd | 半導体ウェハの製造方法 |

| JP3328193B2 (ja) * | 1998-07-08 | 2002-09-24 | 信越半導体株式会社 | 半導体ウエーハの製造方法 |

| JP3664593B2 (ja) * | 1998-11-06 | 2005-06-29 | 信越半導体株式会社 | 半導体ウエーハおよびその製造方法 |

| JP3969956B2 (ja) * | 1999-05-07 | 2007-09-05 | 信越半導体株式会社 | 両面同時研削方法および両面同時研削盤並びに両面同時ラップ方法および両面同時ラップ盤 |

| US6294469B1 (en) * | 1999-05-21 | 2001-09-25 | Plasmasil, Llc | Silicon wafering process flow |

| JP2002307303A (ja) * | 2001-04-10 | 2002-10-23 | Koyo Mach Ind Co Ltd | 薄板円板状ワークの両面研削方法および装置 |

| JP2002307275A (ja) * | 2001-04-16 | 2002-10-23 | Sumitomo Heavy Ind Ltd | 加工システム及び面取り装置 |

| JP2002346924A (ja) * | 2001-05-29 | 2002-12-04 | Sumitomo Heavy Ind Ltd | ワークホルダ |

| JP3848120B2 (ja) * | 2001-10-12 | 2006-11-22 | 住友重機械工業株式会社 | ワーク研削装置 |

| JP2004072076A (ja) * | 2002-06-10 | 2004-03-04 | Nikon Corp | 露光装置及びステージ装置、並びにデバイス製造方法 |

| JP3993856B2 (ja) * | 2004-01-22 | 2007-10-17 | 光洋機械工業株式会社 | 両頭平面研削装置 |

| JP4326974B2 (ja) * | 2004-01-30 | 2009-09-09 | コマツNtc株式会社 | ウェーハの研削装置及び研削方法 |

| DE102004005702A1 (de) * | 2004-02-05 | 2005-09-01 | Siltronic Ag | Halbleiterscheibe, Vorrichtung und Verfahren zur Herstellung der Halbleiterscheibe |

| JP4615275B2 (ja) * | 2004-09-21 | 2011-01-19 | 株式会社ディスコ | ウェーハ研磨装置及びウェーハの研磨方法 |

| JP4752475B2 (ja) * | 2005-12-08 | 2011-08-17 | 信越半導体株式会社 | 半導体ウェーハの両頭研削装置、静圧パッドおよびこれを用いた両頭研削方法 |

| WO2007130708A1 (en) * | 2006-01-30 | 2007-11-15 | Memc Electronic Materials, Inc. | Double side wafer grinder and methods for assessing workpiece nanotopology |

| US7662023B2 (en) * | 2006-01-30 | 2010-02-16 | Memc Electronic Materials, Inc. | Double side wafer grinder and methods for assessing workpiece nanotopology |

| US7930058B2 (en) * | 2006-01-30 | 2011-04-19 | Memc Electronic Materials, Inc. | Nanotopography control and optimization using feedback from warp data |

| EP1870936A1 (fr) * | 2006-06-19 | 2007-12-26 | STMicroelectronics (Rousset) SAS | Procédé de fabrication de lentilles, notamment pour imageur intégré |

| KR20090031571A (ko) * | 2006-07-18 | 2009-03-26 | 제이에스알 가부시끼가이샤 | 화학 기계 연마용 수계 분산체, 그의 제조 방법 및 화학 기계 연마 방법 |

| DE102007030958B4 (de) * | 2007-07-04 | 2014-09-11 | Siltronic Ag | Verfahren zum Schleifen von Halbleiterscheiben |

| US8859396B2 (en) * | 2007-08-07 | 2014-10-14 | Semiconductor Components Industries, Llc | Semiconductor die singulation method |

| US7989319B2 (en) * | 2007-08-07 | 2011-08-02 | Semiconductor Components Industries, Llc | Semiconductor die singulation method |

| US8012857B2 (en) * | 2007-08-07 | 2011-09-06 | Semiconductor Components Industries, Llc | Semiconductor die singulation method |

| JP5245319B2 (ja) * | 2007-08-09 | 2013-07-24 | 富士通株式会社 | 研磨装置及び研磨方法、基板及び電子機器の製造方法 |

| DE102007049811B4 (de) * | 2007-10-17 | 2016-07-28 | Peter Wolters Gmbh | Läuferscheibe, Verfahren zur Beschichtung einer Läuferscheibe sowie Verfahren zur gleichzeitigen beidseitigen Material abtragenden Bearbeitung von Halbleiterscheiben |

| JP4985451B2 (ja) * | 2008-02-14 | 2012-07-25 | 信越半導体株式会社 | ワークの両頭研削装置およびワークの両頭研削方法 |

| JP5390807B2 (ja) * | 2008-08-21 | 2014-01-15 | 株式会社荏原製作所 | 研磨方法および装置 |

| JP2010064214A (ja) * | 2008-09-12 | 2010-03-25 | Koyo Mach Ind Co Ltd | 両頭平面研削盤及びワークの両面研削方法 |

| JP4291405B1 (ja) * | 2008-11-14 | 2009-07-08 | 健治 吉田 | ドットパターン読み取り機能を備えたマウス |

| DE102009048436B4 (de) * | 2009-10-07 | 2012-12-20 | Siltronic Ag | Verfahren zum Schleifen einer Halbleiterscheibe |

-

2011

- 2011-03-16 US US13/049,536 patent/US8712575B2/en active Active

- 2011-03-18 SG SG2012067369A patent/SG184014A1/en unknown

- 2011-03-18 WO PCT/IB2011/051152 patent/WO2011117792A1/en not_active Ceased

- 2011-03-18 CN CN201180016139XA patent/CN102844151A/zh active Pending

- 2011-03-18 KR KR1020127025126A patent/KR101694574B1/ko active Active

- 2011-03-18 JP JP2013500633A patent/JP6013317B2/ja active Active

- 2011-03-18 EP EP11758894.7A patent/EP2552644A4/en not_active Withdrawn

- 2011-03-25 TW TW100110457A patent/TWI520202B/zh active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060009125A1 (en) * | 2002-10-09 | 2006-01-12 | Kenji Okura | Both side grinding method and both side grinder of thin disc-like work |

| CN1933940A (zh) * | 2004-03-19 | 2007-03-21 | Memc电子材料有限公司 | 用于双面研磨机的晶片夹持装置 |

| US20050260922A1 (en) * | 2004-05-21 | 2005-11-24 | Mosel Vitelic, Inc. | Torque-based end point detection methods for chemical mechanical polishing tool which uses ceria-based CMP slurry to polish to protective pad layer |

| JP2007096015A (ja) * | 2005-09-29 | 2007-04-12 | Shin Etsu Handotai Co Ltd | 半導体ウェーハの両頭研削装置、静圧パッドおよびこれを用いた両頭研削方法 |

| US20070179660A1 (en) * | 2006-01-30 | 2007-08-02 | Memc Electronic Materials, Inc. | Double side wafer grinder and methods for assessing workpiece nanotopology |

Cited By (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105881213A (zh) * | 2014-09-01 | 2016-08-24 | 曾庆明 | 一种精密双面研磨机的控制器 |

| CN105881195A (zh) * | 2015-02-17 | 2016-08-24 | 光洋机械工业株式会社 | 双头平面研磨装置 |

| CN108475627B (zh) * | 2015-11-26 | 2022-11-08 | 胜高股份有限公司 | 晶圆抛光方法 |

| CN108475627A (zh) * | 2015-11-26 | 2018-08-31 | 胜高股份有限公司 | 晶圆抛光方法 |

| CN108127560A (zh) * | 2017-12-08 | 2018-06-08 | 中国兵器科学研究院宁波分院 | 用于方形光学元件双面快速抛光的控制系统 |

| CN113396030A (zh) * | 2018-12-27 | 2021-09-14 | 胜高股份有限公司 | 两头磨削方法 |

| CN112930248A (zh) * | 2019-04-01 | 2021-06-08 | 株式会社村田制作所 | 研磨剂供给装置、研磨装置以及研磨剂供给方法 |

| CN112930248B (zh) * | 2019-04-01 | 2023-05-02 | 株式会社村田制作所 | 研磨剂供给装置、研磨装置以及研磨剂供给方法 |

| CN114227524A (zh) * | 2021-12-30 | 2022-03-25 | 西安奕斯伟材料科技有限公司 | 双面研磨装置和双面研磨方法 |

| CN115070604A (zh) * | 2022-06-09 | 2022-09-20 | 西安奕斯伟材料科技有限公司 | 双面研磨装置和双面研磨方法 |

| CN115070604B (zh) * | 2022-06-09 | 2023-09-29 | 西安奕斯伟材料科技股份有限公司 | 双面研磨装置和双面研磨方法 |

| CN115723035A (zh) * | 2022-09-08 | 2023-03-03 | 西安奕斯伟材料科技有限公司 | 用于监控研磨装置的加工状态的系统、方法及双面研磨装置 |

| CN115723035B (zh) * | 2022-09-08 | 2024-05-28 | 西安奕斯伟材料科技股份有限公司 | 用于监控研磨装置的加工状态的系统、方法及双面研磨装置 |

| CN120038618A (zh) * | 2025-04-18 | 2025-05-27 | 浙江求是半导体设备有限公司 | 一种晶圆双面减薄方法和系统 |

| CN120038618B (zh) * | 2025-04-18 | 2025-07-29 | 浙江求是半导体设备有限公司 | 一种晶圆双面减薄方法和系统 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2552644A4 (en) | 2014-05-14 |

| KR101694574B1 (ko) | 2017-01-09 |

| US20110237160A1 (en) | 2011-09-29 |

| KR20130008572A (ko) | 2013-01-22 |

| US8712575B2 (en) | 2014-04-29 |

| JP6013317B2 (ja) | 2016-10-25 |

| SG184014A1 (en) | 2012-10-30 |

| EP2552644A1 (en) | 2013-02-06 |

| TWI520202B (zh) | 2016-02-01 |

| JP2013524484A (ja) | 2013-06-17 |

| WO2011117792A1 (en) | 2011-09-29 |

| TW201201264A (en) | 2012-01-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102844151A (zh) | 同时双面晶片研磨机中的流体静力垫压力调控 | |

| JP2013524484A5 (enExample) | ||

| US7927185B2 (en) | Method for assessing workpiece nanotopology using a double side wafer grinder | |

| CN107107309B (zh) | 抛光研磨处理中研磨量的模拟方法、抛光研磨装置及研磨量的模拟用存储介质 | |

| TW200946284A (en) | Nanotopography control and optimization using feedback from warp data | |

| CN101804589A (zh) | 加工半导体用人造石英玻璃基板的方法 | |

| US9601395B2 (en) | Methods for post-epitaxial warp prediction and control | |

| JP2004154933A (ja) | ピボット機構を有する垂直方向に調整可能な化学機械研磨ヘッドおよびその利用のための方法 | |

| CN101410224B (zh) | 双面晶片磨具以及工件纳米形貌的估计方法 | |

| CN1933940B (zh) | 用于双面研磨机的晶片夹持装置 | |

| de San Román et al. | Analytical-method for polishing-surface prediction considering tool flexibility and grain-material interaction | |

| US7601049B2 (en) | Double side wafer grinder and methods for assessing workpiece nanotopology | |

| Lin et al. | Machine learning-based wheel monitoring for sapphire wafers | |

| US7147540B2 (en) | Magnetic head slider and method of manufacturing the same | |

| JP2005081461A (ja) | ウェハ等の研磨方法およびその装置 | |

| Zhang | Chemical mechanical polishing and grinding of silicon wafers | |

| JP2007318041A (ja) | 研磨装置 | |

| Zhu | Modeling and control of wiresaw and lapping processes in semiconductor wafer fabrication | |

| Baisie | Modeling, Simulation, And Optimization Of Diamond Disc Pad Conditioning In Chemical Mechanical Polishing | |

| Sun | Grinding of silicon wafers: Wafer shape model and its application |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |

Application publication date: 20121226 |