WO2022158348A1 - 樹脂組成物、光学積層体、光学物品、レンズ及び眼鏡 - Google Patents

樹脂組成物、光学積層体、光学物品、レンズ及び眼鏡 Download PDFInfo

- Publication number

- WO2022158348A1 WO2022158348A1 PCT/JP2022/000699 JP2022000699W WO2022158348A1 WO 2022158348 A1 WO2022158348 A1 WO 2022158348A1 JP 2022000699 W JP2022000699 W JP 2022000699W WO 2022158348 A1 WO2022158348 A1 WO 2022158348A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- component

- resin composition

- photochromic

- active hydrogen

- group

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G02—OPTICS

- G02C—SPECTACLES; SUNGLASSES OR GOGGLES INSOFAR AS THEY HAVE THE SAME FEATURES AS SPECTACLES; CONTACT LENSES

- G02C7/00—Optical parts

- G02C7/10—Filters, e.g. for facilitating adaptation of the eyes to the dark; Sunglasses

- G02C7/102—Photochromic filters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/40—Layered products comprising a layer of synthetic resin comprising polyurethanes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/08—Processes

- C08G18/16—Catalysts

- C08G18/22—Catalysts containing metal compounds

- C08G18/24—Catalysts containing metal compounds of tin

- C08G18/244—Catalysts containing metal compounds of tin tin salts of carboxylic acids

- C08G18/246—Catalysts containing metal compounds of tin tin salts of carboxylic acids containing also tin-carbon bonds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/2805—Compounds having only one group containing active hydrogen

- C08G18/2815—Monohydroxy compounds

- C08G18/283—Compounds containing ether groups, e.g. oxyalkylated monohydroxy compounds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/30—Low-molecular-weight compounds

- C08G18/38—Low-molecular-weight compounds having heteroatoms other than oxygen

- C08G18/3855—Low-molecular-weight compounds having heteroatoms other than oxygen having sulfur

- C08G18/3876—Low-molecular-weight compounds having heteroatoms other than oxygen having sulfur containing mercapto groups

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/40—High-molecular-weight compounds

- C08G18/48—Polyethers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/40—High-molecular-weight compounds

- C08G18/48—Polyethers

- C08G18/4825—Polyethers containing two hydroxy groups

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/40—High-molecular-weight compounds

- C08G18/48—Polyethers

- C08G18/4833—Polyethers containing oxyethylene units

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/40—High-molecular-weight compounds

- C08G18/48—Polyethers

- C08G18/4854—Polyethers containing oxyalkylene groups having four carbon atoms in the alkylene group

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/40—High-molecular-weight compounds

- C08G18/64—Macromolecular compounds not provided for by groups C08G18/42 - C08G18/63

- C08G18/6484—Polysaccharides and derivatives thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/70—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the isocyanates or isothiocyanates used

- C08G18/72—Polyisocyanates or polyisothiocyanates

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/70—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the isocyanates or isothiocyanates used

- C08G18/72—Polyisocyanates or polyisothiocyanates

- C08G18/74—Polyisocyanates or polyisothiocyanates cyclic

- C08G18/75—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic

- C08G18/751—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic containing only one cycloaliphatic ring

- C08G18/752—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic containing only one cycloaliphatic ring containing at least one isocyanate or isothiocyanate group linked to the cycloaliphatic ring by means of an aliphatic group

- C08G18/753—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic containing only one cycloaliphatic ring containing at least one isocyanate or isothiocyanate group linked to the cycloaliphatic ring by means of an aliphatic group containing one isocyanate or isothiocyanate group linked to the cycloaliphatic ring by means of an aliphatic group having a primary carbon atom next to the isocyanate or isothiocyanate group

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/70—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the isocyanates or isothiocyanates used

- C08G18/72—Polyisocyanates or polyisothiocyanates

- C08G18/74—Polyisocyanates or polyisothiocyanates cyclic

- C08G18/75—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic

- C08G18/751—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic containing only one cycloaliphatic ring

- C08G18/752—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic containing only one cycloaliphatic ring containing at least one isocyanate or isothiocyanate group linked to the cycloaliphatic ring by means of an aliphatic group

- C08G18/753—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic containing only one cycloaliphatic ring containing at least one isocyanate or isothiocyanate group linked to the cycloaliphatic ring by means of an aliphatic group containing one isocyanate or isothiocyanate group linked to the cycloaliphatic ring by means of an aliphatic group having a primary carbon atom next to the isocyanate or isothiocyanate group

- C08G18/755—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic containing only one cycloaliphatic ring containing at least one isocyanate or isothiocyanate group linked to the cycloaliphatic ring by means of an aliphatic group containing one isocyanate or isothiocyanate group linked to the cycloaliphatic ring by means of an aliphatic group having a primary carbon atom next to the isocyanate or isothiocyanate group and at least one isocyanate or isothiocyanate group linked to a secondary carbon atom of the cycloaliphatic ring, e.g. isophorone diisocyanate

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/70—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the isocyanates or isothiocyanates used

- C08G18/72—Polyisocyanates or polyisothiocyanates

- C08G18/74—Polyisocyanates or polyisothiocyanates cyclic

- C08G18/75—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic

- C08G18/751—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic containing only one cycloaliphatic ring

- C08G18/752—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic containing only one cycloaliphatic ring containing at least one isocyanate or isothiocyanate group linked to the cycloaliphatic ring by means of an aliphatic group

- C08G18/757—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic containing only one cycloaliphatic ring containing at least one isocyanate or isothiocyanate group linked to the cycloaliphatic ring by means of an aliphatic group containing at least two isocyanate or isothiocyanate groups linked to the cycloaliphatic ring by means of an aliphatic group

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/70—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the isocyanates or isothiocyanates used

- C08G18/72—Polyisocyanates or polyisothiocyanates

- C08G18/74—Polyisocyanates or polyisothiocyanates cyclic

- C08G18/75—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic

- C08G18/758—Polyisocyanates or polyisothiocyanates cyclic cycloaliphatic containing two or more cycloaliphatic rings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L75/00—Compositions of polyureas or polyurethanes; Compositions of derivatives of such polymers

- C08L75/04—Polyurethanes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L75/00—Compositions of polyureas or polyurethanes; Compositions of derivatives of such polymers

- C08L75/04—Polyurethanes

- C08L75/08—Polyurethanes from polyethers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K9/00—Tenebrescent materials, i.e. materials for which the range of wavelengths for energy absorption is changed as a result of excitation by some form of energy

- C09K9/02—Organic tenebrescent materials

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B1/00—Optical elements characterised by the material of which they are made; Optical coatings for optical elements

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B1/00—Optical elements characterised by the material of which they are made; Optical coatings for optical elements

- G02B1/04—Optical elements characterised by the material of which they are made; Optical coatings for optical elements made of organic materials, e.g. plastics

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B1/00—Optical elements characterised by the material of which they are made; Optical coatings for optical elements

- G02B1/04—Optical elements characterised by the material of which they are made; Optical coatings for optical elements made of organic materials, e.g. plastics

- G02B1/041—Lenses

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/20—Filters

- G02B5/22—Absorbing filters

- G02B5/23—Photochromic filters

-

- G—PHYSICS

- G02—OPTICS

- G02C—SPECTACLES; SUNGLASSES OR GOGGLES INSOFAR AS THEY HAVE THE SAME FEATURES AS SPECTACLES; CONTACT LENSES

- G02C7/00—Optical parts

- G02C7/10—Filters, e.g. for facilitating adaptation of the eyes to the dark; Sunglasses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/02—2 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/40—Properties of the layers or laminate having particular optical properties

- B32B2307/42—Polarizing, birefringent, filtering

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2375/00—Polyureas; Polyurethanes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2551/00—Optical elements

Definitions

- the present invention relates to resin compositions, optical laminates, optical articles, lenses and spectacles.

- Photochromic spectacle lenses containing a photochromic compound are quickly colored and function as sunglasses outdoors where light including ultraviolet light such as sunlight is irradiated, and fade and become transparent indoors where such light is not irradiated. functions as a pair of glasses.

- the demand for photochromic optical articles having such photochromic properties has increased in recent years.

- the following methods are generally used to impart photochromic properties to spectacle lenses.

- the optical plate may be plastic or inorganic glass.

- Patent Literature 1 describes a dyed lens obtained by dyeing a urethane-based resin (molded body) as an article similar to a photochromic optical article.

- the urethane-based resin that forms this molded product uses thiol as a monomer and has excellent mechanical strength having (thio)urethane bonds in its molecular chain.

- the urethane resin used as the matrix has a (thio)urethane bond, so the monomer formulation needs to be specially adjusted. Otherwise, the molecular mobility of ring-opening/ring-closing of the photochromic compound may be inhibited.

- Patent Document 2 uses a bifunctional active hydrogen compound having a polypropylene glycol chain or the like, and Patent Document 3 uses a monofunctional active hydrogen compound. According to these methods, photochromic properties can be improved by forming spaces in the urethane matrix using a specific active hydrogen compound.

- the inventor of the present invention thought that it might be necessary to control the molecular mobility in the urethane resin by means of cross-linking molecules, rather than simply forming a free space. Then, it was found that a cured product (a urethane resin in which a photochromic compound is dispersed) that satisfies specific molecular mobility parameters can express good photochromic properties and mechanical properties, and the present invention has been completed. rice field.

- the present invention includes the following inventions. 1. Containing a urethane resin having a polyoxypropylene chain in the molecular chain and a photochromic compound, the maximum intensity of the signal within the range of 16 ppm or more and 20 ppm or less in the first spectrum by 13 C-PST/MAS nuclear magnetic resonance spectroscopy (PMI pst ); The ratio (PMI pst /PMI cp ) to the maximum intensity (PMI cp ) of the signal within the range of 16 ppm or more and 20 ppm or less in the second spectrum by 13 C-CP/MAS nuclear magnetic resonance spectroscopy is 8.0 or more and 40. 0 or less resin composition. 2.

- the ratio (EI pst /EI cp ) to the maximum intensity (EI cp ) of the signal within the range of 68 ppm or more and 72 ppm or less in the second spectrum is 5.0 or more and 20.0 or less. of the resin composition. 4.

- the urethane-based resin is (A) a polyiso(thio)cyanate component having two or more iso(thio)cyanate groups in the molecule selected from the group consisting of isocyanate groups and isothiocyanate groups; (B) an active hydrogen-containing component having an active hydrogen-containing group; A resin obtained by reacting Let nB be the total number of moles of active hydrogen-containing groups possessed by the active hydrogen-containing component (B), When the total number of moles of iso(thio)cyanate groups possessed by the (A) polyiso(thio)cyanate component is nA, The ratio (nA/nB) is 1.00 or more and 1.50 or less,

- the (B) active hydrogen-containing component is (B1) a polyfunctional active hydrogen-containing component having 3 or more active hydrogen-containing groups in one molecule; (B2) a first active hydrogen-containing component having one or two active hydrogen-containing groups in one molecule, 5.

- the resin composition according to item 7, wherein the (B2) first active hydrogen-containing component has the alkyl group and has 5 or more and 20 or less carbon atoms. 9. 8. The resin composition according to item 7, wherein the (B2) first active hydrogen-containing component has the polyoxyethylene chain, and the average value of repeating units thereof is 5 or more and 25 or less. 10.

- the (B1) polyfunctional active hydrogen-containing component is 10. The resin composition according to any one of the preceding items 5 to 9, which contains a compound having a quaternary carbon atom in the molecule and all groups bonded to the quaternary carbon atom having an active hydrogen-containing group. . 11.

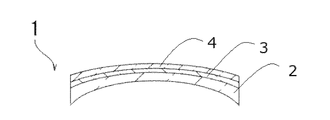

- an optical substrate The resin composition according to any one of the preceding items 1 to 10, which is laminated on at least one main surface of the optical substrate;

- An optical stack comprising: 12. 12.

- An optical article comprising the resin composition according to any one of 1 to 10 above.

- a lens comprising the resin composition according to any one of 1 to 10 above.

- 15. Spectacles comprising the lens according to 14 above.

- a resin composition having excellent photochromic properties and mechanical properties can be obtained.

- a resin composition having excellent photochromic properties and heat resistance can be obtained.

- BRIEF DESCRIPTION OF THE DRAWINGS Sectional drawing which shows schematically an example of the optical laminated body which concerns on embodiment.

- BRIEF DESCRIPTION OF THE DRAWINGS The perspective view which shows schematically an example of the spectacles which concern on embodiment.

- the resin composition is (i) a urethane resin having a polyoxypropylene chain in the molecular chain (component (i)), and (ii) a photochromic compound (component (ii)) including.

- the (i) urethane-based resin has a polyoxypropylene chain in its molecular chain, and when a urethane-based resin in which the molecular mobility of the polyoxypropylene chain satisfies a specific range is used as a matrix, it is excellent. It was found that the effect of Specifically, the motility of the portion containing the carbon atoms of the methyl group of the polyoxypropylene chain is evaluated by solid-state 13 CNMR measurement, and excellent photochromic is obtained by satisfying a specific range for the motility index. It results in a resin composition having properties and mechanical properties.

- Solid-state NMR measurement methods for carbon nuclei include Pulse Saturation Transfer/Magic Angle Spinning (PST/MAS) method and Cross Polarization/Magic Angle Spinning (CP/MAS) method.

- PST/MAS Pulse Saturation Transfer/Magic Angle Spinning

- CP/MAS Cross Polarization/Magic Angle Spinning

- the PST/MAS method is a technique for emphasizing and observing highly mobile parts (amorphous parts).

- the CP/MAS method is a technique for emphasizing and observing a portion with low mobility (crystalline portion). Therefore, by comparing the intensity of specific signals in these spectra, it is possible to evaluate the molecular mobility of the components constituting the urethane-based resin (matrix resin in which the photochromic compound is dispersed).

- the solid-state 13 C NMR spectrum of the resin composition by the PST/MAS method is also referred to as the first spectrum.

- a solid-state 13 C NMR spectrum of the resin composition by the CP/MAS method is also referred to as a second spectrum.

- the intensity of each peak measured by the PST/MAS method is I PST and the intensity of each peak measured by the CP/MAS method is I CP

- the value obtained by dividing I PST by I CP is I PST /I CP is an index of molecular mobility, and the higher the molecular mobility, the larger the I PST /I CP value.

- I PST /I CP 1

- a carbon atom of a C ⁇ O group appearing within the range of 163 to 168 ppm was taken as a reference peak.

- the (i) component essentially contains a polyoxypropylene chain. And it preferably contains an alkyl group and/or an oxyethylene chain.

- the chemical shift values of the carbon nucleus in each unit observed in the solid-state 13 C-NMR measurement are roughly as follows. 10-15 ppm: terminal methyl group in the alkyl group, 16-20 ppm: methyl group in the oxypropylene unit, 68 ppm to 72 ppm: ethylene group in oxyethylene unit 73 ppm to 80 ppm: ethylene group in oxypropylene unit (excluding methyl group).

- component (i) contains an alkyl group having 2 or more carbon atoms, a methyl group at the end of the alkyl group can be confirmed.

- a resin composition containing a photochromic compound or a photochromic optical article can be directly analyzed by NMR to determine the I PST /I CP value of each carbon nucleus.

- PMI pst is the maximum intensity, ie, maximum height, of a signal appearing within the range of 16 ppm to 20 ppm in the first spectrum.

- PMI cp is the maximum intensity, ie, maximum height, of a signal appearing within the range of 16 ppm to 20 ppm in the second spectrum.

- signals appearing within the range of 16 ppm to 20 ppm in the first and second spectra are signals that are believed to originate from the methyl group of the oxypropylene unit.

- the strength ratio (PMI pst /PMI cp ) of the resin composition is within a specific range.

- the urethane resin which constitutes the majority of the matrix of the resin composition, has polyoxypropylene chains in its molecular chains, free space is likely to be secured, and high photochromic properties can be exhibited. That is, since the matrix of the resin composition becomes flexible, the structural change of the photochromic compound is less likely to be hindered, and photochromic properties can be exhibited over a long period of time.

- the proportion of polyoxypropylene chains is excessively increased or the length of the introduced chains is too long, the mechanical properties may be degraded.

- the present inventors considered that it was necessary to evaluate the motility of component (i) itself in order to improve photochromic properties while maintaining high mechanical properties. Then, when the motility of the component (i) is measured by the NMR method described above, by setting the intensity ratio (PMI pst /PMI cp ) of the component (i) to 8.0 or more and 40.0 or less, It was found that excellent effects can be exhibited. In other words, not only does it form a free space, but also the (i) component itself has moderate mobility, so it is thought that the balance between the photochromic properties and the mechanical properties is excellent.

- the intensity ratio (PMI pst /PMI cp ) of component (i) is less than 8.0, the photochromic properties are inferior, which is not preferable.

- the mechanical properties, particularly the heat resistance, are degraded, which is not preferable. That is, if the strength ratio (PMI pst /PMI cp ) is less than 8.0, it may mean that the percentage of flexible polyoxypropylene chains with high molecular mobility in the resin composition is too low. In such a resin composition, the photochromic compound is less likely to undergo a structural change, and the photochromic properties of the photochromic compound, such as the fading rate and color density, are less likely to be exhibited.

- a strength ratio (PMI pst /PMI cp ) of more than 40.0 may mean that the ratio of highly crystalline polyoxypropylene chains in the resin composition is too low. Such resin compositions tend to have insufficient mechanical properties such as heat resistance.

- the intensity ratio (PMI pst /PMI cp ) is preferably 10.0 to 35.0, more preferably 10.0 to 15.0, or 20.0 in order to exhibit better characteristics. It is more preferable to set it to ⁇ 35.0.

- the intensity ratio (PMI pst /PMI cp ) can be 20.0 to 35.0. Especially preferred. When the monofunctional polymerizable monomer is not used, the degree of cross-linking increases, so it is considered that even if the strength ratio (PMI pst /PMI cp ) is high, excellent effects are exhibited. When a monofunctional polymerizable monomer is not used, the intensity ratio (PMI pst /PMI cp ) is preferably 23.5 to 35.0, more preferably 25.5, considering the balance of physical properties. ⁇ 35.0 is preferable.

- the intensity ratio (PMI pst /PMI cp ) is 10.0 to 15.0. And it is most preferable to use the monofunctional polymerizable monomer.

- a resin composition having excellent photochromic properties and mechanical properties is obtained by using a monofunctional polymerizable monomer and satisfying a strength ratio (PMI pst /PMI cp ) of 10.0 to 15.0. can do

- the intensity ratio (PMI pst /PMI cp ) is more preferably 11.0 to 15.0, more preferably 12.5 to 15.0.

- the intensity PMI pst is preferably 1.0 or more and 20.0 or less.

- a resin composition having a strength PMI pst within this range tends to have a sufficient amount of flexible polyoxypropylene chains with high molecular mobility.

- the intensity PMI pst is more preferably 1.1 or more and 17.5 or less, more preferably 1.1 or more and 3.5 or less, or 13.0 or more and 17.5 or less.

- the intensity PMI cp is preferably 0.1 or more and 1.0 or less.

- a resin composition having a strength PMI cp within this range tends to have sufficient polyoxypropylene chains with high crystallinity.

- the intensity PMI cp is more preferably 0.10 or more and 0.70 or less, more preferably 0.15 or more and 0.30 or less, or 0.50 or more and 0.70 or less.

- the component (i) preferably has an alkyl group in its molecule.

- This alkyl group is preferably a group having 5 or more and 20 or less carbon atoms, and is preferably a linear alkyl group.

- This alkyl group may constitute a side chain or a main chain of the component (i).

- Component (i) having an alkyl group in the molecule can be obtained, for example, by using a polymerizable monomer having an alkyl group as the monofunctional polymerizable monomer described above.

- the terminal group located opposite to the reactive group of the monofunctional polymerizable monomer is an alkyl group, preferably a linear alkyl group having 5 or more and 20 or less carbon atoms.

- AMI pst be the spectral intensity of the carbon atom of the methyl group at the end of the alkyl group measured by 13 C-PST/MAS NMR

- AMI cp the intensity ratio of AMI pst to AMI cp (AMI pst /AMI cp ) is preferably 7.0 or more and 23.0 or less.

- the resulting resin composition can have improved photochromic properties and mechanical properties.

- the intensity ratio (AMI pst /AMI cp ) is more preferably 11.5 or more and 20.0 or less, and more preferably 13.5 or more and 16.0 or less.

- the strength AMI pst is preferably 1.0 or more and 5.0 or less.

- a resin composition having a strength AMI pst within this range tends to have a sufficient number of flexible alkyl groups with high molecular mobility.

- the intensity AMI pst is more preferably 1.10 or more and 3.00 or less, and even more preferably 2.0 or more and 2.8 or less.

- the strength AMI cp is preferably 0.1 or more and 0.5 or less.

- a resin composition having a strength AMI cp within this range tends to have sufficient alkyl groups with high crystallinity.

- the strength AMI cp is more preferably 0.10 or more and 0.30 or less, and still more preferably 0.15 or more and 0.20 or less.

- component (i) has an oxyethylene chain in the molecule. Having a polyoxyethylene chain in the molecular chain, Let EI pst be the spectral intensity of the carbon atoms of the polyoxyethylene chain measured by 13 C-PST/MAS NMR, When the spectral intensity of the carbon atoms of the polyoxyethylene chain measured by 13 C-CP/MAS NMR is defined as EI cp , The intensity ratio of EI pst to EI cp (EI pst /EI cp ) is preferably 5.0 or more and 20.0 or less.

- the resulting resin composition can have improved photochromic properties and mechanical properties. More preferably, the intensity ratio (EI pst /EI cp ) is 6.5 or more and 12.0 or less. As noted above, signals believed to be due to ethylene groups in the oxyethylene units appear within the range of 68 ppm to 72 ppm in the first and second spectra.

- the intensity EI pst is preferably 4.0 or more and 20.0 or less. A resin composition having a strength EI pst within this range tends to have a sufficient amount of flexible oxyethylene chains with high molecular mobility.

- the intensity EI pst is more preferably 4.50 or more and 18.00 or less, and even more preferably 9.50 or more and 18.00 or less.

- the intensity EI cp is preferably 0.5 or more and 3.0 or less.

- a resin composition having an intensity EI cp within this range tends to have sufficient oxyethylene chains with high crystallinity.

- the intensity EI cp is more preferably 0.70 or more and 2.10 or less, and even more preferably 1.30 or more and 2.00 or less.

- a first spectrum of the resin composition is obtained by 13 C-PST/MAS NMR spectroscopy.

- a disc-shaped resin composition having a diameter of about 2 mm and a thickness of 1 mm is used as a sample.

- a 4 mm zirconia sample tube filled with this sample is used.

- Measurement conditions are, for example, as follows. Probe: 4 mm ⁇ CP/MAS probe (JEOL Ltd.). 13 C nuclear measurement frequency: 100.53 MHz.

- Measurement method CP/MAS method.

- Contact time 2 msec.

- Delay time 5 sec. Accumulated times: 5000 times.

- Sample amount about 80 mg.

- Sample rotation speed 6000 Hz.

- Temperature 25°C.

- External standard adamantane (29.5 ppm).

- Pre-saturation method Interval 10 msec.

- a second spectrum of the resin composition is obtained by 13 C-CP/MAS NMR spectroscopy.

- a second spectrum is obtained in the same manner as the first spectrum described above, except that the pre-saturation method is not used.

- the intensity and chemical shift of each signal are calculated using analysis software such as JEOL Delta v5.0.4.

- FIG. 1 is a graph showing an example of the first spectrum of the resin composition according to the embodiment.

- the graph shown in FIG. 1 is the first spectrum of the resin composition according to Example 15, which will be described later.

- the horizontal axis indicates the chemical shift

- the vertical axis indicates the intensity.

- the first spectrum shown in FIG. 1 includes a signal exhibiting a maximum PMI pst within a chemical shift range of 16 ppm to 20 ppm and a signal exhibiting a maximum EI pst within a chemical shift range of 68 ppm to 72 ppm.

- FIG. 2 is a graph showing an example of the second spectrum of the resin composition according to the embodiment.

- the graph shown in FIG. 2 is the second spectrum of the resin composition according to Example 15, which will be described later.

- the horizontal axis indicates the chemical shift

- the vertical axis indicates the intensity.

- the second spectrum shown in FIG. 2 includes a signal exhibiting a maximum PMI cp within a chemical shift range of 16 ppm to 20 ppm and a signal exhibiting a maximum EI cp within a chemical shift range of 68 ppm to 72 ppm.

- component (i) has a polyoxypropylene chain in the molecular chain, and if the strength ratio (PMI pst /PMI cp ) is 8.0 to 40.0, the production method is particularly limited. not to be Among them, it is preferable to use a polymerizable monomer having an oxypropylene chain for good polymerization moldability and easy production of a resin composition, and a polymerizable monomer having an oxypropylene chain and an oxyethylene chain. It is more preferable to use a polymerizable monomer (particularly preferably a monofunctional polymerizable monomer) having an oxypropylene chain, an oxyethylene chain, and an alkyl group having 5 to 20 carbon atoms. is preferred.

- photochromic compound (hereinafter also referred to as component (ii)) can be used without any particular limitation as long as it is a compound exhibiting photochromic properties. More than one species can be used in combination.

- photochromic compounds such as chromene compounds, fulgimide compounds, spirooxazine compounds, and spiropyran compounds can be used without any limitation.

- fulgimide compounds, spirooxazine compounds, spiropyran compounds and chromene compounds described above are described in, for example, JP-A-2-28154, JP-A-62-288830, WO94/22850 and WO96/14596. can be mentioned.

- chromene compounds in addition to those described in the above patent documents, chromene compounds having excellent photochromic properties are known, and such chromene compounds can be suitably used as component (ii).

- chromene compounds include JP-A-2001-031670, JP-A-2001-011067, JP-A-2001-011066, JP-A-2000-344761, JP-A-2000-327675, JP-A-2000-256347, JP-A-2000-229976, JP-A-2000-229975, JP-A-2000-229974, JP-A-2000-229973, JP-A-2000-229972, JP-A-2000-219678, JP-A-2000-219686, JP-A-11-322739, JP-A-11-286484, JP-A-11-279171, JP-A-09-218301, JP-A-09-124645, JP-A-08-295690, JP-A-

- chromene compounds having an indeno[2,1-f]naphtho[1,2-b]pyran skeleton are preferred from the viewpoint of photochromic properties such as color density, initial coloring property, durability, and fading speed. It is more preferable to use

- a photochromic compound having an oligomer chain group in the molecule can also be suitably used.

- photochromic compounds having such oligomer chain groups include WO2000/015630, WO2004/041961, WO2009/146509, WO2012/149599, WO2012/162725, WO2013/078086, and WO2019. /013249 pamphlet, WO2019/203205 pamphlet, and many other documents.

- photochromic compounds having an oligomer chain group in the molecule those having an oligomer chain group described in WO2019/013249 and WO2019/203205 pamphlets are preferred for exhibiting superior photochromic properties and durability. It is preferred to use photochromic compounds.

- the resin composition contains the component (i) and the component (ii).

- the mixing ratio of the component (i) and the component (ii) may be appropriately determined according to the intended use of the photochromic optical article. Among other things, considering the general use of It is preferable to contain 0.01 to 10 parts by mass of component (ii) with respect to 100 parts by mass of component (i).

- the component (i) forms a crosslinked structure

- the content of the component (i) is the total amount of polymerizable monomer components forming the component (i) in the photochromic curable composition.

- the resin composition may contain known additives in addition to the components (i) and (ii).

- ultraviolet absorbers antistatic agents, infrared absorbents, ultraviolet stabilizers, antioxidants, anti-coloring agents, antistatic agents, fluorescent dyes, dyes, pigments, additives such as fragrances, solvents, leveling agents , internal mold release agents, and polymerization modifiers such as thiols such as t-dodecylmercaptan.

- additives are preferably blended into the photochromic curable composition described in detail below.

- the total content of alkali metal ions and alkaline earth metal ions in the resin composition is preferably 500 ppm or less.

- a resin composition with a low content of alkali metal ions and alkaline earth metal ions is excellent in the durability of the photochromic compound.

- Alkali metal ions and alkaline earth metal ions are not particularly limited.

- Alkali metal ions include sodium ions, potassium ions, lithium ions, cesium ions, and the like.

- Alkaline earth metal ions include calcium ions, magnesium ions, barium ions, strontium ions, beryllium ions, and radium ions.

- Alkali metal ions and alkaline earth metal ions include, for example, at least one ion selected from the group consisting of sodium ions, potassium ions, cesium ions, and magnesium ions.

- the total content of alkali metal ions and alkaline earth metal ions in the resin composition can be measured by fluorescent X-ray analysis.

- a circular plate-shaped resin composition having a diameter of 40 mm and a thickness of 1 mm is used as a sample.

- a fluorescent X-ray spectrometer ZSX Primus IV

- a detection limit value of a fluorescent X-ray analyzer is, for example, 1 ppm.

- the total content of alkali metal ions and alkaline earth metal ions in the resin composition is preferably 200 ppm or less, more preferably 100 ppm or less.

- the lower limit of alkali metal ions and alkaline earth metal ions in the resin composition is 0 ppm or the detection limit of a fluorescent X-ray spectrometer.

- ⁇ Characteristics of resin composition Color density of 0.55 or more and color fading speed of 200 sec. , and a heat resistance (softening temperature) of 45°C or higher.

- the color density should be 0.60 or more and the color fading speed should be 95 sec. and heat resistance (softening temperature) of 50° C. or higher.

- the color development density is 0.75 or more, and the color fading speed is 80 sec. or lower, and heat resistance (softening temperature) can be 60° C. or higher.

- the heat resistance (softening temperature) can be 70°C or higher.

- the upper and lower limits of these physical properties are not particularly limited, the color density is 1.10 or less, and the color fading speed is 40 sec. Thus, the heat resistance is 90° C. or less.

- the method for producing the resin composition is not particularly limited as long as the urethane resin contained in the resin composition satisfies the requirements.

- component (i) may be impregnated with component (ii), or component (i) and component (ii) may be mixed.

- a photochromic curable composition containing the polymerizable monomer forming the urethane-based resin and the component (ii). is preferred.

- the photochromic curable composition can be easily produced, (A) a polyiso(thio)cyanate component having two or more iso(thio)cyanate groups in the molecule selected from the group consisting of isocyanate groups and isothiocyanate groups; (B) an active hydrogen-containing component having an active hydrogen-containing group; (ii) a component; It is preferred to provide a photochromic curable composition comprising: Then, it is preferable to produce a resin composition by curing (polymerizing) this photochromic curable composition.

- the blending ratio of the monomers forming component (i) is not particularly limited, but in order to stably obtain a resin composition, the blending ratio described later is recommended. is preferred.

- the photochromic curable composition will be explained.

- Photochromic curable composition As described above, (A) a polyiso(thio)cyanate component having two or more iso(thio)cyanate groups in the molecule selected from the group consisting of isocyanate groups and isothiocyanate groups; (B) an active hydrogen-containing component having an active hydrogen-containing group; (ii) a photochromic compound, is preferably included. Each component will be described below.

- polyiso(thio)cyanate component having two or more iso(thio)cyanate groups selected from the group consisting of isocyanate groups and isothiocyanate groups in the molecule>

- A In a polyiso(thio)cyanate component (component (A)) having two or more iso(thio)cyanate groups selected from the group consisting of isocyanate groups and isothiocyanate groups in the molecule, The number is not particularly limited as long as it is two or more. Among them, the number is preferably 2 to 6, more preferably 2 to 4, and even more preferably 2, from the viewpoint of facilitating control of polymerization.

- Polyiso(thio)cyanate compound refers to a group having two or more isocyanate groups and/or isothiocyanate groups.

- the component (A) includes aliphatic isocyanate compounds, alicyclic isocyanate compounds, aromatic isocyanate compounds, sulfur-containing heterocyclic isocyanate compounds, sulfur-containing aliphatic isocyanate compounds, aliphatic sulfide isocyanate compounds, and aromatic sulfide isocyanate compounds. , aliphatic sulfone-based isocyanate compounds, aromatic sulfone-based isocyanate compounds, sulfonic acid ester-based isocyanate compounds, and aromatic sulfonic acid amide-based isocyanate compounds.

- the isocyanate group of the isocyanate compound is at least selected from the group consisting of alcohols, lactams, phenols, oximes, pyrazoles, thiols, active methylene compounds, malonic acid diester compounds, and acetoacetic ester compounds. Also included are blocked isocyanate compounds blocked with one type of blocking agent.

- ((A) component; suitable polyisocyanate compound) compounds suitable for forming a resin composition having excellent transparency and mechanical strength, particularly suitable for producing a resin composition containing a photochromic compound, include the following formula Examples include compounds represented by (I) to (VIII).

- Preferred aliphatic isocyanate compounds include the following formula

- R 100 is an alkylene group having 1 to 10 carbon atoms, and may be a group in which part of the methylene groups in the chain of the alkylene group is substituted with a sulfur atom.

- R 100 It is preferred to use a compound represented by

- R 100 is an alkylene group having 1 to 10 carbon atoms and may be a linear or branched group.

- a pentamethylene group, a hexamethylene group, or a linear group of a heptamethylene group or an octamethylene group, or a part of hydrogen atoms of a pentamethylene group, a hexamethylene group, a heptamethylene group or an octamethylene group is methyl

- a branched group substituted with a group is preferred.

- the alkylene group in which a part of the methylene group is substituted with a sulfur atom is preferably a -CH 2 CH 2 SCH 2 CH 2 SCH 2 CH 2 - group.

- Specific examples of the compound represented by formula (I) include pentamethylene diisocyanate, hexamethylene diisocyanate, heptamethylene diisocyanate, octamethylene diisocyanate, 2,4,4-trimethylhexamethylene diisocyanate, 1,2-bis( 2-isocyanatoethylthio)ethane and the like. These compounds can be used alone, or two or more kinds of compounds can be used.

- aromatic isocyanate compound Preferred aromatic isocyanate compounds and alicyclic isocyanate compounds include the following formula (II) and the following formula (III)

- R 101 is each an alkyl group having 1 to 4 carbon atoms or a hydrogen atom, and may be the same group or different groups;

- R 102 is an alkyl group having 1 to 4 carbon atoms, and when a plurality of groups are present, they may be the same group or different groups, a 100 is an integer of 2 or 3, b 100 is an integer of 0 to 4, and c 100 is an integer of 0 to 4.

- a 100 is an integer of 2 or 3

- b 100 is an integer of 0 to 4

- c 100 is an integer of 0 to 4.

- the difference between the compound represented by the formula (II) and the compound represented by the formula (III) is that the compound having a phenyl group (the compound represented by the formula (II)) and the compound having a cyclohexane group (the compound represented by the formula (III) ) is a compound represented by ).

- the alkyl group having 1 to 4 carbon atoms may be a linear or branched group. Among them, R 101 is particularly preferably a hydrogen atom, a methyl group, or an ethyl group. In R 102 , the alkyl group having 1 to 4 carbon atoms may be a linear or branched group. Among them, R 102 is particularly preferably a methyl group or an ethyl group.

- the compound represented by formula (II) or formula (III) include isophorone diisocyanate, xylene diisocyanate (o-, m-, p-), 2,4-tolylene diisocyanate, 2, 6-tolylene diisocyanate, 1,3-bis(isocyanatomethyl)cyclohexane, 1,4-bis(isocyanatomethyl)cyclohexane and the like. These compounds can be used alone, or two or more kinds of compounds can be used.

- aromatic isocyanate compounds and alicyclic isocyanate compounds, the following formula (IV) and the following formula (V)

- Each R 103 is an alkyl group having 1 to 4 carbon atoms or a hydrogen atom, and may be the same group or different groups, and d 100 is an integer of 0 to 4.

- d 100 is an integer of 0 to 4.

- the difference between the compound represented by the formula (IV) and the compound represented by the formula (V) is that the compound having two phenyl groups (the compound represented by the formula (IV)) and the compound having two cyclohexane groups ( This is the difference from the compound represented by the formula (V)).

- the alkyl group having 1 to 4 carbon atoms may be a linear or branched group.

- R 103 is particularly preferably a hydrogen atom, a methyl group or an ethyl group.

- Specific examples of the compound represented by formula (IV) or formula (V) include 4,4'-diphenylmethane diisocyanate, dicyclohexylmethane-4,4'-diisocyanate, and the like. These compounds can be used alone, or two or more kinds of compounds can be used.

- Each R 104 is an alkyl group having 1 to 4 carbon atoms or a hydrogen atom, and may be the same group or different groups, and e 100 is an integer of 0 to 4. ) is preferably used.

- the alkyl group having 1 to 4 carbon atoms may be a linear or branched group.

- R 104 is particularly preferably a hydrogen atom, a methyl group or an ethyl group.

- the compound represented by the formula (VI) include norbornane diisocyanate, 2,5-bis(isocyanatomethyl)-bicyclo[2,2,1]-heptane, 2,6-bis(isocyanatomethyl) -bicyclo[2,2,1]-heptane. These compounds can be used alone, or two or more kinds of compounds can be used.

- sulfur-containing heterocyclic isocyanate compounds include the following formula (VII) and the following formula (VIII)

- R 105 is each an alkyl group having 1 to 4 carbon atoms or a hydrogen atom, and may be the same group or different groups;

- R 106 is a methylene group or a sulfur atom, and

- R 107 is an alkylene group having 1 to 6 carbon atoms, or a part of the methylene group in the chain of the alkylene group having 1 to 6 carbon atoms is substituted with a sulfur atom.

- f 100 is an integer of 0 to 2.

- compounds represented by formula (VII) or formula (VIII) include 2,5-bis(isocyanatomethyl)thiophene, 2,5-bis(isocyanatomethyl)-1,4 -dithiane, 3,4-bis(isocyanatomethyl)tetrahydrothiophene, 4,5-bis(isocyanatomethyl)-1,3-dithiolane and the like. These compounds can be used alone, or two or more kinds of compounds can be used.

- halogen-substituted, alkyl-substituted, alkoxy-substituted, and nitro-substituted polyisocyanates prepolymer-type modified products with polyhydric alcohols, carbodiimide-modified products, urea-modified products, biuret-modified products, dimerization or trimers Chemical reaction products and the like can also be used.

- Suitable (A) component; polyisothiocyanate compound examples include compounds in which the isocyanate group is replaced with an isothiocyanate group in the polyisocyanate compounds represented by the formulas (I) to (VIII). More specifically, aliphatic isothiocyanate compounds, alicyclic isothiocyanate compounds, aromatic isothiocyanate compounds, sulfur-containing heterocyclic isothiocyanate compounds, heterocyclic isothiocyanate compounds, sulfur-containing aliphatic isothiocyanate compounds, sulfur-containing Aromatic isothiocyanate compounds and the like can be mentioned.

- suitable compounds include aliphatic isothiocyanate compounds such as hexamethylene diisothiacynate, 1,2-diisothiocyanatoethane, 1,3-diisothiocyanatopropane, 1,4-diisothiocyanate, Thiocyanatobutane, 1,6-diisothiocyanatohexane, 2,4,4,-trimethylhexanemethylene diisothiacinate, thiobis(3-isothiocyanatopropane), thiobis(2-isothiocyanatoethane), dithiobis(2-iso thiocyanate ethane) and the like.

- aliphatic isothiocyanate compounds such as hexamethylene diisothiacynate, 1,2-diisothiocyanatoethane, 1,3-diisothiocyanatopropane, 1,4-diisothiocyanate, Thiocyanatobutane,

- Alicyclic isothiocyanate compounds and aromatic isothiocyanate compounds include p-phenylenediisopropylidene diisothiocyanate, 1,2-diisothiocyanatobenzene, 1,3-diisothiocyanatobenzene, 1,4-diisothiocyanate Benzene, 2,4-diisothiocyanatotoluene, isophorone diisothiocyanate, xylene diisothiocyanate (o-, m-, p-), 2,4-tolylene diisothiocyanate, 2,6-tolylene diisothiocyanate, cyclohexane diisothiocyanate and the like, and also 1,1′-methylenebis(4-isothiocyanatobenzene), 1,1′-methylenebis(4-isothiocyanate-2-methylbenzene), 1,1′-methylenebis(4- isothiocyanate 3-methylbenz

- Preferred alicyclic isothiocyanate compounds include 2,4-bis(isothiocyanatomethyl)norbornane, 2,5-bis(isothiocyanatomethyl)norbornane, and 2,6-bis(isothiocyanatomethyl)norbornane. , 3,5-bis(isothiocyanatomethyl)norbornane, norbornane diisothiocyanate, and the like.

- Preferred sulfur-containing heterocyclic isocyanate compounds include thiophene-2,5-diisothiocyanate, 1,4-dithiane-2,5-diisothiocyanate, 2,5-bis(isothiocyanatomethyl)-1,4- dithiane, 4,5-bis(isothiocyanatomethyl)-1,3-dithiolane and the like.

- Component (A) compound having an isocyanate group and an isothiocyanate group

- Compounds having both an isocyanate group and an isothiocyanate group as component (A) include the following compounds.

- at least one isocyanate group is an isothiocyanate group.

- at least one isothiocyanate group is a compound having an isocyanate group.

- a compound having an iso(thio)cyanate group blocked with a blocking agent is an alcohol, lactam, or , phenols, oximes, pyrazoles, thiols, active methylene compounds, malonic acid diester compounds, and acetoacetic ester compounds. can be done.

- the conditions for reacting the iso(thio)cyanate group with the blocking agent vary depending on the type of the blocking agent, and may be appropriately determined according to the selected blocking agent.

- the protection of the iso(thio)cyanate group by the blocking agent can be confirmed by Fourier transform infrared spectroscopy (FT-IR).

- the pot life of the photochromic composition can be extended.

- Preferred examples of component (A) above include pentamethylene diisocyanate, hexamethylene diisocyanate, heptamethylene diisocyanate, octamethylene diisocyanate, 1,3-bis(isocyanatomethyl)cyclohexane, 1,4-bis(isocyanatomethyl)cyclohexane, isophorone diisocyanate, norbornane diisocyanate, 2,5-bis(isocyanatomethyl)-bicyclo[2,2,1]-heptane, 2,6-bis(isocyanatomethyl)-bicyclo[2,2,1]-heptane, 1, 2-bis(2-isocyanato-ethylthio)ethane, xylene diisocyanate (o-, m-, p-), 2,4-tolylene diisocyanate, 2,6-tolylene diisocyanate, and 4,4'-diphenylmethane

- the active hydrogen-containing group in (B) the active hydrogen-containing component having an active hydrogen-containing group (component (B)) is a group containing active hydrogen. That is, the component (B) is an active hydrogen compound having a group containing active hydrogen.

- the active hydrogen-containing group mentioned above refers to a group capable of reacting with an isocyanate group, and includes, for example, a hydroxyl group, an amino group, a carboxyl group and/or a thiol group.

- the (B) component has a polyoxypropylene chain.

- component (B) preferably has an alkyl group having 5 to 20 carbon atoms and/or a polyoxyethylene chain in addition to the polyoxypropylene chain.

- the ratio (nA/nB) is preferably 1.00 or more and 1.50 or less, more preferably is 1.00 or more and 1.20 or less.

- nA/nB is 1.00 or more and 1.50 or less, a resin composition having a strength ratio (PMI pst /PMI cp ) of 8.0 or more and 40.0 or less can be easily produced.

- a resin composition having excellent photochromic properties and heat resistance can be obtained.

- nA/nB ratio When the nA/nB ratio is less than 1.00 or greater than 1.50, the degree of polymerization does not increase, resulting in low heat resistance.

- the mixing ratio of the component (A) and the component (B) is not particularly limited as long as the nA/nB ratio is 1.00 or more and 1.50 or less.

- the intensity ratio (PMI pst /PMI cp ) satisfies 8.0 or more and 40.0 or less, and considering the production of a resin composition excellent in photochromic properties and heat resistance, component (A),

- component (B) is preferably 50 to 70 parts by mass, more preferably 60 to 65 parts by mass.

- component (B) is (B1) polyfunctional active hydrogen-containing groups having 3 or more active hydrogen-containing groups in one molecule. It is desirable to include a component ((B1) component) and (B2) a first active hydrogen-containing component ((B2) component) having one or two active hydrogen-containing groups in one molecule.

- the (B1) component used in the photochromic curable composition is not particularly limited as long as it is a compound having 3 or more active hydrogen-containing groups in the molecule.

- a compound in which the total number of hydroxyl groups and thiol groups in the molecule is 3 or more is preferable.

- the number of hydroxyl groups and thiol groups is not particularly limited as long as it is 3 or more.

- (B1) component examples include aliphatic poly(thiol) compounds and aromatic poly(thiol) compounds. More specifically, the following compounds can be mentioned.

- Suitable poly(thio)ol compound examples include the following compounds. Specific examples include compounds represented by the following formulas (IX) to (XVII).

- Preferred aliphatic poly(thio)ol compounds include the following formula (IX)

- R 108 is a hydrogen atom, or the following formula (X)

- R 111 is an alkylene group having 1 to 6 carbon atoms.

- R 109 is each a hydrogen atom, a methyl group, or an ethyl group and may be the same or different

- R 110 is a hydrogen atom or an alkyl group having 1 to 6 carbon atoms, and when there are more than one, they may be the same or different

- o 100 is 0-2, p 100 is 1-6, q 100 is 0-10, r 100 is 2-4, and o 100 +r 100 is 4.

- ⁇ It is preferred to use a compound represented by

- R 111 is an alkylene group having 1 to 6 carbon atoms and may be a linear or branched group. Among them, R 111 is particularly preferably a methylene group, ethylene group, trimethylene group or propylene group.

- Specific examples of the compound represented by the formula (IX) include trimethylolpropane, pentaerythritol, trimethylolpropane tris(3-mercaptopropionate), pentaerythritol tetrakis(3-mercaptopropionate), and the like. mentioned.

- polyfunctional poly(thiol) compound having an ether bond is represented by the following formula (XI)

- F 100 is each an alkyl group of 1 to 6, or the following formula (XII)

- R 112 is a hydrogen atom or a group as defined in formula (X) above, and may be the same group or a different group;

- R 113 is each a hydrogen atom, a methyl group, or an ethyl group, and may be the same group or different groups, s 100 is 1-6 and t 100 is 0-10. ).

- ⁇ It is preferred to use a compound represented by

- At least two of the F 100 are groups represented by the formula (XII).

- Other groups include 1 to 6 alkyl groups, which may be chain or branched groups. Among them, F 100 is particularly preferably a methyl group, an ethyl group, a trimethyl group, or a propyl group.

- F 100 is particularly preferably a methyl group, an ethyl group, a trimethyl group, or a propyl group.

- two or more of F 100 are groups represented by the formula (XII), they may be the same group or different groups.

- Specific examples of the compound represented by the formula (XI) include ditrimethylolpropane, dipentaerythritol, ditrimethylolpropane tetrakis (3-mercaptopropionate), dipentaerythritol-ruhexakis (3-mercaptopropionate nate) and the like.

- polyfunctional polythiol compounds of the following formula (XIII) are preferred aliphatic poly(thiol) compounds.

- R 114 is a hydrogen atom, an alkyl group having 1 to 6 carbon atoms, or a group in which a part of the methylene group of the alkyl group having 1 to 6 carbon atoms is substituted with a sulfur atom, and when there are a plurality of R 114 may be the same group or different groups

- R 115 is an alkylene group having 1 to 10 carbon atoms, a group in which part of the methylene groups in the chain of the alkylene group having 1 to 10 carbon atoms is substituted with a sulfur atom, or the above 1 to 10 carbon atoms is a group in which a portion of the hydrogen atoms of the alkylene group of is substituted with a thiol group, and when there are a plurality of R 115 , they may be the same group or different groups, u 100 is an integer from 2 to 4, v 100 is an integer from 0 to 2, and u 100 +v 100 is 4. ) It is preferred to use a compound represented

- the alkyl group having 1 to 6 carbon atoms may be a linear or branched group, and R 114 is preferably a hydrogen atom, a methyl group, or an ethyl group.

- R 114 is preferably a hydrogen atom, a methyl group, or an ethyl group.

- Specific examples of groups in which a part of the methylene groups in the chain of an alkyl group having 1 to 6 carbon atoms are substituted with sulfur atoms include -CH 2 SCH 3 and the like.

- the alkylene group having 1 to 10 carbon atoms may be a linear or branched group.

- R 115 is particularly preferably a methylene group, an ethylene group, a trimethylene group or a propylene group.

- Specific groups in which part of the methylene groups in the chain of an alkylene group having 1 to 10 carbon atoms are substituted with sulfur atoms include -CH 2 S-, -CH 2 CH 2 S-, and -CH 2 CH 2 CH 2 S— and the like.

- groups such as —CH 2 SCH(SCH 2 SH)— are examples of the groups in which some of the hydrogen atoms of the alkyl group having 1 to 6 carbon atoms are substituted with thiol groups.

- Specific examples of the compound represented by the formula (XIII) include 4-mercaptomethyl-1,8-dimercapto-3,6-dithiaoctane, 1,1,1,1-tetrakis(mercaptomethyl)methane, 1 , 1,3,3-tetrakis(mercaptomethylthio)propane, 1,1,2,2-tetrakis(mercaptomethylthio)ethane, 4,7-bismercaptomethyl-3,6,9-trithio-1,11-undecane dithiol, 5,7-dimercaptomethyl-1,11-dimercapto-3,6,9-trithiundecane, 4,8-dimercaptomethyl-1,11-dimercapto-3,6,9-trithiundecane, etc. is mentioned.

- the phenyl group-containing polythiol compound is represented by the following formula (XIV)

- R 116 is an alkylene group having 1 to 6 carbon atoms, or a group in which a part of the methylene group in the chain of the alkylene group having 1 to 6 carbon atoms is substituted with a sulfur atom, and w 100 is 3; be.

- the alkylene group having 1 to 6 carbon atoms in R 116 may be a linear or branched group.

- R 116 is preferably a methylene group, ethylene group, trimethylene group or propylene group.

- the group in which a part of the methylene group in the chain of the alkylene group having 1 to 6 carbon atoms is substituted with a sulfur atom is specifically -CH 2 CH 2 CH 2 SCH 2 -, -CH 2 CH 2 SCH 2 -, -CH 2 SCH 2 - and the like.

- a specific example of the compound represented by the formula (XIV) is 1,3,5-tris(mercaptopropylthiomethyl)benzene.

- poly(thiol) compound having a triazine ring is represented by the following formula (XV)

- R 117 is each an alkyl group having 1 to 6 carbon atoms, or the following formula (XVI)

- R 118 and R 119 are an alkylene group having 1 to 6 carbon atoms, R 120 is an oxygen atom or a sulfur atom) wherein at least two of the R 117 are groups represented by the formula (XVI), and the R 117 may be the same group or different groups.

- R 118 and R 119 are an alkylene group having 1 to 6 carbon atoms, R 120 is an oxygen atom or a sulfur atom

- the alkylene group having 1 to 6 carbon atoms may be a linear or branched group.

- R 118 and R 119 are preferably methylene group, ethylene group, trimethylene group and propylene group.

- Specific examples of the compound represented by the formula (XV) include 2-mercaptomethanol and tris- ⁇ (3-mercaptopropionyloxy)-ethyl ⁇ -isocyanurate.

- a plurality of R 500 may be the same or different from each other, a hydrogen atom, an alkyl group, a cycloalkyl group, an alkoxy group, a phenyl group, and at least two hydroxyl groups in one molecule, and/or an organic group containing a thiol group, where n100 is an integer from 3 to 100 ).

- component (B1) can be used without any particular limitation, and can be used in combination in consideration of the photochromic properties and mechanical properties of the resulting photochromic cured product. Among them, in order to be able to produce a resin composition having excellent properties and to have a photochromic curable composition having excellent moldability and good handling properties, the component (B1) should contain 3 per molecule. It is preferred to use component (B1) having ⁇ 6 active hydrogen-containing groups.

- component (B1)a) the polyfunctional active hydrogen-containing component having 3 to 6 active hydrogen-containing groups in one molecule in component (B1) may be simply referred to as component (B1a).

- a component having 4 to 6 active hydrogen-containing groups per molecule is preferable, and a component having 6 active hydrogen-containing groups per molecule is most preferable.

- the active hydrogen-containing group is preferably a thiol group, considering the increase in viscosity when the photochromic curable composition is prepared.

- the component (B1) may consist only of the component (B1a), and may also contain a component having more than 6 active hydrogen-containing groups in one molecule, if necessary.

- this component is also simply referred to as the (B1b) component.

- the (B1a) component will be described.

- Examples of the (B1a) component which is a suitable component of the above (B1) component, include trimethylolpropane tris (3-mercaptopropionate), pentaerythritol tetrakis (3-mercaptopropionate), dipentaerythritol hexakis ( 3-mercaptopropionate), 4-mercaptomethyl-1,8-dimercapto-3,6-dithiaoctane, and tris- ⁇ (3-mercaptopropionyloxy)-ethyl ⁇ -isocyanurate, among which , trimethylolpropane tris (3-mercaptopropionate), pentaerythritol tetrakis (3-mercaptopropionate), and dipentaerythritol hexakis (3-mercaptopropionate).

- trimethylolpropane tris (3-mercaptopropionate

- pentaerythritol tetrakis (3

- dipentaerythritol hexakis (3-mercaptopropionate) is most preferable because it can improve the photochromic properties and mechanical properties of the resulting photochromic cured product (resin composition).

- other components (B1) may be mixed for viscosity adjustment.

- components (B1a) include trimethylolpropane tris(3-mercaptopropionate), pentaerythritol tetrakis(3-mercaptopropionate), 1,6-hexanediol bis(3-mercaptopropionate), 1, 2-bis[(2-mercaptoethyl)thio]-3-mercaptopropane, 2,2-bis(mercaptomethyl)-1,4-butanedithiol, 2,5-bis(mercaptomethyl)-1,4-dithiane , 4-mercaptomethyl-1,8-dimercapto-3,6-dithiaoctane, 1,1,1,1-tetrakis(mercaptomethyl)methane, 1,1,3,3-tetrakis(mercaptomethylthio)propane, 1, 1,2,2-tetrakis(mercaptomethylthio)ethane, 4,6-bis(mercaptomethylthio)-1,3-dithiane, tris

- component (B1) component In order that the strength ratio (PMI pst /PMI cp ) of component (i) satisfies 8.0 to 40.0 and the resin composition exhibits particularly excellent effects, ( B1) component. More specifically, it is preferable to use a component having more active hydrogen-containing groups in the molecule than the component (B1a). Among them, particularly preferred is a polyrotaxane component having a polyrotaxane structure and having 7 or more active hydrogen-containing groups in the molecule (hereinafter sometimes simply referred to as component (B1b)). .

- the photochromic curable composition preferably further contains a polyrotaxane component (component (B1b)) having more than 6 active hydrogen-containing groups in the molecule.

- component (B1b) the mobility of the polyrotaxane itself can enhance the photochromic properties of the resulting resin composition.

- incorporating an oxypropylene chain or the like into the polyrotaxane component facilitates adjustment of the strength ratio (PMI pst /PMI cp ) of component (i) to 8.0 to 40.0.

- the strength ratio (PMI pst /PMI cp ) can be easily increased by incorporating an oxypropylene chain into the polyrotaxane component.

- the resulting resin composition exhibits excellent photochromic properties.

- the (B1b) component is a known compound and has a composite molecular structure formed from a chain-like axial molecule and a cyclic molecule. That is, a chain-shaped axial molecule is enclosed by a plurality of cyclic molecules, and the axial molecule penetrates the inside of the ring possessed by the cyclic molecule. Therefore, the cyclic molecule can slide freely on the axial molecule, but bulky terminal groups are formed at both ends of the axial molecule to prevent the cyclic molecule from falling off from the axial molecule.

- the polyrotaxane component (B1b) component has a composite molecular structure formed from a chain-shaped axial molecule 20 and a cyclic molecule 30. As shown in FIG. More specifically, it has a structure in which a chain-shaped axial molecule 20 is enclosed by a plurality of cyclic molecules 30 , and the axial molecule 20 penetrates the inside of the ring of the cyclic molecule 30 .

- the cyclic molecule 30 can freely slide on the axial molecule 20, but bulky terminal groups 40 are formed at both ends of the axial molecule 20 to prevent the cyclic molecule 30 from falling off from the axial molecule 20. .

- the cyclic molecule 30 of the polyrotaxane 10 can slide on the axial molecule 20, so it is considered that the photochromic properties can be improved.

- the strength ratio (PMI pst /PMI cp ) in the resulting resin composition can be easily adjusted in the range of 8.0 to 40.0, and photochromic properties can be improved. can be improved.

- the polyrotaxane 10 shown in FIG. 3 also shows a side chain 50 introduced into the ring of the cyclic molecule 30 as necessary.

- (B1b) component is a known compound and can be synthesized by the method described in International Publication No. 2015/068798 and the like.

- the axial molecule is not particularly limited as long as it can penetrate the ring of the cyclic molecule, and may be linear or branched.

- This axial molecule is generally formed by a polymer. Suitable polymers forming the axial molecule include those exemplified in WO2015/068798, among which it is preferred to use polyethylene glycol.

- polyethylene glycol By using polyethylene glycol as the axial molecule, oxyethylene chains are introduced into the resulting resin composition, and the strength ratio (EI pst /EI cp ) can be easily adjusted to the range of 5.0 or more and 20.0 or less. can be adjusted to

- the bulky terminal groups formed at both ends of the axial molecule are not particularly limited as long as they are groups that prevent the cyclic molecule from detaching from the axial molecule.

- an adamantyl group is preferable.

- the weight average molecular weight (Mw) of the axial molecule is not particularly limited, but is preferably in the range of 1,000 to 100,000, more preferably in the range of 5,000 to 80,000, and even more preferably in the range of 10,000 to 50,000.

- the weight average molecular weight (Mw) of the axial molecule is 1000 or more, the mobility of the cyclic molecule tends to be improved.

- the mass average molecular weight (Mw) of the axial molecule is 100,000 or less, compatibility with other components tends to be improved.

- the strength ratio (EI pst /EI cp ) of the resulting resin composition can be easily adjusted to 5.0 or more and 20.0 or less. As a result, photochromic properties can be improved.

- the cyclic molecule has a ring that is large enough to enclose the axial molecule.

- Such rings include, for example, cyclodextrin rings.

- the cyclodextrin ring has ⁇ form (ring inner diameter: 0.45 to 0.6 nm), ⁇ form (ring inner diameter: 0.6 to 0.8 nm), and ⁇ form (ring inner diameter: 0.8 to 0.95 nm). ), with the ⁇ -cyclodextrin ring being preferred.

- one axial molecule encloses one or more cyclic molecules.

- the clathrate number of cyclic molecules is generally in the range of 0.001 to 0.6, and 0.002 to 0, when the maximum clathrate number of cyclic molecules that can be clathrated by one axial molecule is 1.0.

- a range of 0.5 is preferred, and a range of 0.003 to 0.4 is more preferred.

- the maximum number of inclusions of cyclic molecules with respect to one axial molecule can be calculated from the length of the axial molecule and the thickness of the ring of the cyclic molecule.

- the maximum inclusion number is calculated as follows. That is, two repeating units [--CH.sub.2-- CH.sub.2 O--] of polyethylene glycol are approximated to the thickness of one ⁇ -cyclodextrin ring.

- the number of repeating units is calculated from the molecular weight of this polyethylene glycol, and 1/2 of this number of repeating units is obtained as the maximum inclusion number of the cyclic molecule. Assuming that this maximum inclusion number is 1.0, the inclusion number of the cyclic molecule is adjusted within the range described above.

- a side chain may be introduced into the cyclic molecule.

- side chains When side chains are introduced in this way, a pseudo-crosslinked structure can be formed in the resulting resin composition (component (i)). Thereby, the mechanical properties of the resin composition can be improved, and the photochromic properties can be improved.

- the side chain is preferably formed of repeating units of organic groups having 3 to 20 carbon atoms.

- the weight average molecular weight (Mw) of the side chain is not particularly limited, but is preferably in the range of 200 to 10,000, more preferably in the range of 250 to 8,000, further preferably in the range of 300 to 5,000, and more preferably in the range of 300 to 1,500. Ranges are particularly preferred.

- the side chain can be introduced by utilizing the functional group (eg, hydroxyl group) of the ring of the cyclic molecule and modifying this functional group.

- the ⁇ -cyclodextrin ring has 18 hydroxyl groups as functional groups, through which side chains can be introduced. That is, up to 18 side chains can be introduced to one ⁇ -cyclodextrin ring.

- the degree of modification is 50%.

- the side chain may be linear or branched.

- the side chain reacts an appropriate compound to the ring possessed by the cyclic molecule using ring-opening polymerization; radical polymerization; cationic polymerization; anionic polymerization; living radical polymerization such as atom transfer radical polymerization, RAFT polymerization, NMP polymerization;

- a side chain of an appropriate size can be introduced by allowing the As the cyclic compound, cyclic lactones and cyclic carbonates are preferred, and ⁇ -caprolactone is more preferred.

- Propylene oxide incorporated into this side chain can be considered an oxypropylene chain. Therefore, particularly when propylene oxide is used to introduce highly reactive hydroxyl groups, the intensity ratio (PMI pst /PMI cp ) can be easily adjusted to 8.0 to 40.0.