WO2022030393A1 - 抗菌性を有する水解性トイレットペーパー及びトイレットロール - Google Patents

抗菌性を有する水解性トイレットペーパー及びトイレットロール Download PDFInfo

- Publication number

- WO2022030393A1 WO2022030393A1 PCT/JP2021/028383 JP2021028383W WO2022030393A1 WO 2022030393 A1 WO2022030393 A1 WO 2022030393A1 JP 2021028383 W JP2021028383 W JP 2021028383W WO 2022030393 A1 WO2022030393 A1 WO 2022030393A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- adhesive

- toilet paper

- sheet

- polyvinyl alcohol

- roll

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47K—SANITARY EQUIPMENT NOT OTHERWISE PROVIDED FOR; TOILET ACCESSORIES

- A47K10/00—Body-drying implements; Toilet paper; Holders therefor

- A47K10/16—Paper towels; Toilet paper; Holders therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B29/00—Layered products comprising a layer of paper or cardboard

- B32B29/002—Layered products comprising a layer of paper or cardboard as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B29/005—Layered products comprising a layer of paper or cardboard as the main or only constituent of a layer, which is next to another layer of the same or of a different material next to another layer of paper or cardboard layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/28—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by a layer comprising a deformed thin sheet, i.e. the layer having its entire thickness deformed out of the plane, e.g. corrugated, crumpled

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/04—Interconnection of layers

- B32B7/12—Interconnection of layers using interposed adhesives or interposed materials with bonding properties

- B32B7/14—Interconnection of layers using interposed adhesives or interposed materials with bonding properties applied in spaced arrangements, e.g. in stripes

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H21/00—Non-fibrous material added to the pulp, characterised by its function, form or properties; Paper-impregnating or coating material, characterised by its function, form or properties

- D21H21/14—Non-fibrous material added to the pulp, characterised by its function, form or properties; Paper-impregnating or coating material, characterised by its function, form or properties characterised by function or properties in or on the paper

- D21H21/36—Biocidal agents, e.g. fungicidal, bactericidal, insecticidal agents

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H27/00—Special paper not otherwise provided for, e.g. made by multi-step processes

- D21H27/002—Tissue paper; Absorbent paper

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H27/00—Special paper not otherwise provided for, e.g. made by multi-step processes

- D21H27/002—Tissue paper; Absorbent paper

- D21H27/004—Tissue paper; Absorbent paper characterised by specific parameters

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H27/00—Special paper not otherwise provided for, e.g. made by multi-step processes

- D21H27/30—Multi-ply

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H27/00—Special paper not otherwise provided for, e.g. made by multi-step processes

- D21H27/30—Multi-ply

- D21H27/32—Multi-ply with materials applied between the sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/26—All layers being made of paper or paperboard

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/714—Inert, i.e. inert to chemical degradation, corrosion

- B32B2307/7145—Rot proof, resistant to bacteria, mildew, mould, fungi

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/716—Degradable

- B32B2307/7166—Water-soluble, water-dispersible

Definitions

- the present invention relates to hydrolyzable toilet paper and toilet roll having antibacterial properties.

- Sheet products such as kitchen paper and toilet paper may be adhered by embossing, etc., but they are glued using carboxymethyl cellulose (CMC) or polyvinyl alcohol (PVA) as an adhesive on the embossed protrusions.

- CMC carboxymethyl cellulose

- PVA polyvinyl alcohol

- a main object of the present invention is to provide toilet paper and toilet roll, which exert an antibacterial effect at the time of use, are soft and sufficiently hydrolyzable.

- the absorbent articles that have solved the above problems are as follows. Consists of 3 or 4 sheet layers

- the basis weight of each sheet is 10.0 to 18.0 g / m 2 .

- the paper thickness of each sheet is 60 to 170 ⁇ m.

- At least one adjacent sheet is bonded with an adhesive at a number of junctions and

- the adhesive is polyvinyl alcohol, and benzalkonium chloride is contained in the adhesive.

- Toilet paper featuring that.

- a water-decomposable toilet paper which exhibits antibacterial properties when used and is composed of a plurality of sheet layers.

- the toilet paper adhered with the water-soluble adhesive containing the antibacterial agent according to the present invention will be described in detail with reference to the attached drawings.

- 2 and 4 show, but are not limited to, 4-ply toilet paper, and the present invention is also applicable to 3-ply and 2-ply toilet paper.

- 3-ply or 4-ply toilet paper toilet roll

- This toilet paper is made by laminating two or more sheets (plies), and one adjacent sheet is bonded with an adhesive at a large number of joint points.

- the basis weight of each sheet obtained by dividing the basis weight of the product by the number of plies is 10.0 to 18.0 g / m 2 , especially 12.0 to 16.0 g / m 2 , and the paper thickness of the product divided by the number of plies.

- the paper thickness of the sheet is preferably 60 to 170 ⁇ m, particularly preferably 80 to 140 ⁇ m. If the basis weight and the paper thickness are excessively low, the paper is likely to break due to contact with moisture, and if the basis weight and the paper thickness are excessively high, the cost is high and the flexibility is impaired.

- the basis weight here is based on the rice tsubo measuring method of JIS P 8124 (1998), and the paper thickness is the condition of sufficient humidity control under the conditions of JIS P 8111 (1998) and then under the same conditions.

- Dial thickness gauge thickness measuring device Refers to the average value measured 5 times using "PEACOCK H type" (manufactured by Ozaki Seisakusho). In addition, the paper density and paper thickness are measured with multiple plies.

- the adhesive is Bonded with an adhesive at a number of junctions, preferably between at least one adjacent sheet, preferably only between one adjacent sheet, the adhesive being polyvinyl alcohol and the adhesive. It contains benzalkonium chloride.

- Polyvinyl alcohol is a water-soluble adhesive.

- This adhesive contains benzalkonium chloride as an antibacterial agent.

- Moisture in body fluids (or warm water for hot water toilet seats) from water and excrement during use permeates the inside of the sheet and comes into contact with a water-soluble adhesive containing an antibacterial agent, and part of the water-soluble adhesive dissolves out.

- the antibacterial agent in the adhesive By contacting with the antibacterial agent in the adhesive, the antibacterial effect can be exerted and the bacteria can be prevented from being transferred to the hand.

- CMC carboxymethyl cellulose

- benzalkonium chloride which is safe and has a high antibacterial effect as an antibacterial agent

- CMC tends to aggregate and lose the adhesiveness, and when this adhesive is to be transferred to a sheet by a transfer coating method, It has been found that the decrease in viscosity causes a decrease in the transfer amount or a situation in which pick-up cannot be performed, which hinders the operation of laminating.

- the area occupied by the embossed EL related to gluing is preferably 2.5 to 30%, particularly 5 to 15% per 1 m 2 . If the area ratio is small, it may appear as a design, and if it is excessively large, it will be an excessive design, which is not desirable as a product design. Moreover, if the area occupied by the embossing is large, the amount of the adhesive used increases and the hardness due to polyvinyl alcohol (PVA) becomes apparent.

- PVA polyvinyl alcohol

- the toilet paper of the embodiment exhibits sufficient water solubility.

- it is desirable that the hydrolyzability based on JIS P 4501 is within 80 seconds after hot air drying for 10 minutes in a dryer in an absolutely dry state at 105 ° C. This is also because the amount of the adhesive used per unit area is not large and the bonding point (area ratio) by the adhesive is small.

- a 50% benzalkonium chloride solution (as is) as an antibacterial agent is 1.2 to 17 with respect to a 7-fold diluted 25% polyvinyl alcohol (7-fold dilution, substantially 3.6%). It is desirable to contain 8.8% by mass, particularly 3.6 to 14.4% by mass.

- the amount of benzalkonium chloride is small, the amount of polyvinyl alcohol eluted by contact with water is limited, and as a result, the antibacterial effect of benzalkonium chloride is difficult to develop.

- the amount of benzalkonium chloride is large, the viscosity of the adhesive containing benzalkonium chloride is lowered, and the adhesiveness is lowered.

- the polyvinyl alcohol adhesive exhibits sufficient adhesiveness and is suitable for laminating operations, for example, with a viscosity of 8.0 to 14.8 (mPa ⁇ s), preferably a viscosity of 8.8 to 8.8. It can be 11.8 (mPa ⁇ s).

- the polyvinyl alcohol (PVA) adhesive does not lose its adhesiveness even when benzalkonium chloride is blended, and its viscosity does not change significantly. Therefore, stable operation is possible. It is thought that this is because the negatively charged -OH (hydroxyl group) of polyvinyl alcohol is less than the -OH group of carboxymethyl cellulose, it is harder to aggregate than benzalkonium chloride, and it does not reduce the adhesiveness or viscosity. Be done.

- the amount of benzalkonium chloride added is 0.01 to 0.1% by mass with respect to the unit mass of toilet paper. It is a desirable amount to exert an antibacterial effect while maintaining safety to the human body, maintain viscosity, and exhibit adhesiveness.

- the amount of the laminated adhesive (polyvinyl alcohol) applied to the laminated ply toilet paper is preferably 0.02 to 0.10% (solid content equivalent), particularly 0.04 to 0.06% by mass (solid content equivalent). If the amount applied is small, not only the ply separation is likely to occur, but also the antibacterial effect may not be sufficient. If the amount applied is large, the flexibility of the obtained sheet is impaired.

- a quaternary ammonium salt such as benzalkonium chloride salt and benzethonium chloride

- other antibacterial cationic surfactants such as pyridinium salt, imidazolinium salt and isoquinolinium salt

- the method for measuring the cold water extraction pH value of toilet paper can be measured by the JIS P 8133-1998 7.2 cold water extraction method.

- a pH of 6.0 or more and 8.0 or less by the cold water extraction method is an appropriate pH range and is suitable.

- the pH of the adhesive is 6.0 to 7.0, the adhesiveness and the adhesive function of the adhesive containing benzalkonium chloride are properly maintained.

- the cold water extraction pH was 6.0 to 8.0, and the multi-layer laminate maintained the antibacterial effect and the adhesive function of the adhesive in a well-balanced manner. Toilet paper is possible.

- the innermost sheet is micro-embossed and should be adhered to the embossing of the adjacent sheet.

- the amount of the adhesive applied is preferably 0.02 to 0.10% (solid content equivalent), particularly 0.04 to 0.06 mass% (solid content equivalent) with respect to the product weight.

- the area ratio of the convex portion of all embossing is 15.0 to 25.0%. It is desirable that the area ratio of the large (deep) embossed portion to which the adhesive (polyvinyl alcohol) is applied is 10.0 to 15.0% among the embossed convex portions. It is desirable that the area ratio of micro-embossing is 5.0 to 10.0%. Embossing enhances the design and gives the product toilet paper flexibility. In addition, as a result of the formation of the space between the plies by embossing, the hydrolyzability is also affected.

- Embossing is applied to a wide range of paper surfaces to improve design, bulkiness, softness, and surface smoothness, and is a technology different from embossing in ply crimping such as contact embossing.

- the bottom area of one recess is 0.3 to 5.0 mm 2

- the embossing area ratio is 5.0 to 15%

- the embossing density is 3 to 25 pieces / cm 2 .

- the embossing density is a value obtained by counting the number of embossing in the range of 10 cm ⁇ 10 cm and converting it per 1 cm ⁇ 1 cm. The average value of 5 locations in the range of 10 cm ⁇ 10 cm is used.

- the embossed area ratio is measured in the range of 10 cm ⁇ 10 cm. Then, the ratio of the total embossed area obtained by multiplying the number of recesses in the range by the bottom area of the recesses is defined as the embossed area ratio. Similar to the embossing density, the average value is set at 5 points in the range of 10 cm ⁇ 10 cm.

- the bottom area of the recess is measured by a one-shot 3D measurement macroscope VR-3200 manufactured by Keyence Co., Ltd.

- the bottom area of the recess is the average value of five recesses having the same shape in design.

- the depth of the recess is measured by a one-shot 3D measurement macroscope VR-3200 manufactured by KEYENCE CORPORATION or its equivalent, and image analysis software "VR-H2A" or its equivalent software. The measurement is performed under the conditions of a magnification of 12 times and a visual field area of 24 mm ⁇ 18 mm. However, the magnification and the viewing area can be appropriately changed depending on the size of the recess.

- the embossing depth (measurement cross-sectional curve) profile at the line segment crossing the longest part of the peripheral edge of one embossing in the image portion shown from the plane viewpoint is obtained by using the above software or the like.

- ⁇ c 800 ⁇ m (where ⁇ c is shorter than the “filter that defines the boundary between the roughness component and the waviness component” described in JIS-B0601 “3.1.1.2”).

- the contour curves of the image portion shown from the cross-sectional viewpoint obtained by removing the surface roughness component of the wavelength with a low-frequency filter, the two concave edge points that are convex upward and have the strongest bend, and the concave edge points.

- the minimum value to be sandwiched is obtained, and the minimum value of the depth is Min.

- the average value of the depth values of the concave edge points is defined as the maximum depth value Max.

- the embossing depth maximum value Max-minimum value Min.

- the distance (length) of the concave edge points on the plane is defined as the length of the longest portion. The two concave edge points that are convex above and have the strongest bend are visually selected. In making the selection, the contour in the image of the plane viewpoint of the concave portion during the measurement may be referred to.

- the depth of the emboss is measured for the shortest part in the direction perpendicular to the longest part, and the larger value is adopted as the depth of the emboss (recess).

- the above measurement is performed for any 10 embosses on the surface, and the average value is taken as the depth of the recess.

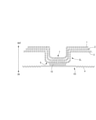

- FIG. 2 shows the structure of 4-ply toilet paper.

- the outside of the toilet roll is shown as OUT, and the inside of the toilet roll is shown as IN.

- the three plies 1, 2, and 3 from the outer OUT are integrally subjected to large (deep) embossing, and a concave portion 7 is formed on the outer OUT and a convex portion 8 is formed on the inner IN.

- the inside of the third ply 3 from the outer OUT and the ply 4 of the inner IN are joined by an adhesive 10.

- the adhesive 10 is polyvinyl alcohol, and benzalkonium chloride is contained in the adhesive 10.

- two embossed EL and ES are formed. That is, a large (deep) embossed EL is applied to the plies 1, 2 and 3, and the layers are laminated to suppress peeling between the plies, and a small (micro) embossed ES is applied to the ply 4 to ply. 3 and the ply 4 are joined by the adhesive 10 and integrated.

- the plies 1, 2, and 3 can be joined with an adhesive at a joining point, but it is desirable to join with an adhesive between one ply.

- the plies 1, 2, and 3 are embossed ES to prevent the plies from coming off. If necessary, contact embossing can be applied to both side portions of plies 1, 2, 3 or, preferably including ply 4, to prevent ply separation.

- the adhesive 10 may be colored by blending ink or the like. Assuming that the adhesive 10 is colored, the adhesive portion (joint portion) formed by embossing is colored, and for example, the pattern of FIG. 1 appears, which can be visually recognized and the design is improved.

- Benzalkonium chloride is a cationic surfactant and has the advantages of being odorless, highly water-soluble, and mild, as well as having a strong antibacterial action. Therefore, it is not limited to benzalkonium chloride, and antibacterial cationic surfactants such as benzethonium chloride, which is the same quaternary ammonium salt, pyridinium salt, imidazolinium salt, and isoquinolinium salt are used. can do.

- the fiber raw material of the base paper is not particularly limited, but an appropriate raw material pulp used for toilet paper can be selected and used.

- NBKP coniferous kraft pulp

- LBKP hardwood kraft pulp

- the above-mentioned dry paper strength enhancer, softener, and transient wet strength enhancer can be appropriately added.

- 3 and 4 show an example of 4-ply toilet paper.

- the 4-ply continuous sheet sent from the four raw rolls 12 is divided into a 3-ply sheet layer 3P and a 1-ply sheet 1P, and enters the laminating embossing facility 13.

- the 3-ply sheet layer 3P is embossed 7 or 8 by embossing between the rubber roll 17 and the emboss roll 18.

- the adhesive 10 containing the antibacterial agent supplied from the anilox roll 15 and applied to the entire surface of the plate 16 is applied to the tip of the convex portion 8 formed on the 3-ply sheet layer 3P and sent to the marriage roll 21. Be done.

- the 1-ply sheet 1P is micro-embossed 4 between the rubber roll 19 and the embossing roll 20 and sent to the marriage roll 21. Then, on the marriage roll 21, the 1-ply sheet 4 is laminated and adhered by the adhesive containing an antibacterial agent applied to the 3-ply sheet layer 3, and becomes 4-ply.

- the 4-ply toilet paper 4P is wound up by the rewinder 14. In the case of 3 plies, it can be manufactured by the same manufacturing method only by combining 2 plies and 1 ply.

- the first example is about toilet paper composed of a plurality of sheet layers, which are bonded with a water-soluble adhesive containing an antibacterial agent at a large number of points between one sheet.

- the basis weight of 4 plies is 14.6 g / m 2

- the paper thickness is 395 ⁇ m.

- Polyvinyl alcohol was used as the adhesive, benzalkonium chloride was added, and a colorant was also added.

- Polyvinyl alcohol containing benzalkonium chloride is controlled at pH 5.0 to 8.0, diluted at a dilution ratio of 1: 6 when the adhesive is applied, and the pH is adjusted to weak acidity of 5.0 to 6.0. ,used.

- polyvinyl alcohol maintained its adhesiveness and had a viscosity of 10.3 mPa ⁇ s suitable for the laminating operation.

- the pH once adjusted does not change significantly over time, and the adhesive having a pH of 7.0 or less has a viscosity and can be stably applied to the toilet paper sheet in the form of FIGS. 3 and 4. did it.

- the pH change with time is shown when the compounding ratio of 0) is changed. Theoretically, if the pH is 7.0 or less, the viscosity is considered to be high. Therefore, if the antibacterial agent of benzalkonium chloride having a pH of 9.0 is 0.20% or more, the viscosity decreases and it is not suitable for application. I understood.

- Table 3 shows the results of measuring the softness and the like of toilet paper by TSA (“emtec TSA” sold by Nihon Rufuto Co., Ltd.).

- HF Feeling parameter. The higher the number, the better the feel.

- TS7 Softness parameter. The lower the number, the softer it is.

- TS750 Smoothness parameter. The lower the number, the smoother.

- D Rigidity parameter. The lower the number, the harder it is. No difference in paper quality was observed between the case where carboxymethyl cellulose (CMC) was used as the adhesive and the case where polyvinyl alcohol (PVA) was used. Polyvinyl alcohol also maintains the same feel and feel as when carboxymethyl cellulose is used.

- CMC carboxymethyl cellulose

- PVA polyvinyl alcohol

- Table 4 shows the results of measuring the time required for the toilet paper to dissolve in water.

- polyvinyl alcohol was used for 4-ply toilet paper, it took faster to dissolve in water than 3-ply and 4-ply toilet paper using carboxymethyl cellulose as an adhesive.

- Polyvinyl alcohol was slightly better in water solubility.

- a colony growth of 50 or more is suppressed to have an antibacterial effect

- a colony growth of 90 or more is suppressed to have a strong antibacterial effect.

- the sample paper piece using polyvinyl alcohol antibacterialized 50 or more colonies of Escherichia coli and Staphylococcus aureus when benzalkonium chloride was contained in an amount of 0.05% based on the mass of the sample paper piece. Even when benzalkonium chloride was contained at 0.08, 0.10% based on the mass of the sample paper piece, 50 or more colonies of Escherichia coli, Staphylococcus aureus and White Candida were antibacterial, so that an antibacterial effect was observed. .. Among them, in Example 3 in which benzalkonium chloride was contained in an amount of 0.10% based on the mass of the sample paper piece, a strong antibacterial effect against Escherichia coli was observed.

- the present invention can impart antibacterial properties to 3-ply or 4-ply toilet paper or toilet rolls.

Landscapes

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Life Sciences & Earth Sciences (AREA)

- Pest Control & Pesticides (AREA)

- Sanitary Thin Papers (AREA)

- Paper (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202180005334.6A CN114401655A (zh) | 2020-08-07 | 2021-07-30 | 具有抗菌性的水解性卫生纸和卷筒卫生纸 |

| US17/763,376 US20220354315A1 (en) | 2020-08-07 | 2021-07-30 | Antibacterial and water-disintegrable toilet paper and toilet roll |

| EP21853063.2A EP4018896A4 (en) | 2020-08-07 | 2021-07-30 | WATER DISINTEGRATED TOILET PAPER WITH ANTIBACTERIAL PROPERTIES AND TOILET PAPER ROLL |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020-135371 | 2020-08-07 | ||

| JP2020135371A JP7287925B2 (ja) | 2020-08-07 | 2020-08-07 | 抗菌性を有する水解性トイレットロール |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2022030393A1 true WO2022030393A1 (ja) | 2022-02-10 |

Family

ID=80118722

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2021/028383 Ceased WO2022030393A1 (ja) | 2020-08-07 | 2021-07-30 | 抗菌性を有する水解性トイレットペーパー及びトイレットロール |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20220354315A1 (enExample) |

| EP (1) | EP4018896A4 (enExample) |

| JP (1) | JP7287925B2 (enExample) |

| CN (1) | CN114401655A (enExample) |

| WO (1) | WO2022030393A1 (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7276933B1 (ja) | 2022-04-28 | 2023-05-18 | コアレックス信栄株式会社 | トイレットペーパーロールの製造方法 |

| JP7276932B1 (ja) | 2022-04-28 | 2023-05-18 | コアレックス信栄株式会社 | トイレットペーパーロールの製造方法 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06346029A (ja) * | 1993-06-11 | 1994-12-20 | Nitto Denko Corp | 抗微生物性粘着シート |

| JP2007061445A (ja) * | 2005-08-31 | 2007-03-15 | Daio Paper Corp | シート製品およびその製造方法 |

| JP2012213508A (ja) * | 2011-03-31 | 2012-11-08 | Daio Paper Corp | トイレットペーパー |

| JP2013046679A (ja) * | 2011-08-29 | 2013-03-07 | Daio Paper Corp | トイレの洗浄及び防汚機能を有するトイレットペーパー製品 |

| JP2015167736A (ja) * | 2014-03-07 | 2015-09-28 | 王子ホールディングス株式会社 | トイレットロールおよびその製造方法 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| MX337891B (es) * | 2010-01-18 | 2016-03-28 | Cascades Canada Ulc | Papel tisu antimicrobiano y proceos para elaborar el mismo. |

| KR102498651B1 (ko) * | 2015-03-31 | 2023-02-09 | 다이오세이시가부시끼가이샤 | 가정용 박엽지 및 수해성 시트 |

| JP6641150B2 (ja) * | 2015-10-09 | 2020-02-05 | 大王製紙株式会社 | 水解性シート及びその製造方法 |

-

2020

- 2020-08-07 JP JP2020135371A patent/JP7287925B2/ja active Active

-

2021

- 2021-07-30 WO PCT/JP2021/028383 patent/WO2022030393A1/ja not_active Ceased

- 2021-07-30 US US17/763,376 patent/US20220354315A1/en not_active Abandoned

- 2021-07-30 CN CN202180005334.6A patent/CN114401655A/zh active Pending

- 2021-07-30 EP EP21853063.2A patent/EP4018896A4/en active Pending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06346029A (ja) * | 1993-06-11 | 1994-12-20 | Nitto Denko Corp | 抗微生物性粘着シート |

| JP2007061445A (ja) * | 2005-08-31 | 2007-03-15 | Daio Paper Corp | シート製品およびその製造方法 |

| JP4420872B2 (ja) | 2005-08-31 | 2010-02-24 | 大王製紙株式会社 | シート製品 |

| JP2012213508A (ja) * | 2011-03-31 | 2012-11-08 | Daio Paper Corp | トイレットペーパー |

| JP2013046679A (ja) * | 2011-08-29 | 2013-03-07 | Daio Paper Corp | トイレの洗浄及び防汚機能を有するトイレットペーパー製品 |

| JP2015167736A (ja) * | 2014-03-07 | 2015-09-28 | 王子ホールディングス株式会社 | トイレットロールおよびその製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2022031007A (ja) | 2022-02-18 |

| CN114401655A (zh) | 2022-04-26 |

| EP4018896A4 (en) | 2023-08-16 |

| JP7287925B2 (ja) | 2023-06-06 |

| US20220354315A1 (en) | 2022-11-10 |

| EP4018896A1 (en) | 2022-06-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8506756B2 (en) | Embossed sheet comprising a ply of water-soluble material and method for manufacturing such a sheet | |

| JP6034004B2 (ja) | トイレットペーパー | |

| JP5395101B2 (ja) | トイレットペーパーの製造方法 | |

| JP5931390B2 (ja) | トイレットロールの製造方法 | |

| US11000162B2 (en) | Multi-ply fibrous product comprising a laminating adhesive with a dermatologically acceptable acid | |

| JP5497310B2 (ja) | 水解性衛生薄葉紙及びトイレットペーパーロール | |

| EP1096069A2 (en) | Multi-ply absorbent paper product having impressed pattern | |

| JP2010202986A5 (enExample) | ||

| WO2022030393A1 (ja) | 抗菌性を有する水解性トイレットペーパー及びトイレットロール | |

| JP4420872B2 (ja) | シート製品 | |

| JP2022031007A5 (enExample) | ||

| JP2007075510A (ja) | 水解性衛生薄葉紙及びその製造方法 | |

| JP2019010366A (ja) | シャワートイレ用トイレットロール | |

| JP2006320688A (ja) | 洗浄便座用トイレットロール | |

| WO2023053496A1 (ja) | トイレットロール | |

| WO2017002416A1 (ja) | 家庭用薄葉紙及び家庭用薄葉紙積層体 | |

| JP2007068577A (ja) | 衛生薄葉紙 | |

| JP2013209778A5 (enExample) | ||

| JP2013209778A (ja) | キッチンペーパー及びその製造方法 | |

| JP5496590B2 (ja) | 衛生用薄葉紙及び衛生用薄葉紙の製造方法 | |

| CA2835873C (en) | Multi-ply absorbent paper product having impressed pattern | |

| JP6846104B2 (ja) | トイレットペーパー | |

| WO2023053494A1 (ja) | トイレットロール | |

| WO2023053495A1 (ja) | トイレットロール | |

| JP2025053853A (ja) | トイレットロール |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 21853063 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2021853063 Country of ref document: EP Effective date: 20220324 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |