WO2020110768A1 - 磁気記録媒体とその製造方法 - Google Patents

磁気記録媒体とその製造方法 Download PDFInfo

- Publication number

- WO2020110768A1 WO2020110768A1 PCT/JP2019/044806 JP2019044806W WO2020110768A1 WO 2020110768 A1 WO2020110768 A1 WO 2020110768A1 JP 2019044806 W JP2019044806 W JP 2019044806W WO 2020110768 A1 WO2020110768 A1 WO 2020110768A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- magnetic

- layer

- recording medium

- particles

- medium according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G11—INFORMATION STORAGE

- G11B—INFORMATION STORAGE BASED ON RELATIVE MOVEMENT BETWEEN RECORD CARRIER AND TRANSDUCER

- G11B5/00—Recording by magnetisation or demagnetisation of a record carrier; Reproducing by magnetic means; Record carriers therefor

- G11B5/62—Record carriers characterised by the selection of the material

- G11B5/68—Record carriers characterised by the selection of the material comprising one or more layers of magnetisable material homogeneously mixed with a bonding agent

- G11B5/70—Record carriers characterised by the selection of the material comprising one or more layers of magnetisable material homogeneously mixed with a bonding agent on a base layer

- G11B5/706—Record carriers characterised by the selection of the material comprising one or more layers of magnetisable material homogeneously mixed with a bonding agent on a base layer characterised by the composition of the magnetic material

-

- G—PHYSICS

- G11—INFORMATION STORAGE

- G11B—INFORMATION STORAGE BASED ON RELATIVE MOVEMENT BETWEEN RECORD CARRIER AND TRANSDUCER

- G11B5/00—Recording by magnetisation or demagnetisation of a record carrier; Reproducing by magnetic means; Record carriers therefor

- G11B5/62—Record carriers characterised by the selection of the material

- G11B5/68—Record carriers characterised by the selection of the material comprising one or more layers of magnetisable material homogeneously mixed with a bonding agent

- G11B5/70—Record carriers characterised by the selection of the material comprising one or more layers of magnetisable material homogeneously mixed with a bonding agent on a base layer

- G11B5/712—Record carriers characterised by the selection of the material comprising one or more layers of magnetisable material homogeneously mixed with a bonding agent on a base layer characterised by the surface treatment or coating of magnetic particles

-

- G—PHYSICS

- G11—INFORMATION STORAGE

- G11B—INFORMATION STORAGE BASED ON RELATIVE MOVEMENT BETWEEN RECORD CARRIER AND TRANSDUCER

- G11B5/00—Recording by magnetisation or demagnetisation of a record carrier; Reproducing by magnetic means; Record carriers therefor

- G11B5/62—Record carriers characterised by the selection of the material

- G11B5/73—Base layers, i.e. all non-magnetic layers lying under a lowermost magnetic recording layer, e.g. including any non-magnetic layer in between a first magnetic recording layer and either an underlying substrate or a soft magnetic underlayer

-

- G—PHYSICS

- G11—INFORMATION STORAGE

- G11B—INFORMATION STORAGE BASED ON RELATIVE MOVEMENT BETWEEN RECORD CARRIER AND TRANSDUCER

- G11B5/00—Recording by magnetisation or demagnetisation of a record carrier; Reproducing by magnetic means; Record carriers therefor

- G11B5/84—Processes or apparatus specially adapted for manufacturing record carriers

- G11B5/852—Orientation in a magnetic field

Definitions

- the present invention relates to a magnetic recording medium.

- a magnetic recording medium having a composite magnetic body in which at least one of a hard magnetic body and a soft magnetic body is dispersed in the other, in a recording layer.

- a magnetic recording medium As a magnetic recording medium, a magnetic film and a magnetic disk in which a recording layer containing a magnetic material is laminated on a sheet-shaped resin base material are known. By moving relative to the magnetic head, such a recording medium can be formed in the recording layer as a magnetic domain corresponding to time-series data and can be reproduced. Therefore, there is a demand for a technique for increasing recording density by arranging finely divided magnetic particles in the recording layer with high density.

- Japanese Unexamined Patent Publication No. 2016-130208 discloses a magnetic recording medium provided with a recording layer in which iron-based magnetic particles containing ⁇ -Fe2O3 having an average particle diameter of 10-30 nm are arranged.

- JP-A-2016-130208 a vehicle in which iron-based magnetic particles are coated with a resin binder such as urethane is applied to a base film to form a magnetic recording film, and magnetic field orientation is performed by an external magnetic field immediately after application. , are disclosed.

- Magnetic recording media are required to have electromagnetic conversion characteristics having high coercive force Hc and high residual magnetic flux density (residual magnetization) Br.

- the high coercive force Hc brings about an effect that the magnetization is not easily inverted due to the influence of the adjacent magnetic domains even if the high coercive force is mounted.

- the high magnetization Br makes it possible to increase the SN ratio when the magnetic head performs magnetoelectric conversion even when the magnetic domain becomes small.

- the recording layer described in Japanese Unexamined Patent Application Publication No. 2016-130208 has a form in which the functional component that contributes to magnetic recording includes only iron-based magnetic particles.

- the coercive force Hc includes a case where Oe is used as a unit

- the residual magnetic flux density Br includes a case where it is paraphrased as a magnetization Br when emu/g is used as a unit.

- An object of the present invention is to provide a magnetic recording medium exhibiting high coercive force Hc and high magnetization Br by a simple method.

- a magnetic recording medium including a plurality of magnetic particles containing a hard magnetic material and a soft magnetic material in contact with the plurality of magnetic particles, and exhibits flexibility to support the recording layer. And a support layer.

- the method for producing a magnetic recording medium according to the second aspect of the present invention is a recording method comprising a support layer having flexibility, a plurality of magnetic particles containing a hard magnetic material, and a soft magnetic material in contact with the plurality of magnetic particles. And a magnetic field applying step of magnetizing the soft magnetic material and the magnetic particles in a predetermined direction by an external magnetic field applied from the outside of the laminated body.

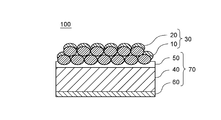

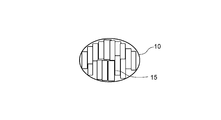

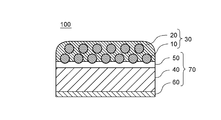

- FIG. 3 is a partially enlarged view of the recording layer of the magnetic recording medium according to the first embodiment. It is a figure which shows typically the laminated

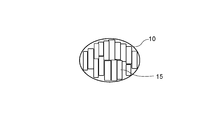

- FIG. 6 is a partially enlarged view of a recording layer of the magnetic recording medium according to the second embodiment.

- a magnetic recording medium 100 according to the first embodiment of the present invention includes a recording layer 30 including a plurality of magnetic particles 10 including a hard magnetic material 15 and a soft magnetic material 20 in contact with the plurality of magnetic particles 10, and a flexible layer. And a support layer 70 that supports the recording layer 30.

- the recording layer 30 includes the magnetic particles 10 including the supporting hard magnetic material 15 and the soft magnetic material 20, the recording layer 30 may be referred to as a composite magnetic material.

- the hard magnetic body 15 of the present embodiment contains ⁇ iron oxide.

- the magnetic particles 10 of the present embodiment contain ⁇ iron oxide as a main component.

- the ⁇ iron oxide contained in the magnetic particles 10 of the present embodiment includes a case where ⁇ -Fe 2 O 3 is represented by a composition formula. In the present specification, the main component is assumed to be more than 50% by weight.

- ⁇ iron oxide includes a form containing a substitution metal substituting iron.

- a substitution metal includes at least one of Co, Ni, Ti, and Ga. Therefore, the ⁇ iron oxide contained in the magnetic particles 10 may be described as ⁇ -P x Q y R z Fe (2-3x-1.5yz) O 3 .

- P, Q, and R each represent a monovalent, divalent, and trivalent metal, and parameters x, y, and z are 0 ⁇ x ⁇ 1.5, 0 ⁇ y ⁇ 2/3, and 0 ⁇ z ⁇ 2. , 0 ⁇ 3x ⁇ 1.5y ⁇ z ⁇ 2.

- the magnetic particles 10 including the ⁇ iron oxide particles included in the recording layer 30 are magnetic particles exhibiting a high coercive force Hc

- the magnetic recording medium containing the ⁇ iron oxide particles alone has a too large coercive force Hc. It may be difficult to record.

- the magnetization Br (remanent magnetization) is small, so that the signal-to-noise ratio (SNR) during recording/reproduction may be reduced. Therefore, the soft magnetic body 20 is arranged to supplement the magnetization Br that is insufficient when only the magnetic particles 10 are used as the magnetic recording layer, and exchange coupling by contacting with the plurality of magnetic particles 10 including the hard magnetic body 15. Is playing.

- the soft magnetic body 20 of the present embodiment covers the magnetic particles 10 so as to bridge the plurality of magnetic particles 10 that include the hard magnetic body 15 and are bonded to each other by sintering.

- the soft magnetic body 20 of the present embodiment covers the plurality of magnetic particles 10 so that the plurality of magnetic particles 10 are sandwiched between the soft magnetic body 20 and the support layer 70. It is also said that the soft magnetic body 20 covers the plurality of magnetic particles 10 on the side opposite to the surface where the magnetic particles 10 face the support layer 70.

- the soft magnetic body 20 of the present embodiment contains ⁇ -Fe as a main component.

- the soft magnetic body 20 may contain iron in another crystalline form such as ⁇ -Fe in the range where exchange coupling with the magnetic particles 10 is possible.

- the soft magnetic body 20 may contain amorphous iron having no crystallinity other than ⁇ -Fe.

- the recording layer 30 may contain additives such as a binder, a lubricant, an abrasive and a rust preventive.

- the layer thickness of the soft magnetic body 20 is increased or the content of the soft magnetic body 20 with respect to the hard magnetic body 15 is increased, the magnetization Br of the recording layer 30 increases and the coercive force Hc decreases.

- the concentration ratio of [soft magnetic material 20]/[hard magnetic material 15] satisfies the predetermined upper limit

- the effect of increasing the magnetization is greater than the decrease of the coercive force Hc. That is, when the relative content [soft magnetic body 20]/[hard magnetic body 15] of the soft magnetic body 20 is not more than the upper limit, the effect of increasing the magnetization Br can be prioritized.

- the layer thickness of the soft magnetic body 20 is preferably 500 nm or less, more preferably 200 nm or less.

- an optimum thickness can be appropriately selected from design values such as the characteristics of the magnetic head, the recording magnetization amount, and the coercive force.

- the recording layer 30 may contain a binder (not shown) for the purpose of improving the binding property between the magnetic particles 10 or for promoting the adhesion between the magnetic particles 10 and the soft magnetic body 20. ..

- the binder may be a homopolymer or a copolymer.

- the binder contained in the recording layer 30 is selected from polyurethane resin, polyester resin, polyamide resin, vinyl chloride resin, epoxy resin, phenoxy resin and polyvinyl acetal.

- the recording layer 30 can also be selected from an acrylic resin copolymerized with styrene, acrylonitrile, methyl methacrylate and the like, a cellulose resin such as nitrocellulose, and a polyvinyl alkaryl resin such as polyvinyl butyral. Furthermore, the recording layer 30 can be used by mixing a plurality of resins.

- the recording layer 30 is particularly preferably made of polyurethane resin, acrylic resin, cellulose resin and vinyl chloride resin.

- the recording layer 30 may be added with additives as required.

- the additive applied to the recording layer 30 include an abrasive, a lubricant, a dispersant, a dispersion aid, an antifungal agent, an antistatic agent, an antioxidant, and carbon black.

- the recording layer 30 includes a form containing a curing agent and a plasticizer.

- the support layer 70 supports the recording layer 30 so that the laminated body of the support layer 70 and the recording layer 30 has flexibility.

- the magnetic recording medium 100 is formed as a laminated body having flexibility, it becomes possible to wind the magnetic recording medium 100 on a reel, thereby increasing the recording capacity, portability and storability. Etc. can be improved. Further, it becomes possible to continue to apply a tension for pressing the magnetic recording medium 100 to the magnetic head during an operation such as recording and reproducing, and there is an effect that the magnetic head and the recording medium 100 slide stably during such an operation.

- the support layer 70 has a flexibility to stably support the recording layer 30 even if the support layer 70 is deformed by an external force.

- the support layer 70 has tensile strength, chemical stability with respect to environment, thermal stability, insensitivity to magnetic field, layer thickness, surface roughness, and antistatic property in consideration of portability of the recording medium 100, scanning form, and the like.

- the material and dimension can be selected in consideration of conductivity for the above.

- the support layer 70 includes a form that is a resin layer that does not exhibit magnetism, and such a configuration can reduce a magnetic field that becomes a background and affects the recording layer 30.

- Embodiments that do not exhibit magnetism include paramagnetism.

- the aspect which does not exhibit magnetism may be paraphrased as nonmagnetic.

- the support layer 70 of the present embodiment includes a substrate 40 made of a flexible resin, an intermediate layer 50 having adhesiveness or plastic deformability for supporting the recording layer 30, a winding property, and a support layer 70. And a back layer 60 that provides a peeling property that reduces sticking between the recording layer 30 and the recording layer 30.

- the base material 40 is a flexible, long film, and can be in the form of a roll.

- polyesters, polyolefins, cellulose derivatives, vinyl resins, polyimides, polyamides, metals, ceramics and the like are selected.

- Polyethylene terephthalate PET is selected for polyesters, and polyethylene, polypropylene, etc. are selected for polyolefins.

- the cellulose derivative is selected from cellulose triacetate, cellulose diacetate, cellulose butyrate and the like

- the vinyl resin is selected from polyvinyl chloride, polyvinylidene chloride and the like.

- the metal a paramagnetic metal or alloy such as titanium or aluminum is selected.

- Alumina or the like formed from a green sheet is selected as the ceramic.

- a thin film containing an oxide of Al or Cu may be disposed on at least one of the front and back surfaces of the base material 40 in order to increase the mechanical strength of the base material 40.

- the back layer 60 preferably contains carbon black and inorganic powder.

- the layer thickness of the back surface layer is preferably 0.9 ⁇ m or less, and more preferably 0.1 ⁇ m or more and 0.7 ⁇ m or less.

- the magnetic recording medium 100 of this embodiment can be manufactured by a manufacturing method including at least the following steps 1 and 2.

- Step 1 Laminated body in which a support layer 70 having flexibility and a recording layer 30 including a plurality of magnetic particles 10 including a hard magnetic body 15 and a soft magnetic body 20 in contact with the plurality of magnetic particles 10 are laminated.

- Step 2 Magnetic field applying step of magnetizing the magnetic particles 10 in a predetermined direction by an external magnetic field applied from the outside of the laminated body

- the magnetic particle 10 is an aspherical body including a long axis and a short axis, and the plurality of magnetic particles 10 include a form in which the long axis is oriented in a predetermined direction as shown in FIG.

- the predetermined direction may coincide with the direction along the easy axis of magnetization.

- the soft magnetic material 20 may be magnetized not only by the magnetic particles 10 but also by the external magnetic field.

- the magnetic particles 10 containing ⁇ iron oxide as the hard magnetic material 15 are produced by producing nanoparticles of iron oxide or iron hydroxide using a chemical process in a solution and heating the produced nanoparticles in an oxidizing atmosphere. can get.

- the chemical process in the solution can be obtained, for example, by subjecting precursor particles formed by a reverse micelle method or a sol-gel method using iron nitrate hydrate as a starting material to heat treatment in an oxidizing atmosphere.

- the method of manufacturing the magnetic recording medium 100 according to the present embodiment includes a support layer 70 having flexibility, a plurality of magnetic particles 10 including the hard magnetic material 15, and a soft magnetic material 20 in contact with the plurality of magnetic particles 10.

- the recording layer 30 and the recording layer 30 are laminated to form a laminated body.

- the method for manufacturing the magnetic recording medium 100 includes a magnetic field applying step of magnetizing the magnetic particles 10 including the hard magnetic material 15 in a predetermined direction by an external magnetic field applied from the outside of the stacked body.

- the magnetic field applying step can be performed after the step of forming the laminated body.

- 1B and 2B are partially enlarged views of the recording layer 30.

- the magnetic particles 10 are magnetized in the vertical direction of the paper surface.

- the hard magnetic material 15 contained in the magnetic particles 10 is oriented in the upper limit direction of the paper surface.

- the easy axis of magnetization in the magnetic domain due to the application of the magnetic field can be identified by measuring the magnetic characteristics while varying the direction and strength of the external magnetization and taking the squareness ratio.

- 1B and 2B show a mode in which the magnetization direction is aligned with the short axis of the magnetic particle 10.

- a form in which the shape of the magnetic particles 10 and the magnetization direction do not necessarily match is included as a modification of the present embodiment.

- Step of preparing the material for the support layer A backing layer 60 is provided and a tape-shaped substrate 40 is prepared.

- the recording layer coating material is prepared by kneading and dispersing the magnetic particles 10 containing ⁇ iron oxide and the additive substance in a solvent.

- the additive substance includes conductive particles and a binder.

- the recording layer 30 is a composite of a hard magnetic material and a soft magnetic material in which the soft magnetic material 20 is contained as the binder matrix of the magnetic particles 10, the soft magnetic material is kneaded and dispersed in the coating material for the recording layer.

- the solvent used for the coating material for the recording layer is selected in consideration of the dispersibility of the magnetic particles 10 and the added substance, and examples thereof include a ketone solvent, an alcohol solvent, an ester solvent, an ether solvent, an aromatic solvent, and a halogen.

- a solvent containing a hydrocarbon and the like are included. These may be used alone or may be appropriately mixed and used.

- the intermediate layer 50 is formed on the base material 40 by applying the intermediate layer coating material to the surface of the base material 40 on which the back surface layer 60 is not formed and drying it. Through this step and the step of preparing the material for the support layer, the support layer 70 having flexibility is created.

- the magnetic particles 10 are formed on the intermediate layer 50 by applying the coating material for the recording layer on the intermediate layer 50 and drying it. Subsequently, the soft magnetic body 20 is formed on the surface on which the magnetic particles 10 are arranged, and the recording layer 30 is formed. This step is in other words the step of stacking the recording layer 30 on the support layer 70.

- the soft magnetic material 20 can be deposited on the magnetic particles 10 by using a sputtering method or a vacuum evaporation method. It is preferable to form the soft magnetic material 20 by a sputtering method because of its controllability of the layer thickness.

- the support layer 70 is wound around the cylindrical core and cured. Next, after calendering the support layer 70, the support layer 70 is cut into a predetermined width to obtain a long tape-shaped support layer 70 cut into a predetermined width.

- the predetermined width corresponds to the length of the core in the tube axis direction.

- the step of forming the back surface layer 60 may be performed after the calendar treatment.

- the present embodiment is related to the first embodiment in that the soft magnetic body 20 is a binder matrix that is in contact with the periphery of the magnetic particles 10 and binds the plurality of magnetic particles 10. It is different from the magnetic recording medium 100. In other words, the magnetic particles 10 of this embodiment are bound to each other via the soft magnetic body 20.

- Example 1 (Preparation of ⁇ -Fe2O3 particles) ⁇ -Fe 2 O 3 particles were produced by the following procedure.

- micelle solution (A) and micelle solution (B) were prepared as follows.

- micellar solution (B) was added dropwise to the micellar solution (A) while thoroughly stirring the micellar solution (A). After the dropping was completed, stirring was continued for 30 minutes.

- TEOS tetraethoxysilane

- ⁇ -Fe2O3 particle layer forming paint 6 g of vinyl chloride resin (30% cyclohexanone solution), 0.5 g of aluminum oxide powder, and 0.2 g of carbon black were weighed and sufficiently mixed with 10 g of the ⁇ -Fe2O3 particles produced as described above.

- the intermediate layer 50 and the recording layer 30 were formed as follows on the polyethylene naphthalate film (PEN film) which is a non-magnetic support.

- PEN film polyethylene naphthalate film

- the intermediate layer 50 was formed on the PEN film by applying and drying the intermediate layer 50 forming coating material on the PEN film having a thickness of 6 ⁇ m which is a non-magnetic support.

- the recording layer 30 forming coating material was applied onto the intermediate layer 50 and dried to form the recording layer 30 on the intermediate layer 50. The drying was performed in a coil that generates a magnetic field of 6 kOe, and the ⁇ -Fe2O3 particles were fixed while being aligned in the direction along the easy axis of magnetization.

- the PEN film on which the intermediate layer 50 and the recording layer 30 were formed was calendered to smooth the ⁇ -Fe2O3 particle layer.

- the average thickness of the intermediate layer 50 after calendering was 1 ⁇ m, and the average thickness of the ⁇ -Fe 2 O 3 particle layer was in the range of 20 to 50 nm.

- an Fe film was formed as a soft magnetic material on the ⁇ -Fe2O3 particle layer by a sputtering method (DC magnetron sputtering apparatus).

- a sputtering method DC magnetron sputtering apparatus.

- the PEN film on which the ⁇ -Fe 2 O 3 particle layer was formed was placed in a vacuum chamber, and vacuum evacuation was performed until the degree of vacuum reached 3 ⁇ 10 ⁇ 4 Pa.

- the pressure was adjusted to 0.5 Pa.

- pre-sputtering was performed at a discharge power of 100 W for 3 minutes, and then an Fe film was deposited to 200 nm on the ⁇ -Fe 2 O 3 particle layer for 1 minute to form the recording layer 30.

- a fluorine-based lubricant was applied on the recording layer 30 to form a top coat layer.

- the PEN film on which the intermediate layer 50, the recording layer 30, and the back layer 60 are formed as described above is cut into a width of 0.5 inch (12.65 mm) to obtain a magnetic tape as a magnetic recording medium. It was

- the measurement magnetic field was set at 50 kOe as a magnetic field sufficient to saturate the hysteresis curve of the magnetic tape. Since the obtained hysteresis curve includes background noise other than that of the recording layer 30, the hysteresis curve of only the recording layer 30 is obtained by linearly approximating the area where the hysteresis curve is saturated and subtracting from the hysteresis curve.

- the magnetization upon application of 50 kOe was calculated as saturation magnetization Ms(emu) and residual magnetization Mr(emu) to obtain the squareness ratio (Mr/Ms) of the magnetic signal. Further, the magnetic field at which the magnetization is zero was defined as the coercive force (Oe).

- the PEN film having the intermediate layer 50, the recording layer 30 having only the ⁇ -Fe2O3 particle layer, and the back layer 60 formed thereon was cut into a 0.5 inch (12.65 mm) width, and magnetic recording was performed. A magnetic tape as a medium was obtained.

- the measurement magnetic field was 50 kOe as a magnetic field sufficient to saturate the MH curve of the magnetic tape. Since the obtained MH curve contains background noise other than that of the recording layer 30, the MH curve of only the recording layer 30 is obtained by linearly approximating the area where the MH curve is saturated and subtracting it from the MH curve. And The magnetization upon application of 50 kOe was calculated as saturation magnetization Ms(emu) and residual magnetization Mr(emu) to obtain the squareness ratio (Mr/Ms) of the magnetic signal.

- Example 2 to 5 A magnetic tape was produced using the same ⁇ -Fe2O3 particle layer forming coating material and intermediate layer 50 forming coating material as in Example 1. However, a magnetic tape was produced by setting the thickness of the Fe film of the soft magnetic material to 20 to 100 nm and the other configurations being the same as in Example 1, and the magnetic characteristics were evaluated.

- Example 6 to 9 Using the production method of ⁇ -Fe2O3 particles of Example 1 as a basic production method, ⁇ -Fe2O3 particles in which a part of Fe element was replaced with another metal element (Co, Ni, Ti or Ga) were synthesized. For each metal element, cobalt nitrate hydrate is used for Co, nickel nitrate hydrate is used for Ni, titanium sulfate hydrate is used for Ti, and gallium nitrate hydrate is used for Ga. % Replaced.

- Example 2 a coating material for forming an ⁇ -Fe2O3 particle layer and a coating material for forming the intermediate layer 50 were prepared, and a magnetic tape was prepared by depositing a Fe film to a thickness of 200 nm on the ⁇ -Fe2O3 particle layer to prepare a magnetic tape. The characteristics were evaluated.

- ⁇ -Fe2O3 particles were produced by substituting a part of Fe element of ⁇ -Fe2O3 particles with another metal element (Co, Ni, Ti or Ga), and a magnetic tape having only the ⁇ -Fe2O3 layer as a recording layer was prepared to produce a magnetic tape. The characteristics were evaluated. The amount of substitution of the metal element was selected such that the coercive force of the ⁇ -Fe2O3 particles was about 3000 Oe.

Landscapes

- Manufacturing Of Magnetic Record Carriers (AREA)

- Magnetic Record Carriers (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018225870A JP2020087497A (ja) | 2018-11-30 | 2018-11-30 | 磁気記録媒体とその製造方法 |

| JP2018-225870 | 2018-11-30 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2020110768A1 true WO2020110768A1 (ja) | 2020-06-04 |

Family

ID=70853191

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2019/044806 Ceased WO2020110768A1 (ja) | 2018-11-30 | 2019-11-15 | 磁気記録媒体とその製造方法 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP2020087497A (enExample) |

| WO (1) | WO2020110768A1 (enExample) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011029620A (ja) * | 2009-06-24 | 2011-02-10 | Univ Of Tokyo | 磁性薄膜の製造方法、磁性薄膜及び磁性体 |

| WO2018062478A1 (ja) * | 2016-09-30 | 2018-04-05 | Dowaエレクトロニクス株式会社 | イプシロン型鉄酸化物磁性粒子及びその製造方法、磁性粒子から構成される磁性粉ならびに磁性塗料および磁気記録媒体 |

| WO2018203468A1 (ja) * | 2017-05-01 | 2018-11-08 | ソニー株式会社 | 磁気記録媒体 |

| JP2018181396A (ja) * | 2017-04-20 | 2018-11-15 | マクセルホールディングス株式会社 | 高記録密度用磁気記録媒体及びその記録再生機構 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05250651A (ja) * | 1992-03-03 | 1993-09-28 | Fujitsu Ltd | 垂直磁気記録媒体 |

| JP2001006151A (ja) * | 1999-06-23 | 2001-01-12 | Fuji Photo Film Co Ltd | 磁気記録媒体 |

| JP2008140460A (ja) * | 2006-11-30 | 2008-06-19 | Toshiba Corp | 垂直磁気記録媒体及び磁気記録再生装置 |

| JP6904888B2 (ja) * | 2016-12-28 | 2021-07-21 | マクセルホールディングス株式会社 | 磁気記録媒体 |

-

2018

- 2018-11-30 JP JP2018225870A patent/JP2020087497A/ja active Pending

-

2019

- 2019-11-15 WO PCT/JP2019/044806 patent/WO2020110768A1/ja not_active Ceased

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011029620A (ja) * | 2009-06-24 | 2011-02-10 | Univ Of Tokyo | 磁性薄膜の製造方法、磁性薄膜及び磁性体 |

| WO2018062478A1 (ja) * | 2016-09-30 | 2018-04-05 | Dowaエレクトロニクス株式会社 | イプシロン型鉄酸化物磁性粒子及びその製造方法、磁性粒子から構成される磁性粉ならびに磁性塗料および磁気記録媒体 |

| JP2018181396A (ja) * | 2017-04-20 | 2018-11-15 | マクセルホールディングス株式会社 | 高記録密度用磁気記録媒体及びその記録再生機構 |

| WO2018203468A1 (ja) * | 2017-05-01 | 2018-11-08 | ソニー株式会社 | 磁気記録媒体 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2020087497A (ja) | 2020-06-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5058889B2 (ja) | 磁気記録媒体 | |

| JP3886969B2 (ja) | 磁気記録媒体および磁気記録カートリッジ | |

| JP2006092672A (ja) | 磁気テープ | |

| JP2002008910A (ja) | 磁性粉末及び磁気記録媒体 | |

| JP2008159259A (ja) | 磁気記録媒体 | |

| JP2001176054A (ja) | 強磁性金属粉末及びこれを用いた磁気記録媒体 | |

| WO2021033330A1 (ja) | 磁気記録媒体、磁気記録再生装置および磁気記録媒体カートリッジ | |

| JPH11238225A (ja) | 磁気テープ | |

| WO2021033333A1 (ja) | 磁気記録媒体、磁気記録再生装置および磁気記録媒体カートリッジ | |

| JP6863444B2 (ja) | 磁気記録媒体、磁気記録再生装置および磁気記録媒体カートリッジ | |

| JP2010147079A (ja) | 窒化鉄系磁性粉末の製造方法と窒化鉄系磁性粉末。 | |

| JP6838633B1 (ja) | 磁気記録媒体、磁気記録再生装置および磁気記録媒体カートリッジ | |

| WO2020110768A1 (ja) | 磁気記録媒体とその製造方法 | |

| JP2021034101A (ja) | 磁気記録媒体、磁気記録再生装置および磁気記録媒体カートリッジ | |

| JP2625708B2 (ja) | 超高保磁力金属粉末の製造方法 | |

| JP5457260B2 (ja) | 磁気記録媒体 | |

| JP2011096312A (ja) | 窒化鉄系磁性粉末、及びそれを用いた磁気記録媒体 | |

| JP2009223970A (ja) | 磁気記録媒体及びその製造方法 | |

| US5686137A (en) | Method of providing hexagonal ferrite magnetic powder with enhanced coercive force stability | |

| JP2011129172A (ja) | 窒化鉄系磁性粉末、及びそれを用いた磁気記録媒体 | |

| JP2561455B2 (ja) | 磁気記録再生装置 | |

| JP2001357511A (ja) | 強磁性金属粉末及びそれを用いた磁気記録媒体 | |

| JP2003119502A (ja) | 強磁性金属粉末及びそれを含む磁気記録媒体 | |

| JP4268628B2 (ja) | 磁気記録媒体および磁気記録カートリッジ | |

| JP2010102803A (ja) | 磁気テープ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 19890553 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 19890553 Country of ref document: EP Kind code of ref document: A1 |