WO2020049392A1 - 表示装置、表示モジュール、電子機器、及び表示装置の作製方法 - Google Patents

表示装置、表示モジュール、電子機器、及び表示装置の作製方法 Download PDFInfo

- Publication number

- WO2020049392A1 WO2020049392A1 PCT/IB2019/057065 IB2019057065W WO2020049392A1 WO 2020049392 A1 WO2020049392 A1 WO 2020049392A1 IB 2019057065 W IB2019057065 W IB 2019057065W WO 2020049392 A1 WO2020049392 A1 WO 2020049392A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- layer

- substrate

- insulating layer

- display device

- oxide

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10D—INORGANIC ELECTRIC SEMICONDUCTOR DEVICES

- H10D86/00—Integrated devices formed in or on insulating or conducting substrates, e.g. formed in silicon-on-insulator [SOI] substrates or on stainless steel or glass substrates

- H10D86/40—Integrated devices formed in or on insulating or conducting substrates, e.g. formed in silicon-on-insulator [SOI] substrates or on stainless steel or glass substrates characterised by multiple TFTs

- H10D86/411—Integrated devices formed in or on insulating or conducting substrates, e.g. formed in silicon-on-insulator [SOI] substrates or on stainless steel or glass substrates characterised by multiple TFTs characterised by materials, geometry or structure of the substrates

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09F—DISPLAYING; ADVERTISING; SIGNS; LABELS OR NAME-PLATES; SEALS

- G09F9/00—Indicating arrangements for variable information in which the information is built-up on a support by selection or combination of individual elements

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09F—DISPLAYING; ADVERTISING; SIGNS; LABELS OR NAME-PLATES; SEALS

- G09F9/00—Indicating arrangements for variable information in which the information is built-up on a support by selection or combination of individual elements

- G09F9/30—Indicating arrangements for variable information in which the information is built-up on a support by selection or combination of individual elements in which the desired character or characters are formed by combining individual elements

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09F—DISPLAYING; ADVERTISING; SIGNS; LABELS OR NAME-PLATES; SEALS

- G09F9/00—Indicating arrangements for variable information in which the information is built-up on a support by selection or combination of individual elements

- G09F9/30—Indicating arrangements for variable information in which the information is built-up on a support by selection or combination of individual elements in which the desired character or characters are formed by combining individual elements

- G09F9/33—Indicating arrangements for variable information in which the information is built-up on a support by selection or combination of individual elements in which the desired character or characters are formed by combining individual elements being semiconductor devices, e.g. diodes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/93—Batch processes

- H01L24/94—Batch processes at wafer-level, i.e. with connecting carried out on a wafer comprising a plurality of undiced individual devices

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L25/00—Assemblies consisting of a plurality of semiconductor or other solid state devices

- H01L25/03—Assemblies consisting of a plurality of semiconductor or other solid state devices all the devices being of a type provided for in a single subclass of subclasses H10B, H10D, H10F, H10H, H10K or H10N, e.g. assemblies of rectifier diodes

- H01L25/04—Assemblies consisting of a plurality of semiconductor or other solid state devices all the devices being of a type provided for in a single subclass of subclasses H10B, H10D, H10F, H10H, H10K or H10N, e.g. assemblies of rectifier diodes the devices not having separate containers

- H01L25/065—Assemblies consisting of a plurality of semiconductor or other solid state devices all the devices being of a type provided for in a single subclass of subclasses H10B, H10D, H10F, H10H, H10K or H10N, e.g. assemblies of rectifier diodes the devices not having separate containers the devices being of a type provided for in group H10D89/00

- H01L25/0657—Stacked arrangements of devices

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L25/00—Assemblies consisting of a plurality of semiconductor or other solid state devices

- H01L25/16—Assemblies consisting of a plurality of semiconductor or other solid state devices the devices being of types provided for in two or more different subclasses of H10B, H10D, H10F, H10H, H10K or H10N, e.g. forming hybrid circuits

- H01L25/167—Assemblies consisting of a plurality of semiconductor or other solid state devices the devices being of types provided for in two or more different subclasses of H10B, H10D, H10F, H10H, H10K or H10N, e.g. forming hybrid circuits comprising optoelectronic devices, e.g. LED, photodiodes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L25/00—Assemblies consisting of a plurality of semiconductor or other solid state devices

- H01L25/18—Assemblies consisting of a plurality of semiconductor or other solid state devices the devices being of the types provided for in two or more different main groups of the same subclass of H10B, H10D, H10F, H10H, H10K or H10N

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L25/00—Assemblies consisting of a plurality of semiconductor or other solid state devices

- H01L25/50—Multistep manufacturing processes of assemblies consisting of devices, the devices being individual devices of subclass H10D or integrated devices of class H10

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10D—INORGANIC ELECTRIC SEMICONDUCTOR DEVICES

- H10D62/00—Semiconductor bodies, or regions thereof, of devices having potential barriers

- H10D62/10—Shapes, relative sizes or dispositions of the regions of the semiconductor bodies; Shapes of the semiconductor bodies

- H10D62/17—Semiconductor regions connected to electrodes not carrying current to be rectified, amplified or switched, e.g. channel regions

- H10D62/213—Channel regions of field-effect devices

- H10D62/221—Channel regions of field-effect devices of FETs

- H10D62/235—Channel regions of field-effect devices of FETs of IGFETs

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10D—INORGANIC ELECTRIC SEMICONDUCTOR DEVICES

- H10D64/00—Electrodes of devices having potential barriers

- H10D64/20—Electrodes characterised by their shapes, relative sizes or dispositions

- H10D64/27—Electrodes not carrying the current to be rectified, amplified, oscillated or switched, e.g. gates

- H10D64/311—Gate electrodes for field-effect devices

- H10D64/411—Gate electrodes for field-effect devices for FETs

- H10D64/511—Gate electrodes for field-effect devices for FETs for IGFETs

- H10D64/512—Disposition of the gate electrodes, e.g. buried gates

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10D—INORGANIC ELECTRIC SEMICONDUCTOR DEVICES

- H10D64/00—Electrodes of devices having potential barriers

- H10D64/20—Electrodes characterised by their shapes, relative sizes or dispositions

- H10D64/27—Electrodes not carrying the current to be rectified, amplified, oscillated or switched, e.g. gates

- H10D64/311—Gate electrodes for field-effect devices

- H10D64/411—Gate electrodes for field-effect devices for FETs

- H10D64/511—Gate electrodes for field-effect devices for FETs for IGFETs

- H10D64/514—Gate electrodes for field-effect devices for FETs for IGFETs characterised by the insulating layers

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10D—INORGANIC ELECTRIC SEMICONDUCTOR DEVICES

- H10D86/00—Integrated devices formed in or on insulating or conducting substrates, e.g. formed in silicon-on-insulator [SOI] substrates or on stainless steel or glass substrates

- H10D86/40—Integrated devices formed in or on insulating or conducting substrates, e.g. formed in silicon-on-insulator [SOI] substrates or on stainless steel or glass substrates characterised by multiple TFTs

- H10D86/441—Interconnections, e.g. scanning lines

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10H—INORGANIC LIGHT-EMITTING SEMICONDUCTOR DEVICES HAVING POTENTIAL BARRIERS

- H10H20/00—Individual inorganic light-emitting semiconductor devices having potential barriers, e.g. light-emitting diodes [LED]

- H10H20/01—Manufacture or treatment

- H10H20/011—Manufacture or treatment of bodies, e.g. forming semiconductor layers

- H10H20/018—Bonding of wafers

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10H—INORGANIC LIGHT-EMITTING SEMICONDUCTOR DEVICES HAVING POTENTIAL BARRIERS

- H10H20/00—Individual inorganic light-emitting semiconductor devices having potential barriers, e.g. light-emitting diodes [LED]

- H10H20/80—Constructional details

- H10H20/85—Packages

-

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F2203/00—Indexing scheme relating to G06F3/00 - G06F3/048

- G06F2203/041—Indexing scheme relating to G06F3/041 - G06F3/045

- G06F2203/04103—Manufacturing, i.e. details related to manufacturing processes specially suited for touch sensitive devices

-

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F3/00—Input arrangements for transferring data to be processed into a form capable of being handled by the computer; Output arrangements for transferring data from processing unit to output unit, e.g. interface arrangements

- G06F3/01—Input arrangements or combined input and output arrangements for interaction between user and computer

- G06F3/03—Arrangements for converting the position or the displacement of a member into a coded form

- G06F3/041—Digitisers, e.g. for touch screens or touch pads, characterised by the transducing means

- G06F3/0412—Digitisers structurally integrated in a display

-

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F3/00—Input arrangements for transferring data to be processed into a form capable of being handled by the computer; Output arrangements for transferring data from processing unit to output unit, e.g. interface arrangements

- G06F3/01—Input arrangements or combined input and output arrangements for interaction between user and computer

- G06F3/03—Arrangements for converting the position or the displacement of a member into a coded form

- G06F3/041—Digitisers, e.g. for touch screens or touch pads, characterised by the transducing means

- G06F3/044—Digitisers, e.g. for touch screens or touch pads, characterised by the transducing means by capacitive means

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/15—Structure, shape, material or disposition of the bump connectors after the connecting process

- H01L2224/16—Structure, shape, material or disposition of the bump connectors after the connecting process of an individual bump connector

- H01L2224/161—Disposition

- H01L2224/16135—Disposition the bump connector connecting between different semiconductor or solid-state bodies, i.e. chip-to-chip

- H01L2224/16145—Disposition the bump connector connecting between different semiconductor or solid-state bodies, i.e. chip-to-chip the bodies being stacked

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/15—Structure, shape, material or disposition of the bump connectors after the connecting process

- H01L2224/16—Structure, shape, material or disposition of the bump connectors after the connecting process of an individual bump connector

- H01L2224/161—Disposition

- H01L2224/16151—Disposition the bump connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive

- H01L2224/16221—Disposition the bump connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked

- H01L2224/16225—Disposition the bump connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked the item being non-metallic, e.g. insulating substrate with or without metallisation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2225/00—Details relating to assemblies covered by the group H01L25/00 but not provided for in its subgroups

- H01L2225/03—All the devices being of a type provided for in the same main group of the same subclass of class H10, e.g. assemblies of rectifier diodes

- H01L2225/04—All the devices being of a type provided for in the same main group of the same subclass of class H10, e.g. assemblies of rectifier diodes the devices not having separate containers

- H01L2225/065—All the devices being of a type provided for in the same main group of the same subclass of class H10

- H01L2225/06503—Stacked arrangements of devices

- H01L2225/06513—Bump or bump-like direct electrical connections between devices, e.g. flip-chip connection, solder bumps

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/10—Bump connectors ; Manufacturing methods related thereto

- H01L24/15—Structure, shape, material or disposition of the bump connectors after the connecting process

- H01L24/16—Structure, shape, material or disposition of the bump connectors after the connecting process of an individual bump connector

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L25/00—Assemblies consisting of a plurality of semiconductor or other solid state devices

- H01L25/03—Assemblies consisting of a plurality of semiconductor or other solid state devices all the devices being of a type provided for in a single subclass of subclasses H10B, H10D, H10F, H10H, H10K or H10N, e.g. assemblies of rectifier diodes

- H01L25/04—Assemblies consisting of a plurality of semiconductor or other solid state devices all the devices being of a type provided for in a single subclass of subclasses H10B, H10D, H10F, H10H, H10K or H10N, e.g. assemblies of rectifier diodes the devices not having separate containers

- H01L25/075—Assemblies consisting of a plurality of semiconductor or other solid state devices all the devices being of a type provided for in a single subclass of subclasses H10B, H10D, H10F, H10H, H10K or H10N, e.g. assemblies of rectifier diodes the devices not having separate containers the devices being of a type provided for in group H10H20/00

- H01L25/0753—Assemblies consisting of a plurality of semiconductor or other solid state devices all the devices being of a type provided for in a single subclass of subclasses H10B, H10D, H10F, H10H, H10K or H10N, e.g. assemblies of rectifier diodes the devices not having separate containers the devices being of a type provided for in group H10H20/00 the devices being arranged next to each other

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/10—Details of semiconductor or other solid state devices to be connected

- H01L2924/11—Device type

- H01L2924/12—Passive devices, e.g. 2 terminal devices

- H01L2924/1204—Optical Diode

- H01L2924/12041—LED

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10D—INORGANIC ELECTRIC SEMICONDUCTOR DEVICES

- H10D86/00—Integrated devices formed in or on insulating or conducting substrates, e.g. formed in silicon-on-insulator [SOI] substrates or on stainless steel or glass substrates

- H10D86/40—Integrated devices formed in or on insulating or conducting substrates, e.g. formed in silicon-on-insulator [SOI] substrates or on stainless steel or glass substrates characterised by multiple TFTs

- H10D86/421—Integrated devices formed in or on insulating or conducting substrates, e.g. formed in silicon-on-insulator [SOI] substrates or on stainless steel or glass substrates characterised by multiple TFTs having a particular composition, shape or crystalline structure of the active layer

- H10D86/423—Integrated devices formed in or on insulating or conducting substrates, e.g. formed in silicon-on-insulator [SOI] substrates or on stainless steel or glass substrates characterised by multiple TFTs having a particular composition, shape or crystalline structure of the active layer comprising semiconductor materials not belonging to the Group IV, e.g. InGaZnO

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10D—INORGANIC ELECTRIC SEMICONDUCTOR DEVICES

- H10D86/00—Integrated devices formed in or on insulating or conducting substrates, e.g. formed in silicon-on-insulator [SOI] substrates or on stainless steel or glass substrates

- H10D86/40—Integrated devices formed in or on insulating or conducting substrates, e.g. formed in silicon-on-insulator [SOI] substrates or on stainless steel or glass substrates characterised by multiple TFTs

- H10D86/60—Integrated devices formed in or on insulating or conducting substrates, e.g. formed in silicon-on-insulator [SOI] substrates or on stainless steel or glass substrates characterised by multiple TFTs wherein the TFTs are in active matrices

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10H—INORGANIC LIGHT-EMITTING SEMICONDUCTOR DEVICES HAVING POTENTIAL BARRIERS

- H10H20/00—Individual inorganic light-emitting semiconductor devices having potential barriers, e.g. light-emitting diodes [LED]

- H10H20/01—Manufacture or treatment

- H10H20/034—Manufacture or treatment of coatings

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10H—INORGANIC LIGHT-EMITTING SEMICONDUCTOR DEVICES HAVING POTENTIAL BARRIERS

- H10H20/00—Individual inorganic light-emitting semiconductor devices having potential barriers, e.g. light-emitting diodes [LED]

- H10H20/01—Manufacture or treatment

- H10H20/036—Manufacture or treatment of packages

- H10H20/0364—Manufacture or treatment of packages of interconnections

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10H—INORGANIC LIGHT-EMITTING SEMICONDUCTOR DEVICES HAVING POTENTIAL BARRIERS

- H10H20/00—Individual inorganic light-emitting semiconductor devices having potential barriers, e.g. light-emitting diodes [LED]

- H10H20/80—Constructional details

- H10H20/84—Coatings, e.g. passivation layers or antireflective coatings

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10H—INORGANIC LIGHT-EMITTING SEMICONDUCTOR DEVICES HAVING POTENTIAL BARRIERS

- H10H20/00—Individual inorganic light-emitting semiconductor devices having potential barriers, e.g. light-emitting diodes [LED]

- H10H20/80—Constructional details

- H10H20/85—Packages

- H10H20/851—Wavelength conversion means

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10H—INORGANIC LIGHT-EMITTING SEMICONDUCTOR DEVICES HAVING POTENTIAL BARRIERS

- H10H20/00—Individual inorganic light-emitting semiconductor devices having potential barriers, e.g. light-emitting diodes [LED]

- H10H20/80—Constructional details

- H10H20/85—Packages

- H10H20/857—Interconnections, e.g. lead-frames, bond wires or solder balls

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10H—INORGANIC LIGHT-EMITTING SEMICONDUCTOR DEVICES HAVING POTENTIAL BARRIERS

- H10H29/00—Integrated devices, or assemblies of multiple devices, comprising at least one light-emitting semiconductor element covered by group H10H20/00

- H10H29/10—Integrated devices comprising at least one light-emitting semiconductor component covered by group H10H20/00

- H10H29/14—Integrated devices comprising at least one light-emitting semiconductor component covered by group H10H20/00 comprising multiple light-emitting semiconductor components

- H10H29/142—Two-dimensional arrangements, e.g. asymmetric LED layout

Definitions

- One embodiment of the present invention relates to a display device, a display module, an electronic device, and a manufacturing method thereof.

- one embodiment of the present invention is not limited to the above technical field.

- Technical fields of one embodiment of the present invention include a semiconductor device, a display device, a light-emitting device, a power storage device, a storage device, an electronic device, a lighting device, an input device (eg, a touch sensor), an input / output device (eg, a touch panel, and the like). ), Their driving method, or their manufacturing method.

- a display device using a micro light emitting diode (micro LED (Light Emitting Diode)) as a display element has been proposed (for example, Patent Document 1).

- a display device using a micro LED as a display element has advantages such as high brightness, high contrast, and a long life, and research and development are being actively conducted as a next-generation display device.

- the time required for mounting an LED chip is extremely long, and reduction of manufacturing cost is an issue.

- red (R), green (G), and blue (B) LEDs are manufactured on different wafers, and the LEDs are cut out one by one and mounted on a circuit board. Therefore, as the number of pixels of the display device increases, the number of LEDs to be mounted increases, and the time required for mounting increases.

- the higher the definition of the display device the higher the difficulty of mounting the LED.

- An object of one embodiment of the present invention is to provide a display device with high definition.

- An object of one embodiment of the present invention is to provide a display device with high display quality.

- An object of one embodiment of the present invention is to provide a display device with low power consumption.

- An object of one embodiment of the present invention is to provide a highly reliable display device.

- An object of one embodiment of the present invention is to reduce manufacturing cost of a display device including a micro LED as a display element.

- An object of one embodiment of the present invention is to manufacture a display device using a micro LED as a display element with high yield.

- a display device includes a substrate, an insulating layer, a plurality of transistors, and a plurality of light-emitting diodes.

- the plurality of light emitting diodes are provided in a matrix on the substrate.

- Each of the plurality of transistors is electrically connected to at least one of the plurality of light emitting diodes.

- the plurality of light emitting diodes are located closer to the substrate than the plurality of transistors.

- the plurality of light emitting diodes emit light toward the substrate.

- Each of the plurality of transistors has a metal oxide layer and a gate electrode.

- the metal oxide layer has a channel formation region.

- the height of the upper surface of the gate electrode substantially matches the height of the upper surface of the insulating layer.

- a display device includes a substrate, an insulating layer, a plurality of transistors, and a plurality of light-emitting diodes.

- the plurality of light emitting diodes are provided in a matrix on the substrate.

- Each of the plurality of transistors is electrically connected to at least one of the plurality of light emitting diodes.

- the plurality of light emitting diodes are located closer to the substrate than the plurality of transistors.

- the plurality of light emitting diodes emit light toward the substrate.

- Each of the transistors includes a metal oxide layer, a gate insulating layer, a gate electrode, a first conductive layer, and a second conductive layer.

- the metal oxide layer has a channel formation region.

- a metal oxide layer a first region overlapping the first conductive layer, a second region overlapping the second conductive layer, a third region between the first region and the second region, Having.

- the first conductive layer and the second conductive layer are spaced apart from each other on the metal oxide layer.

- the insulating layer is located on the first conductive layer and the second conductive layer.

- the insulating layer has an opening overlapping with the third region.

- the gate insulating layer is located inside the opening and overlaps a side surface of the insulating layer and an upper surface of the third region.

- the gate electrode is located inside the opening and overlaps the side surface of the insulating layer and the upper surface of the third region with the gate insulating layer interposed therebetween.

- At least one of the plurality of light emitting diodes is a micro light emitting diode.

- the plurality of light emitting diodes may include a first light emitting diode and a second light emitting diode that emit light of different colors.

- the first transistor electrically connected to the first light-emitting diode and the second transistor electrically connected to the second light-emitting diode have one or both of a channel length and a channel width. May have different structures from each other.

- all of the plurality of light emitting diodes may emit light of the same color.

- the display device of one embodiment of the present invention further include a driver circuit.

- the drive circuit has a plurality of circuit transistors.

- Each of the plurality of circuit transistors has a channel formation region in the semiconductor substrate.

- the insulating layer, the plurality of transistors, and the plurality of light emitting diodes are respectively located between the substrate and the semiconductor substrate.

- the plurality of transistors are located closer to the substrate than the plurality of circuit transistors.

- the display device of one embodiment of the present invention further include a functional layer.

- the functional layer is located between the substrate and at least one of the plurality of light emitting diodes. At least one of the plurality of light emitting diodes emits light toward the substrate via the functional layer.

- the functional layer has one or both of a coloring layer and a color conversion layer.

- the display device of one embodiment of the present invention further include a touch sensor.

- the light emitting diode emits light toward the touch sensor via the substrate.

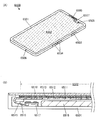

- One embodiment of the present invention is a module including a display device having the above structure, to which a connector such as a flexible printed circuit board (hereinafter, referred to as FPC) or a connector such as TCP (Tape Carrier Package) is attached, or a COG.

- a module such as a module in which an integrated circuit (IC) is mounted by a (Chip On Glass) method, a COF (Chip On Film) method, or the like.

- One embodiment of the present invention is an electronic device including the above module and at least one of an antenna, a battery, a housing, a camera, a speaker, a microphone, and an operation button.

- a plurality of transistors are formed in matrix on a first substrate, and a plurality of light-emitting diodes are formed in matrix on a second substrate.

- a first conductor electrically connected to at least one of the plurality of transistors or at least one of the plurality of light-emitting diodes on the substrate, and at least one of the plurality of transistors is formed through the first conductor.

- the first substrate and the second substrate are attached to each other so that at least one of the plurality of light-emitting diodes is electrically connected to each other, and a plurality of transistors is formed.

- at least one of the plurality of light emitting diodes is a micro light emitting diode.

- At least one of the transistors preferably includes a metal oxide in a channel formation region.

- the first conductor is formed over the first substrate, so that the first conductor is electrically connected to at least one of the plurality of transistors.

- a second conductor electrically connected to at least one of the plurality of light-emitting diodes is formed over the second substrate, and the first substrate is contacted with the first conductor so that the second conductor is in contact with the second conductor. And the second substrate may be bonded.

- At least one of a coloring layer, a color conversion layer, and a touch sensor is formed over a third substrate, and the first substrate and the second substrate are separated.

- the second substrate may be peeled off, and the third substrate may be bonded to a surface exposed by peeling the second substrate.

- a coloring layer is formed over a third substrate, and the first substrate and the second substrate are formed.

- the thickness of the second substrate may be reduced by polishing the second substrate, and the third substrate may be bonded to the polished surface of the second substrate.

- a display device with high definition can be provided.

- a display device with high display quality can be provided.

- a display device with low power consumption can be provided.

- a highly reliable display device can be provided.

- manufacturing cost of a display device including a micro LED as a display element can be reduced.

- a display device including a micro LED as a display element can be manufactured with high yield.

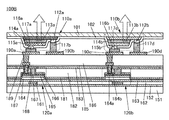

- FIG. 1 is a cross-sectional view illustrating an example of a display device.

- 2A to 2C are cross-sectional views illustrating an example of a method for manufacturing a display device.

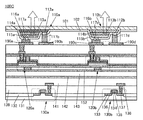

- FIG. 3 is a cross-sectional view illustrating an example of the display device.

- FIG. 4 is a cross-sectional view illustrating an example of the display device.

- 5A and 5B are cross-sectional views illustrating an example of a display device.

- 6A and 6B are cross-sectional views illustrating an example of a method for manufacturing a display device.

- FIG. 7 is a cross-sectional view illustrating an example of a display device.

- FIG. 8A is a top view illustrating an example of a transistor.

- FIGS. 8B and 8C are cross-sectional views illustrating an example of a transistor.

- FIG. 9A is a top view illustrating an example of a transistor.

- FIGS. 9B and 9C are cross-sectional views illustrating an example of a transistor.

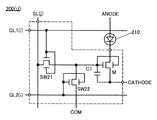

- FIG. 10 is a circuit diagram illustrating an example of a pixel of a display device.

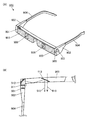

- FIGS. 11A and 11B illustrate an example of an electronic device.

- FIGS. 12A and 12B illustrate an example of an electronic device.

- FIGS. 13A and 13B illustrate an example of an electronic device.

- FIGS. 14A to 14D illustrate an example of an electronic device.

- FIGS. 15A to 15F illustrate an example of an electronic device.

- the word “film” and the word “layer” can be interchanged with each other depending on the case or the situation.

- the term “conductive layer” can be changed to the term “conductive film”.

- the term “insulating film” can be changed to the term “insulating layer”.

- the display device in this embodiment includes a plurality of light-emitting diodes which are display elements and a plurality of transistors which drive the display elements.

- the plurality of light emitting diodes are provided in a matrix on a substrate having a property of transmitting visible light.

- Each of the plurality of transistors is electrically connected to at least one of the plurality of light emitting diodes.

- the plurality of light emitting diodes are located closer to the substrate than the plurality of transistors.

- the plurality of light emitting diodes emit light toward the substrate.

- the display device of this embodiment is formed by bonding a plurality of transistors and a plurality of light-emitting diodes formed over different substrates.

- the method for manufacturing a display device in this embodiment since a plurality of light-emitting diodes and a plurality of transistors are attached at one time, even when a display device with a large number of pixels or a high-definition display device is manufactured, light emission is prevented. Compared with the method of mounting the diodes one by one on a circuit board, the manufacturing time of the display device can be reduced, and the difficulty of manufacturing can be reduced.

- the display device of this embodiment has a function of displaying an image using a light-emitting diode. Since the light-emitting diode is a self-light-emitting element, when a light-emitting diode is used as a display element, the display device does not require a backlight and does not need to include a polarizing plate. Therefore, the power consumption of the display device can be reduced, and the display device can be reduced in thickness and weight. In addition, a display device using a light-emitting diode as a display element has high contrast and a wide viewing angle, so that high display quality can be obtained. In addition, by using an inorganic material as a light-emitting material, the life of a display device can be extended and reliability can be improved.

- a micro LED is used as a light emitting diode.

- a micro LED having a double hetero junction will be described.

- the light emitting diode is not particularly limited, and for example, a micro LED having a quantum well junction, an LED using a nano column, or the like may be used.

- Area of the region that emits light emitting diode is preferably 1 mm 2 or less, more preferably 10000 2 or less, more preferably 3000 .mu.m 2 or less, more preferably 700 .mu.m 2 or less. Note that in this specification and the like, a light-emitting diode whose light-emitting region has an area of 10000 ⁇ m 2 or less may be referred to as a micro LED.

- the transistor included in the display device preferably includes a metal oxide in a channel formation region.

- a transistor including a metal oxide can have low power consumption. Therefore, by combining with a micro LED, a display device with extremely low power consumption can be realized.

- the display device of this embodiment preferably includes a transistor in which the height of the upper surface of the gate electrode is approximately equal to the height of the upper surface of the insulating layer.

- the upper surface of the gate electrode and the upper surface of the insulating layer are flattened, and the height of the upper surface of the gate electrode is made equal to the height of the upper surface of the insulating layer. be able to.

- the transistor having such a structure can be easily reduced in size. Since the size of the pixel can be reduced by reducing the size of the transistor, the definition of the display device can be increased.

- the display device of this embodiment can increase definition, the display device can be suitably used for an electronic device having a relatively small display portion.

- electronic devices include wristwatch-type or bracelet-type information terminals (wearable devices), devices for VR (Virtual Reality) such as head-mounted displays, glasses-type devices for AR (Augmented Reality), and MR.

- Wearable devices that can be worn on the head, such as devices for (Mixed Reality).

- FIG. 1 shows a cross-sectional view of the display device 100A.

- FIG. 2 is a cross-sectional view illustrating a method for manufacturing the display device 100A.

- the display device 100A shown in FIG. 1 is configured by bonding an LED substrate 150A shown in FIG. 2A and a circuit substrate 150B shown in FIG. 2B (see FIG. 2C).

- FIG. 2A is a cross-sectional view of the LED substrate 150A.

- the LED substrate 150A has a substrate 101, a light emitting diode 110a, a light emitting diode 110b, and a protective layer 102.

- the light emitting diode 110a includes an electrode 112a, a semiconductor layer 113a, a light emitting layer 114a, a semiconductor layer 115a, and an electrode 116a.

- the light emitting diode 110b includes an electrode 112b, a semiconductor layer 113b, a light emitting layer 114b, a semiconductor layer 115b, and an electrode 116b.

- the electrode 112a is electrically connected to the semiconductor layer 113a.

- the electrode 116a is electrically connected to the semiconductor layer 115a.

- the electrode 112b is electrically connected to the semiconductor layer 113b.

- the electrode 116b is electrically connected to the semiconductor layer 115b.

- the protective layer 102 is provided so as to cover the substrate 101, the semiconductor layers 113a and 113b, the light-emitting layers 114a and 114b, and the semiconductor layers 115a and 115b.

- the protective layer 102 covers the side surfaces of the electrodes 112a and 112b and the side surfaces of the electrodes 116a and 116b, and has openings overlapping with the upper surfaces of the electrodes 112a and 112b and the upper surfaces of the electrodes 116a and 116b. In the opening, the upper surfaces of the electrodes 112a and 112b and the upper surfaces of the electrodes 116a and 116b are exposed.

- the light emitting layer 114a is sandwiched between the semiconductor layers 113a and 115a.

- the light emitting layer 114b is sandwiched between the semiconductor layers 113b and 115b. In the light emitting layers 114a and 114b, electrons and holes are combined to emit light.

- One of the semiconductor layers 113a and 113b and the semiconductor layers 115a and 115b is an n-type semiconductor layer, and the other is a p-type semiconductor layer.

- the stacked structure including the semiconductor layer 113a, the light-emitting layer 114a, and the semiconductor layer 115a, and the stacked structure including the semiconductor layer 113b, the light-emitting layer 114b, and the semiconductor layer 115b are light sources of red, yellow, green, and blue, respectively. Is formed. Preferably, the two stacked structures present light of different colors.

- These laminated structures include, for example, gallium / phosphorus compounds, gallium / arsenic compounds, gallium / aluminum / arsenic compounds, aluminum / gallium / indium / phosphorous compounds, gallium nitride, indium / gallium nitride compounds, selenium / zinc compounds, etc. Can be used.

- the light emitting diode 110a and the light emitting diode 110b so as to exhibit light of different colors, a step of forming a color conversion layer becomes unnecessary. Therefore, the manufacturing cost of the display device can be reduced.

- the two stacked structures may exhibit light of the same color.

- light emitted from the light emitting layers 114a and 114b may be extracted to the outside of the display device through one or both of the color conversion layer and the coloring layer.

- the configuration in which each color pixel has a light emitting diode that emits light of the same color will be described later in Configuration Example 2 of the display device.

- the display device of this embodiment may include a light-emitting diode that emits infrared light.

- a light emitting diode that emits infrared light can be used, for example, as a light source of an infrared light sensor.

- a single crystal substrate such as a sapphire (Al 2 O 3 ) substrate, a silicon carbide (SiC) substrate, a silicon (Si) substrate, and a gallium nitride (GaN) substrate can be used.

- the substrate 101 has a property of transmitting visible light. For example, by reducing the thickness by polishing or the like, the transmittance of the substrate 101 with respect to visible light can be increased.

- FIG. 2B is a cross-sectional view of the circuit board 150B.

- the circuit board 150B includes a substrate 151, an insulating layer 152, a transistor 120a, a transistor 120b, a conductive layer 184a, a conductive layer 184b, a conductive layer 187, a conductive layer 189, an insulating layer 186, an insulating layer 188, a conductive layer 190a, a conductive layer 190b, It has a conductive layer 190c and a conductive layer 190d.

- the circuit board 150B further includes insulating layers such as an insulating layer 162, an insulating layer 181, an insulating layer 182, an insulating layer 183, and an insulating layer 185. One or more of these insulating layers may be regarded as a component of the transistor in some cases; however, in this embodiment, description will be made without including the component in the transistor.

- an insulating substrate such as a glass substrate, a quartz substrate, a sapphire substrate, or a ceramic substrate, a single crystal semiconductor substrate made of a material such as silicon or silicon carbide, a polycrystalline semiconductor substrate, or a compound semiconductor substrate such as silicon germanium And a semiconductor substrate such as an SOI substrate.

- the substrate 151 preferably blocks visible light (has non-transparency with respect to visible light). When the substrate 151 blocks visible light, light can be prevented from entering the transistors 120a and 120b formed on the substrate 151 from the outside. Note that one embodiment of the present invention is not limited thereto, and the substrate 151 may have a property of transmitting visible light.

- An insulating layer 152 is provided over the substrate 151.

- the insulating layer 152 functions as a barrier layer that prevents impurities such as water and hydrogen from diffusing into the transistors 120a and 120b from the substrate 151 and preventing oxygen from being released from the metal oxide layer 165 to the insulating layer 152 side.

- a film such as an aluminum oxide film, a hafnium oxide film, or a silicon nitride film, to which hydrogen and oxygen are less likely to diffuse than a silicon oxide film can be used.

- Each of the transistors 120a and 120b includes a conductive layer 161, an insulating layer 163, an insulating layer 164, a metal oxide layer 165, a pair of conductive layers 166, an insulating layer 167, a conductive layer 168, and the like.

- the metal oxide layer 165 has a channel formation region.

- the metal oxide layer 165 includes a first region overlapping with one of the pair of conductive layers 166, a second region overlapping with the other of the pair of conductive layers 166, and a region between the first region and the second region. And a third region.

- a conductive layer 161 and an insulating layer 162 are provided over the insulating layer 152, and an insulating layer 163 and an insulating layer 164 are provided so as to cover the conductive layer 161 and the insulating layer 162.

- the metal oxide layer 165 is provided over the insulating layer 164.

- the conductive layer 161 functions as a gate electrode, and the insulating layers 163 and 164 function as gate insulating layers.

- the conductive layer 161 overlaps with the metal oxide layer 165 with the insulating layer 163 and the insulating layer 164 interposed therebetween.

- the insulating layer 163 preferably functions as a barrier layer, similarly to the insulating layer 152.

- an oxide insulating film such as a silicon oxide film is preferably used as the insulating layer 164.

- the height of the upper surface of the conductive layer 161 is approximately equal to the height of the upper surface of the insulating layer 162.

- an opening is provided in the insulating layer 162, the conductive layer 161 is formed so as to fill the opening, and then planarization is performed by a CMP method or the like, so that the height of the upper surface of the conductive layer 161 and the height of the insulating layer 162 are reduced.

- the height of the upper surface can be made uniform.

- the sizes of the transistors 120a and 120b can be reduced.

- the pair of conductive layers 166 is provided separately over the metal oxide layer 165.

- the pair of conductive layers 166 functions as a source and a drain.

- An insulating layer 181 is provided so as to cover the metal oxide layer 165 and the pair of conductive layers 166.

- An insulating layer 182 is provided over the insulating layer 181.

- An opening reaching the metal oxide layer 165 is provided in the insulating layers 181 and 182, and the insulating layer 167 and the conductive layer 168 are embedded in the openings. The opening overlaps the third region.

- the insulating layer 167 overlaps with a side surface of the insulating layer 181 and a side surface of the insulating layer 182.

- the conductive layer 168 overlaps with a side surface of the insulating layer 181 and a side surface of the insulating layer 182 with the insulating layer 167 provided therebetween.

- the conductive layer 168 functions as a gate electrode, and the insulating layer 167 functions as a gate insulating layer.

- the conductive layer 168 overlaps with the metal oxide layer 165 with the insulating layer 167 provided therebetween.

- the height of the upper surface of the conductive layer 168 is approximately equal to the height of the upper surface of the insulating layer 182.

- an opening is provided in the insulating layer 182, the insulating layer 167 and the conductive layer 168 are formed so as to fill the opening, and then planarization treatment is performed, so that the height of the upper surface of the conductive layer 168 and the height of the upper surface of the insulating layer 182 are reduced. Height can be aligned. Thus, the sizes of the transistors 120a and 120b can be reduced.

- an insulating layer 183 and an insulating layer 185 are provided so as to cover upper surfaces of the insulating layer 182, the insulating layer 167, and the conductive layer 168.

- the insulating layers 181 and 183 preferably function as barrier layers, similarly to the insulating layer 152.

- a plug electrically connected to one of the pair of conductive layers 166 and the conductive layer 187 is embedded in an opening provided in the insulating layer 181, the insulating layer 182, the insulating layer 183, and the insulating layer 185.

- the plug preferably includes a conductive layer 184b in contact with a side surface of the opening and one upper surface of the pair of conductive layers 166, and a conductive layer 184a embedded inside the conductive layer 184b. At this time, it is preferable that a conductive material through which hydrogen and oxygen are hardly diffused be used for the conductive layer 184b.

- the conductive layer 187 is provided over the insulating layer 185, and the insulating layer 186 is provided over the conductive layer 187.

- An opening reaching the conductive layer 187 is provided in the insulating layer 186, and the conductive layer 189 is embedded in the opening.

- a conductive layer 187 and an insulating layer 186 may be provided over the insulating layer 185, and an insulating layer 188 may be provided over the conductive layer 187.

- the height of the upper surface of the conductive layer 187 matches or approximately matches the height of the upper surface of the insulating layer 186.

- an opening is provided in the insulating layer 186, the conductive layer 187 is formed so as to fill the opening, and planarization is performed using a CMP method or the like, so that the height of the upper surface of the conductive layer 187 and the height of the insulating layer 186 are reduced.

- the height of the upper surface can be made uniform.

- an opening reaching the conductive layer 187 is provided in the insulating layer 188, and the conductive layer 189 is embedded in the opening.

- the conductive layer 189 functions as a plug for electrically connecting the conductive layer 187 to the conductive layer 190a or 190c.

- One of a pair of conductive layers 166 of the transistor 120a is electrically connected to the conductive layer 190a through the conductive layers 184a, 184b, 187, and 189.

- one of the pair of conductive layers 166 of the transistor 120b is electrically connected to the conductive layer 190c through the conductive layers 184a, 184b, 187, and 189.

- materials that can be used for various conductive layers included in the display device of this embodiment include metals such as aluminum, titanium, chromium, nickel, copper, yttrium, zirconium, molybdenum, silver, tantalum, and tungsten; Alternatively, an alloy containing this as a main component may be used. Further, a film containing any of these materials can be used as a single layer or a stacked structure. For example, a single-layer structure of an aluminum film containing silicon, a two-layer structure of stacking an aluminum film on a titanium film, a two-layer structure of stacking an aluminum film on a tungsten film, and a copper film on a copper-magnesium-aluminum alloy film.

- a two-layer structure in which a copper film is stacked on a titanium film a two-layer structure in which a copper film is stacked on a tungsten film, a titanium film or a titanium nitride film, and an aluminum film or a copper film stacked thereon

- an oxide such as indium oxide, tin oxide, or zinc oxide may be used.

- it is preferable to use copper containing manganese since the controllability of the shape by etching is improved.

- materials that can be used for various insulating layers included in the display device of this embodiment include resins such as acrylic, polyimide, epoxy, and silicone; silicon oxide; silicon oxynitride; silicon nitride oxide; silicon nitride; An inorganic insulating material such as aluminum is used.

- circuit board 150B may include one or both of a reflective layer that reflects light of the light-emitting diode and a light-blocking layer that blocks the light.

- the electrodes 112a, 112b, 116a, and 116b provided on the LED board 150A are electrically connected to the conductive layers 190a, 190b, 190c, and 190d provided on the circuit board 150B, respectively.

- the electrode 116a and the conductive layer 190a are electrically connected via the conductor 117a.

- the transistor 120a and the light emitting diode 110a can be electrically connected.

- the electrode 116a functions as a pixel electrode of the light emitting diode 110a.

- the electrode 112a and the conductive layer 190b are electrically connected via the conductor 117b.

- the electrode 112a functions as a common electrode of the light emitting diode 110a.

- the electrode 116b and the conductive layer 190c are electrically connected via the conductor 117c.

- the transistor 120b and the light emitting diode 110b can be electrically connected.

- the electrode 116b functions as a pixel electrode of the light emitting diode 110b.

- the electrode 112b and the conductive layer 190d are electrically connected via a conductor 117d.

- the electrode 112b functions as a common electrode of the light emitting diode 110b.

- a conductive paste such as silver, carbon, or copper, or a bump such as gold or solder can be suitably used.

- the electrodes 112a, 112b, 116a, 116b connected to the conductors 117a to 117d, and the conductive layers 190a to 190d be made of a conductive material having low contact resistance with the conductors 117a to 117d, respectively.

- the conductive material connected thereto is aluminum, titanium, copper, an alloy of silver (Ag), palladium (Pd), and copper (Cu) (Ag-Pd- Cu (APC)) is preferable because the contact resistance is low.

- FIG. 2C shows an example in which the conductors 117a to 117d are provided on the circuit board 150B side and the LED board 150A and the circuit board 150B are attached to each other.

- the conductors 117a to 117d may be provided on the LED substrate 150A side, and the LED substrate 150A and the circuit substrate 150B may be bonded.

- a plurality of light-emitting diodes may be electrically connected to one transistor.

- FIG. 3 shows a cross-sectional view of the display device 100B.

- the transistor 120a and the transistor 120b have different channel lengths.

- Other configurations are the same as those of the display device 100A.

- the transistor 120a for driving the light emitting diode 110a and the transistor 120b for driving the light emitting diode 110b may be different from each other in at least one of transistor size, channel length, channel width, structure, and the like.

- the configuration of the transistor may be changed for each color.

- one or both of the channel length and the channel width of the transistor may be changed for each color in accordance with the amount of current required to emit light with desired luminance.

- FIG. 4 shows a cross-sectional view of the display device 100C.

- the display device 100C includes transistors in which a channel formation region is formed over a substrate 131 (transistors 130a and 130b) and transistors each including a channel formation region in a metal oxide (transistors 120a and 120b) are stacked.

- Each of the transistors 130a and 130b includes a conductive layer 135, an insulating layer 134, an insulating layer 136, and a pair of low-resistance regions 133.

- the conductive layer 135 functions as a gate.

- the insulating layer 134 is located between the conductive layer 135 and the substrate 131 and functions as a gate insulating layer.

- the insulating layer 136 is provided to cover a side surface of the conductive layer 135 and functions as a sidewall.

- the pair of low-resistance regions 133 is a region in the substrate 131 to which impurities are doped, and one functions as a source of the transistor and the other functions as a drain of the transistor.

- an element isolation layer 132 is provided between two adjacent transistors so as to be embedded in the substrate 131.

- An insulating layer 139 is provided to cover the transistors 130a and 130b, and a conductive layer 138 is provided over the insulating layer 139.

- the conductive layer 138 is electrically connected to one of the pair of low-resistance regions 133 through the conductive layer 137 embedded in the opening of the insulating layer 139.

- An insulating layer 141 is provided to cover the conductive layer 138, and the conductive layer 142 is provided over the insulating layer 141.

- the conductive layers 138 and 142 each function as a wiring.

- An insulating layer 143 and an insulating layer 152 are provided so as to cover the conductive layer 142.

- the transistors 120a and 120b are provided over the insulating layer 152. Since the laminated structure from the insulating layer 152 to the substrate 101 is the same as that of the display device 100A, a detailed description is omitted.

- the transistors 120a and 120b can be used as transistors included in a pixel circuit.

- the transistors 130a and 130b can be used as a transistor included in a pixel circuit or a transistor included in a driver circuit (one or both of a gate driver and a source driver) for driving the pixel circuit. Further, the transistors 120a, 120b, 130a, and 130b can be used as transistors included in various circuits such as an arithmetic circuit and a memory circuit.

- a pixel circuit not only a pixel circuit but also a driver circuit and the like can be formed directly below the light-emitting diode, so that the size of the display device is reduced as compared to a case where a driver circuit is provided outside the display portion. be able to. Further, a display device with a narrow frame (a narrow non-display area) can be realized.

- FIG. 5A is a cross-sectional view of the display device 100D

- FIG. 5B is a cross-sectional view of the display device 100E.

- each color pixel has a light emitting diode that emits light of the same color.

- the display device 100D and the display device 100E include the substrate 191 provided with the coloring layer CFR and the color conversion layer CCMR.

- the substrate 191 has a coloring layer CFR and a color conversion layer CCMR in a region overlapping with the light emitting diode 110a included in the red pixel.

- the color conversion layer CCMR has a function of converting blue light into red light.

- the substrate 191 similarly includes a green coloring layer and a color conversion layer that converts blue light to green in a region overlapping with a light emitting diode included in a green pixel.

- the light emitted from the light emitting diode of the green pixel is converted from blue to green by the color conversion layer, the purity of the green light is increased by the coloring layer, and the green light is emitted to the outside of the display device.

- the substrate 191 does not have a color conversion layer in a region overlapping with the light emitting diode 110b included in the blue pixel.

- the substrate 191 may include a blue coloring layer in a region overlapping with the light-emitting diode 110b included in the blue pixel.

- a blue coloring layer is provided, the purity of blue light can be increased.

- a blue colored layer is not provided, the manufacturing process can be simplified.

- the blue light emitted from the light emitting diode 110b is emitted to the outside of the display device 100D or the display device 100E through the adhesive layer 192 and the substrate 191.

- the substrate 191 Since the substrate 191 is located on the side from which light from the light-emitting diode is extracted, it is preferable to use a material having high transparency to visible light. Examples of a material that can be used for the substrate 191 include glass, quartz, sapphire, and resin. A film such as a resin film may be used for the substrate 191. This makes it possible to reduce the weight and thickness of the display device.

- quantum dots have narrow emission spectrum peak widths and can emit light with good color purity. Thereby, the display quality of the display device can be improved.

- the color conversion layer can be formed by a droplet discharge method (for example, an inkjet method), a coating method, an imprint method, various printing methods (screen printing, offset printing), or the like. Further, a color conversion film such as a quantum dot film may be used.

- the material constituting the quantum dot is not particularly limited, and may be, for example, a Group 14 element, a Group 15 element, a Group 16 element, a compound composed of a plurality of Group 14 elements, or a Group 4 to Group 14 element.

- a compound of an element and a group 16 element, a compound of a group 2 element and a group 16 element, a compound of a group 13 element and a group 15 element, a compound of a group 13 element and a group 17 element examples include compounds of Group 14 elements and Group 15 elements, compounds of Group 11 elements and Group 17 elements, iron oxides, titanium oxides, chalcogenide spinels, and various semiconductor clusters.

- quantum dots examples include a core type, a core-shell type, and a core-multi-shell type.

- quantum dots have a high ratio of surface atoms, and therefore have high reactivity and are likely to aggregate. Therefore, it is preferable that a protective agent is attached to the surface of the quantum dot or a protective group is provided. When the protective agent is attached or the protective group is provided, aggregation can be prevented and solubility in a solvent can be increased. It is also possible to reduce reactivity and improve electrical stability.

- the size of the quantum dot is appropriately adjusted so that light of a desired wavelength is obtained.

- the emission of the quantum dot shifts to the blue side, that is, to the higher energy side.

- the size (diameter) of the quantum dot is, for example, 0.5 nm or more and 20 nm or less, preferably 1 nm or more and 10 nm or less.

- the shape of the quantum dot is not particularly limited, and may be spherical, rod-shaped, disk-shaped, or other shapes.

- a quantum rod, which is a rod-like quantum dot, has a function of exhibiting directional light.

- the coloring layer is a colored layer that transmits light in a specific wavelength range.

- a color filter that transmits light in a red, green, blue, or yellow wavelength range can be used.

- a material that can be used for the coloring layer a metal material, a resin material, a resin material containing a pigment or a dye, or the like can be given.

- the display device 100D first attaches a circuit board and an LED substrate like the display device 100A, and then peels off the substrate 101 included in the LED substrate. It can be manufactured by bonding a substrate 191 provided with a CFR, a color conversion layer CCMR, and the like.

- a method for peeling the substrate 101 there is no limitation on a method for peeling the substrate 101, and, for example, a method of irradiating the entire surface of the substrate 101 with a laser beam (Laser @ beam) as illustrated in FIG. Accordingly, the substrate 101 is separated, so that the protective layer 102 and the light-emitting diodes 110a and 110b can be exposed (FIG. 6B).

- a laser beam Laser @ beam

- an excimer laser As a laser, an excimer laser, a solid-state laser, or the like can be used.

- a diode-pumped solid-state laser DPSS

- DPSS diode-pumped solid-state laser

- a separation layer may be provided between the substrate 101 and the light emitting diodes 110a and 110b.

- the release layer can be formed using an organic material or an inorganic material.

- Examples of the organic material that can be used for the release layer include a polyimide resin, an acrylic resin, an epoxy resin, a polyamide resin, a polyimide amide resin, a siloxane resin, a benzocyclobutene-based resin, and a phenol resin.

- the release layer As an inorganic material that can be used for the release layer, tungsten, molybdenum, titanium, tantalum, niobium, nickel, cobalt, zirconium, zinc, ruthenium, rhodium, palladium, osmium, iridium, a metal containing an element selected from silicon, An alloy containing the element, a compound containing the element, or the like can be given.

- the crystal structure of the layer containing silicon may be any of amorphous, microcrystalline, and polycrystalline.

- various curable adhesives such as a photocurable adhesive such as an ultraviolet curable adhesive, a reaction curable adhesive, a thermosetting adhesive, and an anaerobic adhesive can be used. Further, an adhesive sheet or the like may be used.

- a substrate 191 provided with a coloring layer CFR, a color conversion layer CCMR, and the like may be attached to the substrate 101 with an adhesive layer 192. That is, the substrate 101 need not be peeled off.

- the thickness of the substrate 101 it is preferable to reduce the thickness of the substrate 101 by polishing or the like.

- the efficiency of extracting light emitted from the light emitting diode can be increased.

- the display device can be made thinner and lighter.

- the display device 100E first attaches a circuit substrate and an LED substrate like the display device 100A, and then polishes the substrate 101 included in the LED substrate, and applies a color to the polished surface of the substrate 101 by using an adhesive layer 192. It can be manufactured by bonding a substrate 191 provided with a layer CFR, a color conversion layer CCMR, and the like.

- FIG. 7 shows a cross-sectional view of the display device 100F.

- the display device of one embodiment of the present invention may be a display device provided with a touch sensor (also referred to as an input / output device or a touch panel).

- a touch sensor also referred to as an input / output device or a touch panel.

- the configuration of each display device described above can be applied to a touch panel.

- the display device 100F is an example in which a touch sensor is mounted on the display device 100A.

- sensing element also referred to as a sensor element

- Various sensors capable of detecting the proximity or contact of a detection target such as a finger or a stylus can be applied as the detection element.

- a sensor system various systems such as a capacitance system, a resistive film system, a surface acoustic wave system, an infrared system, an optical system, and a pressure-sensitive system can be used.

- a touch panel having a capacitive sensing element will be described as an example.

- Examples of the capacitance type include a surface type capacitance type and a projection type capacitance type.

- the projection type capacitance method there are a self capacitance method, a mutual capacitance method, and the like. It is preferable to use the mutual capacitance method because simultaneous multipoint detection becomes possible.

- the touch panel of one embodiment of the present invention has a structure in which a display device and a sensing element which are separately manufactured are bonded to each other, an electrode which forms a sensing element is provided on one or both of a substrate supporting the display element and a counter substrate, or the like.

- Various configurations can be applied.

- the laminated structure from the substrate 151 to the substrate 101 is the same as that of the display device 100A, and thus a detailed description is omitted.

- the conductive layer 187b is electrically connected to the FPC 1 through a conductive layer 189b, a conductive layer 190e, and a conductor 195. Signals and power are supplied to the display device 100F via the FPC 1.

- the conductive layer 187b can be formed using the same material and the same step as the conductive layer 187a.

- the conductive layer 189b can be formed using the same material and the same step as the conductive layer 189a.

- the conductive layer 190e can be formed using the same material and the same process as the conductive layers 190a to 190d.

- an anisotropic conductive film (ACF: Anisotropic Conductive Film) or an anisotropic conductive paste (ACP: Anisotropic Conductive Paste) can be used.

- ACF Anisotropic Conductive Film

- ACP Anisotropic Conductive Paste

- a touch sensor is provided on the substrate 171.

- the substrate 171 and the substrate 101 are attached to each other with an adhesive layer 179 with the surface on which the touch sensor is provided of the substrate 171 facing the substrate 101 side.

- An electrode 177 and an electrode 178 are provided on the substrate 101 side of the substrate 171.

- the electrode 177 and the electrode 178 are formed on the same plane.

- a material that transmits visible light is used for the electrodes 177 and 178.

- the insulating layer 173 is provided so as to cover the electrodes 177 and 178.

- the electrode 174 is electrically connected to two electrodes 178 provided so as to sandwich the electrode 177 through an opening provided in the insulating layer 173.

- a wiring 172 obtained by processing the same conductive layer as the electrodes 177 and 178 is connected to a conductive layer 175 obtained by processing the same conductive layer as the electrode 174.

- the conductive layer 175 is electrically connected to the FPC 2 via the connection body 176.

- the transistors that can be used in the display device of one embodiment of the present invention are not limited to the transistors 120a and 120b illustrated in FIGS.

- a structure example of a transistor which can be used for the display device of one embodiment of the present invention will be described with reference to FIGS.

- FIG. 8A is a top view of the transistor 300.

- FIG. 8B is a cross-sectional view taken along dashed-dotted line A1-A2 in FIG.

- FIG. 8B can be a cross-sectional view of the transistor 300 in the channel length direction.

- FIG. 8C is a cross-sectional view taken along dashed-dotted line A3-A4 in FIG.

- FIG. 8C can be a cross-sectional view of the transistor 300 in the channel width direction.

- FIG. 9A is a top view of the transistor 300A. Note that in FIG. 9A, some components are not illustrated for clarity.

- FIG. 9B is a cross-sectional view taken along dashed-dotted line A1-A2 in FIG.

- FIG. 9B can be a cross-sectional view of the transistor 300A in the channel length direction.

- FIG. 9C is a cross-sectional view taken along dashed-dotted line A3-A4 in FIG.

- FIG. 9C can be a cross-sectional view of the transistor 300A in the channel width direction.

- the transistor 300A illustrated in FIG. 9 is a modification example of the transistor 300 illustrated in FIG.

- the oxide layer 330c, the insulating layer 354, and the insulating layer 380 each have a single-layer structure in FIG. 8 and a stacked structure in FIG. Other configurations are the same between FIG. 8 and FIG.

- a transistor is an element having at least three terminals including a gate, a drain, and a source.

- a region where a channel is formed between a drain (a drain terminal, a drain region, or a drain electrode) and a source (a source terminal, a source region, or a source electrode) (hereinafter, also referred to as a channel formation region) is provided.

- current can flow between the source and the drain via the channel formation region.

- a channel formation region refers to a region through which current mainly flows.

- the functions of the source and the drain may be switched when transistors with different polarities are used or when the direction of current changes in circuit operation. For this reason, in this specification and the like, the terms of source and drain may be used interchangeably.

- the channel length refers to, for example, in a top view of a transistor, a region where a semiconductor (or a portion of a semiconductor in which current flows when the transistor is on) and a gate electrode overlap each other, or a source in a channel formation region. It refers to the distance between the (source region or source electrode) and the drain (drain region or drain electrode). Note that in one transistor, the channel length does not always have the same value in all regions. That is, the channel length of one transistor may not be determined to one value. Therefore, in this specification, the channel length is any one of the values, the maximum value, the minimum value, or the average value in the channel formation region.

- the channel width refers to, for example, in a top view of a transistor, a region where a semiconductor (or a portion of a semiconductor in which current flows when the transistor is on) and a gate electrode overlap each other, or a channel formation region in a channel length direction. Refers to the length of the channel formation region in the vertical direction with reference to Note that in one transistor, the channel width does not always have the same value in all regions. That is, the channel width of one transistor may not be determined to one value. Therefore, in this specification, a channel width is any one of values, a maximum value, a minimum value, or an average value in a channel formation region.

- a channel width in a region where a channel is actually formed corresponds to a channel width illustrated in a top view of the transistor.

- apparatus channel width a channel width illustrated in a top view of the transistor.

- the effective channel width becomes larger than the apparent channel width, and the effect may not be ignored.

- the proportion of a channel formation region formed on the side surface of the semiconductor may be large. In that case, the effective channel width is larger than the apparent channel width.

- a simple term "channel width” may refer to an apparent channel width.

- a simple term "channel width” may refer to an effective channel width. The values of the channel length, the channel width, the effective channel width, the apparent channel width, and the like can be determined by analyzing a cross-sectional TEM image or the like.

- the transistor 300 includes a conductive layer 305 which is provided over a substrate (not illustrated) with an insulating layer 314 interposed therebetween and is embedded in the insulating layer 316 and an insulating layer which is provided over the insulating layer 316 and the conductive layer 305.

- the layer 342b part of the top surface of the insulating layer 324, the side surface of the oxide layer 330a, the side surface of the oxide layer 330b, the side surface and the top surface of the conductive layer 342a, and the side surface and the like of the conductive layer 342b. Having an insulating layer 354 disposed in contact with the upper surface.

- An insulating layer 380, an insulating layer 374, and an insulating layer 381 each serving as an interlayer film are provided over the transistor 300.

- the transistor 300 is electrically connected to the conductive layer 340 functioning as a plug (the conductive layers 340a and 340b).

- the insulating layer 341 (the insulating layer 341a and the insulating layer 341b) is provided in contact with a side surface of the conductive layer 340.

- the oxide layer 330 includes an oxide layer 330a provided over the insulating layer 324, an oxide layer 330b provided over the oxide layer 330a, and an oxide layer 330b provided at least partially over the oxide layer 330b.

- An oxide layer 330c which is in contact with the upper surface of the layer 330b. With the oxide layer 330a provided below the oxide layer 330b, diffusion of impurities from a structure formed below the oxide layer 330a to the oxide layer 330b can be suppressed. In addition, when the oxide layer 330c is provided over the oxide layer 330b, diffusion of impurities from a structure formed above the oxide layer 330c to the oxide layer 330b can be suppressed.

- the transistor 300 has an example in which the oxide layer 330 has a three-layer structure of the oxide layer 330a, the oxide layer 330b, and the oxide layer 330c, the present invention is not limited to this.

- the oxide layer 330 is, for example, a single layer of the oxide layer 330b, a two-layer structure of the oxide layer 330a and the oxide layer 330b, a two-layer structure of the oxide layer 330b and the oxide layer 330c, or a stack of four or more layers. It may be a structure. Further, each of the oxide layer 330a, the oxide layer 330b, and the oxide layer 330c may have a stacked structure.