WO2019176221A1 - Dispositif de protection de faisceau électrique et structure de cheminement de faisceau électrique utilisant celui-ci - Google Patents

Dispositif de protection de faisceau électrique et structure de cheminement de faisceau électrique utilisant celui-ci Download PDFInfo

- Publication number

- WO2019176221A1 WO2019176221A1 PCT/JP2018/047233 JP2018047233W WO2019176221A1 WO 2019176221 A1 WO2019176221 A1 WO 2019176221A1 JP 2018047233 W JP2018047233 W JP 2018047233W WO 2019176221 A1 WO2019176221 A1 WO 2019176221A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- branch

- wire

- wire insertion

- wire harness

- portions

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R16/00—Electric or fluid circuits specially adapted for vehicles and not otherwise provided for; Arrangement of elements of electric or fluid circuits specially adapted for vehicles and not otherwise provided for

- B60R16/02—Electric or fluid circuits specially adapted for vehicles and not otherwise provided for; Arrangement of elements of electric or fluid circuits specially adapted for vehicles and not otherwise provided for electric constitutive elements

- B60R16/0207—Wire harnesses

- B60R16/0215—Protecting, fastening and routing means therefor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L3/00—Supports for pipes, cables or protective tubing, e.g. hangers, holders, clamps, cleats, clips, brackets

- F16L3/08—Supports for pipes, cables or protective tubing, e.g. hangers, holders, clamps, cleats, clips, brackets substantially surrounding the pipe, cable or protective tubing

- F16L3/12—Supports for pipes, cables or protective tubing, e.g. hangers, holders, clamps, cleats, clips, brackets substantially surrounding the pipe, cable or protective tubing comprising a member substantially surrounding the pipe, cable or protective tubing

- F16L3/123—Supports for pipes, cables or protective tubing, e.g. hangers, holders, clamps, cleats, clips, brackets substantially surrounding the pipe, cable or protective tubing comprising a member substantially surrounding the pipe, cable or protective tubing and extending along the attachment surface

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L57/00—Protection of pipes or objects of similar shape against external or internal damage or wear

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G3/00—Installations of electric cables or lines or protective tubing therefor in or on buildings, equivalent structures or vehicles

- H02G3/02—Details

- H02G3/04—Protective tubing or conduits, e.g. cable ladders or cable troughs

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G3/00—Installations of electric cables or lines or protective tubing therefor in or on buildings, equivalent structures or vehicles

- H02G3/02—Details

- H02G3/04—Protective tubing or conduits, e.g. cable ladders or cable troughs

- H02G3/0437—Channels

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G3/00—Installations of electric cables or lines or protective tubing therefor in or on buildings, equivalent structures or vehicles

- H02G3/02—Details

- H02G3/04—Protective tubing or conduits, e.g. cable ladders or cable troughs

- H02G3/0406—Details thereof

- H02G3/0418—Covers or lids; Their fastenings

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G3/00—Installations of electric cables or lines or protective tubing therefor in or on buildings, equivalent structures or vehicles

- H02G3/30—Installations of cables or lines on walls, floors or ceilings

- H02G3/32—Installations of cables or lines on walls, floors or ceilings using mounting clamps

Definitions

- the present invention relates to a wire harness protector for inserting and holding a large number of electric wires routed in an automobile or the like, and a wire harness routing structure using the protector.

- such a wire harness protector includes, as described in Japanese Utility Model Publication No. 6-70415 (Patent Document 1) and the like, a bowl-shaped protector body, a lid body that covers the upper opening of the protector body, It is comprised including. And after inserting a large number of wires into the protector body, the cover body is fixed to the protector body via a locking mechanism that protrudes outward from the side wall of the protector body, so that the many wires are held in the housed state. It can be done.

- the present invention has been made in the background of the above-mentioned circumstances, and the solution is to insert and hold the wire harness including the branch portion in a compact state while suppressing the protruding height from the fixed object.

- An object of the present invention is to provide a wire harness protector having a novel structure, and to provide a wiring harness wiring structure using the protector.

- the present invention relating to a protector for a wire harness has a plurality of wire insertion portions in which a plurality of wires constituting the wire harness are subdivided and accommodated, and the plurality of wire insertion portions are arranged in parallel, At least one side in the parallel direction of the wire insertion portion is a branch direction of the wire, and each of the wire insertion portions excluding the wire insertion portion farthest from the branch direction has a longitudinal direction orthogonal to the parallel direction.

- a branch wire insertion window that extends in the longitudinal direction and opens on both side surfaces and into which a branch wire constituted by a part of the wire can be inserted is provided in the middle portion, and is furthest from the branch direction.

- the above-described branch wire insertion window is provided at least on the side surface on the branch direction side.

- the present invention relating to a wiring harness wiring structure is a wiring harness wiring structure using a wire harness protector, wherein the wire harness protector includes the wire according to any one of the first to third aspects.

- the harness protector uses the harness protector, the plurality of electric wires constituting the wire harness are subdivided and held in the plurality of electric wire insertion portions, while the electric wire insertion portion distal to the branch direction has the branch direction.

- the branch wire is pulled out to the side by passing through the branch wire insertion window on the side, while in the other wire insertion portion, adjacent to the branch wire insertion window on the branch direction side and the branch direction side

- the branched electric wires are drawn out sideways through the branched electric wire insertion windows on both side surfaces of the arranged electric wire insertion portion.

- the height of the protector for the wire harness can be reduced. Further, the wire harness including the branch portion can be inserted and held in a compact state. Moreover, it is possible to advantageously realize a reduction in the height of the wire harness protector including the branching portion.

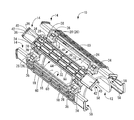

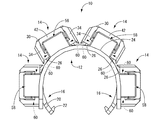

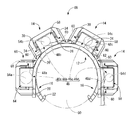

- the front view of FIG. The perspective view which shows the base member of FIG.

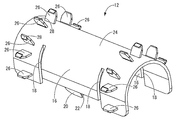

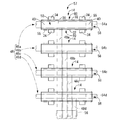

- the perspective view which shows one insertion part structural member of FIG. The top view which shows the state before the attachment to a base member which accommodated the electric wire in the some insertion part structural member, and provided the branch electric wire.

- FIG. 8 It is a top view which shows the state before the attachment to a base member in case a branch direction is both directions, Comprising: The figure corresponded in FIG. It is a front view which shows the wiring structure of the wire harness in case the branch direction shown in FIG. 8 is both directions, Comprising: The figure equivalent to FIG. The perspective view which shows the insertion part structural member of a structure different from FIG. It is a front view which shows the wiring structure of the wire harness using the protector for wire harnesses which has the insertion part structural member shown in FIG. 10, Comprising: The figure equivalent to FIG.

- the protector for wire harnesses has a some electric wire penetration part in which the some electric wire which comprises a wire harness is divided and accommodated, and the said some electric wire penetration part is arrange

- at least one side of the plurality of electric wire insertion portions in the parallel direction is a branch direction of the electric wires, and each of the electric wire insertion portions excluding the electric wire insertion portion farthest from the branch direction has the parallel direction.

- a branch wire insertion window that extends in the longitudinal direction and opens on both side surfaces and into which a branch wire constituted by a part of the wire can be inserted is provided, In the wire insertion portion farthest from the branch direction, the branch wire insertion window is provided at least on the side surface on the branch direction side.

- the plurality of electric wire insertion portions that are accommodated by dividing the plurality of electric wires are arranged in parallel, even when the number of electric wires constituting the wire harness increases, the electric wires are divided into the plurality of electric wire insertion portions. Therefore, the height of the protector for the wire harness can be reduced.

- at least one side in the parallel direction of the plurality of wire insertion portions is a branching direction of the wires, and each wire insertion portion excluding the most distal wire insertion portion from the branching direction has a longitudinal direction in the middle portion of the longitudinal direction.

- Branching wire insertion windows that open to both sides and have a branching wire insertion window that is at the most distal from the branching direction and has at least a branching wire insertion window on the side surface on the branching direction side.

- the branch wire can be pulled out to the side by inserting the branch wire insertion window on the branch direction side in the wire insertion portion farthest in the branch direction.

- the branch wire insertion windows on both sides of the branch wire insertion window on the branch direction side and the wire insertion part arranged adjacent to the branch direction side are inserted and the branch wires are pulled out to the side. Can do.

- the wire harness protector without providing an additional part for inserting and holding the branching portion in the wire harness protector, it is possible to realize stable holding of the branching wire by inserting and holding the branching wire across the plurality of wire inserting portions.

- the containing wire harness can be inserted and held in a compact state.

- each wire insertion portion is provided extending in the longitudinal direction, the position where the wire is branched for each wire insertion portion can be varied in the longitudinal direction.

- each of the electric wire insertion portions has the branch electric wire insertion windows on both side surfaces.

- the both sides of the plurality of electric wire insertion portions in the parallel direction can be the branch direction of the electric wires.

- each of the electric wire insertion portions is provided with the branched electric wire insertion windows on both side surfaces so that both sides in the parallel direction of the plurality of electric wire insertion portions are in the branching direction.

- a base member fixed to an object to be fixed and a gap on the base member are separated.

- An insertion portion configured to include a longitudinal upper wall portion opposed to each other and a pair of support legs projecting from both side edge portions of both side portions in the longitudinal direction of the upper wall portion toward the base member.

- a plurality of constituent members, and the pair of supporting leg portions of each of the insertion portion constituent members are detachably fixed to a plurality of fixing portions provided on the base member, respectively,

- the electric wire insertion portion is configured, and the branch electric wire insertion window is defined on the side surface of each electric wire insertion portion by the base member, the upper wall portion, and the support leg portions on both sides in the longitudinal direction. It is intended.

- each wire insertion portion can be configured by detachably attaching the insertion portion constituting member to the base member fixed to the fixed object on the vehicle side. Therefore, by arranging multiple wires on the base member in order from the wire insertion part on the side away from the branching direction, it is possible to improve workability and to easily and stably route the branching part. Can be.

- the insertion portion constituting member is constituted by the upper wall portion and a pair of supporting leg portions that protrude toward the base member at both side portions thereof, the electric wire that is inserted and arranged in each electric wire insertion portion is projected upward. Is suppressed. Therefore, the height of the wire harness protector can be more reliably reduced.

- a first aspect of the present invention relating to a wiring harness wiring structure is a wiring harness wiring structure using a wire harness protector, wherein the wire harness protector includes any one of the first to third elements.

- the wire harness protector according to the aspect is used, and the plurality of electric wires constituting the wire harness are subdivided and inserted and held in the plurality of electric wire insertion portions, while the electric wire insertion portion farthest in the branch direction In the branch direction side, the branch wire is pulled out to the side through the branch wire insertion window, while in the other wire insertion portion, the branch wire insertion window on the branch direction side and the branch

- the branched electric wires are drawn out sideways through the branched electric wire insertion windows on both side surfaces of the electric wire insertion portion arranged adjacent to the branch direction side.

- the wire harness protector according to the first to third aspects is used, and a plurality of electric wire insertion portions for accommodating a plurality of electric wires divided and accommodated are arranged in parallel. Therefore, even when the number of electric wires constituting the wire harness increases, the electric wires can be accommodated and held in a plurality of electric wire insertion portions, so that the height of the wire harness protector can be reduced.

- at least one side in the parallel direction of the plurality of wire insertion portions is a branching direction of the wires, and each wire insertion portion excluding the most distal wire insertion portion from the branching direction has a longitudinal direction in the middle portion of the longitudinal direction.

- Branching wire insertion windows that open to both sides and have a branching wire insertion window that is at the most distal from the branching direction and has at least a branching wire insertion window on the side surface on the branching direction side.

- the branch wire can be pulled out to the side by inserting the branch wire insertion window on the branch direction side in the wire insertion portion farthest in the branch direction.

- the branch wire insertion windows on both sides of the branch wire insertion window on the branch direction side and the wire insertion part arranged adjacent to the branch direction side are inserted and the branch wires are pulled out to the side. Can do.

- the wire harness protector without providing an additional part for inserting and holding the branching portion in the wire harness protector, it is possible to realize stable holding of the branching wire by inserting and holding the branching wire across the plurality of wire inserting portions.

- the containing wire harness can be inserted and held in a compact state.

- each wire insertion portion is provided extending in the longitudinal direction, the position where the wire is branched for each wire insertion portion can be varied in the longitudinal direction.

- the second aspect of the present invention related to the wiring structure of the wire harness is the wiring structure of the wire harness described in the first aspect, wherein the branch wire pull-out position in the plurality of wire insertion portions is the longitudinal direction. Are different from each other.

- the lead-out positions of the branch wires in the plurality of wire insertion portions are different from each other in the longitudinal direction. Therefore, since it is prevented advantageously that the electric wire branched from each electric wire insertion part overlaps, the height of the branched electric wire can be made still lower.

- the subdivided wire harness that passes through each of the electric wire insertion portions is provided in the wiring structure of the wire harness described in the first or second aspect.

- the cross-sectional area is gradually increased toward the branch direction.

- the cross-sectional area of the wire harness that passes through the wire insertion portion is gradually increased in the branching direction. That is, the electric wire inserted and arranged in the electric wire insertion portion is thinnest in the electric wire insertion portion closest to the branching direction and gradually becomes thicker toward the farthest electric wire insertion portion. Thereby, the branched electric wire does not get over the electric wire thicker than itself, the cross-sectional area of the wire harness that passes through each electric wire insertion portion can be leveled, and the low profile can be realized advantageously.

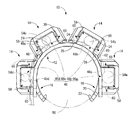

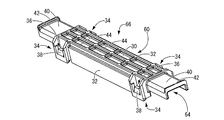

- the wire harness protector 10 includes a base member 12 and a plurality (four in the present embodiment) of insertion portion constituting members 14.

- “upper” means the upper side in FIGS. 1 to 4 and “lower” means the lower side in FIGS. 1 to 4

- “front” means the lower right side in FIG. 1 refers to the upper left diagonal direction

- the longitudinal direction refers to the front-rear direction in FIG.

- the base member 12 has a substantially inverted U-shaped cross section and has a substantially bowl shape that opens downward and extends in the longitudinal direction.

- PP polypropylene

- PA polyamide

- fixed pieces 16 are formed at both sides in the width direction (left and right direction in FIG. 2) in the center portion in the longitudinal direction of the base member 12.

- the fixing piece 16 has a cantilever shape in which both sides in the longitudinal direction are separated from the base member 12 by the notches 18 so that only the base end side is connected to the base member 12 and protrudes downward.

- a substantially rectangular flat plate-like engaging portion 20 that protrudes obliquely inwardly downward is provided at the longitudinal central portion of the protruding end portion of the fixed piece 16.

- An engaging projection 22 is formed which protrudes inward and extends in a substantially trapezoidal cross-sectional shape over substantially the entire length in the longitudinal direction.

- a plurality of pairs (four pairs in this embodiment) of fixing portions 26 and 26 are spaced apart from each other in the circumferential direction of the outer peripheral surface 24 and the outer peripheral surface. It protrudes outward so as to stand upright with respect to 24.

- the fixing portions 26 and 26 are formed so as to be spaced apart from each other in the circumferential direction of the outer peripheral surface 24 and have a substantially rectangular flat plate shape.

- Engaging protrusions 28 are provided that protrude in the longitudinal direction and extend in the longitudinal direction with a substantially triangular cross-sectional shape.

- the protruding end surface of the engagement protrusion 28 is a tapered surface that approaches the fixed portion 26 as the distance from the outer peripheral surface 24 increases.

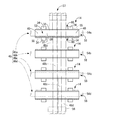

- the insertion portion constituting member 14 has a substantially inverted U-shaped cross-sectional shape and has a substantially bowl shape that opens downward and extends in the longitudinal direction.

- PP polypropylene

- PA polyamide

- the insertion portion constituting member 14 includes an upper wall portion 30 that extends in a strip shape in the longitudinal direction, and a side wall portion that extends downward from both side edges in the width direction of the upper wall portion 30 over substantially the entire length in the longitudinal direction.

- the support leg portion 34 has a substantially frame shape with a base end portion connected to the side wall portion 32, and the upper end edge portion of the engagement hole 36 that opens in the vertical direction faces obliquely upward and inward.

- An engaging projection 38 having a substantially rectangular flat plate shape is provided.

- the insertion portion constituting member 14 has a binding fixing portion 40 that extends further outward from both longitudinal portions of the upper wall portion 30 provided with the pair of support leg portions 34, 34.

- a bundling member retaining protrusion 42 is formed on the extending end of the bundling fixing portion 40 so as to project over substantially the entire length in the width direction.

- the upper wall portion 30 is thick between the portions where the support leg portions 34 are provided, and is formed with a hollow hole 44 that opens upward in a substantially rectangular shape in plan view.

- the synthetic resin material is advantageously saved while increasing the strength of the portion where the portion 34 is provided.

- the wire harness 46 includes wire harnesses 46a to 46d composed of a plurality of subdivided electric wires.

- the wire harnesses 46a to 46d are connected to various electrical devices and the like through connectors and the like at each end.

- FIGS. 5 to 6 the wire harnesses 46a to 46d, the branch wires 48a to 48d branched from the wire harnesses 46a to 46d, the lean force 50 to be fixed, the binding tape 55, Reference numeral 56 denotes an imaginary line.

- a plurality (four in this embodiment) of the insertion member constituting members 14 are arranged so that the horizontal direction is the longitudinal direction and the vertical direction is the parallel direction. It arrange

- the binding wires 55 are used to position and hold the trunks 54a to 54d of the wire harnesses 46a to 46d with respect to the binding fixing portions 40 of the plurality of insertion member constituting members 14, and the branch wires 48a to 48d are The extending end portion is bound and fixed using a binding tape 56.

- the intermediate member 57 in which the plurality of insertion portion constituting members 14 of the present embodiment are attached to the wire harness 46 is completed.

- the trunk lines 54a to 54d of the wire harnesses 46a to 46d can be easily positioned and held at both ends in the longitudinal direction of the wire insertion portion 58, and the binding fixing portion 40 is formed at the central portion in the longitudinal direction of the wire insertion portion 58. Therefore, the branch wire insertion window 60 can be automatically provided.

- an arbitrary binding member such as a binding band can be used as the binding member.

- the intermediate member 57 is turned upside down and the upper wall portion 30 is turned up, and then the plurality of insertion portion constituting members 14 constituting the intermediate member 57 are respectively attached to the base member 12, whereby the wire of the present embodiment.

- the wiring structure of the wire harness 46 using the harness protector 10 is completed. More specifically, the corresponding pair of fixing portions 26 and 26 provided in the base member 12 are inserted into the engagement holes 36 provided in the pair of support legs 34 and 34 of each insertion portion constituting member 14. . Accordingly, the engagement protrusion 28 of the fixing portion 26 elastically deforms the engagement protrusion 38 provided on the upper edge portion of the engagement hole 36 outwardly, thereby allowing further insertion.

- the engagement protrusion 38 of the support leg 34 is elastically restored, whereby the fixing portion 26 of the base member 12 is engaged with the engagement hole 36 of the support leg 34 and the insertion member constituting member is inserted. 14 is fixed to the base member 12. Such fixation can be released using an instrument such as a screwdriver and is detachable.

- the fixing of the insertion portion constituting member 14 and the base member 12 is not limited to the above engagement structure, and any known engagement structure such as a boss and a fitting hole can be adopted.

- the versatility of the protector for the wire harness can be provided by providing a plurality of fixing portions on the base member side at an arbitrary pitch, and providing the necessary number of insertion portion constituent members at arbitrary locations as required, such as the amount of electric wires. It is also possible to improve.

- the upper wall portion 30 of the insertion portion constituting member 14 is disposed oppositely on the outer peripheral surface 24 of the base member 12 with a gap between the upper wall portion 30 and the upper wall portion 30.

- a pair of support legs 34, 34 protrudes toward the base member 12.

- An electric wire insertion portion 58 is configured by a region surrounded by the upper wall portion 30, the pair of support legs 34, 34, and the outer peripheral surface 24 of the base member 12.

- a branch wire insertion window 60 is defined by the base member 12, the upper wall portion 30, and the pair of longitudinal support legs 34, 34. Has been.

- each electric wire insertion portion 58 includes a branched electric wire that is formed by a part of the electric wire that extends in the longitudinal direction and opens on both side surfaces to constitute the wire harness 46 in the intermediate portion in the longitudinal direction orthogonal to the parallel direction.

- a branch wire insertion window 60 into which 48a to 48d can be inserted is provided (see FIGS. 4 to 6). Accordingly, each of the electric wire insertion portions 58 has the branch electric wire insertion windows 60 on both side surfaces, and both sides of the plurality of electric wire insertion portions 58 in the parallel direction can be the branch direction of the branch electric wires 48a to 48d. is there.

- the relationship between the height dimension: h and the width dimension (longitudinal direction): w (see FIG. 1) of the branch wire insertion window 60 is such that the width dimension: w is higher than the height dimension: h.

- the width dimension: w is at least twice the height dimension: h, more preferably the width dimension: w is at least three times the height dimension: h. desirable.

- the width dimension w of the branch wire insertion window 60 is about five times the height dimension h.

- the wire insertion portion 58 is configured by an area surrounded by the upper wall portion 30, the pair of support legs 34, 34, and the outer peripheral surface 24 of the base member 12.

- the wire harnesses 46a to 46d composed of a plurality of subdivided electric wires constituting the wire are inserted and held in a plurality of wire insertion portions 58 arranged in parallel. Therefore, since the upward projection of the wire harnesses 46a to 46d inserted and arranged in the respective wire insertion portions 58 is suppressed, the wire harness protector can be reliably reduced in height.

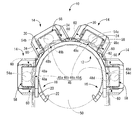

- one side of the plurality of electric wire insertion portions 58 in the parallel direction (clockwise right side in FIG.

- the branch wire 48a is drawn sideways through the branch wire insertion window 60 on the branch direction side (clockwise right side in FIG. 6).

- the branch wire insertion window 60 is inserted through the branch wire insertion window 60 on both sides of the branch wire insertion window 60 on the branch direction side and the wire insertion portion 58 arranged adjacent to the branch direction side. d is pulled out to the side.

- the lead-out positions of the branch wires 48a to 48d in the plurality of wire insertion portions 58 are different from each other in the longitudinal direction (left-right direction in FIG. 5). This advantageously prevents the branch wires 48a to 48d branched from the wire insertion portions 58 from overlapping each other, thereby further reducing the height of the branch wires 48a to 48d.

- the cross-sectional areas Sa to d of the wire harnesses 46a to 46d constituting the wire harness 46 that passes through the wire insertion portion 58 are gradually increased toward the branch direction (clockwise left side in FIG. 6) (see FIG. 6). 6, Sa> Sb> Sc> Sd).

- the trunk lines 54a to 54d of the wire harnesses 46a to 46d that need to get over more branch wires 48a to 48c have a smaller area

- the wire harnesses 46a to 46d that pass through the respective wire insertion portions 58 are used. Since the cross-sectional areas of the main lines 54a to 54d and the branch wires 48a to 48c can be leveled, a reduction in height can be realized advantageously.

- the wire harness protector 10 of the present embodiment in which the wire harness 46 is thus wired is fixed to the lean force 50 that is a fixing target. Yes. More specifically, after the longitudinal direction of the base member 12 is arranged along the longitudinal direction of the lean force 50 with respect to the outer peripheral surface 62 of the tubular reinforcement 50 extending in the longitudinal direction, The base member 12 is pushed toward the lean force 50. As a result, the pair of fixed pieces 16 and 16 of the base member 12 are elastically deformed in a direction away from each other to allow further insertion, and the engagement protrusions 22 of the pair of fixed pieces 16 and 16 become the outer peripheral surface of the lean force 50.

- the wire harness protector 10 of the present embodiment can be stably held with respect to the lean force 50.

- the wire harness protector 10 can be easily attached to a non-flat fixed object such as the lean force 50 by matching the shape of the base member 12 to the shape of the fixed object.

- the cylindrical reinforcement 50 has been described as an example of the fixing target.

- the fixing target may be a body frame or the like, and the shape is not limited to the cylindrical shape, but may be any shape. Of course, it can be adopted.

- the wire harness 46 includes the wire harnesses 46a to 46d composed of a plurality of divided electric wires.

- a plurality of wire insertion portions 58 in which the wire harnesses 46a to 46d are accommodated are arranged in parallel.

- the branch wires 48a to 48d of the wire harnesses 46a to 46d composed of a plurality of subdivided wires constituting the wire harness 46 are branched.

- the direction was set to one side of the plurality of electric wire insertion portions 58 in the parallel direction (the clockwise right side in FIG. 6).

- the branching direction of the branch wires 48a to 48d is the parallel direction of the plurality of wire insertion portions 58.

- the other side in FIG.

- each of the electric wire insertion portions 58 is inserted on both side surfaces so that both sides of the plurality of electric wire insertion portions 58 in the parallel direction are branched. Since the window 60 is provided, the directivity of the wire harness protector 10 is reduced and the versatility is improved.

- each of the electric wire insertion portions 58 is provided with the branch electric wire insertion windows 60 on both side surfaces.

- the insertion portion constituting member 66 constituting the wire insertion portion 64 that is the most distal from the branch direction (clockwise right direction in FIG. 11) is at least in the branch direction side (FIG. 11).

- the branch electric wire insertion window 60 should just be provided in the side surface of the inside (clockwise right side). That is, as shown in FIG. 11, the branch wire insertion window 60 may not be provided on the side surface opposite to the branch direction side (clockwise right side in FIG. 11).

- the wire insertion portions 58 located on both sides of the central portion become the most distal wire insertion portions 58 from the branch direction.

- the branch wire insertion window 60 may be provided only on the side surface on the branch direction side.

- the wire insertion portion 58 is configured by a region surrounded by the upper wall portion 30, the pair of support legs 34, 34, and the outer peripheral surface 24 of the base member 12. It may be formed by an upper wall portion and a pair of support leg portions and open upward. This makes it possible to assemble the wire harness 46 from above after the wire harness protector is configured.

- the wire harness protector 10 has the base member 12, but may not be provided.

- the wire harness protector for the wire harness is formed by configuring each of the plurality of wire insertion portions 58 with a cylindrical body in which branch wire insertion windows 60 are formed on the side surfaces and connecting the wire insertion portions 58 in parallel with an arbitrary connecting member. May be configured.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Details Of Indoor Wiring (AREA)

- Protection Of Pipes Against Damage, Friction, And Corrosion (AREA)

- Supports For Pipes And Cables (AREA)

Abstract

L'invention concerne un dispositif de protection de faisceau électrique comportant une pluralité de parties de passage de fils électriques (58) dans lesquelles une pluralité de fils électriques constituant un faisceau électrique (46) sont logés en petits groupes. La pluralité de parties de passage de fils électriques (58) sont disposées en parallèle. Au moins un côté de la direction parallèle de la pluralité de parties de passage de fils électriques (58) est appelé direction de dérivation des fils électriques. Chaque partie de passage de fils électriques (58), à l'exception de la partie (58) située à la position la plus éloignée de la direction de dérivation, est munie de fenêtres de passage de fils électriques de dérivation (60) qui s'étendent dans la direction longitudinale et s'ouvrent sur les deux surfaces latérales, et à travers lesquelles des fils électriques de dérivation (48b-48d) constitués de quelques fils électriques peuvent être passés. La partie de passage de fils électriques (58) située à la position la plus éloignée de la direction de dérivation est munie d'une fenêtre de passage de fils électriques de dérivation (60) au moins dans une surface latérale sur le côté direction de dérivation. L'invention concerne également une structure de cheminement de faisceau électrique utilisant le dispositif de protection de faisceau électrique.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201880091221.0A CN111886765B (zh) | 2018-03-16 | 2018-12-21 | 线束用保护器及使用其的线束的布线结构 |

| US16/976,111 US11485300B2 (en) | 2018-03-16 | 2018-12-21 | Wire harness protector and routing structure of wire harness using wire harness protector |

| DE112018007293.2T DE112018007293T5 (de) | 2018-03-16 | 2018-12-21 | Kabelbaumschutzvorrichtung und Kabelbaumverlegestruktur unter Verwendung derselben |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018048929A JP6691670B2 (ja) | 2018-03-16 | 2018-03-16 | ワイヤハーネス用プロテクタおよびそれを用いたワイヤハーネスの配索構造 |

| JP2018-048929 | 2018-03-16 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019176221A1 true WO2019176221A1 (fr) | 2019-09-19 |

Family

ID=67907734

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/047233 WO2019176221A1 (fr) | 2018-03-16 | 2018-12-21 | Dispositif de protection de faisceau électrique et structure de cheminement de faisceau électrique utilisant celui-ci |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US11485300B2 (fr) |

| JP (1) | JP6691670B2 (fr) |

| CN (1) | CN111886765B (fr) |

| DE (1) | DE112018007293T5 (fr) |

| WO (1) | WO2019176221A1 (fr) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6870533B2 (ja) * | 2017-08-23 | 2021-05-12 | 株式会社オートネットワーク技術研究所 | 電気部品付ワイヤーハーネスおよび電気部品付ワイヤーハーネスの組付構造 |

| JP6943737B2 (ja) * | 2017-11-21 | 2021-10-06 | 古河電気工業株式会社 | 電線用外装体及び外装体付きワイヤーハーネス |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0321143Y2 (fr) * | 1984-07-30 | 1991-05-08 | ||

| JP2003054330A (ja) * | 2001-06-06 | 2003-02-26 | Furukawa Electric Co Ltd:The | ワイヤハーネス組付け型車両部品 |

| JP2015046991A (ja) * | 2013-08-28 | 2015-03-12 | 株式会社オートネットワーク技術研究所 | プロテクタ |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6052105B2 (ja) | 1982-12-28 | 1985-11-18 | 住友特殊金属株式会社 | 酸化物の熱間静水圧プレス方法 |

| JPH0670415U (ja) | 1993-03-04 | 1994-09-30 | 矢崎総業株式会社 | 噛み込み防止構造を有する電線収容プロテクタ |

| US6844496B2 (en) | 2000-11-02 | 2005-01-18 | The Furukawa Electric Co., Ltd. | Wire harness mounting method, wire harness mounting portion structure, wire harness mounting type vehicle component, wire harness mounting type vehicle component module, and method of assembling and inspecting wire harness |

| JP3752148B2 (ja) * | 2000-12-11 | 2006-03-08 | 矢崎総業株式会社 | ハーネスプロテクタ |

| JP3695354B2 (ja) | 2001-06-08 | 2005-09-14 | 住友電装株式会社 | ワイヤハーネス用のクランプ |

| JP4124104B2 (ja) * | 2003-11-14 | 2008-07-23 | 住友電装株式会社 | プロテクタ |

| JP2007076576A (ja) * | 2005-09-16 | 2007-03-29 | Sumitomo Wiring Syst Ltd | ワイヤハーネスの配索構造 |

| US7939759B2 (en) * | 2008-04-22 | 2011-05-10 | Henry Stephen K | Cable protector with removable dividers |

| GB0915552D0 (en) * | 2009-09-07 | 2009-10-07 | Icore Internat Ltd | Cable-routing |

| JP5657959B2 (ja) * | 2010-09-02 | 2015-01-21 | 矢崎総業株式会社 | ワイヤハーネスの取付構造 |

| JP5768379B2 (ja) * | 2011-01-19 | 2015-08-26 | 住友電装株式会社 | ワイヤハーネス用のプロテクタ |

| JP5915250B2 (ja) | 2012-02-23 | 2016-05-11 | 住友電装株式会社 | ワイヤハーネスの配索構造および該配索構造の形成方法 |

| JP6286141B2 (ja) * | 2013-05-29 | 2018-02-28 | 矢崎総業株式会社 | バスバモジュール及び電源装置 |

| JP6947100B2 (ja) * | 2018-03-28 | 2021-10-13 | 株式会社オートネットワーク技術研究所 | 導電路 |

| JP6607282B1 (ja) * | 2018-05-30 | 2019-11-20 | 株式会社オートネットワーク技術研究所 | 配線部材 |

-

2018

- 2018-03-16 JP JP2018048929A patent/JP6691670B2/ja active Active

- 2018-12-21 US US16/976,111 patent/US11485300B2/en active Active

- 2018-12-21 DE DE112018007293.2T patent/DE112018007293T5/de active Pending

- 2018-12-21 CN CN201880091221.0A patent/CN111886765B/zh active Active

- 2018-12-21 WO PCT/JP2018/047233 patent/WO2019176221A1/fr active Application Filing

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0321143Y2 (fr) * | 1984-07-30 | 1991-05-08 | ||

| JP2003054330A (ja) * | 2001-06-06 | 2003-02-26 | Furukawa Electric Co Ltd:The | ワイヤハーネス組付け型車両部品 |

| JP2015046991A (ja) * | 2013-08-28 | 2015-03-12 | 株式会社オートネットワーク技術研究所 | プロテクタ |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111886765B (zh) | 2021-10-29 |

| CN111886765A (zh) | 2020-11-03 |

| US20200406839A1 (en) | 2020-12-31 |

| US11485300B2 (en) | 2022-11-01 |

| JP6691670B2 (ja) | 2020-05-13 |

| JP2019161965A (ja) | 2019-09-19 |

| DE112018007293T5 (de) | 2021-01-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7507905B2 (en) | Electrical junction box | |

| US8124887B2 (en) | Protector | |

| CN102934305A (zh) | 线束和装配该线束的方法 | |

| WO2012056747A1 (fr) | Collier de serrage à bande | |

| KR101302943B1 (ko) | 커넥터 지지 도구, 배선 도구 및 배선 하네스 | |

| CN103208760A (zh) | 线束和布线器具 | |

| JP2007099007A (ja) | ワイヤハーネスの配索構造 | |

| JP6857338B2 (ja) | ワイヤハーネスプロテクタ及びハーネスアセンブリ | |

| WO2019176221A1 (fr) | Dispositif de protection de faisceau électrique et structure de cheminement de faisceau électrique utilisant celui-ci | |

| JP4597564B2 (ja) | クリップ構造及び線条体の固定方法 | |

| JP2019161965A5 (fr) | ||

| US12097810B2 (en) | Wiring harness unit and wiring harness mounting structure | |

| JP2020115743A (ja) | ワイヤハーネス用プロテクタおよびそれを用いたワイヤハーネスの配索構造 | |

| JP2020115743A5 (fr) | ||

| JP2015033314A (ja) | 結束バンドの取付構造 | |

| WO2016117366A1 (fr) | Dispositif de protection de faisceau | |

| JP5979036B2 (ja) | スライドシート用のワイヤハーネス配索装置 | |

| JP2017135813A (ja) | プロテクタ付ワイヤハーネス | |

| JP6702912B2 (ja) | 電線の保護ケース、及び、スライドシート | |

| KR200466124Y1 (ko) | 다용도 결합형 클립 | |

| US12107401B2 (en) | Wiring harness module and wiring harness routing device | |

| WO2017090597A1 (fr) | Boîte de jonction électrique | |

| JP6014469B2 (ja) | ワイヤハーネスの配索構造 | |

| JP5920663B2 (ja) | 電気接続箱 | |

| KR101959912B1 (ko) | 배터리팩 장착형 와이어링 프로텍터 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18909848 Country of ref document: EP Kind code of ref document: A1 |

|

| DPE1 | Request for preliminary examination filed after expiration of 19th month from priority date (pct application filed from 20040101) | ||

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 18909848 Country of ref document: EP Kind code of ref document: A1 |