WO2019123956A1 - 信号処理装置及び信号処理方法 - Google Patents

信号処理装置及び信号処理方法 Download PDFInfo

- Publication number

- WO2019123956A1 WO2019123956A1 PCT/JP2018/042940 JP2018042940W WO2019123956A1 WO 2019123956 A1 WO2019123956 A1 WO 2019123956A1 JP 2018042940 W JP2018042940 W JP 2018042940W WO 2019123956 A1 WO2019123956 A1 WO 2019123956A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- time

- measurement

- signal

- series signal

- signal processing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/00584—Control arrangements for automatic analysers

- G01N35/00594—Quality control, including calibration or testing of components of the analyser

- G01N35/00613—Quality control

- G01N35/00623—Quality control of instruments

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/17—Systems in which incident light is modified in accordance with the properties of the material investigated

- G01N21/25—Colour; Spectral properties, i.e. comparison of effect of material on the light at two or more different wavelengths or wavelength bands

- G01N21/27—Colour; Spectral properties, i.e. comparison of effect of material on the light at two or more different wavelengths or wavelength bands using photo-electric detection ; circuits for computing concentration

- G01N21/272—Colour; Spectral properties, i.e. comparison of effect of material on the light at two or more different wavelengths or wavelength bands using photo-electric detection ; circuits for computing concentration for following a reaction, e.g. for determining photometrically a reaction rate (photometric cinetic analysis)

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/75—Systems in which material is subjected to a chemical reaction, the progress or the result of the reaction being investigated

- G01N21/77—Systems in which material is subjected to a chemical reaction, the progress or the result of the reaction being investigated by observing the effect on a chemical indicator

- G01N2021/7769—Measurement method of reaction-produced change in sensor

- G01N2021/7786—Fluorescence

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/00584—Control arrangements for automatic analysers

- G01N2035/0097—Control arrangements for automatic analysers monitoring reactions as a function of time

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/62—Systems in which the material investigated is excited whereby it emits light or causes a change in wavelength of the incident light

- G01N21/63—Systems in which the material investigated is excited whereby it emits light or causes a change in wavelength of the incident light optically excited

- G01N21/64—Fluorescence; Phosphorescence

- G01N21/6408—Fluorescence; Phosphorescence with measurement of decay time, time resolved fluorescence

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/75—Systems in which material is subjected to a chemical reaction, the progress or the result of the reaction being investigated

- G01N21/76—Chemiluminescence; Bioluminescence

Definitions

- the present invention relates to a signal processing apparatus and a signal processing method.

- the concentration of the target component using a labeling reagent that specifically binds to the component to be measured and generates luminescence when given a trigger The method of measuring is widely used.

- the labeling reagent include radioactive substances, substances that emit light due to chemical reactions, substances that emit fluorescence upon irradiation with excitation light, and the like.

- the signal intensity of light emission from the labeling reagent after trigger application is measured over time for a fixed time, and the integrated value of the signal intensity at the fixed signal measurement time is converted to the concentration of the target component Do.

- an error in the concentration measurement value may occur due to an abnormality in measurement, which includes an abnormality in each part of the device, a temporal change in the quality of a biological sample or a labeled reagent, and an external noise.

- an abnormality in measurement which includes an abnormality in each part of the device, a temporal change in the quality of a biological sample or a labeled reagent, and an external noise.

- Patent Document 1 determines the measurement abnormality by comparing the peak time of the time-series signal to be measured with the peak time set in advance.

- the method described in Patent Document 2 extracts the attenuation after a certain time from the peak of the time-series signal to be measured, and determines the measurement abnormality by comparing with the attenuation in the normal case. is there.

- Patent Documents 1 and 2 based on a time-series signal to be used for calculation of an integral value converted to the concentration of the measurement target component, one specific feature amount (each from peak time or peak) A method is proposed for extracting the amount of attenuation after a certain time, and using this one feature amount to determine measurement anomalies.

- the present invention provides a signal processing apparatus and a signal processing method that realize more reliable measurement by detecting an abnormality that has only a slight influence on a time-series signal.

- the purpose is

- a signal processing device includes a first measurement unit that acquires a first time-series signal with a first time resolution, and a second measurement unit that is higher than the first time resolution.

- a signal processing apparatus and the signal processing method of the present invention even when an abnormality that has only a slight influence on a time-series signal occurs, more reliable measurement is realized by detecting the abnormality.

- a signal processing apparatus and a signal processing method can be provided.

- FIG. 1 shows a configuration example of a signal processing device according to a first embodiment.

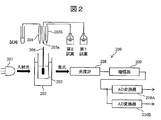

- the structural example of the automatic analyzer 200 as an example of the 1st measurement part 11 shown in FIG. 1 and the 2nd measurement part 12 is shown.

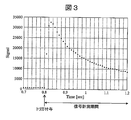

- production of a trigger signal from A / D converter 210A is shown.

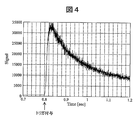

- production of a trigger signal from A / D converter 210B is shown.

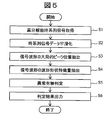

- FIG. 10 is a flowchart illustrating an example of processing to determine the presence or absence of measurement abnormality based on the shape of the signal waveform of the high resolution time-series signal in the first embodiment. It is a conceptual diagram which shows the extraction method of the peak position of a signal waveform. It is a conceptual diagram explaining the feature-value calculated from a signal waveform.

- FIG. 1 shows a configuration example of a signal processing apparatus according to the first embodiment of the present invention.

- This signal processing apparatus is roughly composed of a measuring unit 10, a signal processing unit 20, a reference data waveform shape feature amount database 30, a processor 40, and a display unit 50, and these components and an external network are interface 60 , 70, and are configured to be able to exchange data.

- the measurement unit 10 includes a measurement unit that measures signal strength in time series over a predetermined time, and includes a plurality of measurement units that can measure different time resolutions.

- a first measurement unit 11 that acquires a time-series signal (first time-series signal) with low time resolution

- two measuring units with two measuring units 12 are provided, three or more measuring units may be provided.

- the first measuring unit 11 and the second measuring unit 12 are, for example, automatic analyzers that analyze body fluid components such as blood and urine as samples. In ordinary component analysis, the measurement result of the first measurement unit 11 with low time resolution is used.

- the measurement result of the second measuring unit 12 with high time resolution is used for determination of measurement abnormality. This point will be described in detail later.

- the signal processing unit 20 includes a time-series signal storage unit 21, a time-series signal data processing unit 22, a waveform shape feature amount extraction unit 23, a waveform shape feature amount storage unit 24, an abnormality determination unit 25, and a result output unit 26.

- the time-series signal newly acquired by the measuring unit 10 is first stored in the time-series signal storage unit 21, and then subjected to predetermined data processing by the time-series signal data processing unit 22.

- the time-series signal data processing unit 22 processes the measurement results (time-series signals) of the first measurement unit 11 and the second measurement unit 12 and performs analysis and calculation of other necessary data.

- the waveform shape feature quantity extraction unit 23 extracts feature quantities of the shape of the signal waveform of the measurement signal obtained by the second measurement unit 12 (waveform shape feature quantity: hereinafter may be simply referred to as “feature quantity”). It has a function.

- the extracted waveform shape feature amount is stored in the waveform shape feature amount storage unit 24.

- the abnormality determination unit 25 compares the waveform shape feature amount newly measured and stored in the waveform shape feature amount storage unit 24 with the waveform shape feature amount of the reference data stored in the reference data waveform shape feature amount database 30. And make an abnormality judgment.

- the result output unit 26 outputs the result of the abnormality determination to the display unit 50 and the like.

- the processor 40 cooperates with the signal processing unit 20 to execute various data processing.

- the display unit 50 is a device such as a liquid crystal display, an organic EL display, or a printer that can output the result of the abnormality determination and other measurement results.

- FIG. 2 shows a configuration example of an automatic analyzer 200 as an example of the first measuring unit 11 and the second measuring unit 12.

- the automatic analyzer 200 includes, for example, a light source 201, a thermostatic bath 202, a cell 203, a sample dispensing nozzle 204, a first reagent dispensing nozzle 205a, a second reagent dispensing nozzle 205b, and a stirring mechanism 206. , A photometer 208, an amplifier 209, and A / D converters 210A and 210B.

- the light emitted from the light source (LED) 201 is irradiated to the cell 203 immersed in the thermostatic bath 202, and the light emitted from the sample is incident on the photometer 208.

- the detection signal of the photometer 208 is amplified by the amplifier 209.

- the amplified signal (analog signal) is converted into a digital signal by the A / D converters 210A and 210B and output.

- the A / D converter 210A has a small sampling frequency (a large sampling interval), and functions as the first measurement unit 11 (low resolution) in FIG.

- the A / D converter 210B performs sampling at a sampling frequency (small sampling interval) larger than that of the A / D converter 210A, and functions as the second measurement unit 12 of FIG.

- the sampling interval of the A / D converter 210A can be set to about 10 mS to 50 mS, and the sampling interval of the A / D converter 210B can be set to about 100 ⁇ S to 300 ⁇ S.

- the cell 203 is a reaction container for reacting a sample to be tested with a reagent.

- the sample is injected from the sample dispensing nozzle 204 into the cell 203, the first reagent is dispensed from the first reagent dispensing nozzle 205a, and the second reagent is dispensed from the second reagent dispensing nozzle 205b.

- the sample and the reagent are agitated by the agitation mechanism 206 to cause a chemical reaction inside the cell 203.

- the concentration of the analyte in the sample can be measured by measuring the degree of luminescence time-sequentially (photometry) for the chemical reaction at this time.

- FIG. 3 shows an example of a graph showing measurement results in the case of acquiring data of 40 points at a sampling interval of 10 mS and a signal measurement period of 400 mS after generation of a trigger signal in the A / D converter 210A.

- the measured data of 40 points are integrated over the signal measurement period (400 mS) in the time-series signal data processing unit 22 of the signal processing unit 20, and the concentration of the component to be inspected is obtained based on the obtained integral value.

- the A / D converter 210A the first measurement unit 11

- a signal with a higher time resolution than this is obtained from the A / D converter 210B (second measurement unit 12) as necessary.

- FIG. 4 shows an example of a high resolution time series signal obtained at a sampling interval of 250 ⁇ s after generation of a trigger signal from the A / D converter 210B.

- the high resolution time series signal from the A / D converter 210B may be acquired over the entire signal measurement time of the low time resolution signal from the A / D converter 210A, or the obtained high resolution time may be obtained. Depending on the shape of interest of the series signal, only the time domain shorter than the signal measurement time may be acquired.

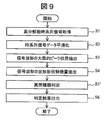

- step S2 the time series signal data processing unit 22 first reduces the influence of noise.

- step S2 data smoothing

- step S3 the position of the peak found in the signal waveform is extracted.

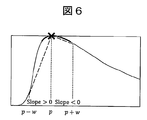

- the method of extracting the position of the peak will be described with reference to FIG.

- a position p defined by the following equation [Equation 1] as a method for extracting a global peak portion while avoiding detection of a local minute peak due to noise Is extracted as a peak part.

- w is an arbitrary value including the peak portion to be extracted. The smaller the value of w, the easier it is to detect a local minute peak. The optimal value of w can be exhaustively searched and determined according to the data.

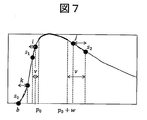

- waveform shape feature quantities representing the shape of the signal waveform are extracted from the smoothed time-series signal (step S4).

- local slopes of the signal waveform are calculated as the following feature quantities s 0 , s 1 , and s 2 .

- ⁇ y when normalized signal strength series signal normalized by the maximum signal strength, x is a function of time.

- b indicates the time of the rising point of the time-series signal

- p 0 indicates the time of the starting point of the peak portion

- v indicates the time width from the starting point and the end point of the peak portion.

- w shows the time width of a peak part.

- i, j, k indicate a minute time width for which the inclination at each point is calculated.

- the feature amount s 0 is a feature amount corresponding to the slope at the rising point of the time-series signal.

- the feature amount s 0 is calculated as a feature amount corresponding to the slope of the minute section k (b to b + k) at time b when the time-series signal rises by the trigger signal as shown in the above equation and FIG. can do.

- the feature amount s 1 is a feature amount corresponding to the inclination of the peak portion (p 0 to p 0 + w) including the peak position p extracted in step s 3 in the vicinity of the starting point.

- the feature s 1 is formula above, and as shown in FIG.

- Feature value s 2 is a characteristic quantity that corresponds to the slope in the vicinity of the end point of the peak portion including the peak positions p extracted in step s3 (p 0 ⁇ p 0 + w).

- the feature amount s 2 is a minute section j (p 0 + w + v ⁇ j) at a time earlier by time width v than time p 0 + w of the end point of the peak portion.

- i, j, k, i, j, k such that the difference between normal data when it is determined that there is no measurement abnormality and data when it is determined that there is measurement abnormality is the largest.

- the search is exhaustive, and the values of i, j, k can be determined according to the search result.

- step S5 the presence or absence of measurement abnormality in the measurement unit 10 is determined based on the waveform shape feature amounts s 0 , s 1 , s 2 calculated in step S4.

- discriminant analysis based on Mahalanobis's general distance can be used.

- the Mahalanobis' general distance D is a generalization of the distance from a data cluster in consideration of the distribution of data in the cluster, and is defined by the following equation.

- ⁇ is a feature quantity vector of data (eg, feature quantities s 0 , s 1 , s 2 ) for which the distance is to be obtained

- ⁇ is an average of feature quantity vectors of data in a cluster

- S is a feature quantity of data in a cluster It is a variance-covariance matrix of vectors.

- Discriminant analysis based on Mahalanobis's general distance D is to measure normal reference data clusters (measurement data group obtained by normal measurement) and abnormal reference data clusters (predetermined abnormal state) with respect to the feature quantities of the new time-series signal.

- the feature quantity s 1 and s 0 An example of data distribution in a two-dimensional space is shown.

- the horizontal axis (slope 1) indicates the distribution of Mahalanobis pan distances of the feature quantity s1

- the vertical axis (slope 0 ) indicates the distribution of the Mahalanobis pan distances of the feature quantity s0.

- the graph of FIG. 8 can be displayed on the display unit 50, and by presenting it to the operator, it can be shown whether or not there is a measurement abnormality in the newly obtained time-series signal (measurement result).

- the measurement result on one side of the curve C1 may be determined as normal, and the measurement result on the other side may be determined as abnormal.

- a high resolution time-series signal is acquired separately from this. By analyzing this, it is possible to accurately detect the measurement abnormality of the measurement device. Since high-resolution time-series signals can be appropriately determined at the timing of determination of measurement abnormality, determination of measurement abnormality can be appropriately performed without lengthening the time required for normal measurement.

- the abnormality determination unit 25 determines not only the presence or absence of the measurement abnormality but also the type of the measurement abnormality. It is configured to estimate.

- Types of measurement abnormalities include, for example, abnormalities of each part of the device, abnormalities due to changes in quality of samples and labeling reagents over time, abnormalities based on extraneous noise, so-called hook effects (measurement results of numerically low numerical values from high concentration samples Abnormalities based on what can be obtained, measurement abnormalities based on reaction inhibitors contained in the sample, and the like.

- hook effects measurement results of numerically low numerical values from high concentration samples Abnormalities based on what can be obtained

- measurement abnormalities based on reaction inhibitors contained in the sample and the like.

- the number of types of measurement anomalies detected simultaneously is not limited to two, and may be three or more.

- a high resolution time-series signal is acquired and stored (step S1), smoothing is performed (step S2), and the peak position of the signal waveform is extracted (step S3).

- step S4 the feature amounts s 0 , s 1 , and s 2 are calculated, and in step S5 ′, the presence or absence of an abnormality and the type thereof are determined.

- step S6 the determination result is output.

- FIG. 10 and FIG. 11 are an example of the graph which plotted the result of the measurement according to 2nd Embodiment.

- the horizontal axis in FIG. 10 corresponds to the feature quantity s 1

- the vertical axis corresponds to the feature quantity s 0 .

- the horizontal axis in FIG. 11 corresponds to the feature amount s 1

- the vertical axis corresponds to the feature amount s 2 .

- the Mahalanobis's functional distances of the feature amounts s 0 , s 1 , and s 2 are represented by three-dimensional coordinates according to FIGS. 10 and 11.

- black diamond dots are data determined to be normal

- cross dots are data determined to be measurement abnormal due to the hook phenomenon

- white dots are cells. It is data that is determined to be measurement abnormality due to the over-life of.

- the type of measurement abnormality can also be determined.

- Automatic analyzer 201: light source (LED), 202: constant temperature bath, 203: cell, 204: sample dispensing nozzle, 205a: first reagent dispensing nozzle, 205b: second reagent dispensing nozzle, 206: stirring mechanism, 208 ... photometer, 209 ... amplifier, 210A, 210B ... A / D converter.

- LED light source

- 202 constant temperature bath

- 203 cell

- 204 sample dispensing nozzle

- 205a first reagent dispensing nozzle

- 205b second reagent dispensing nozzle

- 206 stirring mechanism, 208 ... photometer, 209 ... amplifier, 210A, 210B ... A / D converter.

Landscapes

- Physics & Mathematics (AREA)

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- General Physics & Mathematics (AREA)

- Biochemistry (AREA)

- Pathology (AREA)

- Immunology (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Analytical Chemistry (AREA)

- General Health & Medical Sciences (AREA)

- Quality & Reliability (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Mathematical Physics (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Theoretical Computer Science (AREA)

- Plasma & Fusion (AREA)

- Automatic Analysis And Handling Materials Therefor (AREA)

- Investigating Or Analysing Materials By The Use Of Chemical Reactions (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/772,252 US20210102964A1 (en) | 2017-12-19 | 2018-11-21 | Signal processing device and signal processing method |

| CN201880076352.1A CN111727366B (zh) | 2017-12-19 | 2018-11-21 | 信号处理装置和信号处理方法 |

| EP18890119.3A EP3730930B1 (en) | 2017-12-19 | 2018-11-21 | Signal processing device and signal processing method |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017-242815 | 2017-12-19 | ||

| JP2017242815A JP6762927B2 (ja) | 2017-12-19 | 2017-12-19 | 信号処理装置及び信号処理方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019123956A1 true WO2019123956A1 (ja) | 2019-06-27 |

Family

ID=66993231

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/042940 Ceased WO2019123956A1 (ja) | 2017-12-19 | 2018-11-21 | 信号処理装置及び信号処理方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20210102964A1 (enExample) |

| EP (1) | EP3730930B1 (enExample) |

| JP (1) | JP6762927B2 (enExample) |

| CN (1) | CN111727366B (enExample) |

| WO (1) | WO2019123956A1 (enExample) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7346858B2 (ja) * | 2019-03-14 | 2023-09-20 | 株式会社リコー | 生体情報計測装置、生体情報計測システム、生体情報計測方法及び生体情報計測プログラム |

| JP7323816B2 (ja) * | 2021-06-21 | 2023-08-09 | 東亜ディーケーケー株式会社 | エンドトキシン測定方法 |

| CN115754151A (zh) * | 2022-11-18 | 2023-03-07 | 中冶赛迪工程技术股份有限公司 | 输出信号质量确定方法、报警方法、系统、设备及介质 |

Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63101758A (ja) * | 1986-10-20 | 1988-05-06 | Toshiba Corp | 自動化学分析装置 |

| JPH1137921A (ja) * | 1997-07-14 | 1999-02-12 | Horiba Ltd | 分析装置および分析装置の表示装置 |

| JP2003524753A (ja) * | 1998-04-23 | 2003-08-19 | サンディア コーポレーション | プラズマ処理操作を監視する方法及び装置 |

| JP2004125780A (ja) * | 2002-08-07 | 2004-04-22 | Hitachi High-Technologies Corp | サンプル分注装置およびそれを用いた自動分析装置 |

| JP2004239790A (ja) * | 2003-02-07 | 2004-08-26 | Matsushita Electric Ind Co Ltd | 分析装置 |

| JP2005127757A (ja) * | 2003-10-22 | 2005-05-19 | Hitachi High-Technologies Corp | 自動分析装置 |

| JP2006023214A (ja) * | 2004-07-09 | 2006-01-26 | Hitachi High-Technologies Corp | 測定反応過程の異常の有無判定方法,該方法を実行可能な自動分析装置及び該方法のプログラムを記憶した記憶媒体 |

| JP2007085804A (ja) | 2005-09-21 | 2007-04-05 | Hitachi High-Technologies Corp | 積分型データ演算法におけるチェック機能を備えたデータ処理方法 |

| JP2007248089A (ja) * | 2006-03-14 | 2007-09-27 | Hitachi High-Technologies Corp | 自己診断型自動分析装置 |

| JP2008032582A (ja) * | 2006-07-31 | 2008-02-14 | Hitachi High-Technologies Corp | 異物・欠陥検査装置および異物欠陥・検査方法 |

| JP2009192490A (ja) * | 2008-02-18 | 2009-08-27 | Hamamatsu Photonics Kk | 蛍光解析装置及び解析方法 |

| JP2012035152A (ja) * | 2010-08-03 | 2012-02-23 | Nippon Steel & Sumikin Metal Products Co Ltd | フロック形成状態判定方法、フロック形成状態判定装置、凝集反応槽、pH調整槽、及び異常発生通報システム |

| JP2013036756A (ja) * | 2011-08-03 | 2013-02-21 | Sysmex Corp | 検体分析装置 |

| JP2013152215A (ja) | 2012-01-25 | 2013-08-08 | F. Hoffmann-La Roche Ag | 液体試料中の分析物を検出する発光法及び分析システム |

| JP6126290B1 (ja) * | 2016-10-17 | 2017-05-10 | ヴィスコ・テクノロジーズ株式会社 | 外観検査装置 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008146157A (ja) * | 2006-12-06 | 2008-06-26 | Mitsubishi Electric Corp | ネットワーク異常判定装置 |

| JP2010069065A (ja) * | 2008-09-19 | 2010-04-02 | Panasonic Corp | 非侵襲血糖測定装置 |

| WO2010038546A1 (ja) * | 2008-09-30 | 2010-04-08 | 株式会社 日立ハイテクノロジーズ | 自動分析装置 |

| JP5865633B2 (ja) * | 2011-09-01 | 2016-02-17 | 株式会社日立ハイテクノロジーズ | 自動分析装置 |

| CN103760133B (zh) * | 2014-01-24 | 2016-04-20 | 深圳市安鑫宝科技发展有限公司 | 检测农副产品异常成分的方法及装置 |

| US10288637B2 (en) * | 2014-05-15 | 2019-05-14 | Hitachi High-Technologies Corporation | Automatic analyzer |

| CN106456067A (zh) * | 2014-06-06 | 2017-02-22 | 德克斯康公司 | 基于数据和背景的故障判别和响应处理 |

| CN107110743B (zh) * | 2015-01-21 | 2019-12-10 | 三菱电机株式会社 | 检查数据处理装置以及检查数据处理方法 |

| US9696204B2 (en) * | 2015-08-03 | 2017-07-04 | Spectrasensors, Inc. | Determination and correction of frequency registration deviations for quantitative spectroscopy |

| CN106442574B (zh) * | 2016-08-31 | 2019-05-28 | 上海创和亿电子科技发展有限公司 | 一种基于微波水分仪的产品霉变检测系统和检测方法 |

| WO2019008677A1 (ja) * | 2017-07-04 | 2019-01-10 | オリンパス株式会社 | 信号取得装置 |

-

2017

- 2017-12-19 JP JP2017242815A patent/JP6762927B2/ja active Active

-

2018

- 2018-11-21 EP EP18890119.3A patent/EP3730930B1/en active Active

- 2018-11-21 WO PCT/JP2018/042940 patent/WO2019123956A1/ja not_active Ceased

- 2018-11-21 US US16/772,252 patent/US20210102964A1/en not_active Abandoned

- 2018-11-21 CN CN201880076352.1A patent/CN111727366B/zh active Active

Patent Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63101758A (ja) * | 1986-10-20 | 1988-05-06 | Toshiba Corp | 自動化学分析装置 |

| JPH1137921A (ja) * | 1997-07-14 | 1999-02-12 | Horiba Ltd | 分析装置および分析装置の表示装置 |

| JP2003524753A (ja) * | 1998-04-23 | 2003-08-19 | サンディア コーポレーション | プラズマ処理操作を監視する方法及び装置 |

| JP2004125780A (ja) * | 2002-08-07 | 2004-04-22 | Hitachi High-Technologies Corp | サンプル分注装置およびそれを用いた自動分析装置 |

| JP2004239790A (ja) * | 2003-02-07 | 2004-08-26 | Matsushita Electric Ind Co Ltd | 分析装置 |

| JP2005127757A (ja) * | 2003-10-22 | 2005-05-19 | Hitachi High-Technologies Corp | 自動分析装置 |

| JP2006023214A (ja) * | 2004-07-09 | 2006-01-26 | Hitachi High-Technologies Corp | 測定反応過程の異常の有無判定方法,該方法を実行可能な自動分析装置及び該方法のプログラムを記憶した記憶媒体 |

| JP2007085804A (ja) | 2005-09-21 | 2007-04-05 | Hitachi High-Technologies Corp | 積分型データ演算法におけるチェック機能を備えたデータ処理方法 |

| JP2007248089A (ja) * | 2006-03-14 | 2007-09-27 | Hitachi High-Technologies Corp | 自己診断型自動分析装置 |

| JP2008032582A (ja) * | 2006-07-31 | 2008-02-14 | Hitachi High-Technologies Corp | 異物・欠陥検査装置および異物欠陥・検査方法 |

| JP2009192490A (ja) * | 2008-02-18 | 2009-08-27 | Hamamatsu Photonics Kk | 蛍光解析装置及び解析方法 |

| JP2012035152A (ja) * | 2010-08-03 | 2012-02-23 | Nippon Steel & Sumikin Metal Products Co Ltd | フロック形成状態判定方法、フロック形成状態判定装置、凝集反応槽、pH調整槽、及び異常発生通報システム |

| JP2013036756A (ja) * | 2011-08-03 | 2013-02-21 | Sysmex Corp | 検体分析装置 |

| JP2013152215A (ja) | 2012-01-25 | 2013-08-08 | F. Hoffmann-La Roche Ag | 液体試料中の分析物を検出する発光法及び分析システム |

| JP6126290B1 (ja) * | 2016-10-17 | 2017-05-10 | ヴィスコ・テクノロジーズ株式会社 | 外観検査装置 |

Non-Patent Citations (3)

| Title |

|---|

| JAPAN SPECTROSCOPY SOCIETY: "Chapter 5, Analyzing Spectral Data", SPECTROMETER Q&A, 20 July 2009 (2009-07-20), pages 130 - 152, XP009520851, DOI: 978-4-06-157110-5 * |

| See also references of EP3730930A4 |

| TETSUO SHIBA ET.AL.: "3.6 How to read the chromatogram", INSTRUMENT ANALYSIS TOOL (2), 2ND ED., vol. 2, 30 March 1996 (1996-03-30), pages 48 - 52, XP009520852, ISBN: 4-7598-0293-2 * |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2019109152A (ja) | 2019-07-04 |

| US20210102964A1 (en) | 2021-04-08 |

| EP3730930A1 (en) | 2020-10-28 |

| EP3730930A4 (en) | 2021-11-17 |

| JP6762927B2 (ja) | 2020-09-30 |

| EP3730930B1 (en) | 2023-08-09 |

| CN111727366A (zh) | 2020-09-29 |

| CN111727366B (zh) | 2023-06-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3093270B2 (ja) | 光学的試料分析装置及び方法 | |

| JP4276894B2 (ja) | 異常検出システム及び異常検出方法 | |

| US10203277B2 (en) | Automatic analysis device and automatic analysis method | |

| JP2010008402A (ja) | 反応過程データの異常判定支援方法及び自動分析装置 | |

| EP3828531B1 (en) | Information processing device, information processing method, information processing system, and program | |

| CN111727366B (zh) | 信号处理装置和信号处理方法 | |

| CN102395977B (zh) | 核酸定量的方法 | |

| US20210254125A1 (en) | Method and device for estimating number of cells | |

| JP4728025B2 (ja) | 細胞画像解析装置 | |

| CN114174800B (zh) | 自动分析装置 | |

| JP4117253B2 (ja) | 自動分析装置 | |

| CN112955749B (zh) | 异常判定方法和自动分析装置 | |

| JP5787948B2 (ja) | 反応過程データの異常判定支援方法及び自動分析装置 | |

| JP2007322243A (ja) | 自動分析装置 | |

| JP2017020956A (ja) | 自動分析装置、自動分析方法及びプログラム | |

| JP2010117290A (ja) | 液体試料成分の分析装置および分析方法 | |

| US20180185838A1 (en) | A biochemical analytical technique | |

| JP7719956B2 (ja) | 自動分析装置のデータ処理システム及び方法 | |

| CN105866453A (zh) | 一种临床自动生化分析方法 | |

| HK1014598B (en) | Optical specimen analysis system and method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18890119 Country of ref document: EP Kind code of ref document: A1 |

|

| DPE1 | Request for preliminary examination filed after expiration of 19th month from priority date (pct application filed from 20040101) | ||

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2018890119 Country of ref document: EP Effective date: 20200720 |