WO2017212808A1 - 自動分析装置 - Google Patents

自動分析装置 Download PDFInfo

- Publication number

- WO2017212808A1 WO2017212808A1 PCT/JP2017/016151 JP2017016151W WO2017212808A1 WO 2017212808 A1 WO2017212808 A1 WO 2017212808A1 JP 2017016151 W JP2017016151 W JP 2017016151W WO 2017212808 A1 WO2017212808 A1 WO 2017212808A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- reagent

- ultraviolet light

- automatic analyzer

- ultraviolet

- container

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/10—Devices for transferring samples or any liquids to, in, or from, the analysis apparatus, e.g. suction devices, injection devices

- G01N35/1002—Reagent dispensers

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/00584—Control arrangements for automatic analysers

- G01N35/00594—Quality control, including calibration or testing of components of the analyser

- G01N35/00613—Quality control

- G01N35/00663—Quality control of consumables

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2/00—Methods or apparatus for disinfecting or sterilising materials or objects other than foodstuffs or contact lenses; Accessories therefor

- A61L2/02—Methods or apparatus for disinfecting or sterilising materials or objects other than foodstuffs or contact lenses; Accessories therefor using physical phenomena

- A61L2/08—Radiation

- A61L2/10—Ultraviolet radiation

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2/00—Methods or apparatus for disinfecting or sterilising materials or objects other than foodstuffs or contact lenses; Accessories therefor

- A61L2/24—Apparatus using programmed or automatic operation

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2/00—Methods or apparatus for disinfecting or sterilising materials or objects other than foodstuffs or contact lenses; Accessories therefor

- A61L2/26—Accessories or devices or components used for biocidal treatment

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/30—Treatment of water, waste water, or sewage by irradiation

- C02F1/32—Treatment of water, waste water, or sewage by irradiation with ultraviolet light

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/00584—Control arrangements for automatic analysers

- G01N35/00722—Communications; Identification

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/10—Devices for transferring samples or any liquids to, in, or from, the analysis apparatus, e.g. suction devices, injection devices

- G01N35/1009—Characterised by arrangements for controlling the aspiration or dispense of liquids

- G01N35/1016—Control of the volume dispensed or introduced

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2202/00—Aspects relating to methods or apparatus for disinfecting or sterilising materials or objects

- A61L2202/10—Apparatus features

- A61L2202/14—Means for controlling sterilisation processes, data processing, presentation and storage means, e.g. sensors, controllers, programs

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N15/00—Investigating characteristics of particles; Investigating permeability, pore-volume or surface-area of porous materials

- G01N15/10—Investigating individual particles

- G01N15/1012—Calibrating particle analysers; References therefor

- G01N2015/1016—Particle flow simulating, e.g. liquid crystal cell

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/00584—Control arrangements for automatic analysers

- G01N35/00594—Quality control, including calibration or testing of components of the analyser

- G01N35/00613—Quality control

- G01N35/00663—Quality control of consumables

- G01N2035/00673—Quality control of consumables of reagents

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/00584—Control arrangements for automatic analysers

- G01N35/00722—Communications; Identification

- G01N2035/00891—Displaying information to the operator

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/10—Devices for transferring samples or any liquids to, in, or from, the analysis apparatus, e.g. suction devices, injection devices

- G01N35/1009—Characterised by arrangements for controlling the aspiration or dispense of liquids

- G01N35/1016—Control of the volume dispensed or introduced

- G01N2035/102—Preventing or detecting loss of fluid by dripping

- G01N2035/1023—Preventing or detecting loss of fluid by dripping using a valve in the tip or nozzle

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/10—Devices for transferring samples or any liquids to, in, or from, the analysis apparatus, e.g. suction devices, injection devices

- G01N35/1009—Characterised by arrangements for controlling the aspiration or dispense of liquids

- G01N2035/1025—Fluid level sensing

Definitions

- This disclosure relates to an automatic analyzer.

- sample a sample to be analyzed

- the reagent is provided to the user in a reagent container.

- the user installs the provided reagent container in or near the automatic analyzer, and inserts a suction nozzle into the mouth of the reagent container.

- the automatic analyzer sucks the reagent from the reagent container through the suction nozzle and adds the reagent to the sample, and measures the concentration of the substance to be measured contained in the sample.

- the user pulls out the suction nozzle from the reagent container and cleans or cleans the suction nozzle as necessary. Thereafter, the user replaces the new reagent container filled with the reagent with an empty reagent container, inserts the suction nozzle into the mouth of the new reagent container, and restarts the analysis operation.

- Patent Document 1 describes a sterilization container that can sterilize microorganisms contained in a liquid by irradiating the liquid in the container with ultraviolet rays.

- the irradiation light quantity when ultraviolet light is sterilized, it is necessary to appropriately select the irradiation light quantity so that the irradiation light quantity does not become insufficient or excessive.

- the irradiation light quantity if the irradiation light quantity is insufficient, the germs cannot be sufficiently sterilized, and the characteristics of the reagent may change due to the growth of the germs.

- the amount of irradiation light is excessive, the reagent components are decomposed or changed by ultraviolet light, and the characteristics of the reagent may also be changed.

- the appropriate amount of irradiation light varies depending on the remaining amount of reagent in the reagent container, and it is necessary to decrease the amount of irradiation light as the remaining amount of reagent decreases.

- the amount of irradiation light is not controlled according to the reagent remaining amount. For this reason, in the sterilization container described in Patent Document 1, the amount of irradiation light tends to be excessive as the remaining amount of the reagent decreases.

- the present invention provides a mechanism that can achieve both sterilization of the reagent and suppression of change in the property of the reagent.

- the present invention adopts, for example, the configurations described in the claims.

- the present specification includes a plurality of means for solving the above-mentioned problems. For example, “the generation of ultraviolet light that is detachably attached to the mouth of a container holding a reagent and irradiates ultraviolet light”

- a sterilization mechanism having a portion, a suction nozzle that is detachably attached to the mouth of the container together with the sterilization mechanism, and a reagent aspirated from the container via the suction nozzle is added to the sample to perform an analysis operation

- an automatic analyzer having a control unit that variably controls the amount of ultraviolet light irradiated by the ultraviolet light generation unit.

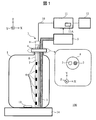

- FIG. 10 is a diagram illustrating a schematic configuration of an automatic analyzer according to Embodiment 1.

- FIG. 10 is a diagram illustrating a schematic configuration of an automatic analyzer according to a fourth embodiment.

- FIG. 10 is a diagram illustrating a schematic configuration of an automatic analyzer according to a fifth embodiment.

- FIG. 10 is a diagram illustrating a schematic configuration of an automatic analyzer according to a sixth embodiment.

- FIG. 10 is a diagram illustrating a schematic configuration of an automatic analyzer according to a seventh embodiment.

- FIG. 10 is a diagram illustrating a schematic configuration of an automatic analyzer according to a fourth embodiment.

- FIG. 10 is a diagram illustrating a schematic configuration of an automatic analyzer according to a fifth embodiment.

- FIG. 10 is a diagram illustrating a schematic configuration of an automatic analyzer according to a sixth embodiment.

- FIG. 10 is a diagram illustrating a schematic configuration of an automatic analyzer according to a seventh embodiment.

- FIG. 10 is a diagram illustrating a schematic configuration of an automatic analyzer according to an eighth embodiment.

- FIG. 10 is a diagram illustrating a schematic configuration of an automatic analyzer according to a ninth embodiment.

- FIG. 10 is a diagram showing a schematic configuration of an automatic analyzer according to a tenth embodiment.

- the term “reagent” includes not only a reaction reagent that reacts with a sample, but also a diluent, a detergent, a buffer, and a surfactant that activates an interface between an analyte and a reaction reagent.

- a reaction reagent that reacts with a sample

- a diluent e.g., a diluent

- a detergent e.g., a diluent

- a detergent e.g., a diluent

- a detergent e.g., a detergent, a buffer

- a surfactant that activates an interface between an analyte and a reaction reagent.

- the expression “sterilization” or “killing microorganisms” is also used in the meaning of “detoxifying microorganisms” in addition to the meaning of “killing microorganisms”.

- these expressions are used not only for the purpose of eradicating

- FIG. 1 shows a schematic configuration of an automatic analyzer 100 according to the present embodiment.

- the reagent container 1 received from the vendor is used by being mounted on the apparatus main body. For this reason, the user removes the lid attached at the time of distribution from the mouth of the reagent container 1 and inserts the suction nozzle 2 and the sterilizing mechanism 3 into the exposed mouth.

- the suction nozzle 2 and the sterilization mechanism 3 are fixed to the fixing portion 4.

- the fixing unit 4 is used as a new lid for the reagent container 1. By attaching the fixing part 4 to the mouth of the reagent container 1, the reagent container 1 is again sealed.

- the fixing unit 4 is detachable with respect to the mouth of the reagent container 1.

- the reagent sucked from the suction nozzle 2 is sent to the analysis unit 5 and used for analysis. Description of known portions of the configuration and processing functions of the analysis unit 5 is omitted. As a function unique to the present embodiment, there is a function of notifying the controller 11 of the remaining amount of the reagent.

- the sterilization mechanism 3 has a configuration in which a substrate 7 mounted with a plurality of ultraviolet LEDs (Light Emitting Diodes) 6 is housed in a cylindrical housing portion 8 whose bottom surface is closed, and the top surface thereof is closed with a lid 9. Have

- the number of ultraviolet LEDs 6 mounted on the substrate 7 is arbitrary, and may be one. In this embodiment, six ultraviolet LEDs 6 are arranged at equal intervals in the depth direction of the reagent container 1 (extension direction of the accommodating portion 8). But arrangement

- the ultraviolet LED 6 is attached to the substrate 7 so as to irradiate ultraviolet light only in the direction opposite to the suction nozzle 2. But you may make it arrange

- disconnecting the accommodating part 8 in parallel with respect to a horizontal surface is arbitrary, A rectangular shape and a triangular shape may be sufficient.

- the wiring 10 is drawn out from the upper surface of the lid 9 and connected to the controller 11. The other end of the wiring 10 is connected to the substrate 7 accommodated in the accommodating portion 8.

- the control unit 11 controls the amount of light emitted from the ultraviolet LED 6 via the wiring 10.

- the ultraviolet LED 6 is a so-called ultraviolet light generation unit, and emits ultraviolet light having a wavelength of 180 nm to 350 nm in a power supply state.

- a suitable wavelength is a wavelength with high sterilization efficiency with respect to the microbial species to be sterilized and hardly decompose the reagent components. More preferred is ultraviolet light having a wavelength of 240 nm to 300 nm.

- the ultraviolet LED 6 is fed through the wiring 10. Irradiation and extinction of the ultraviolet LED 6 are switched and controlled depending on whether or not power is supplied, and the illuminance of ultraviolet light is controlled by the magnitude of the supplied power.

- the housing part 8 has a function of waterproofing the ultraviolet LED 6 and the substrate 7 from the reagent. Moreover, the accommodating part 8 is formed with the material which permeate

- glass or resin that transmits ultraviolet light is used as the accommodating portion 8.

- quartz glass the transmittance of ultraviolet light is 90% or more. In this case, the attenuation of the illuminance of ultraviolet light is small, and the sterilization efficiency can be increased.

- the resin has a lower ultraviolet light transmittance than quartz glass, the mechanical strength of the container 8 increases, and the possibility of accidentally damaging the sterilization mechanism 3 when the reagent container 1 is replaced is reduced.

- the control unit 11 controls one or a combination of the current, voltage, and energization time supplied to the ultraviolet LED 6 to an appropriate value based on the remaining amount of reagent notified from the analysis unit 5.

- the control unit 11 controls any one or a combination of the current, voltage, and energization time so that the amount of ultraviolet light irradiation decreases as the amount of remaining reagent liquid decreases.

- the energization time length can be varied depending on the length of the pulse width corresponding to the energization time. As a result of these combined factors, the amount of ultraviolet light irradiated changes.

- the substrate 7 may have some or all of the functions of the control unit 11.

- the amount of ultraviolet light generated is greater than or equal to the amount of ultraviolet irradiation per unit liquid required for reagent sterilization. It controls so that it may become below the ultraviolet irradiation light quantity to do.

- the amount of ultraviolet irradiation per unit liquid necessary for sterilization of the reagent varies depending on the species of bacteria to be sterilized and the wavelength of ultraviolet light used. For this reason, the ultraviolet irradiation light quantity per unit liquid amount necessary for the sterilization of the reagent is obtained in advance by actual measurement or calculation for the combination of the bacteria species to be sterilized and the wavelength of the ultraviolet light to be used.

- the amount of ultraviolet light irradiation within which the change in reagent characteristics falls within an allowable range varies depending on the combination of reagent components (particularly, chemical bond species of the reagent) and the wavelength of ultraviolet light used. For this reason, for the combination of the reagent component and the wavelength of the ultraviolet light to be used, the ultraviolet irradiation light amount per unit liquid amount necessary for sterilization of the reagent is obtained in advance by actual measurement or calculation.

- the storage unit 11 ⁇ / b> A of the control unit 11 also stores a relationship (table) between these relationships and the reagent remaining liquid amount. Of course, the relationship between these relationships and the remaining amount of the reagent is also obtained in advance by actual measurement or calculation.

- the analysis unit 5 calculates the amount of residual reagent in the reagent container 1 from the value of the number of analyzes (or the number of measurements). Since the amount of reagent used in one analysis (or measurement) is known in advance, the amount used after replacing the reagent container 1 is calculated by multiplying the value by the number of analyzes (or the number of measurements). can do. Moreover, since the liquid amount of the reagent filled in the new reagent container 1 is also known, the residual liquid amount can be obtained by subtracting the calculated usage amount from the known liquid use. The reagent remaining liquid amount can also be obtained by using a reagent liquid level detection mechanism mounted on the analysis unit 5. Since the liquid level detection mechanism is known, detailed description thereof is omitted.

- the automatic analyzer 100 arranges the magnetic stirrer 14 as a mounting table for the reagent container 1.

- the magnetic stirrer 14 constitutes a stirring mechanism together with the stirrer 13 introduced into the reagent container 1 and rotates the stirrer 13 using magnetic force to stir the reagent.

- the stirring mechanism may be a stirring blade, or may be a system in which the suction and discharge of the reagent are repeated by the suction nozzle 2. Further, the stirring mechanism may be a system that uses convection of the reagent generated by the heat generated by the ultraviolet LED 6 that is locally disposed on the bottom side of the reagent container 1.

- the wiring 10 includes not only wiring for power supply to the ultraviolet LED 6 and control, but also a signal line for a temperature sensor such as a thermistor and a signal line for notifying the controller 11 of the state of the ultraviolet LED 6.

- the automatic analyzer 100 includes a display unit 12 that notifies the user that an appropriate reagent has been sterilized or that an abnormality has been detected.

- the user of the apparatus can know the state of the reagent and the sterilization mechanism through the screen displayed on the display unit 12.

- the display unit 12 may display an interface used for operation and control of the automatic analyzer 100, an analysis result, and an apparatus state.

- the notification content includes, for example, whether or not appropriate sterilization is performed and abnormality detection.

- the irradiation amount of ultraviolet light used for sterilization of the reagent is appropriately controlled according to the amount of the reagent remaining in the reagent container 1. Specifically, the control unit 11 can reduce the amount of ultraviolet light irradiation to an appropriate amount as the reagent remaining amount decreases.

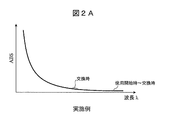

- FIG. 2A shows the time change of the measurement result of absorbance according to this example.

- the vertical axis in FIG. 2A is absorbance, and the horizontal axis is wavelength.

- the absorbance measurement value hardly changes at any wavelength from the start of use of the reagent container 1 to the replacement.

- FIG. 2A there is a change in which the absorbance slightly increases at a certain wavelength determined by the reagent component and the wavelength of ultraviolet light. However, the change is minor, indicating that the reagent properties are maintained.

- FIG. 2B shows the change over time of the absorbance measurement results when used for sterilization while keeping the amount of ultraviolet light constant (comparative example).

- the absorbance at a certain wavelength increases significantly as the sample container 1 is replaced. This increase in absorbance is caused by the decomposition or change of reagent components, and the greater the increase in absorbance, the more the characteristics of the reagent change.

- the irradiation amount of ultraviolet light used for sterilization of the reagent that is, illuminance and irradiation time

- the remaining amount of the reagent it is possible to achieve both sterilization and reagent component maintenance.

- Reagents can be used for a long time.

- the automatic analyzer 100 since the automatic analyzer 100 according to the present embodiment detachably attaches the sterilization mechanism 3 to the reagent container 1 provided by the vendor, it is not necessary to transfer the reagent when replacing the reagent. In addition, there is no fear of contamination of residual reagents and bacteria as in the case of transferring reagents.

- Example 2 In the present embodiment, a case will be described in which a countermeasure against heat generation of the ultraviolet LED 6 is applied to the automatic analyzer 100 described above.

- the ultraviolet LED 6 generates heat when irradiated with ultraviolet light. If the junction temperature of the ultraviolet LED 6 exceeds the absolute maximum rating defined in the specification, it may cause a shortening of the life of the ultraviolet LED 6 or cause a failure.

- the heat of the ultraviolet LED 6 is released to the outside of the reagent through the substrate 7, the housing portion 8 and the wiring 10 in addition to being released into the reagent.

- the ultraviolet LED located at a position higher than the liquid level of the reagent becomes difficult to release heat to the reagent.

- the bonding temperature of the ultraviolet LED 6 at a position higher than the liquid level of the reagent is higher than the bonding temperature of the ultraviolet LED at a position lower than the liquid level of the reagent, and the life is likely to be shortened.

- control unit 11 of the present embodiment is equipped with a function of selectively turning off the ultraviolet LED 6 located at a position higher than the liquid level of the reagent or reducing the amount of light based on the remaining liquid amount of the reagent. It is assumed that the position of the ultraviolet LED 6 mounted on the substrate 7 is stored in the storage unit 11A of the control unit 11. By mounting this function, it is possible to effectively prevent the shortening and failure of the ultraviolet LED 6 located at a relatively high position, and to extend the life of the sterilization mechanism 3.

- Example 3 In the above-described second embodiment, as a countermeasure against the heat generation of the ultraviolet LED 6, the ultraviolet LED 6 located at a position higher than the liquid level of the reagent is selectively turned off or the amount of light is reduced. Instead of or in addition to the functions of the second embodiment, the following functions are provided in the control unit 11.

- a temperature sensor such as a thermistor is disposed on the substrate 7 near the ultraviolet LED 6.

- the temperature sensor may be provided on a one-to-one basis with respect to the ultraviolet LED 6, or a plurality of temperature sensors may be provided at positions that are not necessarily one-to-one with the ultraviolet LED 6. The measurement result of the temperature sensor is notified to the control unit 11 through the substrate 7 and the wiring 10.

- the control unit 11 controls any one or combination of the current, voltage, and energization time supplied to the ultraviolet LED 6 so that the junction temperature of the ultraviolet LED 6 indirectly measured through the temperature sensor does not exceed a predetermined value. Thereby, the situation where the lifetime of ultraviolet LED in the position lower than the liquid level of a reagent becomes shorter than expected can be avoided, or generation

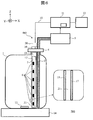

- FIG. 3 shows a schematic configuration of an automatic analyzer 200 according to the fourth embodiment.

- the same or corresponding reference numerals are given to the corresponding parts to those in FIG.

- the automatic analyzer 200 uses a sterilization mechanism 103 instead of the sterilization mechanism 3.

- the sterilization mechanism 103 is different from the sterilization mechanism 3 in that the ultraviolet lamp 15 is used for the ultraviolet light generation unit and the storage unit 108 is used.

- the ultraviolet lamp 15 a low-pressure mercury lamp or a high-pressure mercury lamp is used.

- the low-pressure mercury lamp mainly emits ultraviolet light including a wavelength of 254 nm, which has high sterilization efficiency, and a wavelength of 185 nm, which generates ozone.

- the high-pressure mercury lamp mainly emits ultraviolet light having a wavelength of 365 nm that does not contribute to sterilization, but also irradiates ultraviolet light having a wavelength of 254 nm to 334 nm that contributes to sterilization.

- the ultraviolet lamp 15 is selected from the viewpoint that it has a high sterilization efficiency with respect to the bacterial species to be sterilized and includes a suitable wavelength that is difficult to decompose the reagent components.

- the container 108 is made of glass or resin that transmits ultraviolet light. However, the function of an optical filter may be added to the housing portion 108 so that only ultraviolet light with a suitable wavelength is transmitted.

- the control unit 11 controls one or a combination of the current, voltage, and energization time supplied to the ultraviolet lamp 15 based on the remaining amount of reagent. Also in the present embodiment, the control unit 11 controls one or more of the current, voltage, and energization time so that the amount of ultraviolet light irradiation decreases as the residual amount of reagent decreases.

- the amount of ultraviolet irradiation light per unit liquid amount necessary for sterilization of the reagent varies depending on the fungus species to be sterilized, the ultraviolet lamp 15 to be used, and the filter function of the storage unit 108.

- the amount of ultraviolet irradiation light per unit liquid amount necessary for sterilization of the reagent is obtained in advance by actual measurement or calculation.

- the amount of ultraviolet irradiation light whose reagent characteristics change within an allowable range also varies depending on the combination of the reagent components (particularly chemical bond species of the reagent), the ultraviolet lamp 15, and the filter function of the container 108. Therefore, for the combination of the reagent components, the ultraviolet lamp 15 and the filter function of the storage unit 108, the amount of ultraviolet irradiation light per unit liquid amount necessary for sterilization of the reagent is obtained in advance by actual measurement or calculation.

- the storage unit 11 ⁇ / b> A of the control unit 11 stores a relationship (table) between these relationships and the reagent remaining liquid amount. Of course, the relationship between these relationships and the remaining amount of the reagent is also obtained in advance by actual measurement or calculation.

- the same stirring mechanism as in the first embodiment can be employed, but an ultraviolet lamp 15 shorter than the depth of the reagent container 1 is installed on the bottom side of the reagent container 1, and the ultraviolet lamp 15 emits.

- the reagent may be convected by heat and stirred.

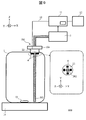

- FIG. 4 shows a schematic configuration of an automatic analyzer 300 according to the fifth embodiment.

- the automatic analyzer 300 uses a sterilization mechanism 203 instead of the sterilization mechanism 3.

- the sterilization mechanism 203 has a configuration in which the substrate 7 on which the ultraviolet LED 6 is mounted is accommodated in the accommodating portion 208.

- the accommodating portion 208 is formed of resin or metal, and an opening that transmits ultraviolet light and a window 16 that closes the opening are disposed at a position facing the ultraviolet LED 6.

- the window 16 is made of glass, for example.

- the accommodating portion 208 may be made of a material that transmits ultraviolet light or a material that does not transmit ultraviolet light.

- the metal accommodating part 208 heat dissipation can be improved compared with the case where the resin accommodating part 208 is used. For this reason, when using the metal housing portion 208, even if the ultraviolet LED 6 is driven with a larger voltage or current than in the case of the resin housing portion 208, the junction temperature of the ultraviolet LED 6 does not exceed the maximum absolute rating. Can keep. However, if the metal storage unit 208 is used, the reagent is easily heated. Therefore, when it is desired to suppress the heating of the reagent, it is desirable to use a resin-made container 208.

- the window 16 is disposed so as to close an opening provided in a region portion irradiated with the ultraviolet light irradiated from the ultraviolet LED 6 in the housing portion 208. Since the window 16 completely closes the opening of the accommodating portion 208, the ultraviolet LED 6 and the substrate 7 are waterproofed from the reagent. The ultraviolet light transmitted through the window 16 irradiates the reagent in the reagent container 1. When quartz glass is used for the window 16, the transmittance of ultraviolet light is 90% or more. In this case, the sterilization efficiency can be increased because the ultraviolet light illuminance is less attenuated.

- FIG. 5 shows a schematic configuration of an automatic analyzer 400 according to the sixth embodiment.

- the same or corresponding reference numerals are given to the corresponding parts to those in FIG.

- the automatic analyzer 400 uses a sterilization mechanism 303 instead of the sterilization mechanism 103.

- the sterilization mechanism 303 has a configuration in which the ultraviolet lamp 15 is accommodated in the accommodating portion 308.

- the housing portion 308 is formed of resin or metal, and the window 16 that transmits ultraviolet light is disposed at a position facing the ultraviolet LED 6 among them.

- the window 16 is made of glass, for example. However, an optical filter function may be added to the window 16 to transmit only a suitable wavelength.

- the container 308 may be made of a material that transmits ultraviolet light or a material that does not transmit light.

- the accommodating part 308 When the accommodating part 308 is comprised with the material which permeate

- an opening is provided in a region of the housing portion 308 that is irradiated with ultraviolet light emitted from the ultraviolet LED 6, and the window 16 is disposed so as to close the opening.

- the ultraviolet lamp 15 is waterproofed from the reagent by the accommodating portion 308 and the window 16.

- the ultraviolet light transmitted through the window 16 irradiates the reagent in the reagent container 1.

- the larger the size of the opening and the window 16 and the larger the number the higher the sterilization efficiency.

- the mechanical strength of the accommodating portion 308 is weakened. For this reason, it is desirable that the total area of the openings is not more than half of the surface area of the accommodating portion 308.

- the control unit 11 controls any one or a combination of the current, voltage, and energization time supplied to the ultraviolet lamp 15 based on the remaining amount of reagent. At this time, the control unit 11 determines that the irradiation amount of ultraviolet light generated from the ultraviolet lamp 15 is equal to or larger than the irradiation amount of ultraviolet light per unit liquid amount necessary for sterilization of the reagent, and the allowable range of change in reagent characteristics. It is controlled to be equal to or less than the amount of ultraviolet irradiation light corresponding to the upper limit of.

- the amount of ultraviolet irradiation light per unit liquid amount necessary for sterilization of the reagent differs depending on the combination of the fungus species to be sterilized, the ultraviolet lamp 15 to be used, the storage unit 308 and the filter function of the window 16. For this reason, for the combination of the fungus species to be sterilized, the ultraviolet lamp 15 to be used, the filter function of the container 308 and the window 16, the ultraviolet irradiation light amount per unit liquid amount necessary for sterilization of the reagent is obtained in advance by actual measurement or calculation. .

- the amount of ultraviolet irradiation light whose change in reagent characteristics is within an allowable range also varies depending on the combination of the reagent components (particularly chemical bond species of the reagent), the ultraviolet lamp 15 to be used, the storage unit 308 and the filter function of the window 16. For this reason, for the combination of the reagent components, the ultraviolet lamp 15 to be used, the storage unit 308, and the filter function of the window 16, the ultraviolet irradiation light amount per unit liquid amount necessary for sterilization of the reagent is obtained in advance by actual measurement or calculation.

- FIG. 6 shows a schematic configuration of an automatic analyzer 500 according to the seventh embodiment.

- the same or corresponding reference numerals are given to the portions corresponding to FIG. 1.

- the automatic analyzer 500 uses a sterilization mechanism 403 instead of the sterilization mechanism 3.

- the sterilization mechanism 403 includes a first housing portion 17 that houses the substrate 7 on which the ultraviolet LED 6 is mounted, a second housing portion 19 that houses the first housing portion 17 and its lid portion 18, and a second housing portion. It comprises 19 lid portions 20 and a heat insulating portion 21.

- the first accommodating portion 17 is sealed with a lid portion 18 through which the wiring 10 passes.

- the second accommodating portion 19 is sealed with a lid portion 20 through which the wiring 10 passes.

- a heat insulating portion 21 is disposed between the first housing portion 17 and the second housing portion 19.

- the first container 17 and the second container 19 are made of glass or resin that transmits ultraviolet light.

- quartz glass When quartz glass is used, the sterilization efficiency can be increased because the attenuation of ultraviolet light illuminance is small.

- resin when the resin is used, the mechanical strength can be increased although the transmittance of ultraviolet light is lower than that of quartz glass.

- the second container 19 is formed of resin, there is less risk of damaging the sterilization mechanism 403 by mistake when replacing the reagent container 1.

- the heat insulating part 21 is formed of air, resin, rubber or the like, and its thermal conductivity is 0.5 W / (m ⁇ K) or less.

- the first accommodating portion 17 and the second accommodating portion 19 are separated by the heat insulating portion 21 (not in direct contact).

- the presence of the heat insulating portion 21 can suppress or reduce the conduction of heat generated when the ultraviolet LED 6 irradiates ultraviolet light to the reagent, and suppress or reduce the heating of the reagent.

- the heat insulating portion 21 is arranged in a portion excluding the ultraviolet light irradiation region so as not to interfere with the ultraviolet light irradiation.

- the automatic analyzer 500 having this configuration can suppress or reduce the possibility of the reagent characteristic change due to the heating of the reagent accompanying the irradiation of ultraviolet light.

- FIG. 7 shows a schematic configuration of an automatic analyzer 600 according to the eighth embodiment.

- the automatic analyzer 600 uses a sterilization mechanism 503.

- the sterilization mechanism 503 includes a first housing portion 17 that houses the substrate 7 on which the ultraviolet LED 6 is mounted, a second housing portion 119 that houses the first housing portion 17 and its lid portion 18, and a second housing portion. 119 includes a lid portion 20 and a heat insulating portion 21.

- This double tube structure is the same as in Example 7.

- the lid 18 through which the wiring 10 penetrates seals the first housing part 17, and the lid 20 through which the wiring 10 penetrates seals the second housing part 119.

- an opening is formed in a position facing the ultraviolet LED 6 (the ultraviolet light irradiation region) in the second housing portion 119, and the opening is closed by the window 16.

- the first accommodating portion 17 is waterproofed from the reagent.

- the window 16 transmits ultraviolet light.

- the first accommodating portion 17 is made of glass or resin that transmits ultraviolet light.

- the 2nd accommodating part 119 is comprised with resin or a metal.

- the window 16 is made of glass that transmits ultraviolet light.

- the second accommodating portion 119 may be made of a material that transmits ultraviolet light or a material that does not transmit ultraviolet light.

- the automatic analyzer 600 having this configuration can suppress or reduce the possibility of the reagent characteristic change due to the heating of the reagent accompanying the irradiation of ultraviolet light.

- FIG. 8 shows a schematic configuration of an automatic analyzer 700 according to the ninth embodiment.

- the automatic analyzer 700 uses a sterilization mechanism 603.

- the sterilization mechanism and the suction nozzle 2 are configured as separate members, and each is fixed to the fixing portion 4.

- the sterilization mechanism 603 has an integrated configuration.

- a configuration in which a sterilization mechanism 603 is attached to the surface of the suction nozzle 102 is employed.

- the sterilization mechanism 603 and the suction nozzle 102 can be pulled out or inserted at the same time when the reagent is replaced, and wiping and cleaning are simplified.

- the sterilization mechanism 603 can irradiate ultraviolet light substantially uniformly in all directions.

- the number of ultraviolet LEDs 6 arranged at the same height is not limited to four, and may be one, two, three, five or more.

- interval of ultraviolet LED6 is not restricted equally, It is desirable to adjust a space

- substrate 107 which mounts ultraviolet LED6 is arrange

- the accommodating portion 408 is formed of resin or metal.

- An opening is formed at a position (ultraviolet light irradiation region) facing the ultraviolet LED 6 in the housing portion 408, and the window 16 is disposed so as to cover the opening.

- the window 16 is made of glass that transmits ultraviolet light.

- the accommodating portion 408 may be made of a material that transmits ultraviolet light or a material that does not transmit ultraviolet light.

- the accommodating portion 408 may be made of a material that transmits ultraviolet light or a material that does not transmit ultraviolet light.

- resin or metal By configuring the container 408 with resin or metal, there is less risk of damaging the sterilization mechanism 603 by mistake when replacing the reagent container 1.

- heat dissipation is improved when using metal compared to when resin is used, and the LED can be driven with a larger voltage or current within a range where the junction temperature of the ultraviolet LED 6 does not exceed the maximum absolute rating.

- the storage portion 408 is made of metal, the reagent is easily heated. Therefore, when it is desired to suppress the heating of the reagent, a resin is used for the storage portion 408.

- the lower opening end of the suction nozzle 102 is exposed to the outside through an opening provided on the bottom surface of the accommodating portion 408 so that the reagent can be sucked from the lower opening end.

- the space between the suction nozzle 102 and the opening provided in the bottom surface of the accommodating portion 408 is sealed with a seal structure or a seal material.

- the window 16 seals the opening provided in the housing portion 408. Thereby, the ultraviolet LED 6 and the substrate 107 housed in the housing portion 408 are waterproofed from the reagent.

- the automatic analyzer 700 having this configuration has a smaller blind spot in the irradiation direction of ultraviolet light than the automatic analyzer 100, and can enhance the bactericidal effect.

- FIG. 9 shows a schematic configuration of an automatic analyzer 800 according to the tenth embodiment.

- the automatic analyzer 800 employs a configuration in which the sterilization mechanism 703 (the ultraviolet LED 6, the substrate and the heat radiating unit 22) is attached to the mouth portion of the reagent container 1.

- the substrate and the heat radiating portion 22 are attached to the lower surface of the fixing portion 104, and when the fixing portion 104 is attached to the mouth of the reagent container 1, the substrate and the heat radiating portion 22 are connected to the mouth of the reagent container 1. Inserted inside.

- the fixing part 104, the substrate and the heat dissipation part 22 are formed with holes penetrating them, and the suction nozzle 202 is attached to these through holes.

- a plurality of ultraviolet LEDs 6 are disposed downward on the lower surface of the substrate and the heat dissipation portion 22. In FIG. 9, four ultraviolet LEDs 6 are attached to the lower surface of the substrate and the heat radiating portion 22.

- the ultraviolet LED 6 is fixed at a position where it does not touch the reagent even when the fixing portion 104 is fixed to the reagent container 1 immediately after replacement (that is, even when the liquid level of the reagent in the reagent container 1 is at the highest position). .

- the sterilization mechanism 703 of this embodiment irradiates ultraviolet light from the upper position of the reagent toward the inner wall surface of the reagent container 1 and the liquid surface of the reagent.

- the ultraviolet LED 6, the substrate, and the heat radiation part 22 it is not necessary to waterproof the ultraviolet LED 6, the substrate, and the heat radiation part 22 from the reagent.

- the reagent may touch the sterilization mechanism 703. Therefore, the sterilization mechanism 703, the substrate, and the heat dissipation part 22 may be waterproofed.

- the suction nozzle 202 may be fixed to the fixing unit 104 integrally with the sterilization mechanism 703, or may be separable from the sterilization mechanism 703. Further, part or all of the functions of the control unit 11 may be mounted on one or both of the substrate and the heat dissipation unit 22.

- the heat of the ultraviolet LED 6 is released into the air through the substrate and the heat radiation part 22. For this reason, the rise in the junction temperature of the ultraviolet LED 6 is suppressed, and the possibility that the junction temperature exceeds the absolute maximum rating determined by the specifications can be reduced. As a result, the lifetime of the ultraviolet LED 6 can be extended, and the frequency of occurrence of failures can also be reduced.

- the substrate and the heat radiating portion 22 are desirable to form with a metal having high thermal conductivity such as aluminum, copper, and stainless steel. Further, a heat sink structure may be adopted for the substrate and the heat radiating portion 22. Further, the fixing portion 104 may have a heat dissipation function. Further, similarly to the other embodiments, a temperature sensor such as a thermistor may be disposed near the ultraviolet LED 6, and the junction temperature of the ultraviolet LED 6 may be indirectly measured by the control unit 11. In this case, the control unit 11 controls one or more of the current, voltage, and energization time of the ultraviolet LED 6 based on the measured junction temperature so that the junction temperature of the ultraviolet LED 6 does not exceed the absolute maximum rating. Control.

- a temperature sensor such as a thermistor

- the automatic analyzer 800 having this configuration, it is possible to achieve both the change in the characteristics of the reagent, the suppression of the propagation of germs, and the sterilization of the reagent, as in the above-described embodiments. Further, since the reagent container 1 is used as it is by being mounted on the automatic analyzer 800, it is possible to minimize the labor and reagent quality degradation associated with the reagent transfer operation.

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Biochemistry (AREA)

- Pathology (AREA)

- Immunology (AREA)

- General Physics & Mathematics (AREA)

- Physics & Mathematics (AREA)

- Analytical Chemistry (AREA)

- Veterinary Medicine (AREA)

- Public Health (AREA)

- Animal Behavior & Ethology (AREA)

- Epidemiology (AREA)

- Engineering & Computer Science (AREA)

- Quality & Reliability (AREA)

- Hydrology & Water Resources (AREA)

- Toxicology (AREA)

- Environmental & Geological Engineering (AREA)

- Water Supply & Treatment (AREA)

- Organic Chemistry (AREA)

- Automatic Analysis And Handling Materials Therefor (AREA)

- Apparatus For Disinfection Or Sterilisation (AREA)

- Physical Water Treatments (AREA)

- Apparatus Associated With Microorganisms And Enzymes (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP17809990.9A EP3470849B1 (en) | 2016-06-09 | 2017-04-24 | Automatic analysis device |

| CN201780034514.0A CN109219751B (zh) | 2016-06-09 | 2017-04-24 | 自动分析装置 |

| US16/307,787 US11293934B2 (en) | 2016-06-09 | 2017-04-24 | Automatic analyzer |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016-114924 | 2016-06-09 | ||

| JP2016114924A JP6591932B2 (ja) | 2016-06-09 | 2016-06-09 | 自動分析装置 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017212808A1 true WO2017212808A1 (ja) | 2017-12-14 |

Family

ID=60577750

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2017/016151 Ceased WO2017212808A1 (ja) | 2016-06-09 | 2017-04-24 | 自動分析装置 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US11293934B2 (enExample) |

| EP (1) | EP3470849B1 (enExample) |

| JP (1) | JP6591932B2 (enExample) |

| CN (1) | CN109219751B (enExample) |

| WO (1) | WO2017212808A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019082524A1 (ja) * | 2017-10-25 | 2019-05-02 | 株式会社日立ハイテクノロジーズ | 分析装置 |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2018149213A (ja) * | 2017-03-15 | 2018-09-27 | 株式会社エンプラス | 紫外線照射装置 |

| JP7034689B2 (ja) | 2017-12-01 | 2022-03-14 | 株式会社日立ハイテク | 自動分析装置 |

| JP2020010830A (ja) * | 2018-07-18 | 2020-01-23 | 旭化成株式会社 | 流体殺菌モジュール |

| GB2576346B (en) * | 2018-08-15 | 2022-06-29 | Vws Uk Ltd | Water purifying apparatus and method |

| EP3914381A4 (en) * | 2019-01-21 | 2022-10-12 | Jon Greenfield | TREATMENT AND AGITATION EQUIPMENT FOR ULTRAVIOLET, TEMPERATURE AND GAS CONTROLLED STERILIZATION, CURING AND TREATMENT OF CANNABIS AGRICULTURAL PRODUCTS AND TREATMENT METHODS |

| JP7224966B2 (ja) * | 2019-03-05 | 2023-02-20 | 株式会社日立ハイテク | 自動分析装置 |

| JP7275700B2 (ja) * | 2019-03-19 | 2023-05-18 | 三菱電機株式会社 | 殺菌装置および給湯装置 |

| CN111569103B (zh) * | 2020-05-18 | 2022-02-11 | 华引芯(武汉)科技有限公司 | 一种便携式双波段uv led杀菌消毒灯 |

| KR20220034456A (ko) * | 2020-09-11 | 2022-03-18 | 주식회사 싸이큐어 | 표면 및 공간 led 살균 조명장치 |

| EP4459259A4 (en) * | 2022-02-04 | 2025-12-17 | Horiba Ltd | PARTICLE SIZE DISTRIBUTION MEASURING DEVICE, PARTICLE SIZE DISTRIBUTION MEASURING METHOD, PARTICLE SIZE DISTRIBUTION MEASURING DEVICE PROGRAM AND PARTICLE SIZE DISTRIBUTION MEASURING DEVICE KIT |

| WO2025225211A1 (ja) * | 2024-04-23 | 2025-10-30 | 株式会社日立ハイテク | 自動分析装置、及び自動分析装置におけるled光源の判定方法 |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS527962U (enExample) * | 1975-07-04 | 1977-01-20 | ||

| JPS63163168A (ja) * | 1986-12-25 | 1988-07-06 | Sumitomo Electric Ind Ltd | 液体分注装置 |

| JPH03503730A (ja) * | 1988-03-29 | 1991-08-22 | イアトロス リミテッド | 血液処理装置 |

| JPH08117742A (ja) * | 1994-10-21 | 1996-05-14 | Tadahide Iwashita | 殺菌装置付き容器用蓋 |

| JPH10216711A (ja) * | 1997-02-06 | 1998-08-18 | Kurihara Kogyo:Kk | 水処理装置 |

| JP2007007083A (ja) * | 2005-06-29 | 2007-01-18 | Univ Of Tokushima | 紫外線殺菌装置 |

| JP2011147362A (ja) * | 2010-01-19 | 2011-08-04 | Hitachi Plant Technologies Ltd | 浮遊菌捕集装置、浮遊菌計測方法及び浮遊菌計測システム |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS527962A (en) | 1975-07-04 | 1977-01-21 | Nikken Kagaku Kk | Preparation of (1-aryl-4,5,6,7- tetrahydro-1h-indazol-3-yloxy) alkanoi c acids |

| ATE179393T1 (de) * | 1995-01-13 | 1999-05-15 | Duras Trading Limited | Kupplungsanordnung zur sterilen übergabe von sterilen materialien zwischen einem transportablen behälter und einem sterilen gehäuse |

| US8754385B1 (en) * | 1999-06-01 | 2014-06-17 | Jose Gutman | Advanced system and method for ozone containing packaging for sanitizing application |

| US6565802B1 (en) | 1999-06-03 | 2003-05-20 | Baxter International Inc. | Apparatus, systems and methods for processing and treating a biological fluid with light |

| JP2001247108A (ja) | 2000-03-08 | 2001-09-11 | Shokuhin Sangyo Denshi Riyo Gijutsu Kenkyu Kumiai | 容器殺菌方法及び装置 |

| US6579495B1 (en) * | 2000-07-27 | 2003-06-17 | Hydro Photon, Inc. | Hand-held ultraviolet water purification system using solid state devices |

| DE102005000845A1 (de) * | 2005-01-05 | 2006-07-20 | Patent-Treuhand-Gesellschaft für elektrische Glühlampen mbH | Entkeimungssystem |

| CN1978333A (zh) * | 2005-12-05 | 2007-06-13 | 王顺忠 | 净水杀菌装置 |

| US7550089B2 (en) * | 2006-08-10 | 2009-06-23 | Meridian Design, Inc. | Floating ultraviolet water purification device |

| US20090250626A1 (en) * | 2008-04-04 | 2009-10-08 | Hexatech, Inc. | Liquid sanitization device |

| JP2010110703A (ja) * | 2008-11-07 | 2010-05-20 | Hitachi Ltd | 紫外線水処理装置 |

| WO2010104225A1 (ko) * | 2009-03-12 | 2010-09-16 | Kim Jong Shin | 자동 소변분석 시스템 및 그 장치 |

| MX2010009169A (es) * | 2010-08-10 | 2012-02-21 | Andres Abelino Choza Romero | Aparato para desinfectar líquidos, mediante el uso de luz ultravioleta. |

| CN102243244A (zh) | 2011-04-13 | 2011-11-16 | 北京吉天仪器有限公司 | 溶液中总氮自动分析仪及其分析方法 |

| JP2013075257A (ja) * | 2011-09-30 | 2013-04-25 | Panasonic Corp | 殺菌容器 |

| JP2013134141A (ja) * | 2011-12-26 | 2013-07-08 | Hitachi High-Technologies Corp | 自動分析装置 |

| US9212067B2 (en) * | 2012-05-30 | 2015-12-15 | Flozinc, Llc | Water bottle with flow meter |

| US20140084179A1 (en) * | 2012-09-25 | 2014-03-27 | Hemalux Technologies LLC | Exposure chamber and a system for reduction of pathogens in a biological fluid using ultraviolet irradiation by light emitting diodes |

| JP5496306B2 (ja) | 2012-10-31 | 2014-05-21 | 株式会社トクヤマ | 紫外線殺菌装置 |

| JP2014126415A (ja) * | 2012-12-26 | 2014-07-07 | Hitachi High-Technologies Corp | 自動分析装置 |

| CN103207284A (zh) * | 2013-03-25 | 2013-07-17 | 山东博科生物产业有限公司 | 生物安全酶免工作站及利用其进行酶联免疫试验的方法 |

| EP3170796B1 (en) * | 2013-05-22 | 2019-02-27 | Merck Patent GmbH | Biocidal purification device |

| WO2015042657A1 (en) * | 2013-09-30 | 2015-04-02 | Yu Lawrence | Portable ultraviolet attachment for water purification |

| JP6438265B2 (ja) | 2014-10-17 | 2018-12-12 | 三菱重工機械システム株式会社 | 飲料用容器の殺菌装置 |

-

2016

- 2016-06-09 JP JP2016114924A patent/JP6591932B2/ja active Active

-

2017

- 2017-04-24 WO PCT/JP2017/016151 patent/WO2017212808A1/ja not_active Ceased

- 2017-04-24 CN CN201780034514.0A patent/CN109219751B/zh active Active

- 2017-04-24 EP EP17809990.9A patent/EP3470849B1/en active Active

- 2017-04-24 US US16/307,787 patent/US11293934B2/en active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS527962U (enExample) * | 1975-07-04 | 1977-01-20 | ||

| JPS63163168A (ja) * | 1986-12-25 | 1988-07-06 | Sumitomo Electric Ind Ltd | 液体分注装置 |

| JPH03503730A (ja) * | 1988-03-29 | 1991-08-22 | イアトロス リミテッド | 血液処理装置 |

| JPH08117742A (ja) * | 1994-10-21 | 1996-05-14 | Tadahide Iwashita | 殺菌装置付き容器用蓋 |

| JPH10216711A (ja) * | 1997-02-06 | 1998-08-18 | Kurihara Kogyo:Kk | 水処理装置 |

| JP2007007083A (ja) * | 2005-06-29 | 2007-01-18 | Univ Of Tokushima | 紫外線殺菌装置 |

| JP2011147362A (ja) * | 2010-01-19 | 2011-08-04 | Hitachi Plant Technologies Ltd | 浮遊菌捕集装置、浮遊菌計測方法及び浮遊菌計測システム |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019082524A1 (ja) * | 2017-10-25 | 2019-05-02 | 株式会社日立ハイテクノロジーズ | 分析装置 |

| US11517636B2 (en) | 2017-10-25 | 2022-12-06 | Hitachi High-Tech Corporation | Analyzer |

Also Published As

| Publication number | Publication date |

|---|---|

| CN109219751A (zh) | 2019-01-15 |

| US20190310275A1 (en) | 2019-10-10 |

| CN109219751B (zh) | 2022-05-03 |

| US11293934B2 (en) | 2022-04-05 |

| EP3470849A1 (en) | 2019-04-17 |

| EP3470849B1 (en) | 2020-12-30 |

| EP3470849A4 (en) | 2020-01-15 |

| JP6591932B2 (ja) | 2019-10-16 |

| JP2017219452A (ja) | 2017-12-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6591932B2 (ja) | 自動分析装置 | |

| JP6506741B2 (ja) | 殺生物性浄化デバイス | |

| JP2017219452A5 (enExample) | ||

| JP6660861B2 (ja) | 自動分析装置 | |

| PT1923356E (pt) | Aparelho de desinfecção de água | |

| JP7716991B2 (ja) | 医療機器消毒用筐体 | |

| JP2021041382A (ja) | 流体殺菌装置 | |

| WO2013153728A1 (ja) | 紫外線殺菌装置 | |

| JP7001702B2 (ja) | 分析装置 | |

| US12292453B2 (en) | Automatic analysis apparatus | |

| US20210087077A1 (en) | Fluid Sterilizer | |

| KR102255508B1 (ko) | 자외선 공기 살균장치 | |

| US11771782B2 (en) | UV-C LED disinfection device | |

| CN220922665U (zh) | 一种切配机 | |

| JP6764810B2 (ja) | 自動分析装置 | |

| KR20240052064A (ko) | 조사(照射) 장치 및 방법 | |

| Steinborn | Safety Check and Maintenance: Or why Maintenance of a Laser Device Makes Good Sense | |

| JP2017077401A (ja) | チェーフィングディッシュ | |

| KR20180000006U (ko) | 자외선 발광 장치를 구비한 컴퓨터 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17809990 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2017809990 Country of ref document: EP Effective date: 20190109 |