WO2017051751A1 - 木管楽器用リード - Google Patents

木管楽器用リード Download PDFInfo

- Publication number

- WO2017051751A1 WO2017051751A1 PCT/JP2016/076984 JP2016076984W WO2017051751A1 WO 2017051751 A1 WO2017051751 A1 WO 2017051751A1 JP 2016076984 W JP2016076984 W JP 2016076984W WO 2017051751 A1 WO2017051751 A1 WO 2017051751A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- woodwind instrument

- instrument lead

- lead

- woodwind

- vamp

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10D—STRINGED MUSICAL INSTRUMENTS; WIND MUSICAL INSTRUMENTS; ACCORDIONS OR CONCERTINAS; PERCUSSION MUSICAL INSTRUMENTS; AEOLIAN HARPS; SINGING-FLAME MUSICAL INSTRUMENTS; MUSICAL INSTRUMENTS NOT OTHERWISE PROVIDED FOR

- G10D9/00—Details of, or accessories for, wind musical instruments

- G10D9/08—Material for manufacturing wind musical instruments; Treatment of the material

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10D—STRINGED MUSICAL INSTRUMENTS; WIND MUSICAL INSTRUMENTS; ACCORDIONS OR CONCERTINAS; PERCUSSION MUSICAL INSTRUMENTS; AEOLIAN HARPS; SINGING-FLAME MUSICAL INSTRUMENTS; MUSICAL INSTRUMENTS NOT OTHERWISE PROVIDED FOR

- G10D7/00—General design of wind musical instruments

- G10D7/06—Beating-reed wind instruments, e.g. single or double reed wind instruments

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10D—STRINGED MUSICAL INSTRUMENTS; WIND MUSICAL INSTRUMENTS; ACCORDIONS OR CONCERTINAS; PERCUSSION MUSICAL INSTRUMENTS; AEOLIAN HARPS; SINGING-FLAME MUSICAL INSTRUMENTS; MUSICAL INSTRUMENTS NOT OTHERWISE PROVIDED FOR

- G10D9/00—Details of, or accessories for, wind musical instruments

- G10D9/02—Mouthpieces; Reeds; Ligatures

Definitions

- the present invention relates to a woodwind instrument lead.

- woodwind instruments such as saxophones and clarinets generate sound by vibrating a strip-shaped lead attached to the mouth where the player breathes.

- Woodwind reeds are generally made of natural materials such as bamboo and bamboo, and have a vamp (Vamp) whose surface has been scraped to gradually reduce the thickness toward the longitudinal end of the player's mouth. ) Is provided.

- woodwind reeds formed from such natural materials have the disadvantage of large individual variations. For this reason, even if the user is a non-skilled player with a relatively low level of skill, select a lead that provides a satisfactory tone from among multiple leads, and do not use a lead that does not provide a satisfactory tone. The actual situation is that they are discarded. Specifically, woodwind reeds are often sold as a set of 10 pieces, but even a general user judges that only 2 to 3 pieces can be used in practice. There are many cases to do.

- Woodwind reeds made of bamboo and bamboo have the disadvantage that their life is relatively short because degradation is accelerated by exposure to such moisture. For this reason, the lead

- Japanese Patent Application Laid-Open No. 2001-75556 proposes forming a woodwind instrument lead from a liquid crystal polymer.

- an object of the present invention is to provide a woodwind instrument lead having a relatively small quality variation and a relatively excellent tone.

- the invention made to solve the above-mentioned problems is a strip-shaped woodwind instrument lead having a synthetic resin as a matrix and a vamp on one end in the longitudinal direction, wherein the vamp A woodwind instrument lead comprising a plurality of concave or convex strips parallel to each other in an overlapping region.

- the woodwind instrument lead has a plurality of concave or convex strips parallel to each other in a region overlapping with the vamp in at least a plan view of the front surface or the rear surface. It can generate a natural sound that is relatively close to the woodwind instrument reed formed from the material and a new sound in the ear that was not obtained in the past.

- the concave valley line or the convex ridge line is along the longitudinal direction of the lead.

- the concave line or the ridge line is formed from a natural material by being along the longitudinal direction of the lead in the same manner as the direction of fibers in the woodwind instrument lead formed from a natural material. A natural tone that is closer to the reed for woodwind instruments.

- the cross-sectional shape of the plurality of grooves or ridges may vary depending on the position of the grooves or ridges in the longitudinal direction.

- vibration characteristics such as the first tone, the body tone, and the original tone are artificially created.

- the tone color can be adjusted.

- the groove has a plurality of grooves, and the opening width of the grooves is larger than the bottom width.

- the plurality of concave stripes, and the opening width of the concave stripes being larger than the bottom width, it becomes easy to clean dirt such as saliva, and hygiene can be improved.

- the plurality of concave stripes or convex stripes may be formed on the surface of the vamp.

- the surface abutting on the mouthpiece can be flattened, and the plurality of grooves or ridges can be designed.

- the woodwind instrument lead of the present invention has a relatively small variation in quality and a relatively excellent tone.

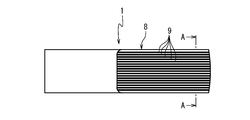

- FIG. 3 is a schematic plan view of the saxophone woodwind reed of FIG. 1.

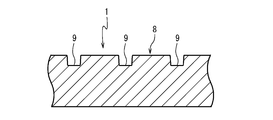

- FIG. 4 is a partial enlarged cross-sectional view taken along the line AA of the woodwind instrument lead in FIG. 3.

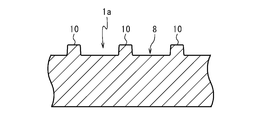

- FIG. 5 is an enlarged partial cross-sectional view corresponding to FIG. 4 of a woodwind instrument lead different from FIG. 4.

- FIG. 6 is an enlarged partial cross-sectional view corresponding to FIG. 4 of a woodwind instrument lead different from FIGS. 4 and 5.

- FIG. 4 is a partial enlarged cross-sectional view taken along the line AA of the woodwind instrument lead in FIG. 3.

- FIG. 5 is an enlarged partial cross-sectional view corresponding to FIG. 4 of a woodwind instrument lead different from FIG. 4.

- FIG. 6 is an enlarged partial cross-sectional view corresponding to FIG. 4 of a woodwind instrument lead different from FIGS. 4 and 5.

- FIG. 4 is a partial enlarged cross-sectional view taken along the line AA of the wood

- FIGS. 7 is a schematic plan view of a woodwind instrument lead different from FIGS. 4 to 6.

- FIG. 8 is a schematic plan view of a woodwind instrument lead different from FIGS. 4 to 7.

- FIG. 9 is a schematic perspective view of a woodwind instrument lead different from FIGS. 4 to 8.

- FIG. 1 shows a saxophone which is a kind of woodwind instrument using a woodwind instrument lead 1 according to an embodiment of the present invention.

- the saxophone shown in FIG. 1 is provided with a mouthpiece 3 having a woodwind instrument lead 1 attached to one end of a saxophone body 2.

- the saxophone body 2 is provided with a mouthpiece 3 attached to one end and a bent tube portion 4 that is opened so that the other end is enlarged in diameter, and a plurality of sound holes formed in the tube portion 4 are provided. A plurality of keys 5 that can be sealed are provided, and a lever 6 for operating these keys 5 is provided.

- the configuration of the saxophone main body 2 can be the same as the configuration of the conventional saxophone main body.

- the mouthpiece 3 is attached to one end of the saxophone main body 2 and is used by the player to blow into the saxophone main body 2 and vibrate the woodwind instrument lead 1.

- the mouthpiece 3 is formed in a substantially cylindrical shape, and has a shape in which one end side where the player gets into the mouth is flat and crushed, and the side in contact with the lower lip of the player is wide open.

- the woodwind instrument lead 1 is attached so as to seal the opening.

- the woodwind instrument lead 1 is fixed to the mouthpiece 3 by a ligature 7 attached to the outer periphery of the mouthpiece 3. As the mouthpiece 3 and the ligature 7, those having a conventional configuration can be used.

- FIG. 3 shows the detailed shape of the woodwind instrument lead 1.

- the woodwind instrument lead 1 is formed in a strip shape using a synthetic resin as a matrix, and has a bump 8 on one end side in the longitudinal direction.

- the woodwind instrument lead 1 has a plurality of recesses (elongate grooves) 9 parallel to each other on the surface of the vamp 8.

- the plurality of concave stripes 9 impart anisotropy to the vibration characteristics of the vamp 8.

- the plurality of recesses 9 reduce the rigidity of the vamp 8, but the decrease in bending rigidity in the direction perpendicular to the plurality of recesses 9 is greater than the decrease in bending rigidity in the direction along the recesses 9.

- the woodwind instrument lead 1 can adjust the vibration characteristics of the vamp 8 by the concave strip 9, and can be brought close to the vibration characteristics of the woodwind instrument lead formed of a natural material. Therefore, the woodwind instrument lead 1 having the plurality of concave strips 9 can generate a relatively natural sound when attached to the woodwind instrument and played.

- the woodwind instrument lead 1 is curved so that the surface of the portion where the vamp 8 is not formed forms part of the cylindrical surface.

- the curved surface has a longitudinal axis parallel to the back surface and bulges to the front surface side.

- the woodwind instrument lead 1 is held integrally with the mouthpiece 3 by tightening the portion where the vamp 8 is not formed with the ligature 7 as shown in FIGS.

- the vamp 8 is formed to gradually reduce the thickness of the woodwind instrument lead 1 toward the end in the longitudinal direction on the side where the player crawls. More specifically, the vamp 8 is generally curved so that the inclination angle becomes larger toward the heel (longitudinal end portion where the vamp 8 is not formed) of the woodwind instrument lead 1, and the tip side is substantially flat. Formed to stretch.

- the curved shape of the vamp 8 is the same as the curved shape with the vamp formed on the conventional lead.

- the rough shape of the woodwind instrument lead 1 that does not take into account the recess 9 is the same shape as that of a conventional lead formed from a bag or the like.

- the width is about 15 mm

- the length is about 70 mm

- the vamp 8 is formed.

- the maximum thickness of the unexposed portion is about 3 mm

- the thickness at the tip of the vamp 8 is about 0.15 mm.

- the lower limit of the modulus of elasticity of the material forming the woodwind instrument lead 1 is preferably 3000 MPa, more preferably 4000 MPa.

- the upper limit of the elastic modulus of the material forming the woodwind instrument lead 1 is preferably 10,000 MPa, and more preferably 8000 MPa.

- the elastic modulus of the material forming the woodwind instrument lead 1 is less than the lower limit, the sound speed may be small and the acoustic effect may be insufficient.

- the elastic modulus of the material forming the woodwind instrument lead 1 exceeds the upper limit, the woodwind instrument lead 1 becomes too hard, and there is a possibility that sufficient vibration cannot be obtained.

- the elastic modulus is a value measured according to JIS-K7171 (2008).

- polypropylene can be used as a synthetic resin that is a matrix of the material forming the woodwind instrument lead 1.

- the material forming the woodwind instrument lead 1 may include, for example, natural fibers such as wood fibers and bamboo fibers, inorganic fibers such as glass fibers, and synthetic fibers such as polyamide fibers in the matrix.

- the fibers in the matrix improve the rigidity of the woodwind reed 1.

- the lower limit of the fiber content in the material forming the woodwind instrument lead 1 is not particularly limited, but is preferably 10% by mass, more preferably 20% by mass.

- the upper limit of the fiber content in the material forming the woodwind reed 1 is preferably 70% by mass, more preferably 60% by mass.

- the lower limit of the average length of fibers contained in the material forming the woodwind instrument lead 1 is preferably 3 ⁇ m, and more preferably 5 ⁇ m.

- the upper limit of the average length of fibers contained in the material forming the woodwind instrument lead 1 is preferably 50 ⁇ m, and more preferably 30 ⁇ m. If the average length of the fibers is less than the lower limit, the rigidity of the woodwind instrument lead 1 may not be sufficiently improved. On the other hand, when the average length of the fibers exceeds the upper limit, it may be difficult to manufacture the woodwind instrument lead 1 by injection molding.

- the physical property of the material becomes constant by forming the woodwind instrument lead 1 from a material having a synthetic resin as a matrix. For this reason, since the woodwind instrument lead 1 has a certain vibration characteristic, the timbre variation generated is small.

- the plurality of concave stripes 9 are formed at substantially constant intervals on the entire surface of the vamp 8.

- the valley lines of these concave strips 9 are oriented along the longitudinal direction of the woodwind instrument lead 1.

- the rigidity in the longitudinal direction of the vamp 8 is relatively increased, and the vibration characteristic of the woodwind instrument lead 1 can be brought close to the vibration characteristic of the woodwind instrument lead formed of a natural material. Therefore, the woodwind instrument lead 1 having the plurality of concave strips 9 can generate a relatively natural sound when attached to the woodwind instrument and played.

- vertical to the longitudinal direction of the said some groove 9 can be made into the substantially square shape which has a pair of side surface and a bottom face.

- the opening width of the recess 9 is preferably larger than the bottom width. That is, it is preferable that the pair of side surfaces of the concave strip 9 having a quadrangular cross section is inclined so that the distance between the side surfaces becomes larger on the opening side.

- the lower limit of the angle of inclination of each side surface of the concave strip 9 with respect to the thickness direction of the woodwind instrument lead 1 is preferably 1 ° and more preferably 3 °.

- the upper limit of the inclination angle of each side surface of the concave strip 9 with respect to the thickness direction of the woodwind instrument lead 1 is preferably 45 °, more preferably 30 °. If the inclination angle of each side surface of the concave strip 9 with respect to the thickness direction of the woodwind instrument lead 1 is less than the lower limit, the releasability from the mold is insufficient when the woodwind instrument lead 1 is injection molded. There is a risk that the drainage performance of saliva, washing water, etc. of the recess 9 will be insufficient.

- the lower limit of the average width of the entire plurality of concave strips 9 is preferably 10 ⁇ m, and more preferably 20 ⁇ m.

- the upper limit of the average width of the entire plurality of concave strips 9 is preferably 500 ⁇ m, and more preferably 200 ⁇ m.

- the concave ridges 9 may give the player a sense of incongruity, and the tone improvement effect by the concave ridges 9 may be insufficient.

- the lower limit of the average depth of the concave strip 9 (the average value of the maximum depth in each cross section) is preferably 10 ⁇ m, and more preferably 20 ⁇ m.

- the upper limit of the average depth of the groove 9 is preferably 300 ⁇ m, and more preferably 200 ⁇ m.

- the tone improvement effect by the groove 9 may be insufficient.

- the groove 9 may give the player a sense of incongruity, or the processing of the groove 9 may be difficult.

- the lower limit of the average center interval (arrangement pitch) of the concave stripes 9 is preferably 0.1 mm, and more preferably 0.2 mm.

- the upper limit of the average center distance of the concave stripes 9 is preferably 2 mm, and more preferably 1 mm.

- the corners of the recess 9 are chamfered in the cross-sectional shape. That is, it is preferable that the side surface and the bottom surface of the recess 9 and the surface of the vamp 8 are connected gently. Thereby, while improving the drainage property of the groove 9, it can make it hard to give a discomfort to a player. Further, by chamfering the corners of the concave strip 9, the woodwind instrument lead 1 can be easily formed by injection molding.

- the cross-sectional shape of the concave strip 9 may vary depending on the position in the longitudinal direction. Thereby, the rigidity of the vamp 8 can be changed according to the position in the longitudinal direction.

- the maximum depth in each cross-section of the groove 9 may be gradually decreased toward the tip of the vamp 8. As a result, it is possible to prevent the strength of the woodwind instrument lead 1 from becoming insufficient at the tip of the vamp 8.

- the concave 9 may not be provided at the tip of the vamp 8. Thereby, since a too thin part is not formed in the front-end

- the rigidity of the vamp 8 can be changed according to the position in the longitudinal direction. That is, the rigidity of the vamp 8 can be partially reduced by increasing the width of the recess 9 in a part of the longitudinal direction. Therefore, due to the change in the width of the concave strip 9, the tip of the vamp 8 has a softer tone, the longitudinal center of the vamp 8 has a relatively soft body tone, and the heel side of the vamp 8 has a relatively soft original tone. Can be granted. Thereby, it is possible to characterize the tone color of the woodwind instrument lead 1.

- the woodwind instrument lead 1 can be manufactured by injection molding using a mold of a composition having a synthetic resin as a matrix.

- the woodwind instrument lead 1 has an end portion, more specifically, a vamp 8, which tends to be unstable in filling the mold cavity with the resin composition after injection molding.

- the tip edge may be excised.

- the woodwind instrument lead 1 is made of a natural material by forming a plurality of concave strips 9 on the surface of the vamp 8 to impart anisotropy to vibration characteristics. Natural sound that is relatively close to can be generated.

- the woodwind instrument lead 1 is not limited to the saxophone as shown in FIG. 1, but can be used for other woodwind instruments such as clarinet.

- a tree using two leads such as oboe and bassoon. It can also be used for wind instruments.

- the woodwind instrument lead 1 is used for only one of the two leads, and the other lead does not have a conventional lead or a concave or convex shape formed from a natural material.

- a conventional resin lead may be used.

- FIG. 5 is a partially enlarged cross-sectional view of the vamp 8 of a woodwind instrument lead 1a according to another embodiment of the present invention.

- the woodwind instrument lead 1a is formed in a band plate shape using a synthetic resin as a matrix, and has a bump 8 on one end side in the longitudinal direction.

- the woodwind instrument lead 1 a has a plurality of ridges (elongated protrusions) 10 parallel to each other on the surface of the vamp 8.

- the woodwind instrument lead 1a in FIG. 5 can be considered to be formed by forming a ridge 10 in place of the recess 9 in the woodwind instrument lead 1 in FIG. Therefore, the material of the woodwind instrument lead 1a in FIG. 5 and the schematic shape including the vamp 8 are the same as the material of the woodwind instrument lead 1 in FIG. Therefore, the description of the woodwind instrument lead 1a in FIG. 5 that is the same as the woodwind instrument lead 1 in FIG. 3 is omitted.

- the plurality of ridges 10 are formed on the entire surface of the vamp 8 at regular intervals.

- the ridgelines of these ridges 10 are oriented along the longitudinal direction of the woodwind instrument lead 1a.

- line 10 can be made into the substantially square shape which has a pair of side surface and a top surface.

- the width of the top surface of the ridge 10 is preferably smaller than the width of the bottom. That is, it is preferable that the ridge 10 has a trapezoidal cross section in which the pair of side surfaces are inclined so that the distance between the side surfaces becomes smaller on the top side.

- the lower limit of the inclination angle of each side surface of the ridge 10 with respect to the thickness direction of the woodwind instrument lead 1a is preferably 1 ° and more preferably 3 °.

- the upper limit of the inclination angle of each side surface of the ridge 10 with respect to the thickness direction of the woodwind instrument lead 1a is preferably 45 °, more preferably 30 °.

- the lower limit of the average width of the ridges 10 is preferably 10 ⁇ m, and more preferably 20 ⁇ m.

- the upper limit of the average width of the ridges 10 is preferably 1000 ⁇ m, and more preferably 2000 ⁇ m.

- the upper limit of the average height of the ridges 10 is preferably 100 ⁇ m, and more preferably 50 ⁇ m. If the average height of the ridges 10 is less than the lower limit, the tone improvement effect by the ridges 10 may be insufficient. On the other hand, when the average height of the ridges 10 exceeds the upper limit, the ridges 10 may give the player a sense of discomfort or the processing of the ridges 10 may be difficult.

- line 10 As a minimum of the average center space

- the upper limit of the average center distance of the ridges 10 is preferably 1.0 mm, and more preferably 0.5 mm.

- line 10 is less than the said minimum, there exists a possibility that the process of the protruding item

- line 10 exceeds the said upper limit, there exists a possibility that the timbre improvement effect by the protruding item

- the ridge 10 has a chamfered corner in the cross-sectional shape. That is, it is preferable that the side surface of the ridge 10 and the top surface and the surface of the vamp 8 are connected gently. Thereby, while improving the drainage property of the protruding item

- the cross-sectional shape of the ridge 10, that is, the maximum height and width in each cross-section of the ridge 10 may vary depending on the position in the longitudinal direction. Thereby, it is possible to characterize the tone color of the woodwind instrument lead 1a.

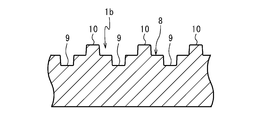

- FIG. 6 is a partially enlarged cross-sectional view of a vamp 8 of a woodwind instrument lead 1b according to another embodiment of the present invention.

- the woodwind instrument lead 1b is formed in a band plate shape using a synthetic resin as a matrix, and has a bump 8 on one end side in the longitudinal direction.

- the woodwind instrument lead 1b has a plurality of concave strips 9 and a plurality of convex strips 10 parallel to each other on the surface of the vamp 8.

- the concave stripes 9 and the convex stripes 10 are alternately arranged.

- the material of the woodwind instrument lead 1b in FIG. 6 and the schematic shape including the vamp 8 are the same as the material of the woodwind instrument lead 1 in FIG. 6 is the same as the groove 9 in the woodwind instrument lead 1 in FIG. 4, and the protrusion 10 in the woodwind lead 1b in FIG. This is the same as the protrusion 10 in the woodwind instrument lead 1a. Therefore, the description of the woodwind instrument lead 1b in FIG. 6 that is the same as the woodwind instrument lead 1 in FIG. 3 or the woodwind instrument lead 1a in FIG. 5 is omitted.

- the woodwind instrument lead 1b has a plurality of ridges 9 and a plurality of ridges 10, the anisotropy of the vibration characteristics of the vamp 8 can be further increased.

- the woodwind instrument lead 1b increases the rigidity in the longitudinal direction of the woodwind instrument lead 1b by increasing / decreasing the number of the grooves 9 and the protrusions 10 so that the ratio of both is kept constant at the time of designing.

- the rigidity in the width direction (short direction) can be changed while being kept substantially constant.

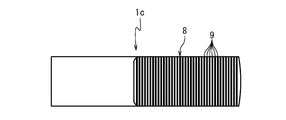

- FIG. 7 shows a woodwind instrument lead 1c according to another embodiment of the present invention.

- the woodwind instrument lead 1c is formed in a band plate shape using a synthetic resin as a matrix, and has a bump 8 on one end side in the longitudinal direction.

- the woodwind instrument lead 1 c has a plurality of concave strips 9 parallel to each other on the surface of the vamp 8.

- the plurality of recesses 9 are formed such that each valley line is along the width direction of the woodwind instrument lead 1c.

- the cross-sectional shape of the groove 9 and the average center interval are as follows. This is the same as the general shape, the cross-sectional shape of the concave strip 9 and the average center interval. Therefore, the description of the woodwind instrument lead 1c in FIG. 7 that is the same as the woodwind instrument lead 1 in FIG. 3 is omitted.

- the woodwind instrument lead 1c is formed such that the plurality of concave strips 9 cross the vamp 8 in the width direction, so that the rigidity of the vamp 8 is greatly reduced by the concave strip 9 in the longitudinal direction. For this reason, the woodwind instrument lead 1c is relatively different in vibration characteristics from a lead formed from a conventional natural material having relatively large longitudinal rigidity. As a result, when the woodwind instrument lead 1c is used by being attached to a mouthpiece of a woodwind instrument, a new timbre can be produced in an ear that is relatively different from the conventional one. In other words, by using the woodwind instrument lead 1c, it is possible to form a woodwind instrument having a characteristic and attractive tone that is not present in the past.

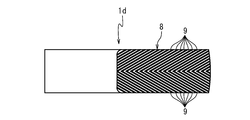

- FIG. 8 shows a woodwind instrument lead 1d according to another embodiment of the present invention.

- the woodwind instrument lead 1d is made of a synthetic resin as a matrix, is formed in a band plate shape, and has a bump 8 on one end side in the longitudinal direction.

- the woodwind instrument lead 1d is formed on the surface of the vamp 8 with a plurality of concave strips 9 that are symmetrical in the width direction and whose valley line is inclined with respect to the longitudinal direction of the woodwind instrument lead 1d. ing.

- the woodwind instrument lead 1d since the plurality of concave strips 9 are arranged to be inclined, the rigidity of the vamp 8 becomes relatively large in the direction along the inclination angle of the concave strip 9. Therefore, the sound generated by the woodwind instrument lead 1d has a different tone color depending on the inclination angle of the groove 9. In other words, the woodwind instrument lead 1d can adjust the timbre according to the inclination angle of the groove 9.

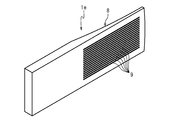

- FIG. 9 shows a woodwind instrument lead 1e according to another embodiment of the present invention.

- the woodwind instrument lead 1e is made of a synthetic resin as a matrix, is formed in a strip shape, and has a bump 8 on one end side in the longitudinal direction.

- the woodwind instrument lead 1e has a plurality of concave strips 9 formed in parallel to each other in a region excluding the vicinity of the outer edge of the back surface of the vamp 8, that is, a region not in contact with the mouthpiece 3.

- the plurality of concave strips 9 are oriented such that the valley lines are along the longitudinal direction of the woodwind instrument lead 1.

- the material and outline shape, the cross-sectional shape of the recess 9 and the average center interval are the same as those of the woodwind instrument lead 1 of FIG. This is the same as the shape, the cross-sectional shape of the recess 9 and the average center distance. Therefore, the description of the woodwind instrument lead 1e in FIG. 9 that is the same as the woodwind instrument lead 1 in FIG. 3 is omitted.

- the woodwind instrument lead 1e is provided with a plurality of grooves 9 on the back surface of the vamp 8, so that the player does not directly touch the grooves 9, and the player feels uncomfortable even when the grooves 9 are relatively large. I don't feel it.

- the plurality of concave stripes 9 are formed in a region that does not come into contact with the mouthpiece 3, the characteristic change due to wear is not promoted.

- the woodwind instrument lead may have concave or convex stripes on the front and back surfaces, respectively.

- the groove or ridge may be formed in a region overlapping at least a part of the vamp in plan view, or may be formed to extend in a region not overlapping with the vamp in plan view.

- the center distance between the ridges or ridges may not be constant.

- interval of a groove or a protrusion may differ in the width direction center vicinity area

- the arrangement of the ridges and the ridges may not be alternate.

- a convex shape may be provided instead of the concave stripe or in addition to the concave stripe.

- the woodwind reed may have a ridge on the back of the vamp. Further, the concave stripes or the convex stripes may be formed in a region in contact with the mouthpiece on the back surface of the vamp.

- the cross-sectional shape of the ridges or ridges is not limited to a square shape, and may be, for example, a semicircular shape or an elliptical shape.

- the concave or convex stripes when there are concave or convex stripes having different directions, it is preferable that the concave or convex stripes do not intersect in a lattice pattern. This is because if the concave stripes or the convex stripes intersect, there is a risk that saliva or the like may not be easily discharged at the intersection. Therefore, the left and right symmetrical concave grooves of the woodwind instrument lead of the fifth embodiment may be formed separately from each other so as not to extend on the axis of symmetry.

- the woodwind instrument lead is not limited to injection molding, and may be formed by cutting out a block or plate material, for example.

- the reed for woodwind instruments of the present invention can be widely used not only for saxophones but also for other woodwind instruments that use reeds.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Acoustics & Sound (AREA)

- Multimedia (AREA)

- Manufacturing & Machinery (AREA)

- Auxiliary Devices For Music (AREA)

- Stringed Musical Instruments (AREA)

- Electrophonic Musical Instruments (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015186712A JP2017062310A (ja) | 2015-09-24 | 2015-09-24 | 木管楽器用リード |

| JP2015-186712 | 2015-09-24 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017051751A1 true WO2017051751A1 (ja) | 2017-03-30 |

Family

ID=58386593

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2016/076984 Ceased WO2017051751A1 (ja) | 2015-09-24 | 2016-09-13 | 木管楽器用リード |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP2017062310A (enExample) |

| WO (1) | WO2017051751A1 (enExample) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109671415A (zh) * | 2019-01-30 | 2019-04-23 | 杭州松联五金制品有限公司 | 萨克斯可调式变音笛头 |

| WO2019079837A1 (de) * | 2017-10-27 | 2019-05-02 | Kueckmeier Nick | Rohrblatt |

| DE102022000664A1 (de) | 2022-02-24 | 2023-08-24 | Neo-Plastic Dr. Doetsch Diespeck Gmbh | Tonerzeugendes Blatt für Blasinstrumente |

| EP4432275A1 (en) * | 2023-03-16 | 2024-09-18 | Yamaha Corporation | Reed and manufacturing method thereof |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2021230361A1 (ja) * | 2020-05-14 | 2021-11-18 | 株式会社タツミ楽器 | ベル挿嵌型管楽器用消音器及び減音作用を有するリード |

| JP2023071544A (ja) * | 2021-11-11 | 2023-05-23 | ヤマハ株式会社 | リード、マウスピースおよび吹き込み部 |

| JPWO2023176475A1 (enExample) * | 2022-03-16 | 2023-09-21 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1667836A (en) * | 1927-03-15 | 1928-05-01 | Jr Frederick Brockman | Reed for musical wind instruments |

| US4014241A (en) * | 1976-02-11 | 1977-03-29 | Gamble George W | Synthetic woodwind reed |

| JPH03117290U (enExample) * | 1990-03-14 | 1991-12-04 | ||

| JP2012190020A (ja) * | 2011-03-10 | 2012-10-04 | Kyong-Hwang Ku | サックスフォン用リード |

-

2015

- 2015-09-24 JP JP2015186712A patent/JP2017062310A/ja active Pending

-

2016

- 2016-09-13 WO PCT/JP2016/076984 patent/WO2017051751A1/ja not_active Ceased

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1667836A (en) * | 1927-03-15 | 1928-05-01 | Jr Frederick Brockman | Reed for musical wind instruments |

| US4014241A (en) * | 1976-02-11 | 1977-03-29 | Gamble George W | Synthetic woodwind reed |

| JPH03117290U (enExample) * | 1990-03-14 | 1991-12-04 | ||

| JP2012190020A (ja) * | 2011-03-10 | 2012-10-04 | Kyong-Hwang Ku | サックスフォン用リード |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019079837A1 (de) * | 2017-10-27 | 2019-05-02 | Kueckmeier Nick | Rohrblatt |

| KR20200078509A (ko) * | 2017-10-27 | 2020-07-01 | 닉 퀴크마이어 | 리드 |

| US20210193089A1 (en) * | 2017-10-27 | 2021-06-24 | Nick KÜCKMEIER | Reed |

| KR102382293B1 (ko) | 2017-10-27 | 2022-04-08 | 닉 퀴크마이어 | 리드 |

| CN109671415A (zh) * | 2019-01-30 | 2019-04-23 | 杭州松联五金制品有限公司 | 萨克斯可调式变音笛头 |

| CN109671415B (zh) * | 2019-01-30 | 2022-09-16 | 遵义中立精工制造有限公司 | 萨克斯可调式变音笛头 |

| DE102022000664A1 (de) | 2022-02-24 | 2023-08-24 | Neo-Plastic Dr. Doetsch Diespeck Gmbh | Tonerzeugendes Blatt für Blasinstrumente |

| WO2023161151A1 (de) | 2022-02-24 | 2023-08-31 | Neo-Plastic Dr. Doetsch Diespeck Gmbh | Tonerzeugendes blatt für blasinstrumente |

| EP4432275A1 (en) * | 2023-03-16 | 2024-09-18 | Yamaha Corporation | Reed and manufacturing method thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2017062310A (ja) | 2017-03-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2017051751A1 (ja) | 木管楽器用リード | |

| US7067729B2 (en) | Plectrum | |

| JP6701759B2 (ja) | 木管楽器用リード | |

| US20100011937A1 (en) | Mouthpiece of brass instrument | |

| ITVR20100026A1 (it) | Plettro rigido per strumenti a corda | |

| US4014241A (en) | Synthetic woodwind reed | |

| US2342836A (en) | Reed for musical instruments | |

| KR101151231B1 (ko) | 색소폰용 리드 | |

| US3611860A (en) | Mouthpiece for musical instruments | |

| JP2017134233A (ja) | 木管楽器用リード及び木管楽器用リードの製造方法 | |

| US20050061137A1 (en) | Reed for single-reed woodwind instruments | |

| US20180322851A1 (en) | Woodwind instrument reed and method for producing woodwind instrument reed | |

| JP7304867B2 (ja) | 通常の把持部と増厚弦接触部分とを有するプレクトラム | |

| JP7317842B2 (ja) | リード | |

| JP6690330B2 (ja) | マウスピース及びアタッチメント | |

| JP2006113141A (ja) | 気流調整具 | |

| TWM579371U (zh) | Mouthpiece | |

| JP2017134350A (ja) | 木管楽器用リード及び木管楽器用リードの製造方法 | |

| KR101812481B1 (ko) | 색소폰 마우스피스용 공명 스티커 | |

| US10204608B1 (en) | Mouthpiece rim for non-french horn labrosone musical brass instruments | |

| JP6022150B2 (ja) | 弦楽器演奏用の指カバー | |

| US2268641A (en) | Reed for musical instruments | |

| KR20200145792A (ko) | 리드악기의 마우스피스용 쿠션패드 | |

| JP7674755B2 (ja) | マウスピース | |

| US1063203A (en) | Mandolin. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 16848539 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 16848539 Country of ref document: EP Kind code of ref document: A1 |