WO2014007229A1 - 改変型アルカリホスファターゼ - Google Patents

改変型アルカリホスファターゼ Download PDFInfo

- Publication number

- WO2014007229A1 WO2014007229A1 PCT/JP2013/068085 JP2013068085W WO2014007229A1 WO 2014007229 A1 WO2014007229 A1 WO 2014007229A1 JP 2013068085 W JP2013068085 W JP 2013068085W WO 2014007229 A1 WO2014007229 A1 WO 2014007229A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- amino acid

- alkaline phosphatase

- lysine

- seq

- acid sequence

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12N—MICROORGANISMS OR ENZYMES; COMPOSITIONS THEREOF; PROPAGATING, PRESERVING, OR MAINTAINING MICROORGANISMS; MUTATION OR GENETIC ENGINEERING; CULTURE MEDIA

- C12N9/00—Enzymes; Proenzymes; Compositions thereof; Processes for preparing, activating, inhibiting, separating or purifying enzymes

- C12N9/14—Hydrolases (3)

- C12N9/16—Hydrolases (3) acting on ester bonds (3.1)

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12Q—MEASURING OR TESTING PROCESSES INVOLVING ENZYMES, NUCLEIC ACIDS OR MICROORGANISMS; COMPOSITIONS OR TEST PAPERS THEREFOR; PROCESSES OF PREPARING SUCH COMPOSITIONS; CONDITION-RESPONSIVE CONTROL IN MICROBIOLOGICAL OR ENZYMOLOGICAL PROCESSES

- C12Q1/00—Measuring or testing processes involving enzymes, nucleic acids or microorganisms; Compositions therefor; Processes of preparing such compositions

- C12Q1/34—Measuring or testing processes involving enzymes, nucleic acids or microorganisms; Compositions therefor; Processes of preparing such compositions involving hydrolase

- C12Q1/42—Measuring or testing processes involving enzymes, nucleic acids or microorganisms; Compositions therefor; Processes of preparing such compositions involving hydrolase involving phosphatase

Definitions

- the present invention relates to a modified alkaline phosphatase and a method for modifying alkaline phosphatase.

- Alkaline phosphatase (EC 3.1.3.1, hereinafter also referred to as AP) is an enzyme that catalyzes the reaction of hydrolyzing phosphate monoesters to produce alcohol and inorganic phosphate. It is known to be widely distributed regardless.

- AP is widely used as a labeling enzyme in enzyme immunoassay (EIA).

- EIA enzyme immunoassay

- CIAPs bovine small intestine derived APs

- CIAP The specific activity of commercially available CIAP varies depending on the manufacturer and grade, but when p-nitrophenyl phosphate is used as a substrate, there is a high specific activity type exceeding 6000 U / mg-protein.

- a number of various high-sensitivity luminescent substrates for CIAP containing 1,2-dioxetane comb and acridan in the basic skeleton are also on the market, realizing high measurement sensitivity in immunoassay.

- CIAP having a plurality of isozymes so far is isolated in the process of purification, or a high specific activity CIAP gene is identified and recombinantly produced.

- those skilled in the art respond to the demand for high sensitivity by increasing specific activity by introducing site-specific amino acid mutations important for realizing high specific activity (Patent Document 1, etc.).

- Patent Document 1 the inventors have found an AP derived from a bacterium belonging to the genus Shewanella, having a high specific activity comparable to CIAP, and high reactivity to various luminescent substrates widely used in immunoassays.

- the inventors have also succeeded in producing AP by obtaining a gene encoding the AP and culturing a microorganism transformed with the gene.

- AP is often used as an enzyme for labeling a protein that can become an antibody or antigen including forms such as reduced IgG and Fab.

- the labeling method the glutaraldehyde method, the periodic acid method, and the maleimide method are preferably used.

- the IgG hinge portion that does not substantially affect the antigen-antibody reaction is labeled.

- the maleimide method that can be used as a target is most preferably used.

- AP is first modified with a maleimide group introduction reagent such as N- (6-maleimidocaproyloxy) succinimide (hereinafter also referred to as EMCS) or N- (4-maleimidobutyryloxy) succinimide (hereinafter also referred to as GMBS). Then, it is converted into maleimide and coupled with the SH group to be labeled to give a conjugate.

- EMCS N- (6-maleimidocaproyloxy) succinimide

- GMBS N- (4-maleimidobutyryloxy) succinimide

- An object of the present invention is to provide an alkaline phosphatase that can have an activity equivalent to that before modification even after modification in immunoassay. More specifically, it is to provide an alkaline phosphatase that does not cause a decrease in activity even after introduction of a maleimide group with various maleimidating reagents used for preparing an alkaline phosphatase conjugate in immunoassay.

- the present invention has the following configuration.

- (1) A modified alkaline phosphatase obtained by substituting a lysine residue located near the active center of alkaline phosphatase with another amino acid residue.

- (2) The modified alkaline phosphatase according to (1), wherein the alkaline phosphatase is derived from bacteria.

- (3) The modified alkaline phosphatase according to (2), wherein the bacterium is of the genus Shewanella.

- the modified alkaline phosphatase according to (1), wherein the alkaline phosphatase is derived from bovine small intestine (6) The modified alkaline phosphatase according to (1), wherein in the amino acid sequence shown in SEQ ID NO: 2, the amino acid corresponding to the 161st lysine and / or the 184th lysine is substituted with another amino acid.

- a method for producing a modified alkaline phosphatase comprising the steps of (A) to (D).

- A A step of identifying or estimating a lysine residue located near the active center of alkaline phosphatase.

- B A step of replacing a codon on the alkaline phosphatase gene encoding the lysine residue specified or estimated in (A) with a codon encoding another amino acid.

- C A step of transforming the gene prepared in (B) into a host cell and culturing the transformant to express the gene.

- D A step of purifying the modified alkaline phosphatase that is the expression product in (C).

- (A) An amino acid residue corresponding to the 161st lysine and / or the 184th lysine of the amino acid sequence shown in SEQ ID NO: 2 is obtained by aligning the amino acid sequence of alkaline phosphatase to be modified with the amino acid sequence shown in SEQ ID NO: 2 Estimating process.

- (B) A step of replacing the codon on the alkaline phosphatase gene encoding the lysine residue estimated in (A) with a codon encoding another amino acid.

- alkaline phosphatase useful as a labeling enzyme for immunoassay and an alkaline phosphatase-labeled antibody capable of detecting a target substance with high sensitivity can be provided.

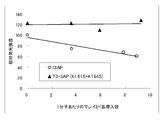

- the relationship between the number of maleimide groups introduced and the specific activity remaining ratio when the wild type and modified enzymes of AP derived from T3-3 strain are maleimidated is shown.

- the relationship between the number of maleimide group introductions and the reactivity to the luminescent substrate per unit protein amount when T3-3 strain-derived mutant AP and bovine small intestine-derived AP (CIAP) are maleimidized is shown.

- the present invention is an alkaline phosphatase obtained by substituting a lysine residue located near the active center with another amino acid.

- the alkaline phosphatase to be mutated for alkaline phosphatase is not particularly limited as long as it can be used for immunoassay. Examples thereof include those derived from mammals and bacteria. Preferable examples of the mammal-derived one include bovine-derived alkaline phosphatase and pink lobster-derived alkaline phosphatase. Among bovine origin, alkaline phosphatase isolated from calf small intestine is a preferred example. Examples of those derived from bacteria include alkaline phosphatase derived from Bacillus bacteria, alkaline phosphatase derived from Shewanella bacteria, and the like.

- an alkaline phosphatase derived from a genus Shewanella is also a more preferable example.

- the genus Shewanella include Shewanella fodinae (for example, NBRC105216 strain), Shewanella chillikensis (for example, NBRC105217 strain), Shewanella baltica (for example, OS185 strain), Shewanella sp. T3-3 strain, and Shewanella sp. W3-18-1 strain.

- Etc. can be exemplified.

- those with NBRC numbers are strains stored in the Biotechnology Center, Biotechnology Center, National Institute of Technology and Evaluation, and may be sold for sale through a prescribed procedure. it can.

- Examples of other organisms from which APs to be mutated are derived include microorganisms present in water systems such as soil, rivers, and lakes or in the ocean, microorganisms that are resident on the surface or inside various animals and plants, and the like. Microorganisms that grow in a low temperature environment, a high temperature environment such as a volcano, an oxygen-free / high-pressure / no-light environment such as the deep sea, and a special environment such as an oil field may be used as the isolation source.

- APs to be mutated include not only APs directly isolated from microorganisms, but also those in which the isolated APs have been modified by amino acid sequences or the like by protein engineering methods, or by genetic engineering methods. included.

- the enzyme obtained by modifying the enzyme obtained from the above-mentioned genus Shewanella or the like and further adding the mutation of the present invention may be used.

- EMCS and GMBS which are maleimidation reagents

- GMBS maleimidation reagents

- the inventors do not occur because the lysine residue in the vicinity of the active center couples with the maleimidating reagent, and the introduced side chain prevents the substrate from contacting the active center.

- the mutant AP in which the lysine residue near the active center was substituted has a higher activity retention rate after maleimidation than the wild-type AP.

- an amino acid residue in the vicinity of the active center is specified for an AP having a known three-dimensional structure, and then an amino acid sequence is aligned between the AP having the known three-dimensional structure and the AP to introduce a mutation.

- an amino acid residue located in the vicinity of the active center of the AP into which a mutation is to be introduced can be estimated. If lysine is present among these residues, that is, it can be assumed that it is a lysine residue near the active center.

- the primary sequence alignment can be calculated using various algorithms used to calculate amino acid identity, for example, using a commercially available analysis tool available through a telecommunication line (Internet). .

- NCBI National Biotechnology Information Center

- BLAST Basic local alignment search tool

- Alignment is performed using default (initial setting) parameters in gov / BLAST /.

- a method for identifying an amino acid located near the active center from a three-dimensional structure has various methods capable of calculating the distance between atoms from a PDB file including coordinate information of all atoms constituting the AP and inorganic phosphate as a substrate analog.

- Software can be used, and in this book, MolFeat manufactured by Firelux is used. Judgment that it is in the vicinity of the active center is based on the fact that at least a part of the amino acid residue is located within 15 angstroms from the phosphorus atom constituting the phosphate group of inorganic phosphate as a substrate analog. It is presumed that the 184th lysine of the AP derived from Shewanella sp.

- T3-3 strain shown in SEQ ID NO: 2 is just 15 angstroms away from the substrate, and after modification by substituting this residue as shown in the Examples The activity remaining rate of is improved. From this, it can be understood that lysine residues at a distance of at least 15 angstroms can be expected to have an effect of avoiding a decrease in activity due to maleimidation by substitution with other amino acids.

- the lysine residue located near the active center cannot be identified by the above method, it can be identified from the three-dimensional structure information of the AP to be mutated. Crystallization of a high-purity AP product to be mutated plus inorganic phosphoric acid or a substrate analog according to conventional methods, and X-ray crystal structure analysis yields three-dimensional structure information.

- the lysine residue in the vicinity of the active center can be identified from the coordinates of the functional group corresponding to the acid group or phosphate group and the coordinates of the atoms constituting the AP.

- 3D structure prediction software includes, for example, Discovery Studio (manufactured by Accelrys), MOE (Chemical Computingu Group), Dessert Scientific Software (manufactured by Infocom), or SwissInstitialSwissIsSMO. Etc. are exemplified.

- any of the above methods can identify a lysine residue located near the active center of an AP, this time, identify a lysine residue located near the active center of another AP. I can do it.

- lysine residues that are located on the alkaline phosphatase sequence and are specified near the active center are shown below.

- the 161st and 184th lysines are applicable. As shown in Example 5 to be described later, this was identified by structural comparison with AP derived from the Chewanella sp. AP1 strain having a known three-dimensional structure and active center.

- these 161st positions This corresponds to the lysine residue corresponding to the 184th lysine.

- the AP derived from the Shewanella fodinae NBRC105216 strain shown in SEQ ID NO: 16 the 157th and 180th lysines, and in the same way, the AP derived from the Shewanella chillensis NBRC105217 strain shown in SEQ ID NO: 18 is also used. Is estimated to be located near the active center.

- the 100th lysine is present in CIAP I of SEQ ID NO: 11, and the 81st lysine is present in CIAP II shown in SEQ ID NO: 12,

- the 100th lysine is specified, and in CIAP IV of SEQ ID NO: 14, the 100th and 127th lysines are located near the active center.

- the 81st and 87th lysines are specified to be located in the vicinity of the active center.

- the other amino acid that substitutes the lysine residue in the vicinity of the substituted amino acid activity center is not particularly limited as long as it is other than lysine and can maintain alkaline phosphatase activity, but alanine, valine, leucine,

- Examples include aliphatic amino acids such as isoleucine, hydrophilic amino acids such as glycine, serine, threonine, methionine and proline, acidic amino acids such as glutamic acid and aspartic acid, and basic amino acids other than lysine such as arginine and histidine.

- arginine which is the same basic amino acid as a glycine, alanine, serine, or lysine residue with low hydrophobicity and a small side chain, and which is presumed not to have a large effect on properties, is given as a suitable example. It is done.

- serine and arginine are further preferable examples, and serine is the most preferable example among them.

- Another aspect of the present invention is a method for producing modified alkaline phosphatase.

- the method comprises (A) identifying a lysine residue located near the active center of alkaline phosphatase, (B) substituting the codon on the alkaline phosphatase gene encoding the lysine residue specified or estimated in (A) with a codon encoding another amino acid, (C) transforming the gene prepared in (B) into a host cell, culturing the transformant to express the gene, (D) purifying the modified alkaline phosphatase that is the expression product in (C), Is included.

- (2-2) Replacing a codon on the alkaline phosphatase gene encoding the specified lysine residue with a codon encoding another amino acid replaces the codon encoding the above-mentioned lysine residue on the alkaline phosphatase gene sequence with another codon.

- the gene can be transformed into a host cell, the transformant is cultured to express the gene, and the modified alkaline phosphatase that is the expression product is purified.

- Such a mutant alkaline phosphatase gene can be produced by chemical synthesis of the designed modified AP gene full-length sequence, and DNA is replicated using a wild-type alkaline phosphatase gene as a template and a mismatch primer. This is also possible.

- the AP of the present invention preferably comprises an expression vector carrying a gene encoding the protein, or is isolated and purified from a transformant culture obtained by inserting the gene into genomic DNA. Can be manufactured.

- the host cell into which the DNA encoding the AP of the present invention is introduced is not particularly limited as long as a recombinant expression system has been established as will be described later, but preferably bacteria such as Escherichia coli and Bacillus subtilis, actinomycetes And microbial hosts such as gonococci and yeast, insect cells, animal cells, higher plants and the like.

- vectors examples include plasmids derived from Escherichia coli, such as pBR322, pBR325, pUC18, pUC19, pBluescript SK (-), pBluescript KS (+), etc., yeast-derived plasmids such as pSH19, pSH15, etc. pUB110, pTP5, pC194, etc. are mentioned.

- bacteriophage such as ⁇ phage, papovirus such as SV40, bovine papilloma virus (BPV), retrovirus such as Moloney murine leukemia virus (MoMuLV), adenovirus (AdV), adeno-associated virus (AAV),

- papovirus such as SV40, bovine papilloma virus (BPV)

- retrovirus such as Moloney murine leukemia virus (MoMuLV), adenovirus (AdV), adeno-associated virus (AAV)

- animal and insect viruses such as vaccinia virus, baculovirus.

- an AP expression vector in which a DNA encoding AP is placed under the control of a promoter functional in the target host cell.

- the vector used include prokaryotic and / or eukaryotic cells.

- Promoter region that functions in various host cells and can control transcription of a gene located downstream thereof (for example, trp promoter, lac promoter, recA promoter when the host is Escherichia coli, SPO1 when the host is Bacillus subtilis, etc. Promoter, SPO2 promoter, penP promoter, etc.

- the host is yeast, PHO5 promoter, PGK promoter, GAP promoter, ADH promoter, etc.

- SV40-derived early promoter When the host is a mammalian cell, SV40-derived early promoter, MoMuLV-derived long terminal repeat, adenovirus A viral promoter such as an early promoter) and a transcription termination signal of the gene, that is, a terminator region, and the promoter region and the terminator region contain at least one restriction enzyme recognition site, preferably the vector only at that site.

- a vector contained upstream of is preferably used.

- the expression vector When a bacterium is used as a host cell, the expression vector generally needs to contain a replicable unit capable of autonomous replication in the host cell in addition to the promoter region and terminator region described above.

- the promoter region includes an operator and a Shine-Dalgarno (SD) sequence in the vicinity of the promoter.

- SD Shine-Dalgarno

- yeast, animal cells, or insect cells are used as the host, the expression vector preferably further includes an enhancer sequence, 5 ′ and 3 ′ untranslated regions of AP mRNA, a polyadenylation site, and the like.

- Host organisms into which the prepared recombinant vector is introduced include bacteria such as Escherichia coli and Bacillus subtilis for which recombinant expression systems have been established, microbial hosts such as actinomycetes, bacilli, and yeast, insect cells, animal cells, higher plants, etc. Among them, it is preferable to use Escherichia coli having excellent protein expression ability.

- introduction by heat shock is possible if the host is made competent by chemical treatment such as calcium chloride.

- Selection for the presence or absence of transfer of the target recombinant plasmid into the host vector may be performed by searching for microorganisms that simultaneously express markers represented by various drug resistance genes of the vector holding the target DNA and AP activity, For example, a microorganism that grows in a selective medium based on a drug resistance marker and expresses AP may be selected.

- the AP of the present invention can be produced by culturing a transformant containing the AP expression vector prepared as described above in a medium, and collecting AP from the resulting culture.

- the medium to be used preferably contains a carbon source, an inorganic nitrogen source or an organic nitrogen source necessary for the growth of the host cell (transformant).

- the carbon source include glucose, dextran, soluble starch, and sucrose.

- the inorganic or organic nitrogen source include ammonium salts, nitrates, amino acids, corn steep liquor, peptone, casein, meat extract, large Examples include soybean cake and potato extract.

- other nutrients for example, inorganic salts (for example, calcium chloride, sodium dihydrogen phosphate, magnesium chloride), vitamins, antibiotics (for example, tetracycline, neomycin, ampicillin, kanamycin, etc.)] may be included as desired. .

- Culturing is performed by methods known in the art. Specific media and culture conditions used according to the host cells are exemplified below, but the culture conditions in the present invention are not limited to these.

- the host is a bacterium, actinomycetes, yeast, filamentous fungus or the like, for example, a liquid medium containing the above nutrient source is suitable. A medium having a pH of 5 to 9 is preferred.

- the host is Escherichia coli, LB medium and M9 medium [Miller. J. et al. , Exp. Mol. Genet, p. 431, Cold Spring Harbor Laboratory, New York (1972)].

- Culturing can be performed usually at 14 to 43 ° C.

- the host is Bacillus subtilis, it can be carried out usually at 30 to 40 ° C. for about 16 to 96 hours with aeration and stirring as necessary.

- yeast as a medium, for example, Burkholder minimal medium [Bostian. K. L. et al, Proc. Natl. Acad. Sci. USA, 77, 4505 (1980)]

- the pH is preferably 5-8.

- the culture is usually carried out at about 20 to 35 ° C. for about 14 to 144 hours, and if necessary, aeration or stirring can be performed.

- the medium is, for example, minimal essential medium (MEM) containing about 5 to 20% fetal calf serum [Science, 122, 501 (1952)], Dulbecco's modified Eagle medium (DMEM) [Virology, 8 , 396 (1959)], RPMI 1640 medium [J. Am. Med. Assoc. , 199, 519 (1967)], 199 medium [Proc. Soc. Exp. Biol. Med. , 73, 1 (1950)] or the like.

- the pH of the medium is preferably about 6 to 8, and the culture is usually carried out at about 30 to 40 ° C. for about 15 to 72 hours, and if necessary, aeration and agitation can be performed.

- the host is an insect cell, for example, Grace's medium containing fetal calf serum [Proc. Natl. Acad. Sci. USA, 82, 8404 (1985)], etc., and the pH is preferably about 5-8. Cultivation is usually carried out at about 20 to 40 ° C. for 15 to 100 hours, and if necessary, aeration or stirring can be performed.

- a metal salt for stabilizing AP may be added to these media, and as such a metal salt, a magnesium salt and / or a zinc salt is preferably used. These metal salts may be set within a range not toxic to the cells to be cultured. A final concentration of 0.001 mM to 10 mM for a magnesium salt and 0.001 mM to 1 mM for a zinc salt are preferred ranges of addition amounts. Although illustrated, it is not limited to this range.

- the purification of AP can be carried out by appropriately combining various commonly used separation techniques depending on the fraction in which AP activity exists.

- the AP present in the culture medium is obtained by centrifuging or filtering the culture to obtain a culture supernatant (filtrate), for example, salting out, solvent precipitation, dialysis, ultrafiltration, gel filtration.

- a culture supernatant for example, salting out, solvent precipitation, dialysis, ultrafiltration, gel filtration.

- a known separation method such as non-denaturing PAGE, SDS-PAGE, ion exchange chromatography, hydroxylapatite chromatography, affinity chromatography, reverse phase high performance liquid chromatography, isoelectric focusing, etc. Obtainable.

- AP present in the cytoplasm collects cells by centrifuging or filtering the culture and suspending it in an appropriate buffer, for example, sonication, lysozyme treatment, freeze-thawing, osmotic shock, and / or triton. After crushing (dissolving) the cells and the organelle membrane by treatment with a surfactant such as -X100, the debris is removed by centrifugation or filtration to obtain a soluble fraction. It can be isolated and purified by treating with a method.

- an amino acid sequence for example, a base such as histidine, arginine, lysine, etc.

- a metal ion chelate at a certain part (preferably the N or C terminus) of the AP coding sequence.

- a DNA sequence encoding an amino acid sequence is added by genetic manipulation and expressed in a host cell, and the metal ion chelate is immobilized from the AP active fraction of the cell culture.

- a method of separating and recovering AP by affinity with the carrier thus obtained is preferably exemplified.

- the DNA sequence encoding the amino acid sequence that can be adsorbed to the metal ion chelate is obtained by, for example, using a hybrid primer in which the DNA sequence is linked to the base sequence encoding the C-terminal amino acid sequence of AP in the process of cloning the DNA encoding AP.

- the DNA can be introduced into the AP coding sequence by performing PCR amplification or by inserting the DNA encoding AP in frame into an expression vector containing the DNA sequence before the stop codon.

- the metal ion chelate adsorbent used for purification contains transition metals such as cobalt, copper, nickel, iron divalent ions, or iron, aluminum trivalent ions, etc., preferably cobalt or nickel divalent ions.

- the solution is prepared by contacting a ligand, such as an iminodiacetic acid (IDA) group, a nitrilotriacetic acid (NTA) group, a tris (carboxymethyl) ethylenediamine (TED) group, etc., in contact with the ligand.

- a ligand such as an iminodiacetic acid (IDA) group, a nitrilotriacetic acid (NTA) group, a tris (carboxymethyl) ethylenediamine (TED) group, etc.

- IDA iminodiacetic acid

- NTA nitrilotriacetic acid

- TED tris (carboxymethyl) ethylenediamine

- the matrix part of the chelate adsorbent is not particularly limited as long as it is a normal insoluble carrier.

- affinity purification can be performed using glutathione-S-transferase (GST), maltose binding protein (MBP), HA, FLAG peptide or the

- treatment such as membrane concentration, concentration under reduced pressure, addition of an activator and a stabilizer can be performed as necessary.

- the solvent used in these steps is not particularly limited, but various buffer solutions represented by K-phosphate buffer solution, Tris-HCl buffer solution, GOOD buffer solution and the like having a buffer capacity in the range of about pH 6-9 are preferable.

- a metal salt may be added to these buffers, and as such a metal salt, a magnesium salt and / or a zinc salt is preferably used.

- These metal salts may be set within a range effective for stabilizing AP, and the final concentration is 0.001 mM to 10 mM for magnesium salts, and 0.001 mM to 1 mM for zinc salts. However, it is not limited to this range.

- the free form can be converted into a salt by a method known per se or a method analogous thereto, and when the protein is obtained as a salt, a method known per se Alternatively, the salt can be converted into a free form or other salt by a method analogous thereto.

- the purified enzyme is liquid and can be used for industrial use, but can also be pulverized or further granulated.

- the liquid enzyme is pulverized by lyophilization by a conventional method.

- phosphate, tris (hydroxymethyl) aminomethane hydrochloride, triethanolamine hydrochloride, GOOD buffer, and the like are preferably selected, but not limited thereto.

- the concentration of the buffer is not particularly limited as long as the pH of the solution can be kept constant, but is preferably in the range of 1 mM to 500 mM, more preferably in the range of 2 mM to 200 mM. Further, the pH of the solution is preferably in a range where the activity of AP can be stably maintained, and is preferably in the range of pH 6-9. As the metal salt, a magnesium salt and / or a zinc salt is preferably used, and the concentration may be set within a range effective for stabilizing the AP. If the magnesium salt is used, the final concentration is 0.001 mM to 10 mM.

- 0.001 mM to 1 mM is exemplified as a preferable range of addition amount, but is not limited to this range.

- preservatives include, but are not limited to, azides, antibiotics, proclin 150, proclin 300, and the like.

- non-protein agents such as glycerin and dimethylsulfoxide are preferable.

- Triton X-100, Tween 20, Tween 80, Emulgen A60, Emulgen 430, Brij 35, etc. are preferably selected.

- a conjugate formed by labeling modified alkaline phosphatase, an immunoassay method using the conjugate, an immunoassay reagent containing the conjugate, and another embodiment of the present invention is labeled with the above-described alkaline phosphatase

- a nucleic acid probe, a biological material such as biotin, a protein such as a polypeptide, avidin, or an antibody is preferably selected as the substance to be labeled.

- the maleimide method is preferably selected as the labeling method.

- An example of a typical immunoassay method is to adsorb to a solid phase by first adding and incubating a solution containing a primary antibody of a substance to be measured.

- This solid phase may be a container used as a reaction layer, or may be magnetic beads prepared separately from the reaction layer. After adsorbing the primary antibody, remove the solution and rinse several times with wash buffer to remove non-adsorbed material.

- wash buffer one having a buffering ability in a neutral pH range where the antibody can stably exist can be used, and a surfactant may be included to enhance the washing ability.

- the washed solid phase is further immersed in a solution containing a protein such as bovine serum albumin or inactivated AP, and blocked by incubation.

- the solid phase after blocking is washed with the above-described washing buffer, then brought into contact with the sample to be measured, and incubated for a fixed time, thereby adsorbing the measurement target to the primary antibody.

- a solution containing an AP-labeled secondary antibody After completely removing the sample solution and washing with the above washing buffer, adding a solution containing an AP-labeled secondary antibody and incubating for a certain period of time, the object to be measured captured by the primary antibody on the solid phase is subjected to AP. A labeled secondary antibody is adsorbed. After completely removing the solution and washing with the above washing buffer, AP substrate is added to detect the activity.

- the substrate for AP As the substrate for AP, p-nitrophenyl phosphate or 5-bromo-4-chloro-3-indolyl phosphate is used when the activity detection method is a colorimetric method, and 4-methylumbellite is used when the method is a fluorescence method.

- ferryl phosphate is a luminescent method

- various luminescent substrates composed of 1,2-dioxetane-based or acridan-based luminescent substrates can be used.

- the AP of the present invention is particularly excellent in reactivity with a luminescent substrate, and a method using this is more preferably selected.

- the luminescent substrate examples include, but are not limited to, AMPPD, CSPD, CDP-star, Lumigen PPD, Lumi-Phos530, and APS-5.

- the substance to be measured is quantified from a calibration curve prepared in advance using a standard solution for the substance to be measured.

- An example of the configuration of a typical immunoassay reagent is as follows: a reaction layer, a solid phase on which a primary antibody is immobilized and blocked with a protein such as bovine serum albumin or inactivated AP, and a standard solution of an antigen to be measured , A secondary antibody labeled with AP, a washing solution for washing after reacting a sample or secondary antibody in a reaction layer, a substrate solution of AP, and a use manual.

- a substrate for AP p-nitrophenyl phosphate or 5-bromo-4-chloro-3-indolyl phosphate is used when the activity detection method is a colorimetric method, and 4-methylumbellite is used when the method is a fluorescence method.

- ferryl phosphate is a luminescent method

- various luminescent substrates composed of 1,2-dioxetane-based or acridan-based luminescent substrates can be used.

- the AP of the present invention is particularly excellent in reactivity with a luminescent substrate, and a method using this is more preferably selected.

- the luminescent substrate include, but are not limited to, AMPPD, CSPD, CDP-star, Lumigen PPD, Lumi-Phos530, and APS-5.

- Example of activity measurement The AP activity described in the present invention was measured by the following method unless otherwise specified.

- Solutions A and B are prepared.

- Prepare 2.9 ml of solution A and 0.1 ml of solution B in a cuvette (optical path length 1.0 cm), and preheat at 37 ° C. for 5 minutes.

- Example of protein quantification and specific activity calculation The amount of protein described in the present invention was measured by measuring absorbance at 280 nm. That is, the enzyme solution was diluted with distilled water so that the absorbance at 280 nm was in the range of 0.1 to 1.0, and the absorbance (Abs) at 280 nm was measured using an absorptiometer corrected with zero point using distilled water. Measure.

- the protein concentration described in the present invention approximates 1 Abs ⁇ 1 mg / ml, and is expressed by a value obtained by multiplying the absorbance measurement and the measured solution dilution rate.

- the specific activity described in the present invention is the activity (U / mg) of AP per mg as the amount of protein according to this measurement method, and the AP activity at this time is obtained by measuring according to the above activity measurement example. Value.

- Example of maleimide group quantification method The method for quantification of maleimide groups in the present invention is as follows. First, 50 ⁇ l of maleimidated AP is mixed with 400 ⁇ l of 0.1 M sodium phosphate buffer (pH 6.0), and 50 ⁇ l of 0.5 mM 2-MEA is added and incubated at 30 ° C. for 20 minutes. As a blind test, 50 ⁇ l of 0.5 mM 2-MEA is added to 450 ⁇ l of 0.1 M sodium phosphate buffer (pH 6.0) and incubated at 30 ° C. for 20 minutes. Furthermore, 20 ⁇ l of 5 mM 4-PDS is added, and after incubation at 30 ° C.

- Maleimide group concentration (mM) (A324 blank ⁇ A324 sample ) ⁇ 520 / (19.8 ⁇ 50) 520: Volume of total liquid ( ⁇ l) 19.8: millimolar molecular extinction coefficient 50: sample volume ( ⁇ l)

- the number of maleimide groups per AP molecule is determined by measuring the protein concentration of the AP solution used for the measurement by the method described above, calculating the AP mmol concentration from the molecular weight of AP of 100,000, and dividing the maleimide group concentration by the AP mmol concentration. Can be determined.

- This genomic DNA was digested with restriction enzymes BamHI or BglII and purified using a DNA purification kit (manufactured by TOYOBO, NPK-6) to remove the restriction enzymes.

- This DNA fragment was mixed with pBR322 that had been digested with BamHI and purified, and an equal amount of ligation solution (Ligation High, manufactured by TOYOBO) was added to the mixture and incubated at 16 ° C. overnight.

- This ligation solution was added to Escherichia coli JM109 strain competent cell (manufactured by TOYOBO, competent high JM109), and the plasmid was transformed by heat shock to prepare a genomic DNA library of T3-3 strain.

- This library was inoculated into an LB agar medium containing 50 ⁇ g / ml BCIP and 100 ⁇ g / ml ampicillin and cultured at 30 ° C. to form transformed colonies.

- the blue colony was attached with a toothpick, inoculated into 5 ml LB medium (containing 100 ⁇ g / ml ampicillin) in a test tube, and cultured with shaking at 30 ° C. for 16 hours.

- a plasmid pBRT3-3LPP

- a plasmid extraction kit manufactured by TOYOBO, NPK-3.

- the obtained plasmid had an insert of about 6 kb, and by sequencing this sequence, the sequence of the full length AP gene and its adjacent region was determined.

- the determined base sequence of the AP gene is shown in SEQ ID NO: 1, and the amino acid sequence deduced from this base sequence is shown in SEQ ID NO: 2.

- This genomic DNA fragment was digested with the restriction enzyme BamHI and ligated to pBluescprSK ( ⁇ ) treated with the restriction enzyme to prepare an expression plasmid (pBST3-3LPP).

- the ligated plasmid was introduced into E. coli strain C600 by electroporation, applied to an LB agar medium containing 100 ⁇ g / ml ampicillin, and cultured at 30 ° C. overnight to form transformed colonies.

- This transformed colony was inoculated with one platinum loop in 60 ml LB medium (containing 100 ⁇ g / ml ampicillin) in a 500 ml Sakaguchi flask and cultured overnight at 30 ° C. and 180 rpm.

- This culture solution was added to a 6 L production medium (1.2% peptone, 2.4% yeast extract, 0.1% NaCl, 0.1 mM zinc sulfate, 100 ⁇ g / ml ampicillin, pH 7.0 in a 10 L jar fermenter. ), And aerated with aeration at an aeration rate of 2 L / min, agitation of 380 rpm, and a temperature of 30 ° C. for 48 hours. This produced 800 U / ml AP.

- Example 3 The culture solution obtained in Example 3 was dispensed into a 500 ml centrifuge tube, centrifuged at 8000 rpm for 30 minutes with a high-speed cooling centrifuge, and the supernatant was removed by decantation to obtain bacterial cells.

- the cells were suspended in 1.5 L of 20 mM Tris-HCl buffer (pH 7.5) and crushed with a French press crusher at a pressure of 80 MPa. 5% (w / v) polyethyleneimine was added to the crushed solution at 3%, and the resulting solid content was removed by centrifugation at 8000 rpm for 30 minutes in a high-speed cooling centrifuge.

- This solution was desalted using G-25 Sepharose gel (GE Healthcare) buffered with 20 mM Tris-HCl buffer (pH 7.5 and containing 1 mM magnesium chloride). This solution is adsorbed on DEAE Sepharose gel (manufactured by GE Healthcare) buffered with 20 mM Tris-HCl buffer (pH 7.5 and containing 1 mM magnesium chloride), and the NaCl concentration is increased to 0.5 M with the same buffer. Gradient elution was performed. Fractions having AP activity were collected, and ammonium sulfate was dissolved so as to be 0.05 saturated.

- lysine residues are residues that are effective for AP modification by substitution. That is, in SEQ ID NO: 2, the 161st and 184th lysines were presumed to be lysine residues located near the active center.

- the template pBST3-3LPP was digested, and the digested product was transferred to E. coli strain JM109 (competent high JM109 manufactured by TOYOBO). Then, an SOC medium was added, shaken at 37 ° C. for 1 hour, applied to an LB agar medium containing 100 ⁇ g / ml ampicillin, and cultured at 30 ° C. overnight to form transformed colonies.

- the transformed colony was inoculated with a toothpick, inoculated into 5 ml of LB medium containing 100 ⁇ g / ml ampicillin, and cultured with shaking at 30 ° C. overnight.

- a plasmid was extracted and purified using a plasmid extraction kit (manufactured by TOYOBO, NPK-3).

- a plasmid extraction kit manufactured by TOYOBO, NPK-3.

- the codon AAG encoding the 184th lysine was converted to TCG encoding serine (that is, the 550th A in the nucleotide sequence shown in SEQ ID NO: 1 was changed to T, the 551st A was converted to C), and this plasmid was named pBST3-3LPP184S.

- a replication reaction was performed using pBSpBST3-3LPP184S as a template and a mismatch primer shown in SEQ ID NOs: 7 and 8 and a PCR kit (KOD plus manufactured by Toyobo).

- the reaction solution composition and reaction conditions followed the recommended conditions for normal PCR described in the manual attached to the kit.

- restriction enzyme DpnI By adding 2 ⁇ L of restriction enzyme DpnI to 50 ⁇ L of the reaction solution containing the replication product and treating at 37 ° C. for 2 hours, the template pBST3-3LPP was digested, and the digested product was transferred to E. coli strain JM109 (competent high JM109 manufactured by TOYOBO).

- an SOC medium was added, shaken at 37 ° C. for 1 hour, applied to an LB agar medium containing 100 ⁇ g / ml ampicillin, and cultured at 30 ° C. overnight to form transformed colonies.

- the transformed colony was inoculated with a toothpick, inoculated into 5 ml of LB medium containing 100 ⁇ g / ml ampicillin, and cultured with shaking at 30 ° C. overnight. From this culture solution, a plasmid was extracted and purified using a plasmid extraction kit (manufactured by TOYOBO, NPK-3).

- the codon AAA encoding the 161st lysine was converted to TCG encoding serine (that is, the 481st A in the nucleotide sequence shown in SEQ ID NO: 1 was changed to T, the 482nd A was converted to C and the 483rd A was converted to G), and this plasmid was named pBST3-3LPP161S184S.

- transformants were prepared and cultured according to the methods described in Examples 3 and 4, and AP was purified to produce K184S single mutation and K161S + K184S double mutant enzymes as modified APs.

- Example 4 [Comparison of residual activity of wild-type and modified AP after maleimidation]

- the EMCS concentration was changed in the range of 0.2 to 1.0 mM in order to change the maleimide group introduction efficiency of the AP molecule.

- Specific activity and the number of maleimide groups introduced were measured for this maleimidated AP. The results are shown in FIG.

- the specific activity is reduced by maleimidation

- the specific activity remaining rate of the AP after maleimidation is higher than in the wild type, and in the K161S + K184S double mutant enzyme, it is almost completely after the maleimidation. It was shown that the specific activity of was maintained. That is, it was shown that the decrease in activity after maleimide group introduction was suppressed by substituting a lysine residue near the active center.

- FIG. 2 shows a plot of the number of maleimide groups introduced and the relative luminescence intensity of each AP (relative value when the luminescence intensity when using a non-maleimidating enzyme of bovine small intestine derived AP is 100).

- the amount of luminescence per unit protein decreases as the number of maleimide groups introduced increases, whereas in K161S + K184S double mutant enzymes, the number of maleimide groups introduced depends on the number of maleimide groups introduced. It showed a certain amount of luminescence.

- amino acid residues of human-derived AP amino acid residues located within 15 angstroms from the active center are specified, and the amino acid sequence is aligned with various bovine small intestine-derived AP amino acid sequences (SEQ ID NOs: 11 to 14).

- amino acid residues located near the active center were estimated, and lysine residues were picked up among them.

- the lysine residues in the vicinity of the active center in the bovine small intestine-derived AP thus estimated are the 100th lysine in SEQ ID NOS: 11 and 13 and the 81st lysine in SEQ ID NO: 12 in SEQ ID NO: 14.

- the 100th lysine and the 127th lysine correspond to this.

- Shewanella Fodinae NBRC105216 and Shewanella Chirikensis NBRC105217 were purchased from the National Institute for Product Evaluation and Technology, respectively, and genomic DNA was extracted from the cells in accordance with the procedure in Example 2, and a library was prepared. Plasmid containing AP gene And the AP gene sequence was determined. The determined base sequence of the AP gene derived from Shewanella fodinae NBRC105216 strain is shown in SEQ ID NO: 15, and the amino acid sequence of the polypeptide encoded by the approximate AP gene is shown in SEQ ID NO: 16.

- the determined base sequence of the AP gene derived from Shewanella chirikensis NBRC105217 strain is shown in SEQ ID NO: 17, and the amino acid sequence of the polypeptide encoded by the approximate AP gene is shown in SEQ ID NO: 18.

- lysine residues located in the vicinity of the active center were estimated according to the procedure of Example 5.

- the residues estimated in this way are the 157th and 180th lysine in the AP derived from the Shewanella fodinae NBRC105216 strain shown in SEQ ID NO: 16, and the AP derived from the Shewanella chillensis NBRC105217 strain shown in the SEQ ID NO: 18.

- the 157th and 180th lysines correspond to this. Similar to the T3-3 strain, by substituting these amino acid residues, it is possible to change to AP that can maintain the activity before modification even after modification such as maleimidation via a lysine residue.

- the alkaline phosphatase of the present invention is useful not only as a labeling enzyme for immunoassay but also as a labeling enzyme for probe hybridization and western blotting.

Landscapes

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Wood Science & Technology (AREA)

- Zoology (AREA)

- Engineering & Computer Science (AREA)

- Bioinformatics & Cheminformatics (AREA)

- Genetics & Genomics (AREA)

- Proteomics, Peptides & Aminoacids (AREA)

- General Health & Medical Sciences (AREA)

- Biotechnology (AREA)

- Molecular Biology (AREA)

- Biochemistry (AREA)

- General Engineering & Computer Science (AREA)

- Microbiology (AREA)

- Biophysics (AREA)

- Physics & Mathematics (AREA)

- Analytical Chemistry (AREA)

- Medicinal Chemistry (AREA)

- Biomedical Technology (AREA)

- Immunology (AREA)

- Enzymes And Modification Thereof (AREA)

- Micro-Organisms Or Cultivation Processes Thereof (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014523743A JP6040987B2 (ja) | 2012-07-06 | 2013-07-02 | 改変型アルカリホスファターゼ |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012152219 | 2012-07-06 | ||

| JP2012-152219 | 2012-07-06 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2014007229A1 true WO2014007229A1 (ja) | 2014-01-09 |

Family

ID=49881985

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2013/068085 Ceased WO2014007229A1 (ja) | 2012-07-06 | 2013-07-02 | 改変型アルカリホスファターゼ |

Country Status (2)

| Country | Link |

|---|---|

| JP (2) | JP6040987B2 (enExample) |

| WO (1) | WO2014007229A1 (enExample) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2017123794A (ja) * | 2016-01-12 | 2017-07-20 | 東ソー株式会社 | アルカリホスファターゼ及びその製造方法 |

| WO2019139891A1 (en) * | 2018-01-09 | 2019-07-18 | Synthetic Biologics, Inc. | Alkaline phosphatase agents for treatment of neurodevelopmental disorders |

| CN112771158A (zh) * | 2018-09-25 | 2021-05-07 | 东丽株式会社 | 碱性磷酸酶组合物以及去磷酸化核酸和标记化核酸的制造方法 |

| WO2022196538A1 (ja) * | 2021-03-17 | 2022-09-22 | 味の素株式会社 | 改変アルカリホスファターゼ |

| US20230310558A1 (en) * | 2018-03-20 | 2023-10-05 | Theriva Biologics, Inc. | Alkaline phosphatase agents for treatment of radiation disorders |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH02502646A (ja) * | 1987-12-23 | 1990-08-23 | ジェネティックス・インスティテュート・インコーポレイテッド | 親水性基に対する共有結合を容易ならしめるためのポリペプチド類の部位特異的均一修飾 |

| JPH06319534A (ja) * | 1983-06-24 | 1994-11-22 | Genentech Inc | サブチリシン突然変異体の製造に有用な桿菌 |

| JP2008005734A (ja) * | 2006-06-28 | 2008-01-17 | Kikkoman Corp | アルカリホスファターゼ |

| WO2012115023A1 (ja) * | 2011-02-23 | 2012-08-30 | 東洋紡績株式会社 | アルカリホスファターゼ |

-

2013

- 2013-07-02 WO PCT/JP2013/068085 patent/WO2014007229A1/ja not_active Ceased

- 2013-07-02 JP JP2014523743A patent/JP6040987B2/ja active Active

-

2016

- 2016-06-15 JP JP2016118930A patent/JP2016168051A/ja active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06319534A (ja) * | 1983-06-24 | 1994-11-22 | Genentech Inc | サブチリシン突然変異体の製造に有用な桿菌 |

| JPH02502646A (ja) * | 1987-12-23 | 1990-08-23 | ジェネティックス・インスティテュート・インコーポレイテッド | 親水性基に対する共有結合を容易ならしめるためのポリペプチド類の部位特異的均一修飾 |

| JP2008005734A (ja) * | 2006-06-28 | 2008-01-17 | Kikkoman Corp | アルカリホスファターゼ |

| WO2012115023A1 (ja) * | 2011-02-23 | 2012-08-30 | 東洋紡績株式会社 | アルカリホスファターゼ |

Non-Patent Citations (2)

| Title |

|---|

| MANDECKI, W. ET AL.: "Mutagenesis of conserved residues within the active site of Escherichia coli alkaline phosphatase yields enzymes with increased kcat", PROTEIN ENGINEERING, vol. 4, no. 7, 1991, pages 801 - 804 * |

| SUZUKI, Y. ET AL.: "Gene Cloning, Overproduction, and Characterization of Thermolabile Alkaline Phosphatase from a Psychrotrophic Bacterium", BIOSCIENCE, BIOTECHNOLOGY, AND BIOCHEMISTRY, vol. 69, no. 2, 2005, pages 364 - 373 * |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2017123794A (ja) * | 2016-01-12 | 2017-07-20 | 東ソー株式会社 | アルカリホスファターゼ及びその製造方法 |

| WO2019139891A1 (en) * | 2018-01-09 | 2019-07-18 | Synthetic Biologics, Inc. | Alkaline phosphatase agents for treatment of neurodevelopmental disorders |

| US11338020B2 (en) | 2018-01-09 | 2022-05-24 | Synthetic Biologics, Inc. | Alkaline phosphatase agents for treatment of neurodevelopmental disorders |

| US20230310558A1 (en) * | 2018-03-20 | 2023-10-05 | Theriva Biologics, Inc. | Alkaline phosphatase agents for treatment of radiation disorders |

| CN112771158A (zh) * | 2018-09-25 | 2021-05-07 | 东丽株式会社 | 碱性磷酸酶组合物以及去磷酸化核酸和标记化核酸的制造方法 |

| US11999978B2 (en) | 2018-09-25 | 2024-06-04 | Toray Industries, Inc. | Alkaline phosphatase composition, method of producing dephosphorylated nucleic acid and method of producing labeled nucleic acid |

| WO2022196538A1 (ja) * | 2021-03-17 | 2022-09-22 | 味の素株式会社 | 改変アルカリホスファターゼ |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2016168051A (ja) | 2016-09-23 |

| JP6040987B2 (ja) | 2016-12-07 |

| JPWO2014007229A1 (ja) | 2016-06-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6065587B2 (ja) | アルカリホスファターゼ | |

| JP6040987B2 (ja) | 改変型アルカリホスファターゼ | |

| Jiang et al. | Identification and characterization of novel esterases from a deep-sea sediment metagenome | |

| ES2543010T3 (es) | Método y reactivo para determinar ácido mevalónico, 3-hidroximetilglutaril-coenzima A y coenzima A | |

| US7871805B2 (en) | Glucose dehydrogenase | |

| JP6079038B2 (ja) | 新規なグルコース脱水素酵素 | |

| JP2017140057A (ja) | 新規なグルコース脱水素酵素 | |

| JP5435180B1 (ja) | 新規なグルコース脱水素酵素 | |

| WO2013065623A1 (ja) | 新規なグルコース脱水素酵素 | |

| CN106011103A (zh) | 一种深海沉积物来源酯酶est4及其编码基因与应用 | |

| CN102964435B (zh) | 截短型溶血链球菌溶菌素o及利用其的检测试剂盒 | |

| CN107475170A (zh) | 一种用于表达恶臭假单胞杆菌肌酐酶的大肠杆菌工程菌及其应用 | |

| WO2013118799A1 (ja) | 新規なグルコース脱水素酵素 | |

| CN106399283B (zh) | 一种提高肌酸酶热稳定性的方法 | |

| CN105505898A (zh) | 一种深海来源羧酸酯酶及其编码基因与应用 | |

| JP5929229B2 (ja) | アルカリホスファターゼ | |

| JP5923995B2 (ja) | アルカリホスファターゼ | |

| Xu et al. | Kinetic, mutagenic, and structural homology analysis of L-serine dehydratase from Legionella pneumophila | |

| JP6045025B2 (ja) | 抗菌剤のスクリーニング方法 | |

| CN120424897B (zh) | 亮氨酸脱氢酶的突变体及其制备方法和应用 | |

| RU2703169C1 (ru) | Штамм-продуцент глутаматоксалоацетаттрансаминазы человека | |

| JP2002325574A (ja) | 高度好熱菌由来タンパク質及びそれをコードする遺伝子 | |

| CN107189955A (zh) | 一种深海新型热稳定性碱性酯酶及应用 | |

| CN114717214A (zh) | 一种重组甘油激酶的制备方法及应用 | |

| JP2004267203A (ja) | 改変した金属酵素 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 13813970 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2014523743 Country of ref document: JP Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 13813970 Country of ref document: EP Kind code of ref document: A1 |