WO2013099557A1 - 吸収性物品 - Google Patents

吸収性物品 Download PDFInfo

- Publication number

- WO2013099557A1 WO2013099557A1 PCT/JP2012/081694 JP2012081694W WO2013099557A1 WO 2013099557 A1 WO2013099557 A1 WO 2013099557A1 JP 2012081694 W JP2012081694 W JP 2012081694W WO 2013099557 A1 WO2013099557 A1 WO 2013099557A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- indicator

- absorbent

- absorbent article

- sheet

- mass

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/42—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators with wetness indicator or alarm

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/42—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators with wetness indicator or alarm

- A61F2013/427—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators with wetness indicator or alarm pH indicator

Definitions

- the present invention relates to an absorbent article such as a disposable diaper, and particularly to an absorbent article that can visually recognize the presence or absence of excretion.

- some absorbent articles such as disposable diapers are provided with an indicator portion that changes color by contact with excretory liquid between the back sheet and the absorber, and the color change is visible from the outside.

- the excreted liquid permeates through the absorbent core in the absorbent body and a covering sheet (also referred to as a mount) covering the outside thereof and comes into contact with the indicator part.

- a covering sheet also referred to as a mount

- discoloration of the indicator portion occurs, and an appropriate replacement time can be determined.

- a hydrophilic composition capable of discoloration is disposed between a portion where the backing sheet covering the absorbent core intersects and overlaps with the back sheet. Diapers are listed.

- Patent Document 2 describes a diaper in which a liquid-permeable intermediate sheet is disposed between an absorbent core and a discolorable composition. Thereby, coloring of the absorptive core which may arise by contact with the said composition and urine can be suppressed.

- the present invention is an absorbent article comprising a top sheet disposed on the skin contact surface side, a back sheet disposed on the non-skin contact surface side, and an absorber disposed between both sheets, Between the back sheet and the absorbent body, an indicator part that visually changes by contact with liquid is disposed, and the absorbent body includes an absorbent core having a fiber material and a water-absorbing polymer, and the absorbent core.

- the absorbent core is placed on the cover sheet raw material that is continuously carried out, both ends in the width direction of the cover sheet raw material are lifted and folded on the absorbent core.

- a hot melt adhesive is applied to each of the opposing surfaces and joined to form a bag-like portion, and the joined ends are folded along the bag-like portion to form a closed mouth portion to obtain the absorbent body.

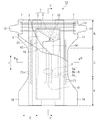

- FIG. 2 is an enlarged sectional view taken along line II-II in FIG.

- FIG. 3 is a partially enlarged sectional view of FIG. 2. It is the partial expanded sectional view typically shown about the other preferable aspect of the closing part which concerns on this embodiment.

- FIG. 5 is an enlarged cross-sectional view taken along the line VV in FIG. 1, and is a vertical cross-sectional view along the center line C1 in the width direction of the diaper 10.

- FIG. 4 is a partially enlarged sectional view corresponding to FIG. 3 schematically showing the relationship. It is the elements on larger scale equivalent to Drawing 3 showing typically another modification of an absorber concerning this embodiment.

- the present invention relates to an absorbent article capable of suppressing unnecessary discoloration by preventing contact between a water-absorbing polymer and an indicator part while maintaining quick discoloration performance during urination. Moreover, this invention relates to the manufacturing method of the absorbent article which can suppress a discoloration appropriately while maintaining a discoloration performance.

- the disposable diaper 10 of the present embodiment includes a liquid-permeable surface sheet 1 disposed on the skin contact surface side, and a moisture permeable and liquid impermeable surface disposed on the non-skin contact surface side.

- the top sheet 1 and the back sheet 2 are substantially vertically long.

- the absorber 3 has a substantially vertically long hourglass shape in which the length in the longitudinal direction (Y direction) and the width direction (X direction) is slightly shorter than these, and is bound inward in the vicinity of the center in the longitudinal direction.

- the absorbent body 3 is disposed substantially in the center with its longitudinal direction coinciding with the longitudinal direction of the top sheet 1 and the back sheet 2. These topsheet 1, backsheet 2 and absorber 3 are joined by a hot melt adhesive or the like.

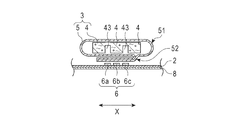

- the absorbent body 3 includes an absorbent core 4 that absorbs and holds a liquid and a covering sheet 5.

- the absorptive core 4 contains a fiber material 41 and a water-absorbing polymer 42 and is mixed and stacked.

- the covering sheet 5 covers the outer surface in order to maintain the shape of the absorbent core 4.

- three indicator portions 6 (6 a, 6 b, 6 c) are located from the crotch C to the ventral side F and the back side R near the center in the width direction of the diaper 10. (See FIGS. 1 and 2).

- the length of the indicator portion 6 in the longitudinal direction is shorter than the length of the absorber 3.

- the indicator unit 6 has a function of visually changing by contact with the liquid.

- “visual change” or “color change” means a color change from one color to another, a color disappearance from colored to colorless, and a color expression from colorless to colored by contact with a liquid. It is.

- the number of the indicator units 6 is not limited to three in the present embodiment and can be arbitrarily set.

- positioning relationship of the coating sheet 5 and the indicator part 6 of the absorber 3 in this embodiment are mentioned later.

- a pair of side sheets 7 and 7 are arranged on the skin surface side of the top sheet 1 from both sides in the longitudinal direction (Y direction) toward the outside in the width direction (X direction).

- an exterior sheet 8 made of a nonwoven fabric is disposed so as to cover the entire surface.

- the outer side of the diaper 10 has a soft touch and texture.

- the lengths in the longitudinal direction (Y direction) of the side sheets 7 and the exterior sheet 8 are approximately the same as the lengths in the longitudinal direction (Y direction) of the top sheet 1 and the back sheet 2, respectively.

- the side sheet 7 and the exterior sheet 8 protrude outward in the width direction (X direction) from the top sheet 1 and the back sheet 2 at the abdominal side F and the back side R, and are joined by a hot melt adhesive or the like.

- the external shape of the disposable diaper 10 shown in FIG. 1 is formed.

- the diaper 10 is disposed on the abdomen side F disposed on the wearer's belly side when worn, the crotch part C disposed on the crotch portion of the wearer, and the wearer's dorsal side in plan view of the unfolded state.

- the crotch part C has an hourglass shape in which the crotch part C is bound inward in the width direction.

- An elastic member 71 is disposed on the inner end of the side seat 7 near the center in the width direction.

- the elastic member 71 contracts, and a leak-proof cuff 72 is formed in the crotch portion C.

- elastic members 73 are arranged on the outer sides of the side seats 7 in the width direction, and leg gathers 74 are formed.

- a plurality of elastic members 13 extending in the width direction are disposed in the vicinity of the end in the longitudinal direction of the diaper 10. Due to the expansion and contraction of the elastic members 13, 71 and 73, the diaper 10 fits well following the body shape change caused by the wearer's movement or the like, and can effectively prevent side leakage of liquid or the like. As shown in FIG.

- seat 8 were laminated

- a portion 18 is formed.

- a fastening tape 19 is provided on the back flap portion 17.

- the diaper can be mounted and fixed by sticking this tape 19 to a tape applying part (not shown) provided on the ventral flap part 18. At this time, the center of the diaper in the longitudinal direction is gently bent inward, and the absorbent body 3 is worn so as to extend from the wearer's buttocks to the lower abdomen. As a result, excreta is absorbed and held in the absorber 3 accurately.

- the surface in contact with the human body is referred to as the skin side surface or skin contact surface or surface

- the opposite surface is referred to as the non-skin surface or non-skin contact surface or back surface.

- the side close to the skin side or the extending direction is called the skin side

- the side close to the non-skin surface or the extending direction is the non-skin side, non-skin It is called the contact side or the back side.

- the direction positioned on the front side of the human body when worn is referred to as the front, and its end is referred to as the front end, and the direction positioned on the rear is referred to as the rear, and the end is referred to as the rear end.

- the normal direction of the front or back surface of the absorbent article is called the thickness direction, and the amount is called thickness.

- the direction from the abdominal side to the back side in the plan view of the absorbent article is referred to as the longitudinal direction or the longitudinal direction (Y direction), and is orthogonal to the longitudinal (longitudinal) direction.

- the direction is referred to as the width direction (X direction).

- the vertical direction typically coincides with the front-rear direction of the human body when worn.

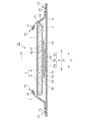

- FIG. 3 only the cross section in the width direction (X direction) of the absorber 3, the indicator section 6, the back sheet 2 and the exterior sheet 8 is shown in an enlarged manner.

- the three indicator sections 6 are arranged between the back sheet 2 and the absorber 3.

- the indicator part 6b is arranged near the center line C1 in the width direction (X direction) of the diaper 10, and the indicator parts 6a and 6c are arranged at equal intervals in the left-right width direction.

- a width direction region from the end of the indicator portion 6a to the end of the indicator portion 6c is referred to as an indicator region 61.

- the indicator part 6 is formed using the hydrophilic composition containing the coloring indicator which a color changes with a change of pH, for example.

- a method for arranging the indicator section 6, a method used for this type of article can be adopted. For example, a method in which a discolorable material such as the composition is directly applied to the back sheet 2 or the covering sheet 5 of the absorbent body 3, or a sheet member such as tissue paper or a hydrophilic nonwoven fabric is applied or impregnated. The method of interposing etc. is mentioned. In the present embodiment, as will be described later, from the viewpoint of preventing unnecessary discoloration of the indicator section 6, it is applied to the surface (skin contact surface) of the back sheet 2 facing the absorber 3.

- the number and interval of the indicator sections 6 are not limited to those of the present embodiment, and can be arbitrarily set according to the use, the size of the article, and the like. In accordance with this setting, the range of the indicator area 61 also changes.

- the diaper 10 is in a worn state and has a urination point p slightly on the stomach side of the crotch C and receives a lot of urination.

- the urination point p shown in FIG. 1 is a position in the case of men, and in the case of women, it is a position slightly closer to the center in the vertical direction.

- the excretion point p means a region where the wearer first receives urine when the wearer wears the disposable diaper 10 and its periphery. Therefore, it is preferable that the above-described closing portion 52 and indicator region 61 are arranged so as to cover the center line C1 in the width direction and to cover the urination point p in the vertical direction and the periphery thereof.

- the absorber 3 is composed of the absorbent core 4 and the covering sheet 5 as described above.

- the absorbent core 4 is a mixed fiber in which a water-absorbing polymer 42 is mixed between fibers of the fiber material 41 (see FIG. 3).

- Examples of the shape of the water-absorbing polymer 42 include a fibrous form in addition to the particulate form shown in FIG.

- the water-absorbing polymer 42 is in the form of particles, there are an indeterminate type, a block type, a bowl type, a spherical agglomeration type, a spherical type and the like due to the difference in shape, and any of these can be arbitrarily adopted.

- the particle size can also be set arbitrarily.

- the water-absorbing polymer 42 contains a very small amount of water to cause viscosity, and is stably fixed between the fiber materials 41.

- the constituent ratio between the fiber material 41 and the water-absorbing polymer 42 can be arbitrarily set depending on the use or size of the article.

- the covering sheet 5 has a length that substantially matches the longitudinal direction (Y direction) length of the absorbent core 4 and covers both side surfaces in the width direction (X direction) from the skin contact surface side of the absorbent core 4. Furthermore, it is joined to the non-skin contact surface side. Thereby, the shape of the absorptive core 4 becomes easy to be maintained. More specifically, the covering sheet 5 has a bag-like portion 51 and a closed mouth portion 52 located outside the bag-like portion 51 in a cross-sectional view of the absorbent body 3 in the width direction (X direction). The bag-like portion 51 is a portion that comes into contact with and covers the outer surface of the absorbent core 4. As shown in FIG.

- the closing opening 52 is composed of left and right end portions 5 a and 5 b (end portions of the bag-like portion 51) of the covering sheet 5 extending from the left and right width direction ends of the absorbent core 4. Yes. Both end portions 5a and 5b of the covering sheet 5 are joined and folded together on the outside of the bag-like portion 51 so that the surfaces facing the absorbent core 4 face each other. By this joining, both end portions 5a and 5b are integrated, and the bag-like portion 51 is sealed. Then, the flat portion of the cover sheet 5 that is folded in the palm (the flat portion of the end portion 5 b in FIG. 3) is folded along the bag-like portion 51 so as to face the indicator portion 6, thereby forming the closed mouth portion 52.

- the closed mouth portion 52 is coupled to the bag-like portion 51 at the closed mouth root portion 54 (see FIG. 3).

- the closing lip portion 54 is slightly lifted from the bag-like portion 51 by palm-folding.

- the connection between the closing port portion 52 and the bag-like portion 51 is not limited to the case where the closing portion 52 and the bag-like portion 51 are continuously provided as a continuous body of the same member.

- bonding of the closing mouth part 52 and the bag-like part 51 includes the form joined partially other than the closing mouth root part 54.

- the closing mouth portion 52 projects outward from the bag-like portion 51 and literally seals the bag-like portion 51 and closes the mouth.

- both the end portions 5 a and 5 b of the covering sheet 5 are structured so as not to enter the bag-like portion 51, and the leakage of the water absorbent polymer 42 is hardly induced. Thereby, the leakage of the water-absorbing polymer 42 scattered in the absorbent core 4 is effectively suppressed.

- the bag-shaped part 51 and the closing mouth part 52 are formed from the continuous coating sheet 5, and the boundary should just be determined functionally based on said division.

- the “joint fold” is to fold two sheet surfaces facing each other so that both hands are aligned, and the opposite surfaces of the two end portions 5a and 5b of the covering sheet 5 to the absorbent core 4 are the absorbent core 4. This means that they are raised at an angle from the horizontal plane and are opposed to each other in a planar shape.

- the closed mouth portion 52 is disposed so as to cover the entire indicator region 61 where the three indicator portions 6 (6a, 6b, 6c) are disposed. That is, a three-layer structure (two layers of the closing mouth portion 52 and one layer of the bag-like portion 51) is interposed between the indicator portion 6 and the absorbent core 4. Thereby, the indicator part 6 can be physically separated from the water absorbing polymer 42, and the contact opportunity of both can be suppressed. As this contact opportunity, for example, in the case where the water-absorbing polymer 42 is fluidized on the non-skin contact surface side of the absorbent core 4 in the bag-like portion 51, it further leaks to the outside of the absorbent body 3 and directly contacts it. There is an opportunity to do this.

- the closing mouth portion 52 tightly seals the mouth of the bag-like portion 51 to confine the water-absorbing polymer 42.

- the closing port portion 52 can be interposed between the indicator portion 6 and the absorbent core 4 to keep the distance between them.

- or indirect contact opportunity of the indicator part 6 and the water absorbing polymer 42 can be suppressed effectively.

- the ratio (t 4 / t 2 ) of the length (t 4 ) to the edge 53 is preferably 0.25 or more, and more preferably 0.40 or more.

- the upper limit is preferably 0.85 or less, and more preferably 0.70 or less.

- the ratio (t 5 / t 3 ) of the length (t 5 ) to the edge is preferably 0.25 or more, and more preferably 0.40 or more.

- the upper limit is preferably 0.85 or less, and more preferably 0.70 or less.

- the length (s 1 ) in the width direction (X direction) of the indicator region 61 in which the indicator portion 6 is disposed and the length (t 1 ) in the width direction (X direction) of the closing mouth portion 52. ) And the ratio (s 1 / t 1 ) (see FIG. 3) are preferably 0.15 or more, and more preferably 0.25 or more.

- the upper limit is preferably 0.75 or less, and more preferably 0.65 or less.

- the ratio (s 2 / t 2 ) (see FIG. 3) to the length (t 2 ) to the outer edge 53 is preferably 0.15 or more, and more preferably 0.25 or more.

- the upper limit is preferably 0.75 or less, and more preferably 0.65 or less.

- the length (s 3 ) from the center in the width direction of the indicator region 61 ( the center of the indicator portion 6 b and the center C1 in the width direction of the diaper 10) to the end of the indicator portion 6 c and the closing mouth of the closing mouth portion 52.

- the ratio (s 3 / t 3 ) (see FIG. 3) to the length (t 3 ) to the outer edge of the base portion 54 is preferably 0.15 or more, and more preferably 0.25 or more.

- the upper limit is preferably 0.75 or less, and more preferably 0.65 or less.

- another preferred embodiment of the closing port 52 may be folding as shown in FIG. In FIG. 4, the outer edge 53 of the closing mouth is further folded toward the bag-like portion 51. In this embodiment, the closed mouth outer edge 53 is hidden without being exposed to the back sheet 2 side. Further, the closing opening 52 itself is wound in a spiral shape so that it is more difficult to leak. Further, the covering sheet 5 between the indicator portion 6 and the absorbent core 4 has a five-layer structure. This is preferable because both the direct contact opportunity due to leakage of the water-absorbing polymer 42 and the indirect contact opportunity due to moisture penetration can be more effectively suppressed.

- the closed mouth portion 52 is not joined to the bag-like portion 51 except for the closed root portion 54 and is in a floating state. That is, the closed mouth portion 52 and the bag-like portion 51 are not joined to each other, and a gap (air layer 56) is formed.

- “entirely bonded” means that two opposing surfaces are bonded together without any gap, and “not fully bonded” means that the opposed surfaces are in close contact with a gap. Means not.

- it is not restricted to the aspect made into the non-joining substantially the whole surface like this embodiment as the state which the closing port part 52 and the bag-like part 51 are not made the whole surface joining.

- a hot melt adhesive in a spiral shape, it may be an intermittent joining form having a gap instead of solid coating.

- moisture content of the water absorbing polymer 42 can be avoided, and excretion urine can permeate

- the closing port 52 is in a floating state without being joined to the indicator unit 6.

- the closed mouth portion 52 is connected and fixed to the bag-like portion 51 at the closed mouth root portion 54, unlike simply stacking members. Thereby, the displacement with respect to the indicator part 6 hardly occurs, and protection against unnecessary discoloration other than urination of the indicator part 6 can be effectively achieved.

- the closed mouth portion 52 has the above-described structure, so that an air layer 56 is formed between the closed mouth portion 52 and the bag-like portion 51.

- an air layer 56 is formed between the closed mouth portion 52 and the bag-like portion 51.

- the closing part 52 in the diaper 10 can suppress the permeation of a trace amount of water contained in the water-absorbing polymer 42 before use, and can permeate the excretion liquid after use moderately. Excellent operational effects.

- the closing mouth portion 52 is relatively fixed easily because it is not fixed to the bag-like portion 51 and the indicator portion 6 at a portion other than the closing mouth root portion 54. This further acts to suppress the opportunity of contact of the water-absorbing polymer 42 with moisture on the indicator unit 6. This point will be described with reference to FIGS.

- the closed mouth part 52 is in a state of floating in a non-joined manner with the bag-like part 51 in the longitudinal direction (X direction) as shown in FIG. Therefore, the closed mouth portion 52 is hardly affected by the rigidity of the thick absorbent core 4 on a wide surface other than the closed mouth root portion 54. As a result, even if an external force is applied to the absorbent body 3 and the absorbent core 4 is deformed, the closed mouth portion 52 is hardly affected as a whole, and the above-described operation continues even when the diaper 10 is deformed.

- the covering sheet 83 forms a joint portion 83c and wraps the absorbent core 82 together, and both are integrated. That is, the entire joint surface (joint portion 83 c) of the both end portions 83 a and 83 b of the covering sheet 83 forms a part of the bag-like portion 84. Therefore, the joint 83C is easily affected by the rigidity of the thick absorbent core 83 as it is. In this respect, the diaper 10 of the present embodiment is greatly different from the conventional diaper 80 and the like.

- the diaper is usually folded in two at the longitudinal center line C2 or folded in three along the longitudinal bisectors D1 and D2 and enclosed in a packaging bag so as to be compressed in a large number.

- the absorbent core 4 is subjected to a folding force toward the skin contact surface side by the two-fold line C2 or the three-fold lines D1 and D2, and becomes a shearing force for peeling the joint portion 83C (FIGS. 5 and 6).

- the water-absorbing polymer inside the absorber 3 leaks out of the absorber from the peeled portion of the joint portion 83C and directly into the indicator portion 6. May come into contact.

- the fluidized water-absorbing polymer 42 may contact with an indicator part indirectly through the coating sheet of the non-skin contact surface side. As described above, if the water-absorbing polymer 42 contains moisture, the indicator portion will be discolored despite no urination. Such a situation is more likely to occur when the absorbent material is thinned to reduce the fiber material and increase the amount of the water-absorbing polymer.

- the combination of the bag-like portion 51 and the closed mouth portion 52 connected to the outside thereof avoids unnecessary discoloration of the indicator portion 6 and provides a quick and quick discoloration due to urination. It is possible to achieve both. Further, the closed mouth portion 52 is not easily affected by the external force acting on the absorbent core 4 as it is. Since most of the closed mouth portions 52 are in a state of floating from the bag-like portion 51, it is difficult to interlock with the absorbent core 4. As a result, it is difficult for a direct shearing force to act on the joint portion of the facing surfaces 5c and 5d in the closed mouth portion 52, and peeling does not easily occur.

- the action of the diaper 10 of this embodiment is an excellent action that cannot be obtained by the conventional absorbent body 81 that is easily affected by external force.

- the indicator part 6 is fixed to the back sheet 2 so that the color indicator does not impregnate the absorber side.

- the indicator part 6 consists of a hot-melt composition containing the mixture of the said color indicator and an adhesive substance. By the adhesive substance, the color indicator can be fixed on the application surface and the penetration into the absorbent body can be prevented.

- the ends 5a and 5b (see FIG. 3) of the covering sheet 5 constituting the closing opening 52 are joined as follows. It is necessary to close the bag-like portion 51 firmly so that the water-absorbing polymer 42 containing a small amount of moisture does not leak to the outside even if the water-absorbing polymer 42 containing a small amount of water is separated from the fiber material 41 and fluidized. Therefore, it is preferable that both ends 5a and 5b are tightly joined so as not to be separated even by an external force before use (for example, when the diaper 10 is packaged or put in and out during use). However, on the other hand, the closed mouth portion 52 needs to pass liquid such as excretion urine from the absorbent core 4 in a timely manner to reach the indicator portion 6.

- the application amount of the hot melt adhesive 52a is adjusted to such an extent that leakage of the water-absorbing polymer 42 is prevented and a large amount of liquid such as excreted urine can be easily permeated without permeating a minute amount of water in the water-absorbing polymer 42

- the edge parts 5a and 5b of the coating sheet 5 are joined.

- the basis weight of the hot melt adhesive applied between the end portions 5a and 5b of the covering sheet 5 is preferably 1.0 g / m 2 or more, and more preferably 2.0 g / m 2 or more.

- the upper limit is preferably 10.0 g / m 2 or less, 5.0 g / m 2 or less is more preferred.

- a joining method using this hot melt adhesive a method of joining by coating with an entire surface by a contact coating method such as a slot coater or an intermittent pattern such as a stripe coating or a spiral pattern can be used.

- the respective surfaces are pulled with adhesive force by applying to the opposing surfaces 5c and 5d (see FIG. 3) of the end portions 5a and 5b of the covering sheet 5, It can be fixed more firmly.

- This double-sided coating method is preferable from the viewpoint of achieving both the above-described prevention of polymer leakage and liquid permeation.

- the hot-melt adhesive 52a applied between the opposing surfaces 5c and 5d is applied at the closed outer edge 53 and the closed root 54 and the indicator contact portion 55 (see FIGS. 3 and 4) therebetween.

- Different basis weights may be used.

- the applied basis weight of the outer edge 53 of the closed mouth and the closed root portion 54 is increased, and the applied basis weight of the indicator contact portion 55 from the viewpoint of permeation of excreted urine.

- the amount may be smaller than that of the closing mouth outer edge 53 and the closing mouth root 54.

- the indicator contact portion 55 is intermittently coated like spiral pattern coating, and the outer edge 53 of the closed mouth and the root portion 54 of the closed mouth are coated by slot coater, spray coating, curtain coating, etc. It is possible to use a substantially solid coating.

- the fiber density of the covering sheet 5 is 0.05 g / cm 3 or more and 0.2 g in order to suppress the permeation of a small amount of moisture of the water-absorbing polymer 42 and cause a timely discoloration of the indicator unit 6 by liquid permeation due to urination.

- / Cm 3 or less is preferable, and 0.1 g / cm 3 or more and 0.2 g / cm 3 or less is more preferable.

- a sample is prepared by cutting the coated sheet 5 into a size of 50 mm in length and 5 mm in width. Subsequently, the mass of the sample is measured using an electronic balance (Electronic balance GR-300 manufactured by A & D, accuracy: 4 digits after the decimal point). Using a constant-pressure thickness meter, the sample thickness is measured, and the measured sample mass is divided by the volume of the sample (thickness ⁇ length ⁇ width) to calculate the density of all the materials in each region in each region. The measurement pressure of the low-pressure thickness gauge is 0.5 g / cm 2 . The average density can be obtained by adjusting 10 samples at arbitrary locations and averaging them.

- the hot melt adhesive 52a applied to the closing port 52 is also solidified by cooling or the like in the previous stage of the assembly process of the member of the diaper 10 as in the solidification of the hot melt composition of the indicator unit 6 described above. It is preferable. That is, it is preferable that the diaper is assembled in a state where the fluidity of both hot melt agents is lost. As a result, the gap between the fibers is filled to some extent due to the solidification of the hot melt adhesive 52a in the closing portion 52, and the hot melt composition of the indicator portion 6 is difficult to be impregnated.

- a hot-melt composition is solidified and it is made difficult to enter even between the fibers of a few closed mouth parts 52, and the clearance gap between fibers is moderately maintained. As a result, the distance between the closed mouth portion 52 and the indicator portion 6 is maintained, and the chance of contact with a small amount of moisture can be effectively suppressed.

- a hot-melt adhesive 44 agent between the bag-like portion 51 in the vicinity of the closed root portion 54 and the absorbent core 4 (see FIG. 3) ) Can be mentioned.

- the connecting portion between the bag-like portion 51 and the closing port portion 52 is more reliably sealed, and leakage of the water-absorbing polymer 42 can be more effectively prevented.

- this embodiment is preferable because the water-absorbing polymer 42 hardly collects at the closed mouth root portion 54 and the moisture permeation hardly occurs.

- the outer edge 53 of the closing mouth 52 and the closing root 54 of the closing mouth 52 are joined to the back sheet 2 by the hot melt adhesive 21 arranged in a streak shape in the vertical direction. Thereby, leakage of the water-absorbing polymer 42 and moisture penetration of the water-absorbing polymer 42 can be more effectively suppressed.

- the indicator contact portion 55 and the indicator portion 6 of the closing port 52 are not joined, but the outer edge 53 and the closing root 54 of the closing port are fixed to the back sheet 2.

- the arrangement relationship between the contact portion 55 and the indicator portion 6 is difficult to shift, which is preferable from the viewpoint of preventing discoloration of the unnecessary indicator portion 6.

- a part of the closed mouth portion 52 is joined to the back surface sheet 2, it is integrated with the flexible back surface sheet 2 different from the thick absorbent core 4, and still from the bag-shaped portion 51. It is preferable that it is not easily affected by the rigidity of the absorbent core 4 in a floating state.

- a plurality of hot melt adhesives are applied intermittently in the width direction in parallel with the outer side of the hot melt adhesive 21 so that the bag-like portion 51 and the back sheet 2 are coated. And may be joined.

- the diaper 10 may have an absorbent core 4 as shown in FIGS. 7, 8-1, and 8-2 to assist the operation of the closing mouth portion 52.

- the absorbent core 4 includes a mixed layer 45 of the fiber material 41 and the water-absorbing polymer 42 and a filter layer 46 made of only the fiber material.

- the single layer 46 is disposed on the non-skin contact surface side.

- the water-absorbing polymer 42 is made difficult to spill between the non-skin contact surface side of the absorptive core 4 and the bag-like part 51 (covering sheet).

- the above-mentioned operation of the closing mouth portion 52 can be enhanced more effectively.

- a three-layer structure in which a layer of only the water-absorbing polymer 42 is sandwiched between layers of only a fiber material is preferable because the above-described action of the closing port portion 52 can be enhanced.

- the absorbent body 3 shown in FIG. 8A includes an absorbent core 4 in which two slit portions 43, 43 are formed in the longitudinal direction (Y direction) in a portion corresponding to the crotch portion C (FIG. 8). -1 (A)).

- the slit portion 43 penetrates from the non-skin surface side of the absorbent core 4 to the skin surface side.

- FIG. 8-1 (B) the disposition of the water-absorbing polymer 42 in the crotch part C is reduced, and unnecessary discoloration is caused at a portion where the discoloration is most likely to occur during urination. Can be suppressed.

- the slit part 43 of the crotch part C is excellent in liquid permeability at the time of urination and brings about a timely discoloration of the indicator part 6.

- the slit 43 may not be penetrated but may have a thin skin-like absorbent material portion on the skin surface side.

- the absorber shown in FIG. 8-2 is also preferable in that the liquid on the skin contact surface side can be efficiently drawn into the inside, and the liquid remaining and liquid return can be effectively suppressed.

- the absorbent core 4 is created using the stacking drum 91 and the duct 92. Specifically, an intake fan (not shown) inside the pile drum 91 is operated to generate a suction force in an accumulation recess (not shown) on the outer surface of the pile drum 91, and the product is loaded in the duct 92. An air flow that flows toward the outer peripheral surface of the fiber drum 91 is generated.

- the fiber material 41 is introduced into the duct 92 so as to be scattered from the introduction port 93, and the water absorbent polymer 42 is introduced from the introduction port 94.

- the fiber material 41 and the water-absorbing polymer 42 are scattered toward the outer surface of the rotating fiber stack drum 91 and accumulated in the accumulation recess. In this way, the absorbent core 41 is formed.

- the absorbent core 4 on the outer surface of the stacking drum 91 is released onto the covering sheet original fabric 59 that is continuously supplied onto the vacuum conveyor 96.

- FIG. 10A shows a state before the absorbent core 4 is coated with the coated sheet original fabric 59.

- both ends 59a and 59b of the covering sheet original fabric 59 are lifted onto the absorbent core 4 to cover the side surface and the upper surface (surface on the non-skin contact surface side of the absorbent body) of the absorbent core 4.

- the left and right ends 59a and 59b of the covering sheet original fabric 59 are aligned so as to rise from the absorbent core 4 (see FIG. 10B).

- the length in the width direction of the covering sheet original fabric 59 is longer than the circumferential length in the cross section of the absorbent core 4, extra lengths are formed at the end portions 59 a and 59 b of the covering sheet original fabric 59.

- the surplus length portion of the covering sheet original fabric 59 is folded and folded so as to stand up with respect to the absorbent core 4, and hot melt or the like is applied to both surfaces of the end portions 59a and 59b to be joined and integrated (this stage)

- the joint portion is referred to as a palm-folded fold portion 58).

- a bag-like portion 51 whose mouth is closed is formed (see FIG. 10C).

- it is folded at the folding base point 57 to form the closed mouth portion 52 along the bag-like portion 51 (see FIG. 10D).

- both end portions 59a and 59b of the covering sheet original fabric 59 are lifted and integrated, so that the bag-like portion 51 can be reliably sealed. Also, by this lifting, it is possible to reliably apply hot melt adhesive or the like to both end portions 59a and 59b.

- the above-described lifting prevents the risk of member blurring and displacement during continuous conveyance on the conveyor 96, and is continuously conveyed with the long covering sheet original 59.

- the absorptive core 4 can be accurately aligned to enable reliable sealing of the absorptive core 4.

- a folding guide can be used as the lifting processing means.

- the closed mouth portion 52 sufficiently covers the indicator region 61 in a post-process (stacking step 203 (see FIG. 9)) of placing the absorber 3 on the back sheet 2.

- the width and arrangement can be. This can be achieved by adjusting the length (q) of the folding base point 57 and the palm folding part 58, and can be easily controlled by the lifting process.

- the closing mouth part 52 can avoid the closing mouth outer edge 53 and the closing mouth root part 54, and can cover the indicator area

- the coated sheet original fabric 59 has a sufficient width so that the required length can be folded at the ends 59a and 59b even if the folding base point 57 is biased.

- the absorbent core 4 may be placed near the center of the covering sheet original fabric 59 in the width direction so that an excessive end portion of the covering sheet original fabric 59 is cut off at the time of palm-folding.

- the closing core 52 may be formed by placing the absorbent core 4 in a position deviated from the center in the width direction of the covering sheet fabric 59 with the folding base point 57 in mind.

- the absorbent body forming step 201 the step of solidifying the hot melt adhesive or the like applied at the time of forming the closing port 52 with the cooling means 95, and the covering sheet original fabric 59 in a predetermined length (MD (Machine Direction) direction length)

- MD Machine Direction

- the absorber 3 is obtained by carrying out the cutting step and the pressing step (not shown) in any order.

- the obtained absorbent body 3 is turned upside down and transferred to the conveyor 97.

- the cooling means 95 include air blow (blowing air) and the like (the same applies to the cooling means 99 described later).

- the indicator part forming step 202 will be described.

- the back sheet original fabric 29 is continuously conveyed from a back sheet original roll 29a wound with a long back sheet original 29, and the width direction (CD direction) of the back sheet original 29 by the indicator coating means 98.

- An indicator composition is applied in the vicinity of the center.

- it consists of a hot melt composition containing a mixture of a color indicator and an adhesive substance, and a slot coater coating device, a spray coating device, a curtain coating device, or the like can be used.

- the indicator part 6 is formed by solidifying the applied hot melt composition by the cooling means 99.

- this indicator part formation process 202 and the absorber formation process 201 are made

- the hot melt adhesive for joining to the absorber 3 is applied along the longitudinal direction (MD direction) by the hot melt adhesive application means 100 to the back sheet original fabric 29 on which the indicator portion 6 is formed.

- a plurality of strips are intermittently applied on the outer side in the width direction of the hot melt adhesive so as not to overlap the indicator portion 6 and to run in parallel therewith. In that case, it is preferable to be at a position that contacts at least the outer edge 53 of the absorbent body 3 and the closing root portion 54 of the absorber 3. Thereby, the contact opportunity of the above-mentioned water-absorbing polymer 42 and the indicator part 6 can be suppressed more effectively.

- the absorber 3 is mounted and joined. At this time, the absorbent body 3 is arranged so that the center line in the width direction of the absorbent body 3 coincides with the center line in the width direction of the back sheet original fabric 29 so that the indicator part 6 is covered with the closed mouth part 52.

- the diaper 10 is obtained by cutting into dimensions and shapes.

- stacking of each member, joining, and cutting can be implemented along a normal process using the method used for the manufacturing method of this kind of articles

- the preferable structural material of the member which comprises the diaper 10 of this embodiment is demonstrated.

- a material for forming the absorbent body 3 those normally used for absorbent articles can be used.

- the fiber material 41 constituting the absorbent core 4 hydrophilic natural fibers such as fiber materials, synthetic fibers (preferably subjected to hydrophilic treatment), and the like can be used.

- the basis weight is not particularly limited, but is preferably 150 g / m 2 or more 500 g / m 2 or less.

- the water-absorbing polymer 42 various polymer materials usually used for this type of article can be used.

- the water-absorbing polymer 42 is preferably a superabsorbent polymer compound having a performance capable of absorbing and retaining water or physiological saline 20 times or more of its own weight.

- thin paper such as hydrophilic tissue paper, non-woven fabric made of hydrophilic fibers such as cotton and rayon, non-woven fabric made by subjecting synthetic resin fibers to hydrophilic treatment (SMS, SMMS) , Composite nonwoven fabrics such as SSMS) can be used.

- the color indicator contained in the hydrophilic composition constituting the indicator section 6 is preferably one that changes color when the pH is 3 or more and 7 or less.

- Examples thereof include bromophenol blue, methyl orange, alizarin S, and bromocresol.

- Examples include, but are not limited to, green, methyl red, and bromocresol purple.

- Particularly preferred among these color indicators are bromophenol blue, bromocresol green, bromocresol purple, and the like.

- These color indicators are preferably 0.01% by mass or more and 50% by mass or less, more preferably 0.01% by mass or more and 40% by mass or less, and still more preferably 0.01% by mass or more with respect to the total amount of the hydrophilic composition.

- the hydrophilic polymer which functions as an adhesive agent is mentioned, for example.

- hydrophilic polymer examples include polyethylene glycol (PEG), polypropylene glycol (PPG), polyvinyl alcohol (PVA), polyamide, vinyl pyrrolidone homopolymer, and the like. These hydrophilic polymers preferably have a number average molecular weight of 1,000 to 50,000, particularly 2,000 to 20,000 from the viewpoint of providing reliable fixation.

- PEG polyethylene glycol

- PPG polypropylene glycol

- PVA polyvinyl alcohol

- polyamide vinyl pyrrolidone homopolymer

- the hydrophilic composition constituting the indicator unit 6 may be the following wet indicator composition.

- the hot melt composition is a pH indicator (a) which is substantially colorless at pH 7 and develops a color in the acidic region, and is a glycerin fatty acid ester (b) having a surfactant activity of 0.1% by mass to 5% by mass.

- the acidic substance (e) contains 0.1% by mass or more and 5% by mass or less. More specifically, it can be formed by the components and coating methods described in paragraphs [0014] to [0039] of JP2009-247409A.

- the hydrophilic composition contains an acidic compound that can be maintained so that its pH does not exceed 4 when it comes into contact with water, and the back sheet 2 contains a water-soluble compound that exhibits alkalinity when dissolved in moisture. It can also be made.

- the hydrophilic composition may contain an antioxidant, an ultraviolet absorber and the like in addition to the components described above. These components are preferably contained in an amount of 0.5 to 5% by mass, more preferably 0.5 to 3% by mass, based on the total amount of the hydrophilic composition.

- the surface sheet 1 is preferably a hydrophilic non-woven fabric, and is a non-woven fabric called an air-through non-woven fabric, a point-bonded non-woven fabric, a spun-bonded non-woven fabric, a spun lace non-woven fabric, or a three-dimensional shaped non-woven fabric.

- a fiber that has been subjected to a hydrophilic treatment with a composite fiber of polyethylene, a composite fiber of polyethylene terephthalate and polyethylene, or the like is preferable, and a fiber having a basis weight of 15 g / m 2 to 50 g / m 2 can be suitably used.

- nonwoven fabric and its constituent fibers can be used singly or in combination of two or more.

- a hydrophilic perforated film or a hydrophilic non-woven fabric may be partially overlapped with the crotch portion of the top sheet 1 on the non-skin surface side of the top sheet 1.

- the material for forming the back sheet 2 is not particularly limited as long as it is waterproof and moisture permeable.

- a hydrophobic inorganic resin and a minute inorganic filler made of calcium carbonate or the like, or an incompatible organic material examples thereof include a porous film obtained by melt-kneading a polymer or the like to form a film, and uniaxially or biaxially stretching the film.

- the thermoplastic resin include polyolefin.

- the polyolefin include high to low density polyethylene, linear low density polyethylene, polypropylene, polybutene and the like, and these can be used alone or in combination.

- a water-repellent nonwoven fabric is preferable, and specifically, a spunbond nonwoven fabric, a spunbond-meltblown (SM) nonwoven fabric, a spunbond-meltblown-spunbond (SMS) nonwoven fabric, or the like is used.

- SM spunbond-meltblown

- SMS spunbond-meltblown-spunbond

- the elastic members 71 and 72 disposed on the side seat 7 and the elastic member 13 forming the waist gather a normal elastic member used for this type of article can be used.

- styrene-butadiene is used as styrene-butadiene.

- synthetic rubber such as butadiene, isoprene and neoprene, natural rubber, EVA, stretchable polyolefin, polyurethane and the like. Rubber or the like, or multifilament type thread-like ones can be used.

- the absorbent article of the present invention has an excellent effect of preventing unnecessary discoloration by preventing contact between the water-absorbing polymer and the indicator part while maintaining quick discoloration performance during urination. Moreover, the manufacturing method of the absorbent article of this invention has the outstanding effect that it can obtain the absorbent article which can suppress a discoloration appropriately while maintaining discoloration performance.

- the shape, size, and number of each indicator portion 6 can also be arbitrarily adopted in view of the above viewpoint, and the arrangement of the closing mouth portion 52 can be set in accordance with the arrangement of the indicator portion 6.

- the shape of the absorber 3 is not particularly limited, and the surface may be a block shape or may be provided with a slit.

- the absorbent article of the present invention is not limited to the deployable disposable diaper in the above embodiment, but may be a pants-type disposable diaper or a urine collecting pad, or a sanitary napkin, a panty liner or a light incontinence pad. .

- An absorbent article comprising a top sheet disposed on the skin contact surface side, a back sheet disposed on the non-skin contact surface side, and an absorber disposed between both sheets, Between the back sheet and the absorbent body, an indicator part that visually changes by contact with liquid is disposed, and the absorbent body includes an absorbent core having a fiber material and a water-absorbing polymer, and the absorbent core.

- the said closed part is arrange

- ⁇ 2> The absorbent article according to ⁇ 1>, wherein the closing mouth portion is coupled to the bag-like portion at a closing root portion.

- ⁇ 3> The absorbent article according to ⁇ 1> or ⁇ 2>, wherein the closing mouth portion is not joined to the indicator portion.

- ⁇ 4> The absorbent article according to any one of ⁇ 1> to ⁇ 3>, wherein the closing portion is joined to the back sheet at an outer edge portion and a base portion of the closing portion. .

- ⁇ 5> The absorbent article according to any one of ⁇ 1> to ⁇ 4>, wherein the bag-like portion in the vicinity of a base portion of the closing mouth portion is joined to the absorbent core.

- ⁇ 6> Any of the above ⁇ 1> to ⁇ 5>, which is an intermittent joined state having a gap between the closed mouth portion and the bag-like portion by applying a hot melt adhesive spirally.

- the absorbent core includes a filter layer that does not contain a water-absorbing polymer, and a mixed layer of a fiber material and a water-absorbing polymer disposed on the skin contact surface side.

- ⁇ 8> The absorbent article according to any one of ⁇ 1> to ⁇ 7>, wherein the indicator section is made of a hydrophilic composition containing a color indicator whose color changes with a change in pH.

- the indicator part is made of a hot melt composition containing a mixture of a color indicator and an adhesive substance whose color changes with a change in pH, and the indicator part is coated with the hot melt composition.

- the absorbent article according to any one of ⁇ 1> to ⁇ 8>, wherein the absorbent article is solidified so as not to penetrate into the covering sheet.

- the ratio t 4 / t 2 of the length t 4 from the edge of the indicator portion to the outer edge of the closed mouth with respect to the length t 2 from the center line in the width direction of the absorbent article to the outer edge of the closed mouth is The absorbent article according to any one of ⁇ 1> to ⁇ 9>, which is 0.25 or more and 0.85 or less, preferably 0.40 or more and 0.70 or less.

- ratio s 1 / t 1 of the width direction of the length t 1 of length s 1 and a closed opening portion in the width direction of the indicator region indicator portion is provided is 0.15 to 0.75

- it is 0.25 or more and 0.65 or less

- the length s 2 from the center of the indicator region in the width direction to the end of the indicator part and the length t to the outer edge of the closing part of the closing part the ratio s 2 / t 2 and 2 are 0.15 to 0.75, the absorption of preferably the 0.25 to 0.65 ⁇ 1> according to any one of the - ⁇ 10> Sex goods.

- ⁇ 12> Joining of both ends in the width direction of the covering sheet is performed by applying a hot melt contact agent, and the basis weight of the applied hot melt adhesive is 1.0 g / m 2 or more and 10.0 g / m 2.

- the fiber density of the cover sheet is a 0.05 g / cm 3 or more 0.2 g / cm 3 or less, preferably, 0.1 g / cm 3 or more 0.2 g / cm 3 or less is the ⁇ 1>

- the indicator portion is made of a hydrophilic composition containing a color indicator whose color changes with a change in pH, and the color indicator contained in the hydrophilic composition has a pH of 3 to 7 and has a color.

- the absorbent article according to any one of the above items ⁇ 1> to ⁇ 13>, which is any one of bromophenol blue, methyl orange, alizarin S, bromocresol green, methyl red, and bromocresol purple.

- the indicator portion is made of a hydrophilic composition containing a color indicator whose color changes with a change in pH. The color indicator is 0.01% by mass or more and 50% by mass or more based on the total amount of the hydrophilic composition.

- the absorption according to any one of ⁇ 1> to ⁇ 14> which is contained in an amount of not more than mass%, preferably not less than 0.01 mass% and not more than 40 mass%, most preferably not less than 0.01 mass% and not more than 0.5 mass%. Sex goods.

- the indicator section is pH indicator (a) which is substantially colorless at pH 7 and develops a color in an acidic region, 0.1 mass% or more and 5 mass% or less, glycerin fatty acid ester (b) having a surface active action (b) 20 mass% 90 mass% or less, polyalkylene glycol (c) 20 mass% or more and 35 mass% or less, polymer having a carboxyl group (d) 0 mass% or more and 70 mass% or less, acidic substances other than (b) and (d) ( e)

- the absorbent article according to any one of ⁇ 1> to ⁇ 15>, comprising a composition containing 0.1% by mass or more and 5% by mass or less.

- the top sheet is a hydrophilic non-woven fabric, and is composed of one type or a combination of two or more types selected from an air-through non-woven fabric, a point-bonded non-woven fabric, a spun-bonded non-woven fabric, a spunlace non-woven fabric, and a three-dimensional shaped non-woven fabric.

- the fiber is a fiber that has been subjected to hydrophilization treatment by one or a combination of two or more selected from a single fiber of polypropylene, a composite fiber of polypropylene and polyethylene, a composite fiber of polyethylene terephthalate and polyethylene, and the sheet.

- the back sheet is formed by melting and kneading a hydrophobic thermoplastic resin and a fine inorganic filler made of calcium carbonate or the like or an incompatible organic polymer, and the film is uniaxially or

- the absorbent article is a disposable diaper, It consists of an abdominal side that is placed on the wearer's belly side when worn, a crotch part that is placed on the wearer's crotch part, and a back side part that is placed on the wearer's back side.

- the method for producing an absorbent article according to any one of ⁇ 1> to ⁇ 20> The absorbent core is placed on the covering sheet raw material that is continuously carried out, both ends in the width direction of the covering sheet raw material are lifted and folded on the absorbent core, and hot is applied to each of the opposing surfaces of the both ends.

- a melt adhesive is applied and joined to form a bag-like portion, and the joined end portions are folded along the bag-like portion to form a closed mouth portion to obtain the absorbent body.

- An absorber forming step of turning upside down Applying a hot melt composition containing a mixture of a color indicator and an adhesive component to the continuously conveyed back sheet original fabric, further cooling and solidifying the indicator part forming step,

- the hot melt adhesive is intermittently applied on the back side sheet raw material on which the indicator part is formed in the outer side in the width direction of the indicator part, and the closing port of the closing part is formed by the hot melt adhesive of the back sheet.

- the manufacturing method of an absorbent article which has the lamination process which mounts and fixes the said absorber so that a base part and the said closing mouth outer edge may be joined with a back surface sheet.

- Example 1 A disposable diaper (test body 1) having a cross-sectional configuration schematically shown in FIG.

- the surface sheet 1 in the disposable diaper test body uses a two-layered uneven surface sheet structure, and each of the top sheet and the lower layer of the surface sheet uses polyethylene terephthalate / polyethylene core-sheath fibers.

- a liquid-permeable air-through nonwoven fabric having an amount of 18 g / m 2 was used, and the upper layer was obtained by embossing the air-through nonwoven fabric by embossing.

- the basis weight of the upper layer after providing irregularities was 23.5 g / m 2 .

- a spunbond / meltblown / polypropylene resin having a basis weight of 15 g / m 2 and a liquid-impermeable and moisture-permeable polyethylene resin film (comprising calcium carbonate) having a basis weight of 20 g / m 2 /

- a non-woven fabric having a structure of spunbond (SMS) bonded with hot melt was used.

- the absorbent body 3 is a fiber aggregate in which particulate water-absorbing polymer is held, and has a total basis weight of 490 g / m 2 composed of a uniform mixture of fluff pulp 200 g / m 2 and water-absorbing polymer 290 g / m 2 .

- An absorbent core was used.

- Example 2 A disposable diaper test body 2 was obtained in the same manner as the test body of Example 1 except that the closing portion and the indicator portion were not adhered (see FIG. 11B).

- a disposable diaper test body 3 was obtained in the same manner as the test body 1 of Example 1 except that the closed mouth part and the indicator part were arranged so as not to partially overlap each other (see FIG. 11C).

- Comparative Example 2 A disposable diaper test body 4 was obtained in the same manner as the test body 1 of Example 1 except that the closed mouth part and the bag-like part were joined on the entire contact surface (see FIG. 11D).

- the disposable diapers of Examples 1 and 2 did not change the indicator part before use. That is, it was found that the resistance to contact between the indicator part and the water-absorbing polymer itself or a small amount of water contained was high. Furthermore, it turned out that the change of a favorable indicator part is shown after use. On the other hand, in the disposable diaper of the comparative example 1, it turns out that contact with the indicator part, the water absorbing polymer itself, or the trace amount water

- the opportunity of contact with the polymer before use and its trace amount of water can be suitably suppressed, and the optimum due to excreted urine during use It has been found that the original function of changing the indicator part can be fully exhibited.

Landscapes

- Health & Medical Sciences (AREA)

- Epidemiology (AREA)

- Engineering & Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Vascular Medicine (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Absorbent Articles And Supports Therefor (AREA)

- Orthopedics, Nursing, And Contraception (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RU2014131052/12A RU2582470C2 (ru) | 2011-12-27 | 2012-12-06 | Абсорбирующее изделие |

| CN201280064673.2A CN104066410B (zh) | 2011-12-27 | 2012-12-06 | 吸收性物品 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011-286849 | 2011-12-27 | ||

| JP2011286849A JP5933973B2 (ja) | 2011-12-27 | 2011-12-27 | 吸収性物品 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2013099557A1 true WO2013099557A1 (ja) | 2013-07-04 |

Family

ID=48697052

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2012/081694 Ceased WO2013099557A1 (ja) | 2011-12-27 | 2012-12-06 | 吸収性物品 |

Country Status (5)

| Country | Link |

|---|---|

| JP (1) | JP5933973B2 (enExample) |

| CN (1) | CN104066410B (enExample) |

| RU (1) | RU2582470C2 (enExample) |

| TW (1) | TWI552734B (enExample) |

| WO (1) | WO2013099557A1 (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3357468A4 (en) * | 2015-09-30 | 2019-05-15 | Daio Paper Corporation | VOIDABLE ARTICLE |

| EP3639803A1 (en) * | 2018-10-17 | 2020-04-22 | Curt G. Joa, Inc. | Expandable absorbent core and method of manufacture |

| US10888472B2 (en) | 2015-09-30 | 2021-01-12 | Daio Paper Corporation | Absorbent article |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6214895B2 (ja) * | 2013-03-29 | 2017-10-18 | 大王製紙株式会社 | 使い捨て紙おむつ |

| JP6183968B2 (ja) | 2015-09-30 | 2017-08-23 | 大王製紙株式会社 | パンツタイプ使い捨ておむつ |

| JP6696854B2 (ja) * | 2016-07-29 | 2020-05-20 | ユニ・チャーム株式会社 | 吸収性物品 |

| JP6283136B2 (ja) * | 2017-03-29 | 2018-02-21 | 大王製紙株式会社 | 使い捨て紙おむつ |

| JP7049185B2 (ja) * | 2018-05-28 | 2022-04-06 | 大王製紙株式会社 | テープタイプ使い捨ておむつ |

| CN110478131B (zh) * | 2019-08-05 | 2022-01-11 | 思必康(厦门)新材料有限公司 | 一种pH响应变色的纱布及其制备方法和该纱布的应用 |

| JP7694071B2 (ja) * | 2021-03-11 | 2025-06-18 | 王子ホールディングス株式会社 | 吸収性物品の製造方法 |

| JP2024154798A (ja) * | 2023-04-19 | 2024-10-31 | 花王株式会社 | 前側パッドと後側パッドとを具備する吸収性物品 |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3289254A (en) * | 1961-02-02 | 1966-12-06 | Curt G Joa | Machine for manufacturing sanitary napkins and the like |

| JP2004337385A (ja) * | 2003-05-16 | 2004-12-02 | Kao Corp | 吸収性物品 |

| JP2005021389A (ja) * | 2003-07-02 | 2005-01-27 | Kao Corp | 吸収性物品 |

| JP2007175390A (ja) * | 2005-12-28 | 2007-07-12 | Daio Paper Corp | 使い捨て紙おむつ |

| JP2007252659A (ja) * | 2006-03-23 | 2007-10-04 | Kao Corp | 吸収性物品 |

| WO2007139154A1 (ja) * | 2006-05-31 | 2007-12-06 | Daio Paper Corporation | 吸収性物品および吸収要素の製造方法 |

| JP2009247409A (ja) * | 2008-04-01 | 2009-10-29 | Kao Corp | 吸収性物品 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TW476640B (en) * | 2000-03-02 | 2002-02-21 | Procter & Gamble | Disposable article, article for detecting the presence of vaginal infections, and absorbent interlabial device |

| EP1384459B1 (en) * | 2002-07-23 | 2007-03-28 | Kao Corporation | Disposable diaper |

| JP4460878B2 (ja) * | 2003-11-20 | 2010-05-12 | ユニ・チャーム株式会社 | 使い捨てのパンツ型着用物品 |

| US20060069362A1 (en) * | 2004-09-28 | 2006-03-30 | Kimberly-Clark Worldwide, Inc. | Absorbent article with indicator |

| TWM308058U (en) * | 2006-08-17 | 2007-03-21 | Kimberly Clark Taiwan Taiwan B | Absorbent article with PH balancing function |

-

2011

- 2011-12-27 JP JP2011286849A patent/JP5933973B2/ja active Active

-

2012

- 2012-12-06 WO PCT/JP2012/081694 patent/WO2013099557A1/ja not_active Ceased

- 2012-12-06 CN CN201280064673.2A patent/CN104066410B/zh active Active

- 2012-12-06 RU RU2014131052/12A patent/RU2582470C2/ru active

- 2012-12-13 TW TW101147234A patent/TWI552734B/zh not_active IP Right Cessation

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3289254A (en) * | 1961-02-02 | 1966-12-06 | Curt G Joa | Machine for manufacturing sanitary napkins and the like |

| JP2004337385A (ja) * | 2003-05-16 | 2004-12-02 | Kao Corp | 吸収性物品 |

| JP2005021389A (ja) * | 2003-07-02 | 2005-01-27 | Kao Corp | 吸収性物品 |

| JP2007175390A (ja) * | 2005-12-28 | 2007-07-12 | Daio Paper Corp | 使い捨て紙おむつ |

| JP2007252659A (ja) * | 2006-03-23 | 2007-10-04 | Kao Corp | 吸収性物品 |

| WO2007139154A1 (ja) * | 2006-05-31 | 2007-12-06 | Daio Paper Corporation | 吸収性物品および吸収要素の製造方法 |

| JP2009247409A (ja) * | 2008-04-01 | 2009-10-29 | Kao Corp | 吸収性物品 |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3357468A4 (en) * | 2015-09-30 | 2019-05-15 | Daio Paper Corporation | VOIDABLE ARTICLE |

| US10888472B2 (en) | 2015-09-30 | 2021-01-12 | Daio Paper Corporation | Absorbent article |

| EP3639803A1 (en) * | 2018-10-17 | 2020-04-22 | Curt G. Joa, Inc. | Expandable absorbent core and method of manufacture |

| US12220304B2 (en) | 2018-10-17 | 2025-02-11 | Curt G. Joa, Inc. | Expandable absorbent core and method of manufacture |

Also Published As

| Publication number | Publication date |

|---|---|

| JP5933973B2 (ja) | 2016-06-15 |

| JP2013132526A (ja) | 2013-07-08 |

| TWI552734B (zh) | 2016-10-11 |

| RU2582470C2 (ru) | 2016-04-27 |

| CN104066410B (zh) | 2015-12-23 |

| CN104066410A (zh) | 2014-09-24 |

| RU2014131052A (ru) | 2016-02-20 |

| TW201330836A (zh) | 2013-08-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5933973B2 (ja) | 吸収性物品 | |

| EP2630939B1 (en) | Absorbent article | |

| CA2757271C (en) | Disposable diaper | |

| JP7150021B2 (ja) | 吸収性物品及びその製造方法 | |

| JP2009232987A (ja) | 吸収性物品 | |

| JP2008023365A (ja) | 折り返し部を有する吸収体製品 | |

| JP2011240050A (ja) | 吸収性物品 | |

| WO2014065072A1 (ja) | 吸収性物品 | |

| JP2003052743A (ja) | 吸収性物品 | |

| RU2747616C1 (ru) | Впитывающее изделие и способ изготовления впитывающего изделия | |

| JP5175702B2 (ja) | 使い捨ておむつ | |

| JP7245624B2 (ja) | 吸収性物品 | |

| JP5052993B2 (ja) | 吸収性物品 | |

| JP2003290277A (ja) | 吸収性物品 | |

| CN101287434B (zh) | 包括处理用紧固装置的吸收制品 | |

| JP7734581B2 (ja) | 吸収性物品個包装体 | |

| JP2001258930A (ja) | 吸収性物品 | |

| JP2024063436A (ja) | ペット用吸収性物品 | |

| US20240164959A1 (en) | Absorbent insert | |

| TW202222286A (zh) | 拋棄式穿著用物品的製造方法 | |

| JP2018015463A (ja) | 吸収性物品 | |

| RU2765708C2 (ru) | Одноразовое гигиеническое изделие с боковыми барьерами для жидкости | |

| JP6701556B2 (ja) | 吸収性物品 | |

| JP7759222B2 (ja) | 吸収体及び吸収性物品 | |

| JP7534967B2 (ja) | 吸収性物品 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 12861984 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2014131052 Country of ref document: RU Kind code of ref document: A |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 12861984 Country of ref document: EP Kind code of ref document: A1 |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 12861984 Country of ref document: EP Kind code of ref document: A1 |