WO2011125591A1 - 永久磁石及び永久磁石の製造方法 - Google Patents

永久磁石及び永久磁石の製造方法 Download PDFInfo

- Publication number

- WO2011125591A1 WO2011125591A1 PCT/JP2011/057572 JP2011057572W WO2011125591A1 WO 2011125591 A1 WO2011125591 A1 WO 2011125591A1 JP 2011057572 W JP2011057572 W JP 2011057572W WO 2011125591 A1 WO2011125591 A1 WO 2011125591A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- magnet

- permanent magnet

- sintering

- organometallic compound

- formula

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F1/00—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties

- H01F1/01—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials

- H01F1/03—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity

- H01F1/032—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of hard-magnetic materials

- H01F1/04—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of hard-magnetic materials metals or alloys

- H01F1/06—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of hard-magnetic materials metals or alloys in the form of particles, e.g. powder

- H01F1/08—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of hard-magnetic materials metals or alloys in the form of particles, e.g. powder pressed, sintered, or bound together

- H01F1/086—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of hard-magnetic materials metals or alloys in the form of particles, e.g. powder pressed, sintered, or bound together sintered

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/16—Metallic particles coated with a non-metal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/12—Both compacting and sintering

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F9/00—Making metallic powder or suspensions thereof

- B22F9/02—Making metallic powder or suspensions thereof using physical processes

- B22F9/04—Making metallic powder or suspensions thereof using physical processes starting from solid material, e.g. by crushing, grinding or milling

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C33/00—Making ferrous alloys

- C22C33/02—Making ferrous alloys by powder metallurgy

- C22C33/0257—Making ferrous alloys by powder metallurgy characterised by the range of the alloying elements

- C22C33/0278—Making ferrous alloys by powder metallurgy characterised by the range of the alloying elements with at least one alloying element having a minimum content above 5%

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/002—Ferrous alloys, e.g. steel alloys containing In, Mg, or other elements not provided for in one single group C22C38/001 - C22C38/60

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F1/00—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties

- H01F1/01—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials

- H01F1/03—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity

- H01F1/032—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of hard-magnetic materials

- H01F1/04—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of hard-magnetic materials metals or alloys

- H01F1/047—Alloys characterised by their composition

- H01F1/053—Alloys characterised by their composition containing rare earth metals

- H01F1/055—Alloys characterised by their composition containing rare earth metals and magnetic transition metals, e.g. SmCo5

- H01F1/057—Alloys characterised by their composition containing rare earth metals and magnetic transition metals, e.g. SmCo5 and IIIa elements, e.g. Nd2Fe14B

- H01F1/0571—Alloys characterised by their composition containing rare earth metals and magnetic transition metals, e.g. SmCo5 and IIIa elements, e.g. Nd2Fe14B in the form of particles, e.g. rapid quenched powders or ribbon flakes

- H01F1/0572—Alloys characterised by their composition containing rare earth metals and magnetic transition metals, e.g. SmCo5 and IIIa elements, e.g. Nd2Fe14B in the form of particles, e.g. rapid quenched powders or ribbon flakes with a protective layer

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F1/00—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties

- H01F1/01—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials

- H01F1/03—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity

- H01F1/032—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of hard-magnetic materials

- H01F1/04—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of hard-magnetic materials metals or alloys

- H01F1/047—Alloys characterised by their composition

- H01F1/053—Alloys characterised by their composition containing rare earth metals

- H01F1/055—Alloys characterised by their composition containing rare earth metals and magnetic transition metals, e.g. SmCo5

- H01F1/057—Alloys characterised by their composition containing rare earth metals and magnetic transition metals, e.g. SmCo5 and IIIa elements, e.g. Nd2Fe14B

- H01F1/0571—Alloys characterised by their composition containing rare earth metals and magnetic transition metals, e.g. SmCo5 and IIIa elements, e.g. Nd2Fe14B in the form of particles, e.g. rapid quenched powders or ribbon flakes

- H01F1/0575—Alloys characterised by their composition containing rare earth metals and magnetic transition metals, e.g. SmCo5 and IIIa elements, e.g. Nd2Fe14B in the form of particles, e.g. rapid quenched powders or ribbon flakes pressed, sintered or bonded together

- H01F1/0577—Alloys characterised by their composition containing rare earth metals and magnetic transition metals, e.g. SmCo5 and IIIa elements, e.g. Nd2Fe14B in the form of particles, e.g. rapid quenched powders or ribbon flakes pressed, sintered or bonded together sintered

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F41/00—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties

- H01F41/02—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties for manufacturing cores, coils, or magnets

- H01F41/0253—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties for manufacturing cores, coils, or magnets for manufacturing permanent magnets

- H01F41/0266—Moulding; Pressing

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F41/00—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties

- H01F41/02—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties for manufacturing cores, coils, or magnets

- H01F41/0253—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties for manufacturing cores, coils, or magnets for manufacturing permanent magnets

- H01F41/0293—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties for manufacturing cores, coils, or magnets for manufacturing permanent magnets diffusion of rare earth elements, e.g. Tb, Dy or Ho, into permanent magnets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F9/00—Making metallic powder or suspensions thereof

- B22F9/02—Making metallic powder or suspensions thereof using physical processes

- B22F9/04—Making metallic powder or suspensions thereof using physical processes starting from solid material, e.g. by crushing, grinding or milling

- B22F2009/042—Making metallic powder or suspensions thereof using physical processes starting from solid material, e.g. by crushing, grinding or milling using a particular milling fluid

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2998/00—Supplementary information concerning processes or compositions relating to powder metallurgy

- B22F2998/10—Processes characterised by the sequence of their steps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2999/00—Aspects linked to processes or compositions used in powder metallurgy

Definitions

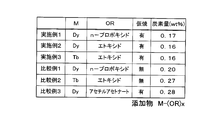

- the permanent magnet according to the present invention is characterized in that R in the structural formula M- (OR) x is an alkyl group.

- the permanent magnet according to the present invention is characterized in that the amount of carbon remaining after sintering is less than 0.2 wt%.

- the method for producing a permanent magnet according to the present invention is characterized in that R in the structural formula M- (OR) x is an alkyl group.

- the magnet powder is calcined in a hydrogen atmosphere. In this case, it is possible to perform thermal decomposition of the organometallic compound at a low temperature. As a result, the pyrolysis of the organometallic compound can be more easily performed on the entire magnet powder.

- FIG. 1 is an overall view showing a permanent magnet according to the present invention.

- FIG. 2 is an enlarged schematic view showing the vicinity of the grain boundary of the permanent magnet according to the present invention.

- FIG. 3 is an explanatory view showing a manufacturing process in the first method for manufacturing a permanent magnet according to the present invention.

- FIG. 4 is an explanatory view showing a manufacturing process in the second method for manufacturing a permanent magnet according to the present invention.

- FIG. 5 is a diagram showing a change in the amount of oxygen when the calcination treatment in hydrogen is performed and when it is not performed.

- FIG. 6 is a diagram showing the amount of carbon remaining in the permanent magnets of the permanent magnets of Examples 1 to 3 and Comparative Examples 1 to 3.

- Dy or Tb can be unevenly distributed in the grain boundaries of the magnet particles. Then, Dy and Tb unevenly distributed at the grain boundaries suppress the generation of reverse magnetic domains at the grain boundaries, so that the coercive force can be improved. In addition, the amount of Dy or Tb added can be reduced as compared with the conventional case, and a decrease in residual magnetic flux density can be suppressed.

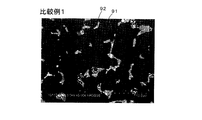

- FIG. 10 is a diagram showing an SEM photograph after sintering of the permanent magnet of Example 3 and the elemental analysis results of the grain boundary phase.

- FIG. 11 is a diagram in which the Tb element distribution state is mapped in the same field of view as the SEM photograph and the SEM photograph after sintering of the permanent magnet of Example 3.

- Dy as an oxide or non-oxide is detected from the grain boundary phase. That is, in the permanent magnets of Examples 1 to 3, Dy diffuses from the grain boundary phase to the main phase, and in the surface portion (outer shell) of the main phase particles, a phase in which a part of Nd is substituted with Dy is the main phase. It turns out that it is produced

- the permanent magnet 1 is manufactured by performing vacuum sintering or pressure sintering.

- the organic compound remaining before sintering is pyrolyzed to burn out the carbon contained in the magnet particles in advance (reduce the carbon content).

- the carbide is hardly formed in the sintering process.

- a large number of ⁇ Fe is not precipitated in the main phase of the magnet after sintering, and the magnet characteristics are not greatly deteriorated.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Power Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Crystallography & Structural Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Hard Magnetic Materials (AREA)

- Powder Metallurgy (AREA)

- Manufacturing Cores, Coils, And Magnets (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201180003981XA CN102549680A (zh) | 2010-03-31 | 2011-03-28 | 永久磁铁及永久磁铁的制造方法 |

| EP11765491.3A EP2503563B1 (en) | 2010-03-31 | 2011-03-28 | Manufacturing method for permanent magnet |

| KR1020127007161A KR101201021B1 (ko) | 2010-03-31 | 2011-03-28 | 영구 자석 및 영구 자석의 제조 방법 |

| US13/499,338 US9053846B2 (en) | 2010-03-31 | 2011-03-28 | Permanent magnet and manufacturing method thereof |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010084206 | 2010-03-31 | ||

| JP2010-084206 | 2010-03-31 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2011125591A1 true WO2011125591A1 (ja) | 2011-10-13 |

Family

ID=44762540

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2011/057572 Ceased WO2011125591A1 (ja) | 2010-03-31 | 2011-03-28 | 永久磁石及び永久磁石の製造方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US9053846B2 (enExample) |

| EP (1) | EP2503563B1 (enExample) |

| JP (2) | JP4923152B2 (enExample) |

| KR (1) | KR101201021B1 (enExample) |

| CN (1) | CN102549680A (enExample) |

| TW (2) | TW201212058A (enExample) |

| WO (1) | WO2011125591A1 (enExample) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013047469A1 (ja) * | 2011-09-30 | 2013-04-04 | 日東電工株式会社 | 永久磁石及び永久磁石の製造方法 |

| WO2013047467A1 (ja) * | 2011-09-30 | 2013-04-04 | 日東電工株式会社 | 希土類永久磁石及び希土類永久磁石の製造方法 |

| CN103503087A (zh) * | 2011-12-27 | 2014-01-08 | 因太金属株式会社 | NdFeB系烧结磁体 |

| CN103650073A (zh) * | 2011-12-27 | 2014-03-19 | 因太金属株式会社 | NdFeB系烧结磁体和该NdFeB系烧结磁体的制造方法 |

| US9412505B2 (en) | 2011-12-27 | 2016-08-09 | Intermetallics Co., Ltd. | NdFeB system sintered magnet |

| WO2018088393A1 (ja) * | 2016-11-09 | 2018-05-17 | Tdk株式会社 | 希土類磁石の製造方法 |

| US10468166B2 (en) | 2011-12-27 | 2019-11-05 | Intermetallics Co., Ltd. | NdFeB system sintered magnet |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5417632B2 (ja) | 2008-03-18 | 2014-02-19 | 日東電工株式会社 | 永久磁石及び永久磁石の製造方法 |

| KR101165937B1 (ko) * | 2010-03-31 | 2012-07-20 | 닛토덴코 가부시키가이샤 | 영구 자석 및 영구 자석의 제조 방법 |

| CN102576602A (zh) * | 2010-03-31 | 2012-07-11 | 日东电工株式会社 | 永久磁铁及永久磁铁的制造方法 |

| WO2011125584A1 (ja) * | 2010-03-31 | 2011-10-13 | 日東電工株式会社 | 永久磁石及び永久磁石の製造方法 |

| JP4923147B2 (ja) * | 2010-03-31 | 2012-04-25 | 日東電工株式会社 | 永久磁石及び永久磁石の製造方法 |

| JP5011420B2 (ja) * | 2010-05-14 | 2012-08-29 | 日東電工株式会社 | 永久磁石及び永久磁石の製造方法 |

| US9963344B2 (en) * | 2015-01-21 | 2018-05-08 | National Technology & Engineering Solution of Sandia, LLC | Method to synthesize bulk iron nitride |

| CN112750612B (zh) * | 2020-02-17 | 2022-08-05 | 北京京磁电工科技有限公司 | 钕铁硼表面渗透铽或镝的工艺方法 |

| CN112768169B (zh) * | 2020-12-30 | 2023-01-10 | 包头天和磁材科技股份有限公司 | 预制品及其制备方法和耐腐蚀磁体的生产方法及用途 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1064746A (ja) * | 1996-08-23 | 1998-03-06 | Sumitomo Special Metals Co Ltd | 薄肉R−Fe−B系焼結磁石の製造方法 |

| JP3298219B2 (ja) | 1993-03-17 | 2002-07-02 | 日立金属株式会社 | 希土類―Fe−Co−Al−V−Ga−B系焼結磁石 |

| JP2005191187A (ja) * | 2003-12-25 | 2005-07-14 | Nissan Motor Co Ltd | 希土類磁石およびその製造方法 |

| WO2009116532A1 (ja) * | 2008-03-18 | 2009-09-24 | 日東電工株式会社 | 永久磁石及び永久磁石の製造方法 |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07263265A (ja) | 1994-03-18 | 1995-10-13 | Hitachi Metals Ltd | 希土類金属間化合物永久磁石およびその製造方法 |

| JP4525072B2 (ja) | 2003-12-22 | 2010-08-18 | 日産自動車株式会社 | 希土類磁石およびその製造方法 |

| TWI302712B (en) * | 2004-12-16 | 2008-11-01 | Japan Science & Tech Agency | Nd-fe-b base magnet including modified grain boundaries and method for manufacturing the same |

| JP2006270087A (ja) * | 2005-02-28 | 2006-10-05 | Tdk Corp | 希土類焼結磁石の製造方法 |

| JP4635832B2 (ja) | 2005-11-08 | 2011-02-23 | 日立金属株式会社 | 希土類焼結磁石の製造方法 |

| US9551052B2 (en) | 2005-07-15 | 2017-01-24 | Hitachi Metals, Ltd. | Rare earth sintered magnet and method for production thereof |

| JP4692634B2 (ja) * | 2007-03-30 | 2011-06-01 | Tdk株式会社 | 磁石の製造方法 |

| JP5266523B2 (ja) * | 2008-04-15 | 2013-08-21 | 日東電工株式会社 | 永久磁石及び永久磁石の製造方法 |

-

2011

- 2011-03-28 CN CN201180003981XA patent/CN102549680A/zh active Pending

- 2011-03-28 JP JP2011069072A patent/JP4923152B2/ja not_active Expired - Fee Related

- 2011-03-28 US US13/499,338 patent/US9053846B2/en not_active Expired - Fee Related

- 2011-03-28 KR KR1020127007161A patent/KR101201021B1/ko not_active Expired - Fee Related

- 2011-03-28 WO PCT/JP2011/057572 patent/WO2011125591A1/ja not_active Ceased

- 2011-03-28 EP EP11765491.3A patent/EP2503563B1/en not_active Not-in-force

- 2011-03-31 TW TW100111451A patent/TW201212058A/zh not_active IP Right Cessation

- 2011-03-31 TW TW101116741A patent/TW201241846A/zh not_active IP Right Cessation

- 2011-12-22 JP JP2011281574A patent/JP4923163B1/ja not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3298219B2 (ja) | 1993-03-17 | 2002-07-02 | 日立金属株式会社 | 希土類―Fe−Co−Al−V−Ga−B系焼結磁石 |

| JPH1064746A (ja) * | 1996-08-23 | 1998-03-06 | Sumitomo Special Metals Co Ltd | 薄肉R−Fe−B系焼結磁石の製造方法 |

| JP2005191187A (ja) * | 2003-12-25 | 2005-07-14 | Nissan Motor Co Ltd | 希土類磁石およびその製造方法 |

| WO2009116532A1 (ja) * | 2008-03-18 | 2009-09-24 | 日東電工株式会社 | 永久磁石及び永久磁石の製造方法 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP2503563A4 |

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013047469A1 (ja) * | 2011-09-30 | 2013-04-04 | 日東電工株式会社 | 永久磁石及び永久磁石の製造方法 |

| WO2013047467A1 (ja) * | 2011-09-30 | 2013-04-04 | 日東電工株式会社 | 希土類永久磁石及び希土類永久磁石の製造方法 |

| US9396851B2 (en) | 2011-12-27 | 2016-07-19 | Intermetallics Co., Ltd. | NdFeB system sintered magnet |

| CN103650073A (zh) * | 2011-12-27 | 2014-03-19 | 因太金属株式会社 | NdFeB系烧结磁体和该NdFeB系烧结磁体的制造方法 |

| US9028624B2 (en) | 2011-12-27 | 2015-05-12 | Intermetallics Co., Ltd. | NdFeB system sintered magnet and method for producing the same |

| CN105206372A (zh) * | 2011-12-27 | 2015-12-30 | 因太金属株式会社 | NdFeB系烧结磁体 |

| CN103503087A (zh) * | 2011-12-27 | 2014-01-08 | 因太金属株式会社 | NdFeB系烧结磁体 |

| US9412505B2 (en) | 2011-12-27 | 2016-08-09 | Intermetallics Co., Ltd. | NdFeB system sintered magnet |

| US10290408B2 (en) | 2011-12-27 | 2019-05-14 | Intermetallics Co., Ltd. | NdFeB system sintered magnet |

| US10468166B2 (en) | 2011-12-27 | 2019-11-05 | Intermetallics Co., Ltd. | NdFeB system sintered magnet |

| WO2018088393A1 (ja) * | 2016-11-09 | 2018-05-17 | Tdk株式会社 | 希土類磁石の製造方法 |

| CN109923629A (zh) * | 2016-11-09 | 2019-06-21 | Tdk株式会社 | 稀土磁铁的制造方法 |

| JPWO2018088393A1 (ja) * | 2016-11-09 | 2019-10-03 | Tdk株式会社 | 希土類磁石の製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP4923163B1 (ja) | 2012-04-25 |

| EP2503563B1 (en) | 2015-01-21 |

| JP2011228664A (ja) | 2011-11-10 |

| EP2503563A1 (en) | 2012-09-26 |

| JP2012119693A (ja) | 2012-06-21 |

| JP4923152B2 (ja) | 2012-04-25 |

| TW201241846A (en) | 2012-10-16 |

| EP2503563A4 (en) | 2012-11-07 |

| CN102549680A (zh) | 2012-07-04 |

| US20120181475A1 (en) | 2012-07-19 |

| TWI378477B (enExample) | 2012-12-01 |

| TW201212058A (en) | 2012-03-16 |

| KR101201021B1 (ko) | 2012-11-14 |

| US9053846B2 (en) | 2015-06-09 |

| TWI378476B (enExample) | 2012-12-01 |

| KR20120049347A (ko) | 2012-05-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4923163B1 (ja) | 永久磁石及び永久磁石の製造方法 | |

| JP4923164B1 (ja) | 永久磁石及び永久磁石の製造方法 | |

| JP4865100B2 (ja) | 永久磁石及び永久磁石の製造方法 | |

| JP5969750B2 (ja) | 希土類永久磁石の製造方法 | |

| JP2011228656A (ja) | 永久磁石及び永久磁石の製造方法 | |

| JP4923147B2 (ja) | 永久磁石及び永久磁石の製造方法 | |

| JP4865097B2 (ja) | 永久磁石及び永久磁石の製造方法 | |

| WO2011125583A1 (ja) | 永久磁石及び永久磁石の製造方法 | |

| JP4865099B2 (ja) | 永久磁石及び永久磁石の製造方法 | |

| JP4981182B2 (ja) | 永久磁石及び永久磁石の製造方法 | |

| JP5908247B2 (ja) | 永久磁石の製造方法 | |

| JP4923149B2 (ja) | 永久磁石及び永久磁石の製造方法 | |

| JP4923150B2 (ja) | 永久磁石及び永久磁石の製造方法 | |

| JP5501832B2 (ja) | 永久磁石及び永久磁石の製造方法 | |

| JP5878325B2 (ja) | 永久磁石の製造方法 | |

| JP2011216596A (ja) | 永久磁石及び永久磁石の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201180003981.X Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 11765491 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 20127007161 Country of ref document: KR Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2869/CHENP/2012 Country of ref document: IN Ref document number: 2011765491 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 13499338 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |