WO2010010734A1 - 車両天井構造 - Google Patents

車両天井構造 Download PDFInfo

- Publication number

- WO2010010734A1 WO2010010734A1 PCT/JP2009/055237 JP2009055237W WO2010010734A1 WO 2010010734 A1 WO2010010734 A1 WO 2010010734A1 JP 2009055237 W JP2009055237 W JP 2009055237W WO 2010010734 A1 WO2010010734 A1 WO 2010010734A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- rib

- divided

- split

- ceiling material

- vehicle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R13/00—Elements for body-finishing, identifying, or decorating; Arrangements or adaptations for advertising purposes

- B60R13/02—Internal Trim mouldings ; Internal Ledges; Wall liners for passenger compartments; Roof liners

- B60R13/0212—Roof or head liners

- B60R13/0231—Roof or head liners specially adapted for roofs with openings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R21/00—Arrangements or fittings on vehicles for protecting or preventing injuries to occupants or pedestrians in case of accidents or other traffic risks

- B60R21/02—Occupant safety arrangements or fittings, e.g. crash pads

- B60R21/04—Padded linings for the vehicle interior ; Energy absorbing structures associated with padded or non-padded linings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R21/00—Arrangements or fittings on vehicles for protecting or preventing injuries to occupants or pedestrians in case of accidents or other traffic risks

- B60R21/02—Occupant safety arrangements or fittings, e.g. crash pads

- B60R21/04—Padded linings for the vehicle interior ; Energy absorbing structures associated with padded or non-padded linings

- B60R2021/0414—Padded linings for the vehicle interior ; Energy absorbing structures associated with padded or non-padded linings using energy absorbing ribs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R21/00—Arrangements or fittings on vehicles for protecting or preventing injuries to occupants or pedestrians in case of accidents or other traffic risks

- B60R21/02—Occupant safety arrangements or fittings, e.g. crash pads

- B60R21/04—Padded linings for the vehicle interior ; Energy absorbing structures associated with padded or non-padded linings

- B60R2021/0442—Padded linings for the vehicle interior ; Energy absorbing structures associated with padded or non-padded linings associated with the roof panel

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16B—DEVICES FOR FASTENING OR SECURING CONSTRUCTIONAL ELEMENTS OR MACHINE PARTS TOGETHER, e.g. NAILS, BOLTS, CIRCLIPS, CLAMPS, CLIPS OR WEDGES; JOINTS OR JOINTING

- F16B2200/00—Constructional details of connections not covered for in other groups of this subclass

- F16B2200/97—Constructional details of connections not covered for in other groups of this subclass having differing thermal expansion coefficients

Definitions

- the present invention relates to a vehicle ceiling structure in which reinforcing ribs are disposed on a ceiling material of a vehicle.

- a ceiling material for a vehicle is provided with a reinforcing material to increase and reinforce the rigidity of the ceiling material.

- a reinforcing material may have an impact absorbing function of absorbing an impact when the head of the occupant collides with the ceiling material (see Patent Documents 1 to 3).

- a reinforcing material a resin molding based on a resin grid rib is known.

- Such a reinforcing material (hereinafter referred to as a reinforcing rib) is fixed to the ceiling material using an adhesive such as hot melt.

- the thermal expansion and contraction of the ceiling material and the reinforcing rib are different because the thermal expansion coefficients of the ceiling material and the reinforcing rib are different from each other. There is a difference in the amount and amount of contraction.

- a material such as resin

- the expansion amount and contraction amount of the reinforcing rib become larger than that of the ceiling material, and as a result, the ceiling material Wrinkles may occur.

- a long reinforcing rib may be divided into a plurality and provided with a gap in the longitudinal direction, in this case, the ceiling material is thermally expanded and thermally shrunk for each divided reinforcing rib.

- the difference between the amount of expansion and contraction can be reduced, stress may be applied to the divisions of the reinforcing rib during handling when assembling the ceiling material to the vehicle body, and the ceiling material may be bent and broken. .

- the present invention has been made in view of such conventional problems, and an object of the present invention is to provide a vehicle ceiling structure capable of suppressing the occurrence of defects such as wrinkles, deflections and breakages of a ceiling material.

- the present invention relates to a vehicle ceiling structure in which a long reinforcing rib made of a resin having a thermal expansion coefficient different from that of a ceiling material of a vehicle is provided.

- the reinforcing rib is constituted by a plurality of divided ribs divided with a gap in the longitudinal direction, Upper and lower protrusions projecting in the longitudinal direction are formed above and below the end of one of the divided ribs adjacent to each other, The lower surface of the upper projection and the upper surface of the lower projection of the one split rib face each other in the vertical direction with the end of the other split rib.

- the vehicle ceiling structure is characterized in that it is fitted.

- the reinforcing rib is not integrally configured, but is configured by a plurality of the dividing ribs divided with a gap in the longitudinal direction. Therefore, even if thermal expansion and thermal contraction occur due to the temperature change after disposing the reinforcing rib on the ceiling material, the difference between the expansion amount and the contraction amount caused by the difference between the thermal expansion coefficients of the two is reduced. be able to. That is, since the reinforcing rib thermally expands and thermally contracts for each of the plurality of divided ribs, the difference between the amount of expansion and the amount of contraction with the ceiling material can be reduced. Thereby, generation

- the one divided rib and the other divided rib adjacent to each other are the lower surface of the upper protruding portion and the upper surface of the lower protruding portion of the one divided rib, respectively.

- the end portions of the ribs are vertically opposed to each other. That is, the one divided rib has the lower surface of the upper protruding portion and the upper surface of the lower protruding portion as contact surfaces against the end of the other divided rib at least at the upper and lower ends of the end The end of the dividing rib is vertically opposed to the contact surface.

- the one split rib and the other split rib adjacent to each other are fitted to the one split rib in a state where the other split rib is sufficiently restrained in the vertical direction.

- deflection of the ceiling material occurs even when stress is applied between the division ribs (division parts) at the time of handling when assembling the ceiling material to the vehicle body. The occurrence of breakage can be suppressed.

- the problem caused by the difference in the coefficient of thermal expansion between the ceiling material and the reinforcing rib can be suppressed by forming the reinforcing rib with a plurality of the dividing ribs.

- the problem which arises by having comprised the said reinforcement rib by several said dividing rib can be suppressed by the fitting structure between the said adjacent dividing ribs.

- a vehicle ceiling structure capable of suppressing the occurrence of defects such as wrinkles, deflection, and breakage of a ceiling material.

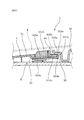

- FIG. 2 is an enlarged perspective view of a part A in FIG. 1; 2.

- A1-A1 sectional drawing in FIG. Explanatory drawing which simplified and showed the fitting state of the 1st division

- Explanatory drawing which shows the state in front of fitting a 1st division

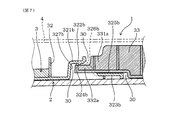

- FIG. 7 is a cross-sectional view taken along line B1-B1 of FIG. Explanatory drawing which shows the state in front of making a 2nd division

- the one divided rib and the other divided rib adjacent to each other be fitted such that twisting in the rotational direction about the longitudinal direction does not occur. That is, the upper projection and the lower projection of the one split rib and the end of the other split rib can be fitted such that twisting in the rotational direction about the longitudinal direction does not occur. Is preferred. In this case, it is possible to sufficiently and reliably fit the one divided rib and the other divided rib adjacent to each other.

- the upper protruding portion and the lower protruding portion of the one split rib have different tip positions protruding in the longitudinal direction.

- the one divided rib and the other divided rib adjacent to each other can be easily fitted.

- the lower protruding portion of the one split rib has a tip end position projecting in the longitudinal direction on the front side of the upper protruding portion.

- the other split rib can be easily fitted to the one split rib previously fixed to the ceiling material. That is, specifically, the end of the other split rib can be easily fitted between the upper protrusion and the lower protrusion of the one split rib in a diagonally upward direction.

- the said ceiling material has an opening part for sunroofs. That is, the ceiling material provided with the opening for the sunroof is lower in rigidity than a normal ceiling material. Therefore, the rigidity of the ceiling material can be sufficiently secured by adopting the vehicle ceiling structure of the present invention and arranging the reinforcing rib with respect to the ceiling material.

- the said ceiling material and the said reinforcement rib are adhere

- the reinforcing rib can be easily and reliably disposed on the ceiling material.

- the hot-melt-adhesive the hot-melt-adhesive of a polyamide type, polyolefin type, polyester type, a synthetic rubber type etc. can be used.

- At least a part of the reinforcing rib also doubles as an impact absorbing material.

- at least a part of the reinforcing rib plays a role as a reinforcing material to improve the rigidity of the ceiling material and, for example, an impact load applied when a head of a passenger in the car collides with the ceiling material It acts as a shock absorber that absorbs and deforms and breaks down.

- At least one of the plurality of dividing ribs is made of a resin different from the other dividing ribs.

- resins different types can be used depending on the arrangement location of the dividing rib, the required performance, and the like, and various configurations can be accommodated.

- high rigidity resin e.g., ABS resin etc.

- a resin for example, PP (polypropylene) resin or the like

- PP polypropylene

- thermoplastic resins such as a polypropylene, a polyurethane, a polyethylene terephthalate, etc.

- fibers such as a wood fiber, glass fiber, etc.

- ABS, PP, Noryl, polycarbonate, polycarbonate ABS, PE etc. can be used as resin which comprises the said reinforcing material.

- FIG. 1 A vehicle ceiling structure according to an embodiment of the present invention will be described using FIG. 1 to FIG.

- the vehicle ceiling structure 1 of this example is adopted to a vehicle provided with a sunroof as shown in FIG. 1, the present invention is not limited to this.

- a ceiling opening 20 for a sunroof is provided in a ceiling material 2 which is an interior material of a vehicle cabin.

- the ceiling opening 20 is provided on the front side of the ceiling material 2 and has a rectangular shape.

- long reinforcing ribs 3 are disposed in the front-rear direction. The reinforcing rib 3 is bonded to the ceiling material 2 by a hot melt adhesive.

- the two reinforcing ribs 3 disposed on the left and right sides of the ceiling opening 20 of the ceiling material 2 have the same configuration except that they are provided symmetrically. . Therefore, for convenience of explanation, one reinforcing rib 3 disposed on the left side of the ceiling opening 20 of the ceiling material 2 will be described below.

- the reinforcing rib 3 is constituted of a plurality of divided ribs divided in the longitudinal direction, that is, a first divided rib 31, a second divided rib 32 and a third divided rib 33 in order from the front side.

- the first divided rib 31 and the second divided rib 32 are fitted to each other with a gap 30 in the longitudinal direction.

- the second divided rib 32 and the third divided rib 33 are fitted to each other with a gap 30 in the longitudinal direction.

- the ceiling material 2 is made of a mixture of a thermoplastic resin and wood fibers.

- the first divided rib 31 and the third divided rib 33 are disposed in the portion of the ceiling material 2 where rigidity is desired to be improved, and made of high rigidity ABS resin.

- the second divided rib 32 is disposed particularly at a portion where shock absorption is required, and is made of PP resin having relatively low rigidity.

- the first divided rib 31, the second divided rib 32 and the third divided rib 33 constituting the reinforcing rib 3 are made of a material having a coefficient of thermal expansion different from that of the ceiling material 2.

- the rear end portion 311b of the first divided rib 31 is provided with a rear protruding portion 312b that protrudes in the rear direction.

- an upper front protrusion 322a that protrudes in the forward direction is provided on the upper side of the front end portion 321a of the second divided rib 32, and a lower lower protrusion 323a that protrudes in the forward direction is provided on the lower side. It is done.

- the front lower protrusion 323a has a tip position projecting in the longitudinal direction on the front side of the front upper protrusion 322a.

- the upper front protrusion 322a and the lower front protrusion 323a are connected by a front connecting portion 326a provided on both sides of the front end 321a of the second divided rib 32. Further, a front fitting portion 327a for fitting the rear protruding portion 312b of the first divided rib 31 is formed between the front upper side protruding portion 322a and the front lower side protruding portion 323a.

- the first divided rib 31 and the second divided rib 32 are fitted by fitting the rear protruding portion 312 b of the first divided rib 31 to the front fitting portion 327 a of the second divided rib 32. It is fixed.

- the lower surface 324 a of the upper front protrusion 322 a of the second divided rib 32 is vertically opposed to the upper surface 314 b of the rear protrusion 312 b of the first divided rib 31.

- the upper surface 325 a of the lower front protrusion 323 a of the second divided rib 32 is vertically opposed to the lower surface 315 b of the rear protrusion 312 b of the first divided rib 31.

- the first divided rib 31 is vertically restrained by the lower surface 324a of the upper front protrusion 322a of the second divided rib 32 and the upper surface 325a of the lower lower projection 323a of the second divided rib 32. It is fitted in the Furthermore, the first divided rib 31 is fitted in a state in which the rear protruding portion 312 b is constrained in the left-right direction by the front connecting portion 326 a of the second divided rib 32.

- 2 is an enlarged perspective view of a portion A of FIG.

- FIG. 3 is a cross-sectional view taken along line A1-A1 of FIG.

- FIG. 4 is the figure which simplified and showed FIG.

- the front end portion 331 a of the third divided rib 33 is provided with a front protrusion 332 a that protrudes in the front direction.

- a rear upper protruding portion 322b that protrudes in the rear direction is provided on the upper side of the rear end portion 321b of the second divided rib 32, and a lower rear protruding portion 323b that protrudes in the rear direction is provided on the lower side. It is provided.

- the rear lower projection 323b has a tip end position projecting in the longitudinal direction ahead of the rear upper projection 322b.

- the upper rear protrusion 322 b and the lower rear protrusion 323 b are connected by a rear connecting portion 326 b provided on both sides of the rear end 321 b of the second split rib 32.

- a rear fitting portion 327b for fitting the front protrusion 332a of the third divided rib 33 is formed between the rear upper protrusion 322b and the rear lower protrusion 323b.

- the second split rib 32 and the third split rib 33 are engaged by fitting the forward projecting portion 332 a of the third split rib 33 to the rear fitting portion 327 b of the second split rib 32. It is fixed.

- the lower surface 324 b of the upper rear protrusion 322 b of the second divided rib 32 is vertically opposed to the upper surface 334 a of the forward protrusion 332 a of the third divided rib 33.

- the upper surface 325 b of the lower rear protrusion 323 b of the second divided rib 32 is vertically opposed to the lower surface 335 a of the forward protrusion 332 a of the third divided rib 33.

- the front protrusion 332a is vertically restrained by the lower surface 324b of the upper rear protrusion 322b of the second divided rib 32 and the upper surface 325b of the lower lower protrusion 323b. It is fitted in the Furthermore, the third divided rib 33 is fitted in a state in which the front protrusion 332 a is restrained in the left-right direction by the rear connection portion 326 b of the second divided rib 32.

- 6 is an enlarged perspective view of a portion B of FIG.

- FIG. 7 is a cross-sectional view taken along line B1-B1 of FIG.

- the front projection 332a of the third divided rib 33 is inserted in the front direction into the rear fitting portion 327b of the second divided rib 32, and The two split ribs 32 and the third split rib 33 are assembled.

- the reinforcing rib 3 in which the first divided rib 31, the second divided rib 32, and the third divided rib are assembled is obtained.

- a hot melt adhesive in a molten state is applied to the place on the ceiling material 2 where the reinforcing rib 3 is to be disposed.

- a polyamide-based hot melt adhesive was used as the hot melt adhesive.

- the hot melt adhesive is cooled and solidified to bond the reinforcing rib 3. Thereby, the reinforcing rib 3 is provided to the ceiling material 2.

- the assist grip fixing portion 71, the room lamp fixing portion 72, the sun visor fixing portion 73 and the like fixes to the body material 4 (refer FIG.3, FIG.4, FIG.7) which comprises a vehicle body at the same time.

- the reinforcing rib 3 is not necessarily configured integrally, but is configured by a plurality of divided ribs 31 to 33 divided with a gap 30 in the longitudinal direction. Therefore, even if thermal expansion and thermal contraction occur after the reinforcing ribs 3 are disposed on the ceiling material 2 due to these temperature changes, the difference between the expansion amount and the contraction amount caused by the difference between the thermal expansion coefficients of the two is reduced. be able to.

- the reinforcing rib 3 thermally expands and thermally contracts for each of the divided ribs 31 to 33 divided into a plurality, the difference between the amount of expansion and the amount of contraction between the reinforcing member 3 and the ceiling material 2 can be reduced. Thereby, generation

- positioning can be suppressed.

- the first divided rib 31 and the second divided rib 32 adjacent to each other are taken as an example, and a diagram in which the fitting state of the both is simplified (FIG.

- the first divided rib 31 and the second divided rib 32 are respectively provided on the lower surface 324a of the upper front protrusion 322a of the second divided rib 32 and the upper surface 325a of the lower front protrusion 323a.

- the rear end portion 312 b of the dividing rib 31 is vertically fitted in the opposite direction.

- the second divided rib 32 has the lower surface 324a of the upper front protrusion 322a and the upper surface 325a of the lower front protrusion 323a as contact surfaces with respect to the first divided rib 31 at the top and bottom of the front end 321a.

- the rear end portion 312 b of the first divided rib 31 is vertically opposed to the contact surface of the first divided rib 31.

- the first divided rib 31 and the second divided rib 32 are fitted to the second divided rib 32 in a state where the first divided rib 31 is sufficiently restrained in the vertical direction.

- the problem caused by the difference in the thermal expansion coefficient between the ceiling material 2 and the reinforcing rib 3 can be suppressed by configuring the reinforcing rib 3 with the plurality of divided ribs 31 to 33. it can.

- the problem caused by forming the reinforcing rib 3 with the plurality of divided ribs 31 to 33 can be suppressed by the fitting structure between the adjacent divided ribs 31 to 33.

- the first divided rib 31 and the second divided rib 32 which are adjacent to each other are fitted such that no twist in the rotational direction around the longitudinal direction is generated. That is, the first divided rib 31 is fitted in the state in which the rear protrusion 312 b is restrained in the vertical direction with respect to the second divided rib 32 and is fitted in the state in which it is restrained in the lateral direction. Therefore, adjacent first divided ribs 31 and second divided ribs 32 can be fitted sufficiently and reliably.

- the second divided rib 32 and the third divided rib 33 adjacent to each other are fitted such that twisting in the rotational direction about the longitudinal direction does not occur. That is, the third split rib 33 is fitted in the state in which the front protrusion 332 a is restrained in the vertical direction with respect to the second split rib 32 and is fitted in the state in which it is restrained in the lateral direction. Therefore, the second divided rib 32 and the third divided rib 33 adjacent to each other can be fitted sufficiently and reliably.

- the front lower side projecting portion 323a of the second divided rib 32 has a tip end position projecting in the longitudinal direction ahead of the front upper side projecting portion 322a. Therefore, as shown in FIGS. 5 (a) and 5 (b), the rear projection 312b of the first split rib 31 is easily inserted into the front fitting portion 327a of the second split rib 32 obliquely from above It can be done.

- the lower end protrusion 323b of the second divided rib 32 has a tip end position projecting in the longitudinal direction ahead of the upper rear protrusion 322b. Therefore, as shown in FIGS. 8A and 8B, the front projection 332a of the third divided rib 33 is easily inserted from the diagonal upper direction into the rear fitting portion 327b of the second divided rib 32 and engaged. It can be done.

- the ceiling material 2 also has an opening 20 for a sunroof. That is, the ceiling material 2 provided with the opening portion 20 for the sunroof becomes lower in rigidity than the normal ceiling material 2. Therefore, the rigidity of the ceiling material 2 can be sufficiently secured by adopting the vehicle ceiling structure 1 of the present example and arranging the reinforcing rib 3 with respect to the ceiling material 2. In addition, the ceiling material 2 and the reinforcing rib 3 are bonded by a hot melt adhesive. Therefore, the reinforcing rib 3 can be easily and reliably disposed on the ceiling material 2.

- the reinforcing rib 3 also serves as an impact absorbing material.

- the second divided rib 32 corresponds thereto. Therefore, the second divided rib 32 plays a role as a reinforcing material to improve the rigidity of the ceiling material 2 and, for example, is deformed against an impact load applied when the head of an occupant in the vehicle collides with the ceiling material 2 It acts as a shock absorber that breaks down and absorbs shock.

- the second divided rib 32 is made of a resin different from the first divided rib 31 and the third divided rib 33. That is, by dividing the reinforcing rib 3 into a plurality of divided ribs 31 to 33, different types of resins can be used properly depending on the arrangement location of the divided ribs 31 to 33, the required performance, etc. Various configurations can be accommodated.

- the first split rib 31 and the third split rib 33 disposed in the portion of the ceiling material 2 where the rigidity is to be improved in particular require a resin (ABS resin) having high rigidity, particularly shock absorption.

- the second split rib 32 disposed at the portion is made of a resin (PP resin) which is easily deformed and broken by impact, and which has relatively low rigidity.

- a dividing rib for example, the second dividing rib 32

- a dividing rib for example, a resin that is compatible with the adhesive to be used

- the vehicle ceiling structure 1 capable of suppressing the occurrence of defects such as wrinkles, deflection, and breakage of the ceiling material 2.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Vehicle Interior And Exterior Ornaments, Soundproofing, And Insulation (AREA)

- Body Structure For Vehicles (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/055,365 US8091953B2 (en) | 2008-07-21 | 2009-03-18 | Vehicle ceiling structure |

| AU2009275077A AU2009275077B2 (en) | 2008-07-21 | 2009-03-18 | Vehicle ceiling structure |

| EP09800250A EP2305517B1 (en) | 2008-07-21 | 2009-03-18 | Vehicle ceiling structure |

| CN200980128509.1A CN102099224B (zh) | 2008-07-21 | 2009-03-18 | 车辆顶棚结构 |

| CA2731540A CA2731540C (en) | 2008-07-21 | 2009-03-18 | Vehicle ceiling structure |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008187990A JP5137248B2 (ja) | 2008-07-21 | 2008-07-21 | 車両天井構造 |

| JP2008-187990 | 2008-07-21 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2010010734A1 true WO2010010734A1 (ja) | 2010-01-28 |

Family

ID=41570202

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2009/055237 Ceased WO2010010734A1 (ja) | 2008-07-21 | 2009-03-18 | 車両天井構造 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8091953B2 (enExample) |

| EP (1) | EP2305517B1 (enExample) |

| JP (1) | JP5137248B2 (enExample) |

| CN (1) | CN102099224B (enExample) |

| AU (1) | AU2009275077B2 (enExample) |

| CA (1) | CA2731540C (enExample) |

| WO (1) | WO2010010734A1 (enExample) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5818097B2 (ja) * | 2012-03-30 | 2015-11-18 | トヨタ紡織株式会社 | 車両天井構造 |

| ES2707949T3 (es) | 2015-03-18 | 2019-04-08 | Antolin Grupo Ing Sa | Guarnecido para techo de vehículo con una porción transparente |

| CN106143386B (zh) * | 2015-03-30 | 2020-02-04 | 天津博信汽车零部件有限公司 | 车内顶棚吸能结构、车辆顶棚以及车辆 |

| DE102018205683B4 (de) * | 2018-04-13 | 2024-02-29 | Bayerische Motoren Werke Aktiengesellschaft | Dachsystem für ein fahrzeug, fahrzeug mit einem solchen dachsystem, dachelement und herstellungsverfahren |

| JP2020094204A (ja) | 2018-12-03 | 2020-06-18 | トヨタ紡織株式会社 | 二剤型ホットメルト接着剤、固化物及び架橋時間の制御方法 |

| JP7331668B2 (ja) | 2018-12-03 | 2023-08-23 | トヨタ紡織株式会社 | 接着方法 |

| US11648891B2 (en) * | 2019-11-04 | 2023-05-16 | Nyx, Inc. | Low-pressure molded vehicle headliner with bridge |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5861039A (ja) * | 1981-10-05 | 1983-04-11 | Nissan Motor Co Ltd | 車輛用ガ−ニツシユの合わせ部構造 |

| JP2003320915A (ja) | 2002-05-07 | 2003-11-11 | Fuji Heavy Ind Ltd | 車室内衝撃吸収リブ構造 |

| JP2006001478A (ja) | 2004-06-18 | 2006-01-05 | Inoac Corp | 衝撃吸収部材 |

| JP2006206030A (ja) * | 2004-12-28 | 2006-08-10 | Toyota Auto Body Co Ltd | 車両用天井材 |

| JP2006306257A (ja) * | 2005-04-28 | 2006-11-09 | Suzuki Motor Corp | 車両ルーフ部における緩衝部材取付構造 |

| JP2007145234A (ja) | 2005-11-29 | 2007-06-14 | Kasai Kogyo Co Ltd | 車両用衝撃吸収体 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19632055C1 (de) * | 1996-08-09 | 1997-11-13 | Benecke Kaliko Ag | Verfahren zur Herstellung einer Dachversteifung für Fahrzeuge |

| US6267436B1 (en) * | 1998-07-22 | 2001-07-31 | Toyota Jidosha Kabushiki Kaisha | Impact energy absorbing structure in upper vehicle body portion, and impact energy absorbing component |

| US6250711B1 (en) * | 1998-07-31 | 2001-06-26 | Toyota Jidosha Kabushiki Kaisha | Energy absorber securing structure and method |

| US6264238B1 (en) * | 1999-09-28 | 2001-07-24 | Daimlerchrysler Corporation | Reactive surface rib cartridge countermeasure for vehicle interior hard trim applications |

| US6475937B1 (en) * | 2000-03-17 | 2002-11-05 | Patent Holding Company | Lightweight, thermoplastic, vehicle headliner having at least one integrally-formed, energy-absorbing, head-impact mechanism and injection molding method for making same |

| US6588557B2 (en) * | 2001-04-04 | 2003-07-08 | Daimlerchrysler Corporation | Blow molded (HIC) formation with energy buffers |

| ATE290481T1 (de) * | 2001-07-24 | 2005-03-15 | Antolin Grupo Ing Sa | Verfahren zur herstellung von dachbeplankung mit einem integrierten beleuchtungssytem und so erhaltene beplankung |

| US6779835B2 (en) * | 2001-12-06 | 2004-08-24 | Lear Corporation | Energy absorbing structure for automobile interior |

| US6679544B1 (en) * | 2002-04-05 | 2004-01-20 | Lear Corporation | Molded energy absorber |

| US6652021B1 (en) * | 2002-11-06 | 2003-11-25 | Lear Corporation | Integrated headliner assembly |

| US20050168015A1 (en) * | 2004-01-29 | 2005-08-04 | Intier Automotive Inc. | Headliner with integrally-molded energy distribution zone |

| US7841647B2 (en) * | 2006-11-15 | 2010-11-30 | Sika Technology Ag | Baffle assembly |

-

2008

- 2008-07-21 JP JP2008187990A patent/JP5137248B2/ja active Active

-

2009

- 2009-03-18 EP EP09800250A patent/EP2305517B1/en not_active Not-in-force

- 2009-03-18 CN CN200980128509.1A patent/CN102099224B/zh not_active Expired - Fee Related

- 2009-03-18 CA CA2731540A patent/CA2731540C/en not_active Expired - Fee Related

- 2009-03-18 US US13/055,365 patent/US8091953B2/en not_active Expired - Fee Related

- 2009-03-18 WO PCT/JP2009/055237 patent/WO2010010734A1/ja not_active Ceased

- 2009-03-18 AU AU2009275077A patent/AU2009275077B2/en not_active Ceased

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5861039A (ja) * | 1981-10-05 | 1983-04-11 | Nissan Motor Co Ltd | 車輛用ガ−ニツシユの合わせ部構造 |

| JP2003320915A (ja) | 2002-05-07 | 2003-11-11 | Fuji Heavy Ind Ltd | 車室内衝撃吸収リブ構造 |

| JP2006001478A (ja) | 2004-06-18 | 2006-01-05 | Inoac Corp | 衝撃吸収部材 |

| JP2006206030A (ja) * | 2004-12-28 | 2006-08-10 | Toyota Auto Body Co Ltd | 車両用天井材 |

| JP2006306257A (ja) * | 2005-04-28 | 2006-11-09 | Suzuki Motor Corp | 車両ルーフ部における緩衝部材取付構造 |

| JP2007145234A (ja) | 2005-11-29 | 2007-06-14 | Kasai Kogyo Co Ltd | 車両用衝撃吸収体 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP2305517A4 |

Also Published As

| Publication number | Publication date |

|---|---|

| AU2009275077A1 (en) | 2010-01-28 |

| US20110187158A1 (en) | 2011-08-04 |

| CN102099224A (zh) | 2011-06-15 |

| EP2305517B1 (en) | 2012-12-05 |

| CA2731540C (en) | 2013-05-28 |

| US8091953B2 (en) | 2012-01-10 |

| CN102099224B (zh) | 2012-12-26 |

| JP2010023694A (ja) | 2010-02-04 |

| EP2305517A1 (en) | 2011-04-06 |

| JP5137248B2 (ja) | 2013-02-06 |

| CA2731540A1 (en) | 2010-01-28 |

| AU2009275077B2 (en) | 2011-11-03 |

| EP2305517A4 (en) | 2012-01-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2010010734A1 (ja) | 車両天井構造 | |

| CN104010885B (zh) | 内置纤维复合增强材料的保险杠后梁及保险杠 | |

| KR101787933B1 (ko) | 차량 부재들의 접착 구조 및 백 도어의 접착 구조 | |

| JP2010168036A (ja) | 遮蔽板およびその遮蔽板を備える車両構造 | |

| JP2006273057A (ja) | ピラー構造 | |

| US10414307B2 (en) | Back frame of vehicle seat | |

| US20190217899A1 (en) | Vehicle pillar structure and vehicle side portion structure | |

| WO2013191093A1 (ja) | Frp製部材 | |

| JP2009061864A (ja) | 車体フレーム構造 | |

| JP5228841B2 (ja) | 車体上部構造 | |

| KR102414188B1 (ko) | 충격저감형 결합구조가 부설된 일체형 카울크로스맴버 | |

| JP2018114794A (ja) | 自動車用燃料タンクの支柱部品 | |

| JP6145489B2 (ja) | 遮蔽板 | |

| KR101247311B1 (ko) | 3열 시트 백 프레임의 백 보드 조립체 | |

| KR20200093118A (ko) | 경량화된 일체형 윈도채널조립체 | |

| JP2014004728A (ja) | Frp製パネル部材 | |

| JP3942597B2 (ja) | 成形品組立体及びその製造方法 | |

| KR102009793B1 (ko) | 시트백 프레임 및 그 제조방법 | |

| JP2021059299A (ja) | 車両用接合構造体 | |

| KR102772268B1 (ko) | 차량의 복합재 빔 | |

| JP5199817B2 (ja) | エアバッグドア | |

| JP3803117B2 (ja) | 車両用カウルルーバ | |

| JP2008114633A (ja) | ルーフピラー一体成形部材及びルーフピラーガーニッシュ一体成形部材 | |

| JP2015140092A (ja) | 分割補強材の接続構造 | |

| JP2025006989A (ja) | 乗物用天井内装材 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 200980128509.1 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 09800250 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2731540 Country of ref document: CA |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2009800250 Country of ref document: EP |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2009275077 Country of ref document: AU |

|

| ENP | Entry into the national phase |

Ref document number: 2009275077 Country of ref document: AU Date of ref document: 20090318 Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 13055365 Country of ref document: US |