RU2485149C2 - Стойкие к гидролизу смеси полиамид - эластомер, формованные изделия, полученные из них, и их применение - Google Patents

Стойкие к гидролизу смеси полиамид - эластомер, формованные изделия, полученные из них, и их применение Download PDFInfo

- Publication number

- RU2485149C2 RU2485149C2 RU2010137320/05A RU2010137320A RU2485149C2 RU 2485149 C2 RU2485149 C2 RU 2485149C2 RU 2010137320/05 A RU2010137320/05 A RU 2010137320/05A RU 2010137320 A RU2010137320 A RU 2010137320A RU 2485149 C2 RU2485149 C2 RU 2485149C2

- Authority

- RU

- Russia

- Prior art keywords

- polyamide

- mixture

- meth

- elastomer

- acrylate

- Prior art date

Links

- 239000000203 mixture Substances 0.000 title claims abstract description 105

- 229920001971 elastomer Polymers 0.000 title claims abstract description 79

- 239000000806 elastomer Substances 0.000 title claims abstract description 74

- 230000007062 hydrolysis Effects 0.000 title abstract description 10

- 238000006460 hydrolysis reaction Methods 0.000 title abstract description 10

- 229920002647 polyamide Polymers 0.000 claims abstract description 75

- 239000004952 Polyamide Substances 0.000 claims abstract description 72

- 239000000178 monomer Substances 0.000 claims abstract description 47

- RLSSMJSEOOYNOY-UHFFFAOYSA-N m-cresol Chemical compound CC1=CC=CC(O)=C1 RLSSMJSEOOYNOY-UHFFFAOYSA-N 0.000 claims abstract description 22

- 239000004816 latex Substances 0.000 claims abstract description 21

- 229920000126 latex Polymers 0.000 claims abstract description 21

- 150000001993 dienes Chemical class 0.000 claims abstract description 17

- 239000000654 additive Substances 0.000 claims abstract description 16

- 150000002825 nitriles Chemical class 0.000 claims abstract description 12

- 238000001694 spray drying Methods 0.000 claims abstract description 10

- 229920006114 semi-crystalline semi-aromatic polyamide Polymers 0.000 claims abstract description 7

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 claims description 54

- -1 PA69 Polymers 0.000 claims description 48

- 238000006116 polymerization reaction Methods 0.000 claims description 38

- KAKZBPTYRLMSJV-UHFFFAOYSA-N Butadiene Chemical compound C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 claims description 25

- 238000007720 emulsion polymerization reaction Methods 0.000 claims description 23

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 claims description 20

- 239000000047 product Substances 0.000 claims description 18

- NLHHRLWOUZZQLW-UHFFFAOYSA-N Acrylonitrile Chemical compound C=CC#N NLHHRLWOUZZQLW-UHFFFAOYSA-N 0.000 claims description 16

- 150000003839 salts Chemical class 0.000 claims description 15

- 125000004432 carbon atom Chemical group C* 0.000 claims description 14

- 238000012360 testing method Methods 0.000 claims description 14

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 14

- 150000001875 compounds Chemical class 0.000 claims description 12

- 238000006243 chemical reaction Methods 0.000 claims description 11

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 claims description 10

- 238000004132 cross linking Methods 0.000 claims description 10

- 235000014113 dietary fatty acids Nutrition 0.000 claims description 10

- 150000002148 esters Chemical class 0.000 claims description 10

- 239000000194 fatty acid Substances 0.000 claims description 10

- 229930195729 fatty acid Natural products 0.000 claims description 10

- 125000001931 aliphatic group Chemical group 0.000 claims description 9

- 150000004665 fatty acids Chemical class 0.000 claims description 9

- 150000003254 radicals Chemical class 0.000 claims description 9

- MYRTYDVEIRVNKP-UHFFFAOYSA-N 1,2-Divinylbenzene Chemical compound C=CC1=CC=CC=C1C=C MYRTYDVEIRVNKP-UHFFFAOYSA-N 0.000 claims description 8

- RRHGJUQNOFWUDK-UHFFFAOYSA-N Isoprene Chemical compound CC(=C)C=C RRHGJUQNOFWUDK-UHFFFAOYSA-N 0.000 claims description 8

- OFOBLEOULBTSOW-UHFFFAOYSA-N Propanedioic acid Natural products OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 claims description 8

- 239000002253 acid Substances 0.000 claims description 8

- 125000000217 alkyl group Chemical group 0.000 claims description 8

- 230000009477 glass transition Effects 0.000 claims description 8

- 239000003999 initiator Substances 0.000 claims description 8

- 238000003860 storage Methods 0.000 claims description 8

- CERQOIWHTDAKMF-UHFFFAOYSA-N Methacrylic acid Chemical compound CC(=C)C(O)=O CERQOIWHTDAKMF-UHFFFAOYSA-N 0.000 claims description 7

- 150000001735 carboxylic acids Chemical class 0.000 claims description 7

- 150000001991 dicarboxylic acids Chemical class 0.000 claims description 7

- WGCNASOHLSPBMP-UHFFFAOYSA-N hydroxyacetaldehyde Natural products OCC=O WGCNASOHLSPBMP-UHFFFAOYSA-N 0.000 claims description 7

- 229920001223 polyethylene glycol Polymers 0.000 claims description 7

- 229920000642 polymer Polymers 0.000 claims description 7

- 230000008961 swelling Effects 0.000 claims description 7

- VZCYOOQTPOCHFL-UHFFFAOYSA-N trans-butenedioic acid Natural products OC(=O)C=CC(O)=O VZCYOOQTPOCHFL-UHFFFAOYSA-N 0.000 claims description 7

- OZAIFHULBGXAKX-UHFFFAOYSA-N 2-(2-cyanopropan-2-yldiazenyl)-2-methylpropanenitrile Chemical compound N#CC(C)(C)N=NC(C)(C)C#N OZAIFHULBGXAKX-UHFFFAOYSA-N 0.000 claims description 6

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 claims description 6

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 claims description 6

- VZCYOOQTPOCHFL-OWOJBTEDSA-N Fumaric acid Chemical compound OC(=O)\C=C\C(O)=O VZCYOOQTPOCHFL-OWOJBTEDSA-N 0.000 claims description 6

- PEDCQBHIVMGVHV-UHFFFAOYSA-N Glycerine Chemical compound OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 claims description 6

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 claims description 6

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 claims description 6

- 150000001252 acrylic acid derivatives Chemical class 0.000 claims description 6

- 229920006147 copolyamide elastomer Polymers 0.000 claims description 6

- 229920006017 homo-polyamide Polymers 0.000 claims description 6

- 150000003951 lactams Chemical class 0.000 claims description 6

- 229920000728 polyester Polymers 0.000 claims description 6

- 229910000019 calcium carbonate Inorganic materials 0.000 claims description 5

- 229920000098 polyolefin Polymers 0.000 claims description 5

- 239000005060 rubber Substances 0.000 claims description 5

- 238000009864 tensile test Methods 0.000 claims description 5

- JAHNSTQSQJOJLO-UHFFFAOYSA-N 2-(3-fluorophenyl)-1h-imidazole Chemical compound FC1=CC=CC(C=2NC=CN=2)=C1 JAHNSTQSQJOJLO-UHFFFAOYSA-N 0.000 claims description 4

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 claims description 4

- KUDUQBURMYMBIJ-UHFFFAOYSA-N 2-prop-2-enoyloxyethyl prop-2-enoate Chemical compound C=CC(=O)OCCOC(=O)C=C KUDUQBURMYMBIJ-UHFFFAOYSA-N 0.000 claims description 4

- HGINCPLSRVDWNT-UHFFFAOYSA-N Acrolein Chemical compound C=CC=O HGINCPLSRVDWNT-UHFFFAOYSA-N 0.000 claims description 4

- KXDHJXZQYSOELW-UHFFFAOYSA-N Carbamic acid Chemical class NC(O)=O KXDHJXZQYSOELW-UHFFFAOYSA-N 0.000 claims description 4

- 239000002202 Polyethylene glycol Substances 0.000 claims description 4

- 229920006121 Polyxylylene adipamide Polymers 0.000 claims description 4

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 claims description 4

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical compound [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 claims description 4

- 150000003926 acrylamides Chemical class 0.000 claims description 4

- 150000001253 acrylic acids Chemical class 0.000 claims description 4

- 229910052784 alkaline earth metal Inorganic materials 0.000 claims description 4

- TZCXTZWJZNENPQ-UHFFFAOYSA-L barium sulfate Chemical compound [Ba+2].[O-]S([O-])(=O)=O TZCXTZWJZNENPQ-UHFFFAOYSA-L 0.000 claims description 4

- IISBACLAFKSPIT-UHFFFAOYSA-N bisphenol A Chemical compound C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 IISBACLAFKSPIT-UHFFFAOYSA-N 0.000 claims description 4

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 claims description 4

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 claims description 4

- HQKMJHAJHXVSDF-UHFFFAOYSA-L magnesium stearate Chemical compound [Mg+2].CCCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCCC([O-])=O HQKMJHAJHXVSDF-UHFFFAOYSA-L 0.000 claims description 4

- VZCYOOQTPOCHFL-UPHRSURJSA-N maleic acid Chemical compound OC(=O)\C=C/C(O)=O VZCYOOQTPOCHFL-UPHRSURJSA-N 0.000 claims description 4

- 239000011976 maleic acid Substances 0.000 claims description 4

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 claims description 4

- LVHBHZANLOWSRM-UHFFFAOYSA-N methylenebutanedioic acid Natural products OC(=O)CC(=C)C(O)=O LVHBHZANLOWSRM-UHFFFAOYSA-N 0.000 claims description 4

- 125000004108 n-butyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 claims description 4

- 125000003396 thiol group Chemical group [H]S* 0.000 claims description 4

- WRXCBRHBHGNNQA-UHFFFAOYSA-N (2,4-dichlorobenzoyl) 2,4-dichlorobenzenecarboperoxoate Chemical compound ClC1=CC(Cl)=CC=C1C(=O)OOC(=O)C1=CC=C(Cl)C=C1Cl WRXCBRHBHGNNQA-UHFFFAOYSA-N 0.000 claims description 3

- XMNIXWIUMCBBBL-UHFFFAOYSA-N 2-(2-phenylpropan-2-ylperoxy)propan-2-ylbenzene Chemical compound C=1C=CC=CC=1C(C)(C)OOC(C)(C)C1=CC=CC=C1 XMNIXWIUMCBBBL-UHFFFAOYSA-N 0.000 claims description 3

- OMPJBNCRMGITSC-UHFFFAOYSA-N Benzoylperoxide Chemical compound C=1C=CC=CC=1C(=O)OOC(=O)C1=CC=CC=C1 OMPJBNCRMGITSC-UHFFFAOYSA-N 0.000 claims description 3

- GAWIXWVDTYZWAW-UHFFFAOYSA-N C[CH]O Chemical group C[CH]O GAWIXWVDTYZWAW-UHFFFAOYSA-N 0.000 claims description 3

- 229920000572 Nylon 6/12 Polymers 0.000 claims description 3

- CDBYLPFSWZWCQE-UHFFFAOYSA-L Sodium Carbonate Chemical compound [Na+].[Na+].[O-]C([O-])=O CDBYLPFSWZWCQE-UHFFFAOYSA-L 0.000 claims description 3

- ZJCCRDAZUWHFQH-UHFFFAOYSA-N Trimethylolpropane Chemical compound CCC(CO)(CO)CO ZJCCRDAZUWHFQH-UHFFFAOYSA-N 0.000 claims description 3

- 150000004984 aromatic diamines Chemical class 0.000 claims description 3

- 235000019400 benzoyl peroxide Nutrition 0.000 claims description 3

- 239000007795 chemical reaction product Substances 0.000 claims description 3

- 239000002826 coolant Substances 0.000 claims description 3

- LSXWFXONGKSEMY-UHFFFAOYSA-N di-tert-butyl peroxide Chemical compound CC(C)(C)OOC(C)(C)C LSXWFXONGKSEMY-UHFFFAOYSA-N 0.000 claims description 3

- 239000000446 fuel Substances 0.000 claims description 3

- 239000001530 fumaric acid Substances 0.000 claims description 3

- 229910052738 indium Inorganic materials 0.000 claims description 3

- 229920006139 poly(hexamethylene adipamide-co-hexamethylene terephthalamide) Polymers 0.000 claims description 3

- 229920006131 poly(hexamethylene isophthalamide-co-terephthalamide) Polymers 0.000 claims description 3

- 229920006111 poly(hexamethylene terephthalamide) Polymers 0.000 claims description 3

- 229920000570 polyether Polymers 0.000 claims description 3

- 229920001296 polysiloxane Polymers 0.000 claims description 3

- GJBRNHKUVLOCEB-UHFFFAOYSA-N tert-butyl benzenecarboperoxoate Chemical compound CC(C)(C)OOC(=O)C1=CC=CC=C1 GJBRNHKUVLOCEB-UHFFFAOYSA-N 0.000 claims description 3

- BQCIDUSAKPWEOX-UHFFFAOYSA-N 1,1-Difluoroethene Chemical compound FC(F)=C BQCIDUSAKPWEOX-UHFFFAOYSA-N 0.000 claims description 2

- HIACAHMKXQESOV-UHFFFAOYSA-N 1,2-bis(prop-1-en-2-yl)benzene Chemical compound CC(=C)C1=CC=CC=C1C(C)=C HIACAHMKXQESOV-UHFFFAOYSA-N 0.000 claims description 2

- IPJGAEWUPXWFPL-UHFFFAOYSA-N 1-[3-(2,5-dioxopyrrol-1-yl)phenyl]pyrrole-2,5-dione Chemical compound O=C1C=CC(=O)N1C1=CC=CC(N2C(C=CC2=O)=O)=C1 IPJGAEWUPXWFPL-UHFFFAOYSA-N 0.000 claims description 2

- LIFLRQVHKGGNSG-UHFFFAOYSA-N 2,3-dichlorobuta-1,3-diene Chemical compound ClC(=C)C(Cl)=C LIFLRQVHKGGNSG-UHFFFAOYSA-N 0.000 claims description 2

- BJELTSYBAHKXRW-UHFFFAOYSA-N 2,4,6-triallyloxy-1,3,5-triazine Chemical compound C=CCOC1=NC(OCC=C)=NC(OCC=C)=N1 BJELTSYBAHKXRW-UHFFFAOYSA-N 0.000 claims description 2

- JGBAASVQPMTVHO-UHFFFAOYSA-N 2,5-dihydroperoxy-2,5-dimethylhexane Chemical compound OOC(C)(C)CCC(C)(C)OO JGBAASVQPMTVHO-UHFFFAOYSA-N 0.000 claims description 2

- AXWJKQDGIVWVEW-UHFFFAOYSA-N 2-(dimethylamino)butanedioic acid Chemical compound CN(C)C(C(O)=O)CC(O)=O AXWJKQDGIVWVEW-UHFFFAOYSA-N 0.000 claims description 2

- 125000000022 2-aminoethyl group Chemical group [H]C([*])([H])C([H])([H])N([H])[H] 0.000 claims description 2

- KRDXTHSSNCTAGY-UHFFFAOYSA-N 2-cyclohexylpyrrolidine Chemical compound C1CCNC1C1CCCCC1 KRDXTHSSNCTAGY-UHFFFAOYSA-N 0.000 claims description 2

- DBCAQXHNJOFNGC-UHFFFAOYSA-N 4-bromo-1,1,1-trifluorobutane Chemical compound FC(F)(F)CCCBr DBCAQXHNJOFNGC-UHFFFAOYSA-N 0.000 claims description 2

- KFDVPJUYSDEJTH-UHFFFAOYSA-N 4-ethenylpyridine Chemical compound C=CC1=CC=NC=C1 KFDVPJUYSDEJTH-UHFFFAOYSA-N 0.000 claims description 2

- HRPVXLWXLXDGHG-UHFFFAOYSA-N Acrylamide Chemical compound NC(=O)C=C HRPVXLWXLXDGHG-UHFFFAOYSA-N 0.000 claims description 2

- 238000004438 BET method Methods 0.000 claims description 2

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 claims description 2

- FBPFZTCFMRRESA-FSIIMWSLSA-N D-Glucitol Natural products OC[C@H](O)[C@H](O)[C@@H](O)[C@H](O)CO FBPFZTCFMRRESA-FSIIMWSLSA-N 0.000 claims description 2

- FBPFZTCFMRRESA-JGWLITMVSA-N D-glucitol Chemical compound OC[C@H](O)[C@@H](O)[C@H](O)[C@H](O)CO FBPFZTCFMRRESA-JGWLITMVSA-N 0.000 claims description 2

- 239000004641 Diallyl-phthalate Substances 0.000 claims description 2

- PEEHTFAAVSWFBL-UHFFFAOYSA-N Maleimide Chemical compound O=C1NC(=O)C=C1 PEEHTFAAVSWFBL-UHFFFAOYSA-N 0.000 claims description 2

- WHNWPMSKXPGLAX-UHFFFAOYSA-N N-Vinyl-2-pyrrolidone Chemical compound C=CN1CCCC1=O WHNWPMSKXPGLAX-UHFFFAOYSA-N 0.000 claims description 2

- 229920006152 PA1010 Polymers 0.000 claims description 2

- 229920003171 Poly (ethylene oxide) Polymers 0.000 claims description 2

- 239000004372 Polyvinyl alcohol Substances 0.000 claims description 2

- 229920002472 Starch Polymers 0.000 claims description 2

- DAKWPKUUDNSNPN-UHFFFAOYSA-N Trimethylolpropane triacrylate Chemical compound C=CC(=O)OCC(CC)(COC(=O)C=C)COC(=O)C=C DAKWPKUUDNSNPN-UHFFFAOYSA-N 0.000 claims description 2

- QYKIQEUNHZKYBP-UHFFFAOYSA-N Vinyl ether Chemical compound C=COC=C QYKIQEUNHZKYBP-UHFFFAOYSA-N 0.000 claims description 2

- 239000003513 alkali Substances 0.000 claims description 2

- 125000003277 amino group Chemical group 0.000 claims description 2

- QUDWYFHPNIMBFC-UHFFFAOYSA-N bis(prop-2-enyl) benzene-1,2-dicarboxylate Chemical compound C=CCOC(=O)C1=CC=CC=C1C(=O)OCC=C QUDWYFHPNIMBFC-UHFFFAOYSA-N 0.000 claims description 2

- WERYXYBDKMZEQL-UHFFFAOYSA-N butane-1,4-diol Chemical compound OCCCCO WERYXYBDKMZEQL-UHFFFAOYSA-N 0.000 claims description 2

- 229910052791 calcium Inorganic materials 0.000 claims description 2

- 239000001506 calcium phosphate Substances 0.000 claims description 2

- 229910000389 calcium phosphate Inorganic materials 0.000 claims description 2

- 235000011010 calcium phosphates Nutrition 0.000 claims description 2

- CJZGTCYPCWQAJB-UHFFFAOYSA-L calcium stearate Chemical compound [Ca+2].CCCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCCC([O-])=O CJZGTCYPCWQAJB-UHFFFAOYSA-L 0.000 claims description 2

- 235000013539 calcium stearate Nutrition 0.000 claims description 2

- 239000008116 calcium stearate Substances 0.000 claims description 2

- 229910052799 carbon Inorganic materials 0.000 claims description 2

- 239000001913 cellulose Substances 0.000 claims description 2

- 229920002678 cellulose Polymers 0.000 claims description 2

- YACLQRRMGMJLJV-UHFFFAOYSA-N chloroprene Chemical compound ClC(=C)C=C YACLQRRMGMJLJV-UHFFFAOYSA-N 0.000 claims description 2

- AFOSIXZFDONLBT-UHFFFAOYSA-N divinyl sulfone Chemical compound C=CS(=O)(=O)C=C AFOSIXZFDONLBT-UHFFFAOYSA-N 0.000 claims description 2

- 150000002170 ethers Chemical class 0.000 claims description 2

- 229940052303 ethers for general anesthesia Drugs 0.000 claims description 2

- STVZJERGLQHEKB-UHFFFAOYSA-N ethylene glycol dimethacrylate Substances CC(=C)C(=O)OCCOC(=O)C(C)=C STVZJERGLQHEKB-UHFFFAOYSA-N 0.000 claims description 2

- HCDGVLDPFQMKDK-UHFFFAOYSA-N hexafluoropropylene Chemical compound FC(F)=C(F)C(F)(F)F HCDGVLDPFQMKDK-UHFFFAOYSA-N 0.000 claims description 2

- ACCCMOQWYVYDOT-UHFFFAOYSA-N hexane-1,1-diol Chemical compound CCCCCC(O)O ACCCMOQWYVYDOT-UHFFFAOYSA-N 0.000 claims description 2

- 229920001477 hydrophilic polymer Polymers 0.000 claims description 2

- 125000002887 hydroxy group Chemical group [H]O* 0.000 claims description 2

- 239000007788 liquid Substances 0.000 claims description 2

- ZLNQQNXFFQJAID-UHFFFAOYSA-L magnesium carbonate Chemical compound [Mg+2].[O-]C([O-])=O ZLNQQNXFFQJAID-UHFFFAOYSA-L 0.000 claims description 2

- 239000001095 magnesium carbonate Substances 0.000 claims description 2

- 229910000021 magnesium carbonate Inorganic materials 0.000 claims description 2

- 235000019359 magnesium stearate Nutrition 0.000 claims description 2

- 150000002734 metacrylic acid derivatives Chemical class 0.000 claims description 2

- 239000010445 mica Substances 0.000 claims description 2

- 229910052618 mica group Inorganic materials 0.000 claims description 2

- 125000004123 n-propyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])* 0.000 claims description 2

- SLCVBVWXLSEKPL-UHFFFAOYSA-N neopentyl glycol Chemical compound OCC(C)(C)CO SLCVBVWXLSEKPL-UHFFFAOYSA-N 0.000 claims description 2

- 229920006119 nylon 10T Polymers 0.000 claims description 2

- 150000001451 organic peroxides Chemical class 0.000 claims description 2

- 125000006353 oxyethylene group Chemical group 0.000 claims description 2

- WXZMFSXDPGVJKK-UHFFFAOYSA-N pentaerythritol Chemical compound OCC(CO)(CO)CO WXZMFSXDPGVJKK-UHFFFAOYSA-N 0.000 claims description 2

- 229920000233 poly(alkylene oxides) Polymers 0.000 claims description 2

- 229920006115 poly(dodecamethylene terephthalamide) Polymers 0.000 claims description 2

- 229920006128 poly(nonamethylene terephthalamide) Polymers 0.000 claims description 2

- 229920006396 polyamide 1012 Polymers 0.000 claims description 2

- 229920005862 polyol Polymers 0.000 claims description 2

- 150000003077 polyols Chemical class 0.000 claims description 2

- 239000005077 polysulfide Substances 0.000 claims description 2

- 229920001021 polysulfide Polymers 0.000 claims description 2

- 150000008117 polysulfides Polymers 0.000 claims description 2

- 229920002451 polyvinyl alcohol Polymers 0.000 claims description 2

- 229920000036 polyvinylpyrrolidone Polymers 0.000 claims description 2

- 239000001267 polyvinylpyrrolidone Substances 0.000 claims description 2

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 claims description 2

- VPJDULFXCAQHRC-UHFFFAOYSA-N prop-2-enylurea Chemical compound NC(=O)NCC=C VPJDULFXCAQHRC-UHFFFAOYSA-N 0.000 claims description 2

- 150000004760 silicates Chemical class 0.000 claims description 2

- 125000005624 silicic acid group Chemical class 0.000 claims description 2

- 235000012239 silicon dioxide Nutrition 0.000 claims description 2

- HYHCSLBZRBJJCH-UHFFFAOYSA-N sodium polysulfide Chemical compound [Na+].S HYHCSLBZRBJJCH-UHFFFAOYSA-N 0.000 claims description 2

- 239000000600 sorbitol Substances 0.000 claims description 2

- 239000008107 starch Substances 0.000 claims description 2

- 235000019698 starch Nutrition 0.000 claims description 2

- 150000005846 sugar alcohols Polymers 0.000 claims description 2

- 239000000454 talc Substances 0.000 claims description 2

- 229910052623 talc Inorganic materials 0.000 claims description 2

- 125000006318 tert-butyl amino group Chemical group [H]N(*)C(C([H])([H])[H])(C([H])([H])[H])C([H])([H])[H] 0.000 claims description 2

- BFKJFAAPBSQJPD-UHFFFAOYSA-N tetrafluoroethene Chemical group FC(F)=C(F)F BFKJFAAPBSQJPD-UHFFFAOYSA-N 0.000 claims description 2

- 239000004408 titanium dioxide Substances 0.000 claims description 2

- QORWJWZARLRLPR-UHFFFAOYSA-H tricalcium bis(phosphate) Chemical compound [Ca+2].[Ca+2].[Ca+2].[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=O QORWJWZARLRLPR-UHFFFAOYSA-H 0.000 claims description 2

- 229940096522 trimethylolpropane triacrylate Drugs 0.000 claims description 2

- GRPURDFRFHUDSP-UHFFFAOYSA-N tris(prop-2-enyl) benzene-1,2,4-tricarboxylate Chemical compound C=CCOC(=O)C1=CC=C(C(=O)OCC=C)C(C(=O)OCC=C)=C1 GRPURDFRFHUDSP-UHFFFAOYSA-N 0.000 claims description 2

- 229920006305 unsaturated polyester Polymers 0.000 claims description 2

- 238000009423 ventilation Methods 0.000 claims description 2

- 229960000834 vinyl ether Drugs 0.000 claims description 2

- 239000011787 zinc oxide Substances 0.000 claims description 2

- 125000002924 primary amino group Chemical group [H]N([H])* 0.000 claims 2

- DHBXNPKRAUYBTH-UHFFFAOYSA-N 1,1-ethanedithiol Chemical compound CC(S)S DHBXNPKRAUYBTH-UHFFFAOYSA-N 0.000 claims 1

- 239000005062 Polybutadiene Substances 0.000 claims 1

- 239000003568 Sodium, potassium and calcium salts of fatty acids Substances 0.000 claims 1

- BHKBQLFNRMDEAV-UHFFFAOYSA-I [Al+3].[Zn+2].CCCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCCC([O-])=O Chemical compound [Al+3].[Zn+2].CCCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCCC([O-])=O BHKBQLFNRMDEAV-UHFFFAOYSA-I 0.000 claims 1

- HTKFORQRBXIQHD-UHFFFAOYSA-N allylthiourea Chemical compound NC(=S)NCC=C HTKFORQRBXIQHD-UHFFFAOYSA-N 0.000 claims 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 claims 1

- 235000013969 calcium salts of fatty acid Nutrition 0.000 claims 1

- 239000000470 constituent Substances 0.000 claims 1

- 239000000539 dimer Substances 0.000 claims 1

- 239000012948 isocyanate Substances 0.000 claims 1

- 150000002513 isocyanates Chemical class 0.000 claims 1

- 235000010933 magnesium salts of fatty acid Nutrition 0.000 claims 1

- 239000001778 magnesium salts of fatty acids Substances 0.000 claims 1

- 229920002857 polybutadiene Polymers 0.000 claims 1

- 125000000467 secondary amino group Chemical class [H]N([*:1])[*:2] 0.000 claims 1

- CDMIYIVDILNBIJ-UHFFFAOYSA-N triazinane-4,5,6-trithione Chemical compound SC1=NN=NC(S)=C1S CDMIYIVDILNBIJ-UHFFFAOYSA-N 0.000 claims 1

- 239000000463 material Substances 0.000 abstract description 5

- 230000000694 effects Effects 0.000 abstract description 2

- 239000000126 substance Substances 0.000 abstract description 2

- 239000000839 emulsion Substances 0.000 abstract 2

- 229920000459 Nitrile rubber Polymers 0.000 description 21

- 239000011734 sodium Substances 0.000 description 20

- 239000003995 emulsifying agent Substances 0.000 description 18

- 235000002639 sodium chloride Nutrition 0.000 description 16

- 239000003963 antioxidant agent Substances 0.000 description 11

- 235000006708 antioxidants Nutrition 0.000 description 11

- 238000000034 method Methods 0.000 description 9

- 239000003921 oil Substances 0.000 description 9

- 235000019198 oils Nutrition 0.000 description 9

- 238000012545 processing Methods 0.000 description 9

- 239000000243 solution Substances 0.000 description 9

- 239000002245 particle Substances 0.000 description 8

- 229910052708 sodium Inorganic materials 0.000 description 7

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 6

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 6

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 6

- 125000000129 anionic group Chemical group 0.000 description 6

- 238000002360 preparation method Methods 0.000 description 6

- RWSOTUBLDIXVET-UHFFFAOYSA-N Dihydrogen sulfide Chemical class S RWSOTUBLDIXVET-UHFFFAOYSA-N 0.000 description 5

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 description 5

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 5

- KWYUFKZDYYNOTN-UHFFFAOYSA-M potassium hydroxide Inorganic materials [OH-].[K+] KWYUFKZDYYNOTN-UHFFFAOYSA-M 0.000 description 5

- 239000007921 spray Substances 0.000 description 5

- 150000007934 α,β-unsaturated carboxylic acids Chemical class 0.000 description 5

- RSWGJHLUYNHPMX-UHFFFAOYSA-N Abietic-Saeure Natural products C12CCC(C(C)C)=CC2=CCC2C1(C)CCCC2(C)C(O)=O RSWGJHLUYNHPMX-UHFFFAOYSA-N 0.000 description 4

- MHAJPDPJQMAIIY-UHFFFAOYSA-N Hydrogen peroxide Chemical compound OO MHAJPDPJQMAIIY-UHFFFAOYSA-N 0.000 description 4

- VQTUBCCKSQIDNK-UHFFFAOYSA-N Isobutene Chemical compound CC(C)=C VQTUBCCKSQIDNK-UHFFFAOYSA-N 0.000 description 4

- LSDPWZHWYPCBBB-UHFFFAOYSA-N Methanethiol Chemical compound SC LSDPWZHWYPCBBB-UHFFFAOYSA-N 0.000 description 4

- WCUXLLCKKVVCTQ-UHFFFAOYSA-M Potassium chloride Chemical compound [Cl-].[K+] WCUXLLCKKVVCTQ-UHFFFAOYSA-M 0.000 description 4

- QQONPFPTGQHPMA-UHFFFAOYSA-N Propene Chemical compound CC=C QQONPFPTGQHPMA-UHFFFAOYSA-N 0.000 description 4

- UIIMBOGNXHQVGW-UHFFFAOYSA-M Sodium bicarbonate Chemical compound [Na+].OC([O-])=O UIIMBOGNXHQVGW-UHFFFAOYSA-M 0.000 description 4

- 150000007513 acids Chemical class 0.000 description 4

- 150000001412 amines Chemical class 0.000 description 4

- 150000003863 ammonium salts Chemical class 0.000 description 4

- 150000001491 aromatic compounds Chemical class 0.000 description 4

- 239000003638 chemical reducing agent Substances 0.000 description 4

- 239000003795 chemical substances by application Substances 0.000 description 4

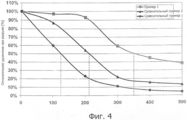

- 230000000052 comparative effect Effects 0.000 description 4

- 150000004985 diamines Chemical class 0.000 description 4

- 238000001035 drying Methods 0.000 description 4

- 238000000227 grinding Methods 0.000 description 4

- QQVIHTHCMHWDBS-UHFFFAOYSA-N isophthalic acid Chemical compound OC(=O)C1=CC=CC(C(O)=O)=C1 QQVIHTHCMHWDBS-UHFFFAOYSA-N 0.000 description 4

- XMGQYMWWDOXHJM-UHFFFAOYSA-N limonene Chemical compound CC(=C)C1CCC(C)=CC1 XMGQYMWWDOXHJM-UHFFFAOYSA-N 0.000 description 4

- 239000012778 molding material Substances 0.000 description 4

- 150000002763 monocarboxylic acids Chemical class 0.000 description 4

- PSZYNBSKGUBXEH-UHFFFAOYSA-N naphthalene-1-sulfonic acid Chemical class C1=CC=C2C(S(=O)(=O)O)=CC=CC2=C1 PSZYNBSKGUBXEH-UHFFFAOYSA-N 0.000 description 4

- 230000007935 neutral effect Effects 0.000 description 4

- 150000002978 peroxides Chemical class 0.000 description 4

- 150000002989 phenols Chemical class 0.000 description 4

- 239000011591 potassium Substances 0.000 description 4

- 229910052700 potassium Inorganic materials 0.000 description 4

- 150000003871 sulfonates Chemical class 0.000 description 4

- YHMYGUUIMTVXNW-UHFFFAOYSA-N 1,3-dihydrobenzimidazole-2-thione Chemical compound C1=CC=C2NC(S)=NC2=C1 YHMYGUUIMTVXNW-UHFFFAOYSA-N 0.000 description 3

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 3

- DZIHTWJGPDVSGE-UHFFFAOYSA-N 4-[(4-aminocyclohexyl)methyl]cyclohexan-1-amine Chemical compound C1CC(N)CCC1CC1CCC(N)CC1 DZIHTWJGPDVSGE-UHFFFAOYSA-N 0.000 description 3

- UDQCDDZBBZNIFA-UHFFFAOYSA-N 4-methyl-1,3-dihydrobenzimidazole-2-thione Chemical compound CC1=CC=CC2=C1NC(=S)N2 UDQCDDZBBZNIFA-UHFFFAOYSA-N 0.000 description 3

- UXVMQQNJUSDDNG-UHFFFAOYSA-L Calcium chloride Chemical compound [Cl-].[Cl-].[Ca+2] UXVMQQNJUSDDNG-UHFFFAOYSA-L 0.000 description 3

- OAKJQQAXSVQMHS-UHFFFAOYSA-N Hydrazine Chemical class NN OAKJQQAXSVQMHS-UHFFFAOYSA-N 0.000 description 3

- XQVWYOYUZDUNRW-UHFFFAOYSA-N N-Phenyl-1-naphthylamine Chemical compound C=1C=CC2=CC=CC=C2C=1NC1=CC=CC=C1 XQVWYOYUZDUNRW-UHFFFAOYSA-N 0.000 description 3

- 229910019142 PO4 Inorganic materials 0.000 description 3

- OKKRPWIIYQTPQF-UHFFFAOYSA-N Trimethylolpropane trimethacrylate Chemical compound CC(=C)C(=O)OCC(CC)(COC(=O)C(C)=C)COC(=O)C(C)=C OKKRPWIIYQTPQF-UHFFFAOYSA-N 0.000 description 3

- XSQUKJJJFZCRTK-UHFFFAOYSA-N Urea Chemical compound NC(N)=O XSQUKJJJFZCRTK-UHFFFAOYSA-N 0.000 description 3

- 150000008052 alkyl sulfonates Chemical class 0.000 description 3

- 150000001356 alkyl thiols Chemical class 0.000 description 3

- 239000001110 calcium chloride Substances 0.000 description 3

- 229910001628 calcium chloride Inorganic materials 0.000 description 3

- 230000001112 coagulating effect Effects 0.000 description 3

- 238000005345 coagulation Methods 0.000 description 3

- 229920001577 copolymer Polymers 0.000 description 3

- 150000002432 hydroperoxides Chemical class 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- 229910052757 nitrogen Inorganic materials 0.000 description 3

- 239000007800 oxidant agent Substances 0.000 description 3

- 235000021317 phosphate Nutrition 0.000 description 3

- 150000003013 phosphoric acid derivatives Chemical class 0.000 description 3

- 239000000843 powder Substances 0.000 description 3

- 230000005855 radiation Effects 0.000 description 3

- 229920005989 resin Polymers 0.000 description 3

- 239000011347 resin Substances 0.000 description 3

- 150000003467 sulfuric acid derivatives Chemical class 0.000 description 3

- GRWFGVWFFZKLTI-IUCAKERBSA-N (-)-α-pinene Chemical compound CC1=CC[C@@H]2C(C)(C)[C@H]1C2 GRWFGVWFFZKLTI-IUCAKERBSA-N 0.000 description 2

- PMJHHCWVYXUKFD-SNAWJCMRSA-N (E)-1,3-pentadiene Chemical group C\C=C\C=C PMJHHCWVYXUKFD-SNAWJCMRSA-N 0.000 description 2

- PMBXCGGQNSVESQ-UHFFFAOYSA-N 1-Hexanethiol Chemical compound CCCCCCS PMBXCGGQNSVESQ-UHFFFAOYSA-N 0.000 description 2

- ZNRLMGFXSPUZNR-UHFFFAOYSA-N 2,2,4-trimethyl-1h-quinoline Chemical compound C1=CC=C2C(C)=CC(C)(C)NC2=C1 ZNRLMGFXSPUZNR-UHFFFAOYSA-N 0.000 description 2

- YAJYJWXEWKRTPO-UHFFFAOYSA-N 2,3,3,4,4,5-hexamethylhexane-2-thiol Chemical compound CC(C)C(C)(C)C(C)(C)C(C)(C)S YAJYJWXEWKRTPO-UHFFFAOYSA-N 0.000 description 2

- SDJHPPZKZZWAKF-UHFFFAOYSA-N 2,3-dimethylbuta-1,3-diene Chemical compound CC(=C)C(C)=C SDJHPPZKZZWAKF-UHFFFAOYSA-N 0.000 description 2

- BVUXDWXKPROUDO-UHFFFAOYSA-N 2,6-di-tert-butyl-4-ethylphenol Chemical compound CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 BVUXDWXKPROUDO-UHFFFAOYSA-N 0.000 description 2

- KGIGUEBEKRSTEW-UHFFFAOYSA-N 2-vinylpyridine Chemical compound C=CC1=CC=CC=N1 KGIGUEBEKRSTEW-UHFFFAOYSA-N 0.000 description 2

- RNLHGQLZWXBQNY-UHFFFAOYSA-N 3-(aminomethyl)-3,5,5-trimethylcyclohexan-1-amine Chemical compound CC1(C)CC(N)CC(C)(CN)C1 RNLHGQLZWXBQNY-UHFFFAOYSA-N 0.000 description 2

- BTXXTMOWISPQSJ-UHFFFAOYSA-N 4,4,4-trifluorobutan-2-one Chemical compound CC(=O)CC(F)(F)F BTXXTMOWISPQSJ-UHFFFAOYSA-N 0.000 description 2

- IGSBHTZEJMPDSZ-UHFFFAOYSA-N 4-[(4-amino-3-methylcyclohexyl)methyl]-2-methylcyclohexan-1-amine Chemical compound C1CC(N)C(C)CC1CC1CC(C)C(N)CC1 IGSBHTZEJMPDSZ-UHFFFAOYSA-N 0.000 description 2

- BQACOLQNOUYJCE-FYZZASKESA-N Abietic acid Natural products CC(C)C1=CC2=CC[C@]3(C)[C@](C)(CCC[C@@]3(C)C(=O)O)[C@H]2CC1 BQACOLQNOUYJCE-FYZZASKESA-N 0.000 description 2

- PAYRUJLWNCNPSJ-UHFFFAOYSA-N Aniline Chemical compound NC1=CC=CC=C1 PAYRUJLWNCNPSJ-UHFFFAOYSA-N 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- HEDRZPFGACZZDS-UHFFFAOYSA-N Chloroform Chemical compound ClC(Cl)Cl HEDRZPFGACZZDS-UHFFFAOYSA-N 0.000 description 2

- 229920001174 Diethylhydroxylamine Polymers 0.000 description 2

- YNQLUTRBYVCPMQ-UHFFFAOYSA-N Ethylbenzene Chemical compound CCC1=CC=CC=C1 YNQLUTRBYVCPMQ-UHFFFAOYSA-N 0.000 description 2

- IAYPIBMASNFSPL-UHFFFAOYSA-N Ethylene oxide Chemical compound C1CO1 IAYPIBMASNFSPL-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 2

- ZPDKJNLVLAYEKH-UHFFFAOYSA-M NC(C(=O)[O-])N.C=C.[Na+] Chemical compound NC(C(=O)[O-])N.C=C.[Na+] ZPDKJNLVLAYEKH-UHFFFAOYSA-M 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- IOVCWXUNBOPUCH-UHFFFAOYSA-M Nitrite anion Chemical compound [O-]N=O IOVCWXUNBOPUCH-UHFFFAOYSA-M 0.000 description 2

- 229920000299 Nylon 12 Polymers 0.000 description 2

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 2

- KKEYFWRCBNTPAC-UHFFFAOYSA-N Terephthalic acid Chemical compound OC(=O)C1=CC=C(C(O)=O)C=C1 KKEYFWRCBNTPAC-UHFFFAOYSA-N 0.000 description 2

- GSEJCLTVZPLZKY-UHFFFAOYSA-N Triethanolamine Chemical compound OCCN(CCO)CCO GSEJCLTVZPLZKY-UHFFFAOYSA-N 0.000 description 2

- 239000012190 activator Substances 0.000 description 2

- 150000001298 alcohols Chemical class 0.000 description 2

- 125000004183 alkoxy alkyl group Chemical group 0.000 description 2

- 150000008055 alkyl aryl sulfonates Chemical class 0.000 description 2

- 125000005907 alkyl ester group Chemical group 0.000 description 2

- 229940045714 alkyl sulfonate alkylating agent Drugs 0.000 description 2

- ANVAOWXLWRTKGA-XHGAXZNDSA-N all-trans-alpha-carotene Chemical compound CC=1CCCC(C)(C)C=1/C=C/C(/C)=C/C=C/C(/C)=C/C=C/C=C(C)C=CC=C(C)C=CC1C(C)=CCCC1(C)C ANVAOWXLWRTKGA-XHGAXZNDSA-N 0.000 description 2

- 150000001408 amides Chemical class 0.000 description 2

- ROOXNKNUYICQNP-UHFFFAOYSA-N ammonium persulfate Chemical compound [NH4+].[NH4+].[O-]S(=O)(=O)OOS([O-])(=O)=O ROOXNKNUYICQNP-UHFFFAOYSA-N 0.000 description 2

- 239000012935 ammoniumperoxodisulfate Substances 0.000 description 2

- 230000003078 antioxidant effect Effects 0.000 description 2

- 239000007864 aqueous solution Substances 0.000 description 2

- 125000003118 aryl group Chemical group 0.000 description 2

- 235000015278 beef Nutrition 0.000 description 2

- 230000015271 coagulation Effects 0.000 description 2

- ZPUCINDJVBIVPJ-LJISPDSOSA-N cocaine Chemical compound O([C@H]1C[C@@H]2CC[C@@H](N2C)[C@H]1C(=O)OC)C(=O)C1=CC=CC=C1 ZPUCINDJVBIVPJ-LJISPDSOSA-N 0.000 description 2

- 239000003240 coconut oil Substances 0.000 description 2

- 235000019864 coconut oil Nutrition 0.000 description 2

- 239000008139 complexing agent Substances 0.000 description 2

- RWGFKTVRMDUZSP-UHFFFAOYSA-N cumene Chemical compound CC(C)C1=CC=CC=C1 RWGFKTVRMDUZSP-UHFFFAOYSA-N 0.000 description 2

- GHVNFZFCNZKVNT-UHFFFAOYSA-N decanoic acid Chemical compound CCCCCCCCCC(O)=O GHVNFZFCNZKVNT-UHFFFAOYSA-N 0.000 description 2

- FVCOIAYSJZGECG-UHFFFAOYSA-N diethylhydroxylamine Chemical compound CCN(O)CC FVCOIAYSJZGECG-UHFFFAOYSA-N 0.000 description 2

- MZGNSEAPZQGJRB-UHFFFAOYSA-N dimethyldithiocarbamic acid Chemical compound CN(C)C(S)=S MZGNSEAPZQGJRB-UHFFFAOYSA-N 0.000 description 2

- DMBHHRLKUKUOEG-UHFFFAOYSA-N diphenylamine Chemical compound C=1C=CC=CC=1NC1=CC=CC=C1 DMBHHRLKUKUOEG-UHFFFAOYSA-N 0.000 description 2

- AUZONCFQVSMFAP-UHFFFAOYSA-N disulfiram Chemical compound CCN(CC)C(=S)SSC(=S)N(CC)CC AUZONCFQVSMFAP-UHFFFAOYSA-N 0.000 description 2

- WBZKQQHYRPRKNJ-UHFFFAOYSA-L disulfite Chemical compound [O-]S(=O)S([O-])(=O)=O WBZKQQHYRPRKNJ-UHFFFAOYSA-L 0.000 description 2

- POULHZVOKOAJMA-UHFFFAOYSA-N dodecanoic acid Chemical compound CCCCCCCCCCCC(O)=O POULHZVOKOAJMA-UHFFFAOYSA-N 0.000 description 2

- 125000003438 dodecyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 2

- MOTZDAYCYVMXPC-UHFFFAOYSA-N dodecyl hydrogen sulfate Chemical compound CCCCCCCCCCCCOS(O)(=O)=O MOTZDAYCYVMXPC-UHFFFAOYSA-N 0.000 description 2

- 229940043264 dodecyl sulfate Drugs 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 229940017705 formaldehyde sulfoxylate Drugs 0.000 description 2

- 230000004927 fusion Effects 0.000 description 2

- 150000008282 halocarbons Chemical class 0.000 description 2

- IPCSVZSSVZVIGE-UHFFFAOYSA-N hexadecanoic acid Chemical compound CCCCCCCCCCCCCCCC(O)=O IPCSVZSSVZVIGE-UHFFFAOYSA-N 0.000 description 2

- 125000004051 hexyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 2

- 125000002768 hydroxyalkyl group Chemical group 0.000 description 2

- SBGKURINHGJRFN-UHFFFAOYSA-N hydroxymethanesulfinic acid Chemical compound OCS(O)=O SBGKURINHGJRFN-UHFFFAOYSA-N 0.000 description 2

- 238000003973 irrigation Methods 0.000 description 2

- 230000002262 irrigation Effects 0.000 description 2

- 229910052744 lithium Inorganic materials 0.000 description 2

- 239000011159 matrix material Substances 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- QIQXTHQIDYTFRH-UHFFFAOYSA-N octadecanoic acid Chemical compound CCCCCCCCCCCCCCCCCC(O)=O QIQXTHQIDYTFRH-UHFFFAOYSA-N 0.000 description 2

- 125000002347 octyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- IWDCLRJOBJJRNH-UHFFFAOYSA-N p-cresol Chemical compound CC1=CC=C(O)C=C1 IWDCLRJOBJJRNH-UHFFFAOYSA-N 0.000 description 2

- 125000005385 peroxodisulfate group Chemical group 0.000 description 2

- 150000004965 peroxy acids Chemical class 0.000 description 2

- 239000002530 phenolic antioxidant Substances 0.000 description 2

- AQSJGOWTSHOLKH-UHFFFAOYSA-N phosphite(3-) Chemical class [O-]P([O-])[O-] AQSJGOWTSHOLKH-UHFFFAOYSA-N 0.000 description 2

- PMJHHCWVYXUKFD-UHFFFAOYSA-N piperylene Natural products CC=CC=C PMJHHCWVYXUKFD-UHFFFAOYSA-N 0.000 description 2

- 229920006110 poly(m-benzoyl4,4'-methylenebis(cyclohexylamine)) Polymers 0.000 description 2

- 239000001103 potassium chloride Substances 0.000 description 2

- 235000011164 potassium chloride Nutrition 0.000 description 2

- 125000001436 propyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])[H] 0.000 description 2

- 235000017557 sodium bicarbonate Nutrition 0.000 description 2

- 229910000030 sodium bicarbonate Inorganic materials 0.000 description 2

- 239000001488 sodium phosphate Substances 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 238000011105 stabilization Methods 0.000 description 2

- BDHFUVZGWQCTTF-UHFFFAOYSA-N sulfonic acid Chemical group OS(=O)=O BDHFUVZGWQCTTF-UHFFFAOYSA-N 0.000 description 2

- 239000003760 tallow Substances 0.000 description 2

- 125000000999 tert-butyl group Chemical group [H]C([H])([H])C(*)(C([H])([H])[H])C([H])([H])[H] 0.000 description 2

- CIHOLLKRGTVIJN-UHFFFAOYSA-N tert‐butyl hydroperoxide Chemical compound CC(C)(C)OO CIHOLLKRGTVIJN-UHFFFAOYSA-N 0.000 description 2

- UMGDCJDMYOKAJW-UHFFFAOYSA-N thiourea Chemical compound NC(N)=S UMGDCJDMYOKAJW-UHFFFAOYSA-N 0.000 description 2

- 229960002447 thiram Drugs 0.000 description 2

- RYFMWSXOAZQYPI-UHFFFAOYSA-K trisodium phosphate Chemical compound [Na+].[Na+].[Na+].[O-]P([O-])([O-])=O RYFMWSXOAZQYPI-UHFFFAOYSA-K 0.000 description 2

- 229910000406 trisodium phosphate Inorganic materials 0.000 description 2

- 235000019801 trisodium phosphate Nutrition 0.000 description 2

- WTARULDDTDQWMU-RKDXNWHRSA-N (+)-β-pinene Chemical compound C1[C@H]2C(C)(C)[C@@H]1CCC2=C WTARULDDTDQWMU-RKDXNWHRSA-N 0.000 description 1

- WTARULDDTDQWMU-IUCAKERBSA-N (-)-Nopinene Natural products C1[C@@H]2C(C)(C)[C@H]1CCC2=C WTARULDDTDQWMU-IUCAKERBSA-N 0.000 description 1

- ZOKCNEIWFQCSCM-UHFFFAOYSA-N (2-methyl-4-phenylpent-4-en-2-yl)benzene Chemical compound C=1C=CC=CC=1C(C)(C)CC(=C)C1=CC=CC=C1 ZOKCNEIWFQCSCM-UHFFFAOYSA-N 0.000 description 1

- OYHQOLUKZRVURQ-NTGFUMLPSA-N (9Z,12Z)-9,10,12,13-tetratritiooctadeca-9,12-dienoic acid Chemical compound C(CCCCCCC\C(=C(/C\C(=C(/CCCCC)\[3H])\[3H])\[3H])\[3H])(=O)O OYHQOLUKZRVURQ-NTGFUMLPSA-N 0.000 description 1

- WRIDQFICGBMAFQ-UHFFFAOYSA-N (E)-8-Octadecenoic acid Natural products CCCCCCCCCC=CCCCCCCC(O)=O WRIDQFICGBMAFQ-UHFFFAOYSA-N 0.000 description 1

- 229920002818 (Hydroxyethyl)methacrylate Polymers 0.000 description 1

- ZUDLIFVTNPYZJH-UHFFFAOYSA-N 1,1,2,2-tetraphenylethylbenzene Chemical compound C1=CC=CC=C1C(C(C=1C=CC=CC=1)(C=1C=CC=CC=1)C=1C=CC=CC=1)C1=CC=CC=C1 ZUDLIFVTNPYZJH-UHFFFAOYSA-N 0.000 description 1

- GEYOCULIXLDCMW-UHFFFAOYSA-N 1,2-phenylenediamine Chemical compound NC1=CC=CC=C1N GEYOCULIXLDCMW-UHFFFAOYSA-N 0.000 description 1

- KOMNUTZXSVSERR-UHFFFAOYSA-N 1,3,5-tris(prop-2-enyl)-1,3,5-triazinane-2,4,6-trione Chemical compound C=CCN1C(=O)N(CC=C)C(=O)N(CC=C)C1=O KOMNUTZXSVSERR-UHFFFAOYSA-N 0.000 description 1

- ROUYUBHVBIKMQO-UHFFFAOYSA-N 1,4-diiodobutane Chemical compound ICCCCI ROUYUBHVBIKMQO-UHFFFAOYSA-N 0.000 description 1

- QLIMAARBRDAYGQ-UHFFFAOYSA-N 1,6-diiodohexane Chemical compound ICCCCCCI QLIMAARBRDAYGQ-UHFFFAOYSA-N 0.000 description 1

- XSZYESUNPWGWFQ-UHFFFAOYSA-N 1-(2-hydroperoxypropan-2-yl)-4-methylcyclohexane Chemical compound CC1CCC(C(C)(C)OO)CC1 XSZYESUNPWGWFQ-UHFFFAOYSA-N 0.000 description 1

- PIBIAJQNHWMGTD-UHFFFAOYSA-N 1-n,3-n-bis(4-methylphenyl)benzene-1,3-diamine Chemical compound C1=CC(C)=CC=C1NC1=CC=CC(NC=2C=CC(C)=CC=2)=C1 PIBIAJQNHWMGTD-UHFFFAOYSA-N 0.000 description 1

- WJFKNYWRSNBZNX-UHFFFAOYSA-N 10H-phenothiazine Chemical compound C1=CC=C2NC3=CC=CC=C3SC2=C1 WJFKNYWRSNBZNX-UHFFFAOYSA-N 0.000 description 1

- HECLRDQVFMWTQS-RGOKHQFPSA-N 1755-01-7 Chemical compound C1[C@H]2[C@@H]3CC=C[C@@H]3[C@@H]1C=C2 HECLRDQVFMWTQS-RGOKHQFPSA-N 0.000 description 1

- KGRVJHAUYBGFFP-UHFFFAOYSA-N 2,2'-Methylenebis(4-methyl-6-tert-butylphenol) Chemical compound CC(C)(C)C1=CC(C)=CC(CC=2C(=C(C=C(C)C=2)C(C)(C)C)O)=C1O KGRVJHAUYBGFFP-UHFFFAOYSA-N 0.000 description 1

- DKCPKDPYUFEZCP-UHFFFAOYSA-N 2,6-di-tert-butylphenol Chemical compound CC(C)(C)C1=CC=CC(C(C)(C)C)=C1O DKCPKDPYUFEZCP-UHFFFAOYSA-N 0.000 description 1

- DQTKCIVHDDGAFK-UHFFFAOYSA-N 2-(5,6-dihydro-4H-cyclopenta[d][1,3]dithiol-2-ylidene)-1,3-dithiole-4,5-dithiol Chemical compound S1C(S)=C(S)SC1=C1SC(CCC2)=C2S1 DQTKCIVHDDGAFK-UHFFFAOYSA-N 0.000 description 1

- HZAXFHJVJLSVMW-UHFFFAOYSA-N 2-Aminoethan-1-ol Chemical compound NCCO HZAXFHJVJLSVMW-UHFFFAOYSA-N 0.000 description 1

- HFCUBKYHMMPGBY-UHFFFAOYSA-N 2-methoxyethyl prop-2-enoate Chemical compound COCCOC(=O)C=C HFCUBKYHMMPGBY-UHFFFAOYSA-N 0.000 description 1

- TVONJMOVBKMLOM-UHFFFAOYSA-N 2-methylidenebutanenitrile Chemical compound CCC(=C)C#N TVONJMOVBKMLOM-UHFFFAOYSA-N 0.000 description 1

- VKKXREABWZPFQJ-UHFFFAOYSA-N 2-methylprop-1-ene;naphthalene-1-sulfonic acid Chemical compound CC(C)=C.CC(C)=C.C1=CC=C2C(S(=O)(=O)O)=CC=CC2=C1 VKKXREABWZPFQJ-UHFFFAOYSA-N 0.000 description 1

- FRQQKWGDKVGLFI-UHFFFAOYSA-N 2-methylundecane-2-thiol Chemical compound CCCCCCCCCC(C)(C)S FRQQKWGDKVGLFI-UHFFFAOYSA-N 0.000 description 1

- LQJBNNIYVWPHFW-UHFFFAOYSA-N 20:1omega9c fatty acid Natural products CCCCCCCCCCC=CCCCCCCCC(O)=O LQJBNNIYVWPHFW-UHFFFAOYSA-N 0.000 description 1

- FRIBMENBGGCKPD-UHFFFAOYSA-N 3-(2,3-dimethoxyphenyl)prop-2-enal Chemical compound COC1=CC=CC(C=CC=O)=C1OC FRIBMENBGGCKPD-UHFFFAOYSA-N 0.000 description 1

- DKIDEFUBRARXTE-UHFFFAOYSA-N 3-mercaptopropanoic acid Chemical compound OC(=O)CCS DKIDEFUBRARXTE-UHFFFAOYSA-N 0.000 description 1

- CBEVWPCAHIAUOD-UHFFFAOYSA-N 4-[(4-amino-3-ethylphenyl)methyl]-2-ethylaniline Chemical compound C1=C(N)C(CC)=CC(CC=2C=C(CC)C(N)=CC=2)=C1 CBEVWPCAHIAUOD-UHFFFAOYSA-N 0.000 description 1

- MLBYBBUZURKHAW-UHFFFAOYSA-N 4-epi-Palustrinsaeure Natural products CC12CCCC(C)(C(O)=O)C1CCC1=C2CCC(C(C)C)=C1 MLBYBBUZURKHAW-UHFFFAOYSA-N 0.000 description 1

- ZZMVLMVFYMGSMY-UHFFFAOYSA-N 4-n-(4-methylpentan-2-yl)-1-n-phenylbenzene-1,4-diamine Chemical compound C1=CC(NC(C)CC(C)C)=CC=C1NC1=CC=CC=C1 ZZMVLMVFYMGSMY-UHFFFAOYSA-N 0.000 description 1

- UHJVLUYSDYOULM-UHFFFAOYSA-N 4-n-(5-methylhexan-2-yl)-1-n-phenylbenzene-1,4-diamine Chemical compound C1=CC(NC(C)CCC(C)C)=CC=C1NC1=CC=CC=C1 UHJVLUYSDYOULM-UHFFFAOYSA-N 0.000 description 1

- QSBYPNXLFMSGKH-UHFFFAOYSA-N 9-Heptadecensaeure Natural products CCCCCCCC=CCCCCCCCC(O)=O QSBYPNXLFMSGKH-UHFFFAOYSA-N 0.000 description 1

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical compound [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 description 1

- 239000005632 Capric acid (CAS 334-48-5) Substances 0.000 description 1

- 239000004971 Cross linker Substances 0.000 description 1

- 239000004593 Epoxy Substances 0.000 description 1

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 1

- JOYRKODLDBILNP-UHFFFAOYSA-N Ethyl urethane Chemical compound CCOC(N)=O JOYRKODLDBILNP-UHFFFAOYSA-N 0.000 description 1

- 239000005977 Ethylene Substances 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- AVXURJPOCDRRFD-UHFFFAOYSA-N Hydroxylamine Chemical compound ON AVXURJPOCDRRFD-UHFFFAOYSA-N 0.000 description 1

- RWWVEQKPFPXLGL-ONCXSQPRSA-N L-Pimaric acid Chemical compound [C@H]1([C@](CCC2)(C)C(O)=O)[C@@]2(C)[C@H]2CC=C(C(C)C)C=C2CC1 RWWVEQKPFPXLGL-ONCXSQPRSA-N 0.000 description 1

- 239000005639 Lauric acid Substances 0.000 description 1

- RWWVEQKPFPXLGL-UHFFFAOYSA-N Levopimaric acid Natural products C1CCC(C(O)=O)(C)C2C1(C)C1CC=C(C(C)C)C=C1CC2 RWWVEQKPFPXLGL-UHFFFAOYSA-N 0.000 description 1

- KGMSWPSAVZAMKR-UHFFFAOYSA-N Me ester-3, 22-Dihydroxy-29-hopanoic acid Natural products C1CCC(C(O)=O)(C)C2C1(C)C1CCC(=C(C)C)C=C1CC2 KGMSWPSAVZAMKR-UHFFFAOYSA-N 0.000 description 1

- GYCMBHHDWRMZGG-UHFFFAOYSA-N Methylacrylonitrile Chemical compound CC(=C)C#N GYCMBHHDWRMZGG-UHFFFAOYSA-N 0.000 description 1

- JLTDJTHDQAWBAV-UHFFFAOYSA-N N,N-dimethylaniline Chemical compound CN(C)C1=CC=CC=C1 JLTDJTHDQAWBAV-UHFFFAOYSA-N 0.000 description 1

- KEQFTVQCIQJIQW-UHFFFAOYSA-N N-Phenyl-2-naphthylamine Chemical compound C=1C=C2C=CC=CC2=CC=1NC1=CC=CC=C1 KEQFTVQCIQJIQW-UHFFFAOYSA-N 0.000 description 1

- OUBMGJOQLXMSNT-UHFFFAOYSA-N N-isopropyl-N'-phenyl-p-phenylenediamine Chemical compound C1=CC(NC(C)C)=CC=C1NC1=CC=CC=C1 OUBMGJOQLXMSNT-UHFFFAOYSA-N 0.000 description 1

- KGMSWPSAVZAMKR-ONCXSQPRSA-N Neoabietic acid Chemical compound [C@H]1([C@](CCC2)(C)C(O)=O)[C@@]2(C)[C@H]2CCC(=C(C)C)C=C2CC1 KGMSWPSAVZAMKR-ONCXSQPRSA-N 0.000 description 1

- 239000005642 Oleic acid Substances 0.000 description 1

- ZQPPMHVWECSIRJ-UHFFFAOYSA-N Oleic acid Natural products CCCCCCCCC=CCCCCCCCC(O)=O ZQPPMHVWECSIRJ-UHFFFAOYSA-N 0.000 description 1

- 235000021314 Palmitic acid Nutrition 0.000 description 1

- MLBYBBUZURKHAW-MISYRCLQSA-N Palustric acid Chemical compound C([C@@]12C)CC[C@@](C)(C(O)=O)[C@@H]1CCC1=C2CCC(C(C)C)=C1 MLBYBBUZURKHAW-MISYRCLQSA-N 0.000 description 1

- 235000019483 Peanut oil Nutrition 0.000 description 1

- CYTYCFOTNPOANT-UHFFFAOYSA-N Perchloroethylene Chemical compound ClC(Cl)=C(Cl)Cl CYTYCFOTNPOANT-UHFFFAOYSA-N 0.000 description 1

- GOOHAUXETOMSMM-UHFFFAOYSA-N Propylene oxide Chemical compound CC1CO1 GOOHAUXETOMSMM-UHFFFAOYSA-N 0.000 description 1

- WTARULDDTDQWMU-UHFFFAOYSA-N Pseudopinene Natural products C1C2C(C)(C)C1CCC2=C WTARULDDTDQWMU-UHFFFAOYSA-N 0.000 description 1

- 235000019484 Rapeseed oil Nutrition 0.000 description 1

- PMZURENOXWZQFD-UHFFFAOYSA-L Sodium Sulfate Chemical compound [Na+].[Na+].[O-]S([O-])(=O)=O PMZURENOXWZQFD-UHFFFAOYSA-L 0.000 description 1

- DBMJMQXJHONAFJ-UHFFFAOYSA-M Sodium laurylsulphate Chemical compound [Na+].CCCCCCCCCCCCOS([O-])(=O)=O DBMJMQXJHONAFJ-UHFFFAOYSA-M 0.000 description 1

- 229920002125 Sokalan® Polymers 0.000 description 1

- 235000021355 Stearic acid Nutrition 0.000 description 1

- QAOWNCQODCNURD-UHFFFAOYSA-L Sulfate Chemical compound [O-]S([O-])(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-L 0.000 description 1

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical group [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 1

- LSNNMFCWUKXFEE-UHFFFAOYSA-N Sulfurous acid Chemical compound OS(O)=O LSNNMFCWUKXFEE-UHFFFAOYSA-N 0.000 description 1

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 1

- FDLQZKYLHJJBHD-UHFFFAOYSA-N [3-(aminomethyl)phenyl]methanamine Chemical compound NCC1=CC=CC(CN)=C1 FDLQZKYLHJJBHD-UHFFFAOYSA-N 0.000 description 1

- JYPKXWYQBSCZGE-UHFFFAOYSA-M [Na+].[O-]O.CC(C)C1=CC=CC=C1 Chemical compound [Na+].[O-]O.CC(C)C1=CC=CC=C1 JYPKXWYQBSCZGE-UHFFFAOYSA-M 0.000 description 1

- 230000002378 acidificating effect Effects 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 150000001338 aliphatic hydrocarbons Chemical class 0.000 description 1

- 150000003973 alkyl amines Chemical class 0.000 description 1

- OENHQHLEOONYIE-UKMVMLAPSA-N all-trans beta-carotene Natural products CC=1CCCC(C)(C)C=1/C=C/C(/C)=C/C=C/C(/C)=C/C=C/C=C(C)C=CC=C(C)C=CC1=C(C)CCCC1(C)C OENHQHLEOONYIE-UKMVMLAPSA-N 0.000 description 1

- XCPQUQHBVVXMRQ-UHFFFAOYSA-N alpha-Fenchene Natural products C1CC2C(=C)CC1C2(C)C XCPQUQHBVVXMRQ-UHFFFAOYSA-N 0.000 description 1

- XYLMUPLGERFSHI-UHFFFAOYSA-N alpha-Methylstyrene Chemical compound CC(=C)C1=CC=CC=C1 XYLMUPLGERFSHI-UHFFFAOYSA-N 0.000 description 1

- 239000011795 alpha-carotene Substances 0.000 description 1

- 235000003903 alpha-carotene Nutrition 0.000 description 1

- ANVAOWXLWRTKGA-HLLMEWEMSA-N alpha-carotene Natural products C(=C\C=C\C=C(/C=C/C=C(\C=C\C=1C(C)(C)CCCC=1C)/C)\C)(\C=C\C=C(/C=C/[C@H]1C(C)=CCCC1(C)C)\C)/C ANVAOWXLWRTKGA-HLLMEWEMSA-N 0.000 description 1

- DTOSIQBPPRVQHS-PDBXOOCHSA-N alpha-linolenic acid Chemical compound CC\C=C/C\C=C/C\C=C/CCCCCCCC(O)=O DTOSIQBPPRVQHS-PDBXOOCHSA-N 0.000 description 1

- 235000020661 alpha-linolenic acid Nutrition 0.000 description 1

- MVNCAPSFBDBCGF-UHFFFAOYSA-N alpha-pinene Natural products CC1=CCC23C1CC2C3(C)C MVNCAPSFBDBCGF-UHFFFAOYSA-N 0.000 description 1

- 229920006020 amorphous polyamide Polymers 0.000 description 1

- 239000003429 antifungal agent Substances 0.000 description 1

- 229940121375 antifungal agent Drugs 0.000 description 1

- 239000004599 antimicrobial Substances 0.000 description 1

- 239000002216 antistatic agent Substances 0.000 description 1

- 239000008346 aqueous phase Substances 0.000 description 1

- 150000004945 aromatic hydrocarbons Chemical class 0.000 description 1

- 125000005228 aryl sulfonate group Chemical group 0.000 description 1

- 125000004429 atom Chemical group 0.000 description 1

- 239000002585 base Substances 0.000 description 1

- 229940077388 benzenesulfonate Drugs 0.000 description 1

- 239000011648 beta-carotene Substances 0.000 description 1

- 235000013734 beta-carotene Nutrition 0.000 description 1

- TUPZEYHYWIEDIH-WAIFQNFQSA-N beta-carotene Natural products CC(=C/C=C/C=C(C)/C=C/C=C(C)/C=C/C1=C(C)CCCC1(C)C)C=CC=C(/C)C=CC2=CCCCC2(C)C TUPZEYHYWIEDIH-WAIFQNFQSA-N 0.000 description 1

- 229930006722 beta-pinene Natural products 0.000 description 1

- 229960002747 betacarotene Drugs 0.000 description 1

- RDHPKYGYEGBMSE-UHFFFAOYSA-N bromoethane Chemical compound CCBr RDHPKYGYEGBMSE-UHFFFAOYSA-N 0.000 description 1

- CQEYYJKEWSMYFG-UHFFFAOYSA-N butyl acrylate Chemical compound CCCCOC(=O)C=C CQEYYJKEWSMYFG-UHFFFAOYSA-N 0.000 description 1

- 239000011575 calcium Substances 0.000 description 1

- 239000004202 carbamide Substances 0.000 description 1

- 239000006229 carbon black Substances 0.000 description 1

- 239000004359 castor oil Substances 0.000 description 1

- 235000019438 castor oil Nutrition 0.000 description 1

- 229910017052 cobalt Inorganic materials 0.000 description 1

- 239000010941 cobalt Substances 0.000 description 1

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 1

- 238000004737 colorimetric analysis Methods 0.000 description 1

- 238000004590 computer program Methods 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 239000002385 cottonseed oil Substances 0.000 description 1

- 235000012343 cottonseed oil Nutrition 0.000 description 1

- LDHQCZJRKDOVOX-NSCUHMNNSA-N crotonic acid Chemical compound C\C=C\C(O)=O LDHQCZJRKDOVOX-NSCUHMNNSA-N 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- KVBKAPANDHPRDG-UHFFFAOYSA-N dibromotetrafluoroethane Chemical compound FC(F)(Br)C(F)(F)Br KVBKAPANDHPRDG-UHFFFAOYSA-N 0.000 description 1

- PGAXJQVAHDTGBB-UHFFFAOYSA-N dibutylcarbamothioylsulfanyl n,n-dibutylcarbamodithioate Chemical compound CCCCN(CCCC)C(=S)SSC(=S)N(CCCC)CCCC PGAXJQVAHDTGBB-UHFFFAOYSA-N 0.000 description 1

- ZBCBWPMODOFKDW-UHFFFAOYSA-N diethanolamine Chemical compound OCCNCCO ZBCBWPMODOFKDW-UHFFFAOYSA-N 0.000 description 1

- 125000004177 diethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 1

- SOEBNUZZZSSRNB-UHFFFAOYSA-N difluoro(diiodo)methane Chemical compound FC(F)(I)I SOEBNUZZZSSRNB-UHFFFAOYSA-N 0.000 description 1

- HRKQOINLCJTGBK-UHFFFAOYSA-N dihydroxidosulfur Chemical class OSO HRKQOINLCJTGBK-UHFFFAOYSA-N 0.000 description 1

- NZZFYRREKKOMAT-UHFFFAOYSA-N diiodomethane Chemical compound ICI NZZFYRREKKOMAT-UHFFFAOYSA-N 0.000 description 1

- 238000006471 dimerization reaction Methods 0.000 description 1

- 125000000118 dimethyl group Chemical group [H]C([H])([H])* 0.000 description 1

- 239000001177 diphosphate Substances 0.000 description 1

- XPPKVPWEQAFLFU-UHFFFAOYSA-J diphosphate(4-) Chemical compound [O-]P([O-])(=O)OP([O-])([O-])=O XPPKVPWEQAFLFU-UHFFFAOYSA-J 0.000 description 1

- 235000011180 diphosphates Nutrition 0.000 description 1

- 238000002845 discoloration Methods 0.000 description 1

- 238000007323 disproportionation reaction Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- GRWZHXKQBITJKP-UHFFFAOYSA-L dithionite(2-) Chemical compound [O-]S(=O)S([O-])=O GRWZHXKQBITJKP-UHFFFAOYSA-L 0.000 description 1

- 239000000975 dye Substances 0.000 description 1

- 239000003792 electrolyte Substances 0.000 description 1

- 125000004185 ester group Chemical group 0.000 description 1

- HQQADJVZYDDRJT-UHFFFAOYSA-N ethene;prop-1-ene Chemical group C=C.CC=C HQQADJVZYDDRJT-UHFFFAOYSA-N 0.000 description 1

- 125000005448 ethoxyethyl group Chemical group [H]C([H])([H])C([H])([H])OC([H])([H])C([H])([H])* 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 239000003925 fat Substances 0.000 description 1

- 235000019197 fats Nutrition 0.000 description 1

- 239000011152 fibreglass Substances 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 235000021323 fish oil Nutrition 0.000 description 1

- 239000003063 flame retardant Substances 0.000 description 1

- 229920005570 flexible polymer Polymers 0.000 description 1

- 229920002313 fluoropolymer Polymers 0.000 description 1

- 238000007710 freezing Methods 0.000 description 1

- 230000008014 freezing Effects 0.000 description 1

- LCWMKIHBLJLORW-UHFFFAOYSA-N gamma-carene Natural products C1CC(=C)CC2C(C)(C)C21 LCWMKIHBLJLORW-UHFFFAOYSA-N 0.000 description 1

- ZEMPKEQAKRGZGQ-XOQCFJPHSA-N glycerol triricinoleate Natural products CCCCCC[C@@H](O)CC=CCCCCCCCC(=O)OC[C@@H](COC(=O)CCCCCCCC=CC[C@@H](O)CCCCCC)OC(=O)CCCCCCCC=CC[C@H](O)CCCCCC ZEMPKEQAKRGZGQ-XOQCFJPHSA-N 0.000 description 1

- 125000003055 glycidyl group Chemical group C(C1CO1)* 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- ZGCHATBSUIJLRL-UHFFFAOYSA-N hydrazine sulfate Chemical compound NN.OS(O)(=O)=O ZGCHATBSUIJLRL-UHFFFAOYSA-N 0.000 description 1

- 229910000377 hydrazine sulfate Inorganic materials 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 229910000037 hydrogen sulfide Inorganic materials 0.000 description 1

- 238000005984 hydrogenation reaction Methods 0.000 description 1

- 125000000687 hydroquinonyl group Chemical class C1(O)=C(C=C(O)C=C1)* 0.000 description 1

- VGYYSIDKAKXZEE-UHFFFAOYSA-L hydroxylammonium sulfate Chemical compound O[NH3+].O[NH3+].[O-]S([O-])(=O)=O VGYYSIDKAKXZEE-UHFFFAOYSA-L 0.000 description 1

- 229910000378 hydroxylammonium sulfate Inorganic materials 0.000 description 1

- 230000002401 inhibitory effect Effects 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 239000011256 inorganic filler Substances 0.000 description 1

- 239000001023 inorganic pigment Substances 0.000 description 1

- HVTICUPFWKNHNG-UHFFFAOYSA-N iodoethane Chemical compound CCI HVTICUPFWKNHNG-UHFFFAOYSA-N 0.000 description 1

- INQOMBQAUSQDDS-UHFFFAOYSA-N iodomethane Chemical compound IC INQOMBQAUSQDDS-UHFFFAOYSA-N 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- QXJSBBXBKPUZAA-UHFFFAOYSA-N isooleic acid Natural products CCCCCCCC=CCCCCCCCCC(O)=O QXJSBBXBKPUZAA-UHFFFAOYSA-N 0.000 description 1

- 239000004611 light stabiliser Substances 0.000 description 1

- 235000001510 limonene Nutrition 0.000 description 1

- 229940087305 limonene Drugs 0.000 description 1

- 229960004488 linolenic acid Drugs 0.000 description 1

- KQQKGWQCNNTQJW-UHFFFAOYSA-N linolenic acid Natural products CC=CCCC=CCC=CCCCCCCCC(O)=O KQQKGWQCNNTQJW-UHFFFAOYSA-N 0.000 description 1

- 239000000944 linseed oil Substances 0.000 description 1

- 235000021388 linseed oil Nutrition 0.000 description 1

- 159000000003 magnesium salts Chemical class 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000010907 mechanical stirring Methods 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 125000001570 methylene group Chemical group [H]C([H])([*:1])[*:2] 0.000 description 1

- XLLLBDRHCNJFPU-UHFFFAOYSA-N methylsulfanylbenzene;zinc Chemical compound [Zn].CSC1=CC=CC=C1 XLLLBDRHCNJFPU-UHFFFAOYSA-N 0.000 description 1

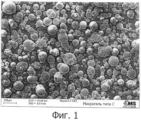

- 238000001000 micrograph Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- OQAIUHLITJGRMM-UHFFFAOYSA-N n,n-di(propan-2-yl)hydroxylamine Chemical compound CC(C)N(O)C(C)C OQAIUHLITJGRMM-UHFFFAOYSA-N 0.000 description 1

- WQEPLUUGTLDZJY-UHFFFAOYSA-N n-Pentadecanoic acid Natural products CCCCCCCCCCCCCCC(O)=O WQEPLUUGTLDZJY-UHFFFAOYSA-N 0.000 description 1

- SYSQUGFVNFXIIT-UHFFFAOYSA-N n-[4-(1,3-benzoxazol-2-yl)phenyl]-4-nitrobenzenesulfonamide Chemical class C1=CC([N+](=O)[O-])=CC=C1S(=O)(=O)NC1=CC=C(C=2OC3=CC=CC=C3N=2)C=C1 SYSQUGFVNFXIIT-UHFFFAOYSA-N 0.000 description 1

- KYTZHLUVELPASH-UHFFFAOYSA-N naphthalene-1,2-dicarboxylic acid Chemical compound C1=CC=CC2=C(C(O)=O)C(C(=O)O)=CC=C21 KYTZHLUVELPASH-UHFFFAOYSA-N 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 229920000847 nonoxynol Polymers 0.000 description 1

- SNQQPOLDUKLAAF-UHFFFAOYSA-N nonylphenol Chemical class CCCCCCCCCC1=CC=CC=C1O SNQQPOLDUKLAAF-UHFFFAOYSA-N 0.000 description 1

- 239000002667 nucleating agent Substances 0.000 description 1

- ZWWQICJTBOCQLA-UHFFFAOYSA-N o-propan-2-yl (propan-2-yloxycarbothioyldisulfanyl)methanethioate Chemical compound CC(C)OC(=S)SSC(=S)OC(C)C ZWWQICJTBOCQLA-UHFFFAOYSA-N 0.000 description 1

- OQCDKBAXFALNLD-UHFFFAOYSA-N octadecanoic acid Natural products CCCCCCCC(C)CCCCCCCCC(O)=O OQCDKBAXFALNLD-UHFFFAOYSA-N 0.000 description 1

- ZQPPMHVWECSIRJ-KTKRTIGZSA-N oleic acid Chemical compound CCCCCCCC\C=C/CCCCCCCC(O)=O ZQPPMHVWECSIRJ-KTKRTIGZSA-N 0.000 description 1

- 235000021313 oleic acid Nutrition 0.000 description 1

- 238000006384 oligomerization reaction Methods 0.000 description 1

- 239000004006 olive oil Substances 0.000 description 1

- 235000008390 olive oil Nutrition 0.000 description 1

- 239000012766 organic filler Substances 0.000 description 1

- 239000012860 organic pigment Substances 0.000 description 1

- 150000002924 oxiranes Chemical class 0.000 description 1

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 1

- 239000006174 pH buffer Substances 0.000 description 1

- 239000003346 palm kernel oil Substances 0.000 description 1

- 235000019865 palm kernel oil Nutrition 0.000 description 1

- 239000000312 peanut oil Substances 0.000 description 1

- 125000000864 peroxy group Chemical group O(O*)* 0.000 description 1

- JRKICGRDRMAZLK-UHFFFAOYSA-N peroxydisulfuric acid Chemical class OS(=O)(=O)OOS(O)(=O)=O JRKICGRDRMAZLK-UHFFFAOYSA-N 0.000 description 1

- 239000003208 petroleum Substances 0.000 description 1

- 239000012071 phase Substances 0.000 description 1

- 229950000688 phenothiazine Drugs 0.000 description 1

- 150000004986 phenylenediamines Chemical class 0.000 description 1

- 239000004014 plasticizer Substances 0.000 description 1

- 229920002589 poly(vinylethylene) polymer Polymers 0.000 description 1

- 239000004584 polyacrylic acid Substances 0.000 description 1

- 238000006068 polycondensation reaction Methods 0.000 description 1

- 239000003505 polymerization initiator Substances 0.000 description 1

- 229920000417 polynaphthalene Polymers 0.000 description 1

- 229920001451 polypropylene glycol Polymers 0.000 description 1

- 235000007686 potassium Nutrition 0.000 description 1

- 235000011118 potassium hydroxide Nutrition 0.000 description 1

- USHAGKDGDHPEEY-UHFFFAOYSA-L potassium persulfate Chemical compound [K+].[K+].[O-]S(=O)(=O)OOS([O-])(=O)=O USHAGKDGDHPEEY-UHFFFAOYSA-L 0.000 description 1

- 159000000001 potassium salts Chemical class 0.000 description 1

- 230000002028 premature Effects 0.000 description 1

- 150000003141 primary amines Chemical class 0.000 description 1

- GRWFGVWFFZKLTI-UHFFFAOYSA-N rac-alpha-Pinene Natural products CC1=CCC2C(C)(C)C1C2 GRWFGVWFFZKLTI-UHFFFAOYSA-N 0.000 description 1

- 239000007870 radical polymerization initiator Substances 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 150000003335 secondary amines Chemical class 0.000 description 1

- 235000015424 sodium Nutrition 0.000 description 1

- 229910000029 sodium carbonate Inorganic materials 0.000 description 1

- 235000017550 sodium carbonate Nutrition 0.000 description 1

- 239000011780 sodium chloride Substances 0.000 description 1

- HRZFUMHJMZEROT-UHFFFAOYSA-L sodium disulfite Chemical compound [Na+].[Na+].[O-]S(=O)S([O-])(=O)=O HRZFUMHJMZEROT-UHFFFAOYSA-L 0.000 description 1

- JVBXVOWTABLYPX-UHFFFAOYSA-L sodium dithionite Chemical compound [Na+].[Na+].[O-]S(=O)S([O-])=O JVBXVOWTABLYPX-UHFFFAOYSA-L 0.000 description 1

- 235000011121 sodium hydroxide Nutrition 0.000 description 1

- 235000019333 sodium laurylsulphate Nutrition 0.000 description 1

- DZCAZXAJPZCSCU-UHFFFAOYSA-K sodium nitrilotriacetate Chemical compound [Na+].[Na+].[Na+].[O-]C(=O)CN(CC([O-])=O)CC([O-])=O DZCAZXAJPZCSCU-UHFFFAOYSA-K 0.000 description 1

- 229910052938 sodium sulfate Inorganic materials 0.000 description 1

- 235000011152 sodium sulphate Nutrition 0.000 description 1

- 239000003549 soybean oil Substances 0.000 description 1

- 235000012424 soybean oil Nutrition 0.000 description 1

- 239000012798 spherical particle Substances 0.000 description 1

- 239000008117 stearic acid Substances 0.000 description 1

- 125000001424 substituent group Chemical group 0.000 description 1

- 239000011593 sulfur Substances 0.000 description 1

- 229910052717 sulfur Inorganic materials 0.000 description 1

- 239000003784 tall oil Substances 0.000 description 1

- 150000003505 terpenes Chemical class 0.000 description 1

- 235000007586 terpenes Nutrition 0.000 description 1

- WMOVHXAZOJBABW-UHFFFAOYSA-N tert-butyl acetate Chemical compound CC(=O)OC(C)(C)C WMOVHXAZOJBABW-UHFFFAOYSA-N 0.000 description 1

- GDVVYWWFZVDULK-UHFFFAOYSA-N tetracene-1-carbaldehyde Chemical compound C1=CC=C2C=C(C=C3C(C=O)=CC=CC3=C3)C3=CC2=C1 GDVVYWWFZVDULK-UHFFFAOYSA-N 0.000 description 1

- VZGDMQKNWNREIO-UHFFFAOYSA-N tetrachloromethane Chemical compound ClC(Cl)(Cl)Cl VZGDMQKNWNREIO-UHFFFAOYSA-N 0.000 description 1

- TUNFSRHWOTWDNC-HKGQFRNVSA-N tetradecanoic acid Chemical compound CCCCCCCCCCCCC[14C](O)=O TUNFSRHWOTWDNC-HKGQFRNVSA-N 0.000 description 1

- 239000012815 thermoplastic material Substances 0.000 description 1

- 125000000101 thioether group Chemical group 0.000 description 1

- KUAZQDVKQLNFPE-UHFFFAOYSA-N thiram Chemical compound CN(C)C(=S)SSC(=S)N(C)C KUAZQDVKQLNFPE-UHFFFAOYSA-N 0.000 description 1

- LDHQCZJRKDOVOX-UHFFFAOYSA-N trans-crotonic acid Natural products CC=CC(O)=O LDHQCZJRKDOVOX-UHFFFAOYSA-N 0.000 description 1

- 229910052723 transition metal Inorganic materials 0.000 description 1

- 150000003623 transition metal compounds Chemical class 0.000 description 1

- 150000003624 transition metals Chemical class 0.000 description 1

- NOYPYLRCIDNJJB-UHFFFAOYSA-N trimetrexate Chemical compound COC1=C(OC)C(OC)=CC(NCC=2C(=C3C(N)=NC(N)=NC3=CC=2)C)=C1 NOYPYLRCIDNJJB-UHFFFAOYSA-N 0.000 description 1

- AAAQKTZKLRYKHR-UHFFFAOYSA-N triphenylmethane Chemical compound C1=CC=CC=C1C(C=1C=CC=CC=1)C1=CC=CC=C1 AAAQKTZKLRYKHR-UHFFFAOYSA-N 0.000 description 1

- WGKLOLBTFWFKOD-UHFFFAOYSA-N tris(2-nonylphenyl) phosphite Chemical compound CCCCCCCCCC1=CC=CC=C1OP(OC=1C(=CC=CC=1)CCCCCCCCC)OC1=CC=CC=C1CCCCCCCCC WGKLOLBTFWFKOD-UHFFFAOYSA-N 0.000 description 1

- 229920002554 vinyl polymer Polymers 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

- 238000004260 weight control Methods 0.000 description 1

- 239000012991 xanthate Substances 0.000 description 1

- 229910052725 zinc Inorganic materials 0.000 description 1

- 239000011701 zinc Substances 0.000 description 1

- OENHQHLEOONYIE-JLTXGRSLSA-N β-Carotene Chemical compound CC=1CCCC(C)(C)C=1\C=C\C(\C)=C\C=C\C(\C)=C\C=C\C=C(/C)\C=C\C=C(/C)\C=C\C1=C(C)CCCC1(C)C OENHQHLEOONYIE-JLTXGRSLSA-N 0.000 description 1

- DGVVWUTYPXICAM-UHFFFAOYSA-N β‐Mercaptoethanol Chemical compound OCCS DGVVWUTYPXICAM-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J3/00—Processes of treating or compounding macromolecular substances

- C08J3/12—Powdering or granulating

- C08J3/122—Pulverisation by spraying

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L13/00—Compositions of rubbers containing carboxyl groups

- C08L13/02—Latex

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L21/00—Compositions of unspecified rubbers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L77/00—Compositions of polyamides obtained by reactions forming a carboxylic amide link in the main chain; Compositions of derivatives of such polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L77/00—Compositions of polyamides obtained by reactions forming a carboxylic amide link in the main chain; Compositions of derivatives of such polymers

- C08L77/02—Polyamides derived from omega-amino carboxylic acids or from lactams thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L9/00—Compositions of homopolymers or copolymers of conjugated diene hydrocarbons

- C08L9/10—Latex

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2321/00—Characterised by the use of unspecified rubbers

- C08J2321/02—Latex

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/04—Oxygen-containing compounds

- C08K5/14—Peroxides

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L11/00—Compositions of homopolymers or copolymers of chloroprene

- C08L11/02—Latex

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L21/00—Compositions of unspecified rubbers

- C08L21/02—Latex

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2205/00—Polymer mixtures characterised by other features

- C08L2205/02—Polymer mixtures characterised by other features containing two or more polymers of the same C08L -group

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L9/00—Compositions of homopolymers or copolymers of conjugated diene hydrocarbons

- C08L9/02—Copolymers with acrylonitrile

- C08L9/04—Latex

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/13—Hollow or container type article [e.g., tube, vase, etc.]

- Y10T428/1352—Polymer or resin containing [i.e., natural or synthetic]

- Y10T428/139—Open-ended, self-supporting conduit, cylinder, or tube-type article

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/13—Hollow or container type article [e.g., tube, vase, etc.]

- Y10T428/1352—Polymer or resin containing [i.e., natural or synthetic]

- Y10T428/139—Open-ended, self-supporting conduit, cylinder, or tube-type article

- Y10T428/1393—Multilayer [continuous layer]

Landscapes

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Compositions Of Macromolecular Compounds (AREA)

- Manufacture Of Macromolecular Shaped Articles (AREA)

- Addition Polymer Or Copolymer, Post-Treatments, Or Chemical Modifications (AREA)

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102008008098A DE102008008098A1 (de) | 2008-02-08 | 2008-02-08 | Hydrolysebeständige Polyamid-Elastomer-Mischungen, hieraus hergestellte Formteile sowie deren Verwendung |

| DE102008008098.5 | 2008-02-08 | ||

| DE200810042368 DE102008042368A1 (de) | 2008-09-25 | 2008-09-25 | Hydrolysebeständige Polyamid-Elastomer-Mischungen, hieraus hergestellte Formteile sowie deren Verwendung |

| DE102008042368.8 | 2008-09-25 | ||

| PCT/EP2009/051398 WO2009098305A2 (de) | 2008-02-08 | 2009-02-06 | Hydrolysebeständige polyamid-elastomer-mischungen, hieraus hergestellte formteile sowie deren verwendung |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| RU2010137320A RU2010137320A (ru) | 2012-03-20 |

| RU2485149C2 true RU2485149C2 (ru) | 2013-06-20 |

Family

ID=40751047

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2010137320/05A RU2485149C2 (ru) | 2008-02-08 | 2009-02-06 | Стойкие к гидролизу смеси полиамид - эластомер, формованные изделия, полученные из них, и их применение |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US20110229672A1 (enExample) |

| EP (1) | EP2242802B1 (enExample) |

| JP (1) | JP5620276B2 (enExample) |

| KR (1) | KR101691567B1 (enExample) |

| CN (1) | CN102027067B (enExample) |

| BR (1) | BRPI0908146B1 (enExample) |

| CA (1) | CA2714060C (enExample) |

| ES (1) | ES2552223T3 (enExample) |

| PL (1) | PL2242802T3 (enExample) |

| RU (1) | RU2485149C2 (enExample) |

| WO (1) | WO2009098305A2 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2724496C2 (ru) * | 2015-07-23 | 2020-06-23 | 3Рт Холдинг Птй Лтд | Искусственные древесные материалы и способы изготовления |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013532747A (ja) * | 2010-07-26 | 2013-08-19 | ディーエスエム アイピー アセッツ ビー.ブイ. | 燃料部品および燃料部品の製造方法 |

| KR101584410B1 (ko) * | 2013-12-04 | 2016-01-13 | 지에스칼텍스 주식회사 | 내열성 및 충격강도가 개선된 나일론 블렌드 조성물 및 이의 제조방법 |

| EP3053938A1 (de) | 2015-02-05 | 2016-08-10 | LANXESS Deutschland GmbH | Zusammensetzungen, enthaltend NBR-basierte Mikrogele |

| CN107043595A (zh) * | 2016-11-29 | 2017-08-15 | 安徽腾龙泵阀制造有限公司 | 一种化工泵泵体耐高温油漆 |

| CN107501554B (zh) * | 2017-09-14 | 2019-04-19 | 安徽农业大学 | 一种超高强度热塑性弹性体及其制备方法 |

| CN109265983A (zh) * | 2018-08-17 | 2019-01-25 | 北京旭阳科技有限公司 | 介电聚酰胺弹性体组合物及其制备方法 |

| US11787939B2 (en) | 2019-10-24 | 2023-10-17 | Inv Nylon Polymers Americas, Llc | Polyamide compositions and articles made therefrom |

| CN113024802B (zh) * | 2021-03-03 | 2022-02-18 | 四川大学 | 含吡咯烷酮结构无定型尼龙段的热塑性尼龙弹性体及其制备方法和应用 |

| JP7748233B2 (ja) * | 2021-09-08 | 2025-10-02 | 株式会社クラレ | 成形体、及び成形体の使用方法 |

| WO2023100065A1 (en) | 2021-12-01 | 2023-06-08 | Inv Nylon Polymers Americas, Llc | Polyamide compositions and articles made therefrom |