RU2391167C1 - Способ и устройство для намотки металлических полос на оправку - Google Patents

Способ и устройство для намотки металлических полос на оправку Download PDFInfo

- Publication number

- RU2391167C1 RU2391167C1 RU2009115695/02A RU2009115695A RU2391167C1 RU 2391167 C1 RU2391167 C1 RU 2391167C1 RU 2009115695/02 A RU2009115695/02 A RU 2009115695/02A RU 2009115695 A RU2009115695 A RU 2009115695A RU 2391167 C1 RU2391167 C1 RU 2391167C1

- Authority

- RU

- Russia

- Prior art keywords

- strip

- roller

- tension

- shaft

- winding

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES, PROFILES OR LIKE SEMI-MANUFACTURED PRODUCTS OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES, PROFILES OR LIKE SEMI-MANUFACTURED PRODUCTS OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/003—Regulation of tension or speed; Braking

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES, PROFILES OR LIKE SEMI-MANUFACTURED PRODUCTS OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/02—Winding-up or coiling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES, PROFILES OR LIKE SEMI-MANUFACTURED PRODUCTS OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/02—Winding-up or coiling

- B21C47/04—Winding-up or coiling on or in reels or drums, without using a moving guide

- B21C47/06—Winding-up or coiling on or in reels or drums, without using a moving guide with loaded rollers, bolts, or equivalent means holding the material on the reel or drum

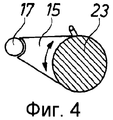

- B21C47/063—Winding-up or coiling on or in reels or drums, without using a moving guide with loaded rollers, bolts, or equivalent means holding the material on the reel or drum with pressure rollers only

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES, PROFILES OR LIKE SEMI-MANUFACTURED PRODUCTS OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/02—Winding-up or coiling

- B21C47/10—Winding-up or coiling by means of a moving guide

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES, PROFILES OR LIKE SEMI-MANUFACTURED PRODUCTS OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/34—Feeding or guiding devices not specially adapted to a particular type of apparatus

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES, PROFILES OR LIKE SEMI-MANUFACTURED PRODUCTS OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/34—Feeding or guiding devices not specially adapted to a particular type of apparatus

- B21C47/3408—Feeding or guiding devices not specially adapted to a particular type of apparatus for monitoring the lateral position of the material

- B21C47/3425—Feeding or guiding devices not specially adapted to a particular type of apparatus for monitoring the lateral position of the material without lateral edge contact

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES, PROFILES OR LIKE SEMI-MANUFACTURED PRODUCTS OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/34—Feeding or guiding devices not specially adapted to a particular type of apparatus

- B21C47/3433—Feeding or guiding devices not specially adapted to a particular type of apparatus for guiding the leading end of the material, e.g. from or to a coiler

- B21C47/3441—Diverting the leading end, e.g. from main flow to a coiling device

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES, PROFILES OR LIKE SEMI-MANUFACTURED PRODUCTS OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/34—Feeding or guiding devices not specially adapted to a particular type of apparatus

- B21C47/345—Feeding or guiding devices not specially adapted to a particular type of apparatus for monitoring the tension or advance of the material

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Winding, Rewinding, Material Storage Devices (AREA)

- Controlling Rewinding, Feeding, Winding, Or Abnormalities Of Webs (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102006045608.4 | 2006-09-25 | ||

| DE102006045608 | 2006-09-25 | ||

| DE102007045425.4 | 2007-09-21 | ||

| DE102007045425A DE102007045425A1 (de) | 2006-09-25 | 2007-09-21 | Verfahren und Vorrichtung zum Aufwickeln von Metallbändern auf einen Wickeldorn |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| RU2391167C1 true RU2391167C1 (ru) | 2010-06-10 |

Family

ID=39185155

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2009115695/02A RU2391167C1 (ru) | 2006-09-25 | 2007-09-21 | Способ и устройство для намотки металлических полос на оправку |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US20100025514A1 (enExample) |

| EP (1) | EP2109510B1 (enExample) |

| JP (1) | JP2010504216A (enExample) |

| KR (1) | KR101071117B1 (enExample) |

| CN (1) | CN101516539B (enExample) |

| BR (1) | BRPI0716770B1 (enExample) |

| CA (1) | CA2664263C (enExample) |

| DE (1) | DE102007045425A1 (enExample) |

| RU (1) | RU2391167C1 (enExample) |

| WO (1) | WO2008037395A1 (enExample) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009058875A1 (de) | 2009-12-18 | 2011-07-07 | SMS Siemag AG, 40237 | Haspelvorrichtung und Verfahren zum Betreiben einer Haspelvorrichtung |

| KR101421814B1 (ko) * | 2012-11-02 | 2014-07-22 | 주식회사 포스코 | 권취유도장치 |

| DE102012224351A1 (de) | 2012-12-21 | 2014-06-26 | Sms Siemag Ag | Verfahren und Vorrichtung zum Wickeln eines Metallbandes |

| US9908137B2 (en) | 2013-11-14 | 2018-03-06 | Illinois Tool Works Inc. | Fluid application device having a modular non-contact nozzle for applying fluid to an article |

| US9718083B2 (en) | 2013-11-14 | 2017-08-01 | Illinois Tool Works Inc. | Fluid application device having a modular nozzle assembly for applying fluid to an article |

| US9932704B2 (en) * | 2013-11-22 | 2018-04-03 | Illinois Tool Works Inc. | Fluid application device, strand engagement device and method of controlling the same |

| CN103743953B (zh) * | 2013-12-29 | 2017-01-04 | 中国计量学院 | 热双金属带材电阻随动同步连续测量系统 |

| MX374255B (es) * | 2015-05-18 | 2025-03-05 | Danieli Off Mecc | Unidad tensora para aparato de laminación. |

| PL226814B1 (pl) * | 2015-05-29 | 2017-09-29 | Przedsiębiorstwo Concept Stal B&S Lejman Spółka Jawna | Zwijarka doblachy |

| CN107774728A (zh) * | 2016-08-31 | 2018-03-09 | 扬中凯悦铜材有限公司 | 铜排拉拔收卷一体化装置 |

| CN109650123A (zh) * | 2019-02-27 | 2019-04-19 | 中冶赛迪工程技术股份有限公司 | 一种带钢穿带装置及方法 |

| JP7413547B2 (ja) | 2020-01-22 | 2024-01-15 | ノベリス・インコーポレイテッド | コイル形成動作におけるイベントの力の検知及び相殺 |

| ES2966258T3 (es) * | 2020-12-23 | 2024-04-19 | Primetals Technologies Austria GmbH | Dispositivo de bobinado para una amplia gama de grosores de bandas metálicas |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4269051A (en) * | 1978-03-31 | 1981-05-26 | Loewy Robertson Engineering Co. Ltd. | Rolling mills and operation thereof |

| WO2000041823A1 (en) * | 1999-01-11 | 2000-07-20 | Sms Demag Innse Spa | Hot rolling mill for thin strip with high-speed winding of individual strips |

| WO2003004963A1 (de) * | 2001-06-30 | 2003-01-16 | Sms Demag Aktiengesellschaft | Dünnbandhaspel mit planheitsmessrolle |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS51127988A (en) * | 1975-04-30 | 1976-11-08 | Ishikawajima Harima Heavy Ind Co Ltd | Tension control device having looper and this looper |

| JPS5865674A (ja) * | 1981-10-16 | 1983-04-19 | Ricoh Co Ltd | プリンタ |

| JPS60231516A (ja) * | 1984-04-28 | 1985-11-18 | Sumitomo Metal Ind Ltd | ル−パ機構を有する巻取機 |

| DE3507251A1 (de) * | 1985-03-01 | 1986-09-04 | SMS Schloemann-Siemag AG, 4000 Düsseldorf | Treibapparat fuer walzband |

| GB8608494D0 (en) * | 1986-04-08 | 1986-05-14 | Davy Mckee Sheffield | Strip guiding for downcoilers |

| JPH01109314U (enExample) * | 1988-01-20 | 1989-07-24 | ||

| SE461298B (sv) * | 1988-06-02 | 1990-01-29 | Asea Brown Boveri | Planhetsmaetare foer valsade band |

| CN2198987Y (zh) * | 1994-08-23 | 1995-05-31 | 陈平 | 型钢绕带式压力容器的绕带装置 |

| DE19520709A1 (de) * | 1995-06-09 | 1996-12-12 | Schloemann Siemag Ag | Treiber für Walzbänder |

| JPH10137846A (ja) * | 1996-11-06 | 1998-05-26 | Mitsubishi Heavy Ind Ltd | 熱間圧延設備の帯鋼巻取り装置 |

| DE19704447A1 (de) * | 1997-02-06 | 1998-08-13 | Schloemann Siemag Ag | Planheitsmeßrolle |

| DE19818207C2 (de) * | 1998-04-23 | 2000-05-31 | Schloemann Siemag Ag | Steckel-Warmwalzwerk |

| US6039283A (en) * | 1998-05-19 | 2000-03-21 | Hylsa S.A. De C.V. | Thin strip coiling system |

| US6146411A (en) * | 1998-12-24 | 2000-11-14 | Alsius Corporation | Cooling system for indwelling heat exchange catheter |

| US6321052B1 (en) * | 1999-09-08 | 2001-11-20 | Fuji Xerox Co., Ltd. | Method and apparatus for correcting running state and tension for an endless belt in an image-forming apparatus |

| DE19953524A1 (de) * | 1999-11-05 | 2001-05-10 | Sms Demag Ag | Schlingenheber |

| US6722087B1 (en) * | 2000-09-21 | 2004-04-20 | Mic Industries | Building panel and panel crimping machine |

| FI114391B (fi) * | 2002-04-30 | 2004-10-15 | Pesmel Oy | Kehäratarakenteen käsittävä käärintälaitteisto ja kalvonjakolaitteisto |

| DE10258499A1 (de) * | 2002-12-14 | 2004-07-01 | Sms Demag Ag | Umlenkvorrichtung einer Haspelanlage zum Aufhaspeln von Bändern |

-

2007

- 2007-09-21 EP EP07818307.6A patent/EP2109510B1/de active Active

- 2007-09-21 CN CN2007800356368A patent/CN101516539B/zh active Active

- 2007-09-21 CA CA2664263A patent/CA2664263C/en not_active Expired - Fee Related

- 2007-09-21 KR KR1020097003037A patent/KR101071117B1/ko active Active

- 2007-09-21 US US12/442,715 patent/US20100025514A1/en not_active Abandoned

- 2007-09-21 RU RU2009115695/02A patent/RU2391167C1/ru active

- 2007-09-21 DE DE102007045425A patent/DE102007045425A1/de not_active Withdrawn

- 2007-09-21 BR BRPI0716770-9A patent/BRPI0716770B1/pt active IP Right Grant

- 2007-09-21 JP JP2009528648A patent/JP2010504216A/ja active Pending

- 2007-09-21 WO PCT/EP2007/008217 patent/WO2008037395A1/de not_active Ceased

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4269051A (en) * | 1978-03-31 | 1981-05-26 | Loewy Robertson Engineering Co. Ltd. | Rolling mills and operation thereof |

| WO2000041823A1 (en) * | 1999-01-11 | 2000-07-20 | Sms Demag Innse Spa | Hot rolling mill for thin strip with high-speed winding of individual strips |

| WO2003004963A1 (de) * | 2001-06-30 | 2003-01-16 | Sms Demag Aktiengesellschaft | Dünnbandhaspel mit planheitsmessrolle |

Also Published As

| Publication number | Publication date |

|---|---|

| BRPI0716770B1 (pt) | 2019-03-26 |

| CA2664263A1 (en) | 2008-04-03 |

| CN101516539A (zh) | 2009-08-26 |

| EP2109510B1 (de) | 2014-02-12 |

| KR20090031622A (ko) | 2009-03-26 |

| CN101516539B (zh) | 2012-02-15 |

| KR101071117B1 (ko) | 2011-10-07 |

| US20100025514A1 (en) | 2010-02-04 |

| BRPI0716770A2 (pt) | 2013-09-17 |

| JP2010504216A (ja) | 2010-02-12 |

| WO2008037395A1 (de) | 2008-04-03 |

| CA2664263C (en) | 2011-04-19 |

| DE102007045425A1 (de) | 2008-04-17 |

| EP2109510A1 (de) | 2009-10-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2391167C1 (ru) | Способ и устройство для намотки металлических полос на оправку | |

| RU2391169C1 (ru) | Способ и устройство для намотки металлических лент на навивочную оправку | |

| JP2010504216A5 (enExample) | ||

| US5611500A (en) | Reel wound roll load sensing arrangement | |

| US2984429A (en) | Single rollstand web handling machine | |

| RU2442671C2 (ru) | Печная моталка | |

| CN111299351B (zh) | 带钢导向装置及其使用方法、带钢卷取系统 | |

| NO316219B1 (no) | Fremgangsmåte for å spole en papirbane | |

| JPH0756083Y2 (ja) | 出口ガイドの位置制御装置 | |

| CN107555256A (zh) | 一种织物张力控制装置 | |

| RU2820556C1 (ru) | Торсионная направляющая, направляющее устройство и соответствующий способ использования | |

| US5441213A (en) | Diameter feedback controlled winding device | |

| JP3590657B2 (ja) | ロール曲げ装置 | |

| KR20060021190A (ko) | 권취기의 스트립 선단부 굽힘 유도장치 | |

| RU2210450C1 (ru) | Устройство для центрирования рулонного материала | |

| RU2254951C1 (ru) | Устройство для центрирования рулонного материала | |

| SU1186311A1 (ru) | Н т жное устройство | |

| JPS6142642Y2 (enExample) | ||

| JP7209100B2 (ja) | 転向リール並びに転向リールの作動のための方法 | |

| KR100761740B1 (ko) | 스트립 센터링장치 | |

| JPS6093911A (ja) | ロ−ル形状測定方法及び装置 | |

| JPH0337803B2 (enExample) | ||

| KR19980033625U (ko) | 강편(billet) 소재의 전단길이 측정장치 |