RU2237649C2 - Способ дистиллятивного получения моноэтиленгликоля высокой чистоты - Google Patents

Способ дистиллятивного получения моноэтиленгликоля высокой чистоты Download PDFInfo

- Publication number

- RU2237649C2 RU2237649C2 RU2001111007A RU2001111007A RU2237649C2 RU 2237649 C2 RU2237649 C2 RU 2237649C2 RU 2001111007 A RU2001111007 A RU 2001111007A RU 2001111007 A RU2001111007 A RU 2001111007A RU 2237649 C2 RU2237649 C2 RU 2237649C2

- Authority

- RU

- Russia

- Prior art keywords

- column

- stripping

- pressure

- water

- distillation unit

- Prior art date

Links

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 title claims abstract description 55

- 238000004821 distillation Methods 0.000 title claims abstract description 28

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 11

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 52

- 238000000034 method Methods 0.000 claims abstract description 51

- 238000000926 separation method Methods 0.000 claims abstract description 17

- 230000007062 hydrolysis Effects 0.000 claims abstract description 13

- 238000006460 hydrolysis reaction Methods 0.000 claims abstract description 13

- IAYPIBMASNFSPL-UHFFFAOYSA-N Ethylene oxide Chemical compound C1CO1 IAYPIBMASNFSPL-UHFFFAOYSA-N 0.000 claims abstract description 9

- 238000000746 purification Methods 0.000 claims abstract description 9

- 239000000047 product Substances 0.000 claims description 27

- 239000006227 byproduct Substances 0.000 claims description 5

- 239000003990 capacitor Substances 0.000 claims description 2

- 239000000126 substance Substances 0.000 abstract description 6

- 239000000463 material Substances 0.000 abstract description 4

- 230000000694 effects Effects 0.000 abstract description 2

- 238000003786 synthesis reaction Methods 0.000 abstract 1

- 238000007738 vacuum evaporation Methods 0.000 abstract 1

- WSFSSNUMVMOOMR-UHFFFAOYSA-N Formaldehyde Chemical compound O=C WSFSSNUMVMOOMR-UHFFFAOYSA-N 0.000 description 55

- IKHGUXGNUITLKF-UHFFFAOYSA-N Acetaldehyde Chemical compound CC=O IKHGUXGNUITLKF-UHFFFAOYSA-N 0.000 description 39

- WGCNASOHLSPBMP-UHFFFAOYSA-N hydroxyacetaldehyde Natural products OCC=O WGCNASOHLSPBMP-UHFFFAOYSA-N 0.000 description 18

- MTHSVFCYNBDYFN-UHFFFAOYSA-N diethylene glycol Chemical compound OCCOCCO MTHSVFCYNBDYFN-UHFFFAOYSA-N 0.000 description 10

- 150000002334 glycols Chemical class 0.000 description 7

- ZIBGPFATKBEMQZ-UHFFFAOYSA-N triethylene glycol Chemical compound OCCOCCOCCO ZIBGPFATKBEMQZ-UHFFFAOYSA-N 0.000 description 6

- 150000001299 aldehydes Chemical class 0.000 description 5

- 238000009835 boiling Methods 0.000 description 5

- 239000000203 mixture Substances 0.000 description 5

- HGINCPLSRVDWNT-UHFFFAOYSA-N Acrolein Chemical compound C=CC=O HGINCPLSRVDWNT-UHFFFAOYSA-N 0.000 description 4

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 4

- 238000010926 purge Methods 0.000 description 4

- 239000002202 Polyethylene glycol Substances 0.000 description 3

- 230000005540 biological transmission Effects 0.000 description 3

- 238000009833 condensation Methods 0.000 description 3

- 230000005494 condensation Effects 0.000 description 3

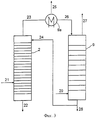

- 238000010586 diagram Methods 0.000 description 3

- 238000011031 large-scale manufacturing process Methods 0.000 description 3

- 229920001223 polyethylene glycol Polymers 0.000 description 3

- 239000007864 aqueous solution Substances 0.000 description 2

- 238000007664 blowing Methods 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 239000000945 filler Substances 0.000 description 2

- 229910052757 nitrogen Inorganic materials 0.000 description 2

- 238000010992 reflux Methods 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 241000607479 Yersinia pestis Species 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 239000003957 anion exchange resin Substances 0.000 description 1

- 230000002528 anti-freeze Effects 0.000 description 1

- 230000033228 biological regulation Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- -1 bisulfite ions Chemical class 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- MLUCVPSAIODCQM-NSCUHMNNSA-N crotonaldehyde Chemical compound C\C=C\C=O MLUCVPSAIODCQM-NSCUHMNNSA-N 0.000 description 1

- MLUCVPSAIODCQM-UHFFFAOYSA-N crotonaldehyde Natural products CC=CC=O MLUCVPSAIODCQM-UHFFFAOYSA-N 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 238000007380 fibre production Methods 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- WSFSSNUMVMOOMR-NJFSPNSNSA-N methanone Chemical compound O=[14CH2] WSFSSNUMVMOOMR-NJFSPNSNSA-N 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 150000003018 phosphorus compounds Chemical class 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 239000003507 refrigerant Substances 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 238000007086 side reaction Methods 0.000 description 1

- 238000001577 simple distillation Methods 0.000 description 1

- 238000002798 spectrophotometry method Methods 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

- 238000005292 vacuum distillation Methods 0.000 description 1

- 239000002351 wastewater Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C29/00—Preparation of compounds having hydroxy or O-metal groups bound to a carbon atom not belonging to a six-membered aromatic ring

- C07C29/74—Separation; Purification; Use of additives, e.g. for stabilisation

- C07C29/76—Separation; Purification; Use of additives, e.g. for stabilisation by physical treatment

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C29/00—Preparation of compounds having hydroxy or O-metal groups bound to a carbon atom not belonging to a six-membered aromatic ring

- C07C29/74—Separation; Purification; Use of additives, e.g. for stabilisation

- C07C29/76—Separation; Purification; Use of additives, e.g. for stabilisation by physical treatment

- C07C29/80—Separation; Purification; Use of additives, e.g. for stabilisation by physical treatment by distillation

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

- Vaporization, Distillation, Condensation, Sublimation, And Cold Traps (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19843652A DE19843652A1 (de) | 1998-09-23 | 1998-09-23 | Verfahren zur Herstellung von hochreinem Monoethylenglykol |

| DE19843652.1 | 1998-09-23 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| RU2001111007A RU2001111007A (ru) | 2003-02-10 |

| RU2237649C2 true RU2237649C2 (ru) | 2004-10-10 |

Family

ID=7881987

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2001111007A RU2237649C2 (ru) | 1998-09-23 | 1999-09-21 | Способ дистиллятивного получения моноэтиленгликоля высокой чистоты |

Country Status (20)

| Country | Link |

|---|---|

| US (1) | US6514388B1 (enExample) |

| EP (1) | EP1115681B1 (enExample) |

| JP (1) | JP4427189B2 (enExample) |

| KR (1) | KR100670881B1 (enExample) |

| CN (1) | CN1183077C (enExample) |

| AR (1) | AR020654A1 (enExample) |

| AT (1) | ATE234799T1 (enExample) |

| AU (1) | AU6466399A (enExample) |

| BR (1) | BR9913891B1 (enExample) |

| CA (1) | CA2345140C (enExample) |

| DE (2) | DE19843652A1 (enExample) |

| ES (1) | ES2194518T3 (enExample) |

| ID (1) | ID29489A (enExample) |

| MY (1) | MY122385A (enExample) |

| PL (1) | PL196671B1 (enExample) |

| RU (1) | RU2237649C2 (enExample) |

| SA (1) | SA99200782B1 (enExample) |

| TW (1) | TW498061B (enExample) |

| UA (1) | UA60381C2 (enExample) |

| WO (1) | WO2000017140A1 (enExample) |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2833951A1 (fr) * | 2001-12-21 | 2003-06-27 | Bp Chemicals Snc | Procede de fabrication et de recuperation d'oxyde d'ethylene |

| CN100413833C (zh) * | 2004-04-16 | 2008-08-27 | 中国石油化工股份有限公司上海石油化工研究院 | 环氧乙烷水合制乙二醇的方法 |

| CN1321099C (zh) * | 2005-09-28 | 2007-06-13 | 蓝仁水 | 从稀水溶液中浓缩低级多元醇的工艺方法 |

| DE602006012549D1 (de) * | 2005-12-29 | 2010-04-08 | Basf Se | Verfahren zur trennung von propylenglykol von wässrigen zusammensetzungen |

| TW200838838A (en) * | 2006-12-22 | 2008-10-01 | Dow Technology Investments Llc | Process for reducing side-reactions during alkylene glycol and poly-alkylene glycol manufacturing |

| RU2511442C2 (ru) * | 2008-10-09 | 2014-04-10 | Шелл Интернэшнл Рисерч Маатсхаппий Б.В. | Способ регенерации моноэтиленгликоля |

| WO2010053900A2 (en) * | 2008-11-10 | 2010-05-14 | Dow Technology Investments, Llc | Process for producing low color glycols |

| PL217778B1 (pl) | 2011-06-20 | 2014-08-29 | Piotr Medoń | Sposób osuszania glikolu i układ do osuszania glikolu |

| CN102951999B (zh) * | 2012-11-15 | 2014-09-10 | 四川亚联高科技股份有限公司 | 一种乙二醇生产过程中的脱水方法 |

| CN103553877B (zh) * | 2013-10-22 | 2015-06-17 | 新疆天业(集团)有限公司 | 电石炉气制乙二醇中乙二醇精馏的方法 |

| KR101527394B1 (ko) * | 2014-01-06 | 2015-06-09 | 한국과학기술원 | 원료 내 회수대상물질을 회수하는 공정에 구비되는 저용해도 염 제거장치 |

| KR102395386B1 (ko) * | 2015-04-13 | 2022-05-09 | 삼성디스플레이 주식회사 | 고순도 글리콜계 화합물의 제조방법 |

| HUE043822T2 (hu) * | 2015-12-16 | 2019-09-30 | Repsol Sa | Eljárás glikolok elõállítására |

| CN107867973A (zh) * | 2016-12-31 | 2018-04-03 | 福建双环能源科技股份有限公司 | 一种乙二醇脱水装置及使用方法 |

| GB201710508D0 (en) | 2017-06-30 | 2017-08-16 | Johnson Matthey Davy Technologies Ltd | Process |

| WO2019101707A1 (en) | 2017-11-23 | 2019-05-31 | Shell Internationale Research Maatschappij B.V. | Processes for the production of ethylene oxide and ethylene glycol |

| AU2021325856A1 (en) * | 2020-08-10 | 2023-03-09 | Auriga Polymers, Inc. | Process for purification of recovered glycol from chemical recycling of waste polyester |

| EP4567020A1 (de) | 2023-12-06 | 2025-06-11 | Basf Se | Reinigung von kühlmittelzusammensetzungen |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2510548A (en) * | 1947-06-20 | 1950-06-06 | Lummus Co | Multiple-effect distillation |

| US3875019A (en) * | 1972-12-22 | 1975-04-01 | Sir Soc Italiana Resine Spa | Recovery of ethylene glycol by plural stage distillation using vapor compression as an energy source |

| US4349417A (en) * | 1980-01-18 | 1982-09-14 | Hoechst Aktiengesellschaft | Process for the manufacture of extremely pure monoethylene glycol |

| US4622104A (en) * | 1984-05-15 | 1986-11-11 | Atochem | Process for the recovery of ethylene glycol in concentrated form |

| RU2111949C1 (ru) * | 1996-08-19 | 1998-05-27 | Акционерное общество "Нижнекамскнефтехим" | Способ извлечения моно- и диэтиленгликолей из кубового остатка процесса выделения моноэтиленгликоля |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1942094A1 (de) | 1968-08-22 | 1970-02-26 | Union Carbide Corp | Verfahren zur Reinigung von verunreinigten Glykolen |

| US3847754A (en) * | 1970-08-03 | 1974-11-12 | Ppg Industries Inc | Recovery of glycols from mixed glycol composition by distillation with acid treatment |

| DE3338488A1 (de) | 1982-10-29 | 1984-05-03 | Basf Ag, 6700 Ludwigshafen | Verfahren zur gewinnung von temperaturempfindlichen produkten durch thermisch schonende destillation mittels eines mit einer destillationskolonne verbundenen duennschichtverdampfers und eine anordnung zur durchfuehrung des verfahrens |

| JPS6089439A (ja) | 1983-10-24 | 1985-05-20 | Mitsui Toatsu Chem Inc | エチレングリコ−ルの製造方法 |

| DE19602116A1 (de) | 1996-01-22 | 1997-07-24 | Basf Ag | Verfahren zur Gewinnung von Glykolen mit niedrigem Aldehydgehalt |

-

1998

- 1998-09-23 DE DE19843652A patent/DE19843652A1/de not_active Withdrawn

-

1999

- 1999-09-09 TW TW088115551A patent/TW498061B/zh not_active IP Right Cessation

- 1999-09-18 MY MYPI99004056A patent/MY122385A/en unknown

- 1999-09-21 PL PL346752A patent/PL196671B1/pl unknown

- 1999-09-21 UA UA2001042715A patent/UA60381C2/uk unknown

- 1999-09-21 KR KR1020017003680A patent/KR100670881B1/ko not_active Expired - Lifetime

- 1999-09-21 CN CNB998111538A patent/CN1183077C/zh not_active Expired - Lifetime

- 1999-09-21 RU RU2001111007A patent/RU2237649C2/ru active

- 1999-09-21 CA CA002345140A patent/CA2345140C/en not_active Expired - Lifetime

- 1999-09-21 US US09/744,433 patent/US6514388B1/en not_active Expired - Lifetime

- 1999-09-21 EP EP99952457A patent/EP1115681B1/de not_active Expired - Lifetime

- 1999-09-21 ES ES99952457T patent/ES2194518T3/es not_active Expired - Lifetime

- 1999-09-21 WO PCT/EP1999/006967 patent/WO2000017140A1/de not_active Ceased

- 1999-09-21 AT AT99952457T patent/ATE234799T1/de not_active IP Right Cessation

- 1999-09-21 ID IDW20010666A patent/ID29489A/id unknown

- 1999-09-21 DE DE59904662T patent/DE59904662D1/de not_active Expired - Lifetime

- 1999-09-21 JP JP2000574052A patent/JP4427189B2/ja not_active Expired - Lifetime

- 1999-09-21 BR BRPI9913891-3A patent/BR9913891B1/pt not_active IP Right Cessation

- 1999-09-21 AU AU64663/99A patent/AU6466399A/en not_active Abandoned

- 1999-09-22 AR ARP990104762A patent/AR020654A1/es active IP Right Grant

- 1999-11-30 SA SA99200782A patent/SA99200782B1/ar unknown

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2510548A (en) * | 1947-06-20 | 1950-06-06 | Lummus Co | Multiple-effect distillation |

| US3875019A (en) * | 1972-12-22 | 1975-04-01 | Sir Soc Italiana Resine Spa | Recovery of ethylene glycol by plural stage distillation using vapor compression as an energy source |

| US4349417A (en) * | 1980-01-18 | 1982-09-14 | Hoechst Aktiengesellschaft | Process for the manufacture of extremely pure monoethylene glycol |

| US4622104A (en) * | 1984-05-15 | 1986-11-11 | Atochem | Process for the recovery of ethylene glycol in concentrated form |

| RU2111949C1 (ru) * | 1996-08-19 | 1998-05-27 | Акционерное общество "Нижнекамскнефтехим" | Способ извлечения моно- и диэтиленгликолей из кубового остатка процесса выделения моноэтиленгликоля |

Also Published As

| Publication number | Publication date |

|---|---|

| CA2345140C (en) | 2009-06-16 |

| TW498061B (en) | 2002-08-11 |

| MY122385A (en) | 2006-04-29 |

| BR9913891A (pt) | 2001-07-03 |

| JP4427189B2 (ja) | 2010-03-03 |

| SA99200782B1 (ar) | 2006-07-31 |

| AU6466399A (en) | 2000-04-10 |

| KR100670881B1 (ko) | 2007-01-18 |

| EP1115681B1 (de) | 2003-03-19 |

| US6514388B1 (en) | 2003-02-04 |

| PL346752A1 (en) | 2002-02-25 |

| BR9913891B1 (pt) | 2011-01-11 |

| UA60381C2 (uk) | 2003-10-15 |

| CN1183077C (zh) | 2005-01-05 |

| DE19843652A1 (de) | 2000-03-30 |

| AR020654A1 (es) | 2002-05-22 |

| CA2345140A1 (en) | 2000-03-30 |

| JP2002526462A (ja) | 2002-08-20 |

| ID29489A (id) | 2001-08-30 |

| CN1319079A (zh) | 2001-10-24 |

| WO2000017140A1 (de) | 2000-03-30 |

| PL196671B1 (pl) | 2008-01-31 |

| EP1115681A1 (de) | 2001-07-18 |

| ATE234799T1 (de) | 2003-04-15 |

| ES2194518T3 (es) | 2003-11-16 |

| KR20010075294A (ko) | 2001-08-09 |

| DE59904662D1 (de) | 2003-04-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2237649C2 (ru) | Способ дистиллятивного получения моноэтиленгликоля высокой чистоты | |

| US4039395A (en) | Purification of acetic acid | |

| FI80218C (fi) | Foerfarande och anlaeggning foer rening av en tvaokomponentvaetskeblandning medelst destillering. | |

| JP3712903B2 (ja) | グリセリンの製造方法 | |

| US20020010378A1 (en) | Method for production of ethylene oxide | |

| RU2235710C2 (ru) | Способ получения высокочистого моноэтиленгликоля | |

| CN1443157A (zh) | 改进的乙腈精制和回收方法 | |

| EP1888194B1 (en) | New stripper configuration for the production of ethylene oxide | |

| US4966657A (en) | Process for separating ethylene oxide from aldehyde impurities by distillation | |

| CN111328325B (zh) | 生产环氧乙烷和乙二醇的方法 | |

| EP2934712B1 (en) | Production of ethanol products | |

| US6395142B1 (en) | Method and apparatus for purifying low grade acetonitrile and other constituents from hazardous waste | |

| KR20000028897A (ko) | 공정흐름을 정제하기 위한 방법 | |

| JP2001031600A (ja) | 高純度モノエチレングリコールの製法 | |

| RU2785430C2 (ru) | Способы производства этиленоксида и этиленгликоля | |

| MXPA01002578A (en) | Method for producing highly pure monoethylene glycol | |

| MXPA01002968A (en) | Method for producing highly pure monoethylene glycol | |

| RU2186053C2 (ru) | Способ получения моноэтиленгликоля волоконной чистоты | |

| RU2317970C2 (ru) | Очистка 1,3-пропандиола путем перегонки |