KR20110020760A - 선택된 물질의 패턴 식각 방법 - Google Patents

선택된 물질의 패턴 식각 방법 Download PDFInfo

- Publication number

- KR20110020760A KR20110020760A KR1020107019558A KR20107019558A KR20110020760A KR 20110020760 A KR20110020760 A KR 20110020760A KR 1020107019558 A KR1020107019558 A KR 1020107019558A KR 20107019558 A KR20107019558 A KR 20107019558A KR 20110020760 A KR20110020760 A KR 20110020760A

- Authority

- KR

- South Korea

- Prior art keywords

- layer

- etching

- treated

- component

- predetermined pattern

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10F—INORGANIC SEMICONDUCTOR DEVICES SENSITIVE TO INFRARED RADIATION, LIGHT, ELECTROMAGNETIC RADIATION OF SHORTER WAVELENGTH OR CORPUSCULAR RADIATION

- H10F77/00—Constructional details of devices covered by this subclass

- H10F77/20—Electrodes

- H10F77/206—Electrodes for devices having potential barriers

- H10F77/211—Electrodes for devices having potential barriers for photovoltaic cells

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/3105—After-treatment

- H01L21/311—Etching the insulating layers by chemical or physical means

- H01L21/31105—Etching inorganic layers

- H01L21/31111—Etching inorganic layers by chemical means

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/50—Photovoltaic [PV] energy

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Inorganic Chemistry (AREA)

- Physics & Mathematics (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Weting (AREA)

- Photovoltaic Devices (AREA)

- Electrodes Of Semiconductors (AREA)

Applications Claiming Priority (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AU2008900477A AU2008900477A0 (en) | 2008-02-01 | Method of processing | |

| AU2008900477 | 2008-02-01 | ||

| AU2008903289A AU2008903289A0 (en) | 2008-06-27 | Method for patterned etching of selected material | |

| AU2008903289 | 2008-06-27 | ||

| AU2008906040A AU2008906040A0 (en) | 2008-11-21 | Method for patterened etching of selected material | |

| AU2008906040 | 2008-11-21 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20110020760A true KR20110020760A (ko) | 2011-03-03 |

Family

ID=40912168

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020107019558A Withdrawn KR20110020760A (ko) | 2008-02-01 | 2009-01-29 | 선택된 물질의 패턴 식각 방법 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US8273659B2 (enExample) |

| EP (1) | EP2245655A4 (enExample) |

| JP (1) | JP5242703B2 (enExample) |

| KR (1) | KR20110020760A (enExample) |

| CN (1) | CN101990705A (enExample) |

| AU (1) | AU2009208384A1 (enExample) |

| TW (1) | TW200947555A (enExample) |

| WO (1) | WO2009094711A1 (enExample) |

Families Citing this family (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011017740A1 (en) * | 2009-08-11 | 2011-02-17 | Newsouth Innovations Pty Limited | A method for the selective delivery of material to a substrate |

| CA2774442A1 (en) * | 2009-09-18 | 2011-03-24 | Merck Patent Gmbh | Ink jet printable etching inks and associated process |

| WO2011032218A1 (en) * | 2009-09-18 | 2011-03-24 | Newsouth Innovations Pty Limited | Method for texturing surfaces |

| EP2363299B1 (en) | 2010-03-05 | 2012-10-17 | Spanolux N.V.- DIV. Balterio | A method of manufacturing a floor board |

| KR101399419B1 (ko) * | 2011-04-26 | 2014-06-30 | 엔젯 주식회사 | 태양전지의 전면전극 형성방법 |

| CN102320752B (zh) * | 2011-06-09 | 2013-06-19 | 中国科学院化学研究所 | 材料的图案化方法 |

| WO2013062727A1 (en) * | 2011-10-24 | 2013-05-02 | Applied Materials, Inc. | Method and apparatus of removing a passivation film and improving contact resistance in rear point contact solar cells |

| CN103091747B (zh) * | 2011-10-28 | 2015-11-25 | 清华大学 | 一种光栅的制备方法 |

| CN103086607B (zh) | 2011-10-28 | 2015-08-26 | 清华大学 | 光栅的制备方法 |

| WO2014071458A1 (en) * | 2012-11-09 | 2014-05-15 | Newsouth Innovations Pty Ltd | Formation of metal contacts |

| US8815633B1 (en) * | 2013-04-18 | 2014-08-26 | National Tsing Hua University | Method of fabricating 3D structure on CIGS material |

| TWI480947B (zh) * | 2013-04-18 | 2015-04-11 | Nat Univ Tsing Hua | 於銅銦鎵硒製備三維結構的方法 |

| CN103606634B (zh) * | 2013-11-14 | 2016-02-10 | 中国科学院化学研究所 | 一种图案化金属电极及其制备方法 |

| KR102290209B1 (ko) * | 2013-12-31 | 2021-08-20 | 엔테그리스, 아이엔씨. | 규소 및 게르마늄을 선택적으로 에칭하기 위한 배합물 |

| KR20170008291A (ko) * | 2014-05-20 | 2017-01-23 | 알파 메탈즈, 인코포레이티드 | 태양 전지 및 반도체 제작을 위한 분사가능한 잉크 |

| WO2016149043A1 (en) * | 2015-03-13 | 2016-09-22 | Dow Global Technologies Llc | Nanostructure material methods and devices |

| TWI593547B (zh) * | 2015-11-13 | 2017-08-01 | 財團法人工業技術研究院 | 三維組織列印裝置、三維組織列印方法及人工皮膚 |

| WO2017109786A1 (en) | 2015-12-23 | 2017-06-29 | Kornit Digital Ltd. | Rub-resistant inkjet composition |

| CN109932354B (zh) * | 2019-05-06 | 2021-10-08 | 中山大学 | 一种用于表面增强拉曼光谱痕量分析的原位分离富集装置及应用 |

| CN110634795B (zh) * | 2019-10-23 | 2022-12-02 | 京东方科技集团股份有限公司 | 阵列基板的制备方法、阵列基板及显示装置 |

| CN110760847B (zh) * | 2019-11-28 | 2022-06-17 | 东莞市图创智能制造有限公司 | 使用喷墨打印的蚀刻方法及用于蚀刻方法的喷墨打印机 |

| JP7513454B2 (ja) * | 2020-07-27 | 2024-07-09 | 株式会社Screenホールディングス | 基板処理方法および基板処理装置 |

| JP7580217B2 (ja) * | 2020-07-27 | 2024-11-11 | 株式会社Screenホールディングス | 基板処理方法、基板処理装置、および、処理液 |

| US20220035251A1 (en) * | 2020-07-31 | 2022-02-03 | Applied Materials, Inc. | Methods to fabricate 2d wedge and localized encapsulation for diffractive optics |

| CN114106588B (zh) * | 2020-08-25 | 2023-01-03 | 上海迪赢生物科技有限公司 | 一种用于3d喷墨法高通量核酸原位合成的功能化表面处理方法 |

| JP7606896B2 (ja) * | 2021-03-19 | 2024-12-26 | 株式会社Screenホールディングス | 基板処理方法、および、基板処理装置 |

| JP7682656B2 (ja) * | 2021-03-19 | 2025-05-26 | 株式会社Screenホールディングス | 基板処理方法、および、基板処理装置 |

| JP7603517B2 (ja) * | 2021-04-26 | 2024-12-20 | 株式会社Screenホールディングス | 基板処理方法、および、基板処理装置 |

| KR102874254B1 (ko) * | 2021-07-16 | 2025-10-21 | 삼성디스플레이 주식회사 | 표시 장치 및 표시 장치의 제조방법 |

| CN115613032B (zh) * | 2022-10-11 | 2024-09-20 | 苏州华星光电技术有限公司 | 蚀刻液 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0325937A (ja) * | 1989-06-22 | 1991-02-04 | Mitsubishi Electric Corp | 半導体装置の製造方法 |

| JPH04288649A (ja) | 1991-02-20 | 1992-10-13 | Mitsubishi Electric Corp | メモリ装置 |

| FR2775280B1 (fr) * | 1998-02-23 | 2000-04-14 | Saint Gobain Vitrage | Procede de gravure d'une couche conductrice |

| AU779878B2 (en) * | 1999-12-21 | 2005-02-17 | Flexenable Limited | Forming interconnects |

| KR100940110B1 (ko) * | 1999-12-21 | 2010-02-02 | 플라스틱 로직 리미티드 | 잉크젯으로 제조되는 집적회로 및 전자 디바이스 제조 방법 |

| KR100812891B1 (ko) * | 2000-04-28 | 2008-03-11 | 메르크 파텐트 게엠베하 | 무기물 표면용 에칭 페이스트 |

| GB2367788A (en) * | 2000-10-16 | 2002-04-17 | Seiko Epson Corp | Etching using an ink jet print head |

| US7384862B2 (en) * | 2003-06-30 | 2008-06-10 | Semiconductor Energy Laboratory Co., Ltd. | Method for fabricating semiconductor device and display device |

| TWI228389B (en) * | 2003-12-26 | 2005-02-21 | Ind Tech Res Inst | Method for forming conductive plugs |

| JP4575098B2 (ja) * | 2004-09-28 | 2010-11-04 | 株式会社東芝 | パターン形成方法および電子デバイスの製造方法 |

| TW200620451A (en) * | 2004-11-09 | 2006-06-16 | Univ Osaka | Method for forming hole in crystal substrate, and crystal substrate having hole formed by the method |

| US8367551B2 (en) * | 2005-03-25 | 2013-02-05 | E I Du Pont De Nemours And Company | Spin-printing of etchants and modifiers |

| JP4657068B2 (ja) * | 2005-09-22 | 2011-03-23 | シャープ株式会社 | 裏面接合型太陽電池の製造方法 |

| JP5201789B2 (ja) * | 2005-11-14 | 2013-06-05 | シャープ株式会社 | 太陽電池およびその製造方法 |

| JP2009524523A (ja) * | 2006-01-25 | 2009-07-02 | フラオンホファー−ゲゼルシャフト・ツア・フェルデルング・デア・アンゲヴァンテン・フォルシュング・エー・ファオ | 基板を精密加工するための方法および装置ならびにその使用 |

| US7416989B1 (en) * | 2006-06-30 | 2008-08-26 | Novellus Systems, Inc. | Adsorption based material removal process |

| AU2008210253A1 (en) * | 2007-01-31 | 2008-08-07 | Newsouth Innovations Pty Limited | Method of forming openings in selected material |

-

2009

- 2009-01-29 AU AU2009208384A patent/AU2009208384A1/en not_active Abandoned

- 2009-01-29 JP JP2010544535A patent/JP5242703B2/ja not_active Expired - Fee Related

- 2009-01-29 CN CN2009801115599A patent/CN101990705A/zh active Pending

- 2009-01-29 KR KR1020107019558A patent/KR20110020760A/ko not_active Withdrawn

- 2009-01-29 WO PCT/AU2009/000098 patent/WO2009094711A1/en not_active Ceased

- 2009-01-29 EP EP09706758A patent/EP2245655A4/en not_active Withdrawn

- 2009-02-02 TW TW098103223A patent/TW200947555A/zh unknown

-

2010

- 2010-07-30 US US12/847,061 patent/US8273659B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN101990705A (zh) | 2011-03-23 |

| JP2011511442A (ja) | 2011-04-07 |

| EP2245655A4 (en) | 2012-11-21 |

| WO2009094711A1 (en) | 2009-08-06 |

| JP5242703B2 (ja) | 2013-07-24 |

| US8273659B2 (en) | 2012-09-25 |

| EP2245655A1 (en) | 2010-11-03 |

| TW200947555A (en) | 2009-11-16 |

| US20110111599A1 (en) | 2011-05-12 |

| AU2009208384A1 (en) | 2009-08-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20110020760A (ko) | 선택된 물질의 패턴 식각 방법 | |

| TWI481693B (zh) | 二組份蝕刻 | |

| US7837890B2 (en) | Printable medium for the etching of silicon dioxide and silicon nitride layers | |

| US8398877B2 (en) | Method of forming openings in selected material | |

| US20120196444A1 (en) | Method for the selective delivery of material to a substrate | |

| CN100546006C (zh) | 蚀刻硅的改进方法 | |

| JP2007505487A (ja) | 有機樹脂材料に開口部を形成する方法の改良 | |

| WO2011032218A1 (en) | Method for texturing surfaces | |

| EP2170611B1 (en) | Fluid ejector device | |

| Newby et al. | Inkjet printing of fluorinated materials and their application to patterning organic semiconductors | |

| US20170330780A1 (en) | Method and device for treating the underside of a substrate | |

| US20240247113A1 (en) | Method of forming an aqueous polymer composition | |

| CN101636829A (zh) | 在选定材料中形成开口的方法 | |

| JP6562789B2 (ja) | 除去対象物の除去方法 | |

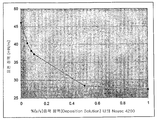

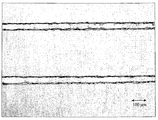

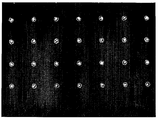

| Lennon et al. | Maskless patterned etching of silicon dioxide by inkjet printing | |

| KR20190123855A (ko) | 다중 스케일 실리콘 패턴 제조 방법 및 그 방법으로 제조된 디바이스 | |

| HK1169136B (en) | Two component etching |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20100901 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |