KR20110008319A - 액체 내에 가스의 무기포 용액을 제조하기 위한 기화 시스템 및 방법 - Google Patents

액체 내에 가스의 무기포 용액을 제조하기 위한 기화 시스템 및 방법 Download PDFInfo

- Publication number

- KR20110008319A KR20110008319A KR1020107027647A KR20107027647A KR20110008319A KR 20110008319 A KR20110008319 A KR 20110008319A KR 1020107027647 A KR1020107027647 A KR 1020107027647A KR 20107027647 A KR20107027647 A KR 20107027647A KR 20110008319 A KR20110008319 A KR 20110008319A

- Authority

- KR

- South Korea

- Prior art keywords

- gas

- liquid

- contactor

- feed

- flow rate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 239000007788 liquid Substances 0.000 title claims abstract description 467

- 238000009834 vaporization Methods 0.000 title claims description 76

- 238000000034 method Methods 0.000 title claims description 71

- 230000008016 vaporization Effects 0.000 title claims description 68

- 239000006260 foam Substances 0.000 title description 3

- 239000007789 gas Substances 0.000 claims description 560

- 239000012528 membrane Substances 0.000 claims description 103

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 claims description 55

- 230000008859 change Effects 0.000 claims description 45

- 239000001569 carbon dioxide Substances 0.000 claims description 27

- 229910002092 carbon dioxide Inorganic materials 0.000 claims description 27

- 239000012530 fluid Substances 0.000 claims description 26

- 238000004891 communication Methods 0.000 claims description 18

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 12

- 238000012423 maintenance Methods 0.000 claims description 10

- 229910052757 nitrogen Inorganic materials 0.000 claims description 5

- 230000007935 neutral effect Effects 0.000 claims description 3

- 238000001704 evaporation Methods 0.000 claims description 2

- 238000002309 gasification Methods 0.000 claims 1

- 230000004044 response Effects 0.000 abstract description 8

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 172

- 239000000203 mixture Substances 0.000 description 49

- 230000008569 process Effects 0.000 description 27

- 239000000243 solution Substances 0.000 description 23

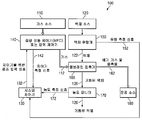

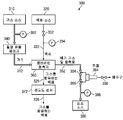

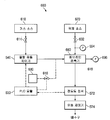

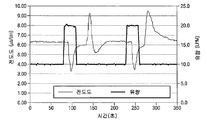

- 238000010586 diagram Methods 0.000 description 19

- 238000004519 manufacturing process Methods 0.000 description 14

- 238000004140 cleaning Methods 0.000 description 13

- 239000012510 hollow fiber Substances 0.000 description 13

- 238000002156 mixing Methods 0.000 description 13

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 12

- 238000002347 injection Methods 0.000 description 12

- 239000007924 injection Substances 0.000 description 12

- 235000012431 wafers Nutrition 0.000 description 11

- 229920001774 Perfluoroether Polymers 0.000 description 10

- 239000003085 diluting agent Substances 0.000 description 9

- 239000004065 semiconductor Substances 0.000 description 9

- 239000011261 inert gas Substances 0.000 description 8

- 238000010926 purge Methods 0.000 description 8

- 238000005259 measurement Methods 0.000 description 7

- 230000001276 controlling effect Effects 0.000 description 6

- 238000010790 dilution Methods 0.000 description 6

- 239000012895 dilution Substances 0.000 description 6

- 239000011148 porous material Substances 0.000 description 6

- 230000000875 corresponding effect Effects 0.000 description 5

- 230000003247 decreasing effect Effects 0.000 description 5

- 239000008367 deionised water Substances 0.000 description 5

- 229910021641 deionized water Inorganic materials 0.000 description 5

- 238000007865 diluting Methods 0.000 description 5

- 238000012986 modification Methods 0.000 description 5

- 230000004048 modification Effects 0.000 description 5

- 239000002245 particle Substances 0.000 description 5

- 238000012546 transfer Methods 0.000 description 5

- 238000007792 addition Methods 0.000 description 4

- 239000012159 carrier gas Substances 0.000 description 4

- 238000009833 condensation Methods 0.000 description 4

- 230000005494 condensation Effects 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 238000003860 storage Methods 0.000 description 4

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 238000013500 data storage Methods 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 238000012544 monitoring process Methods 0.000 description 3

- 230000000737 periodic effect Effects 0.000 description 3

- 229920000642 polymer Polymers 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- 230000008707 rearrangement Effects 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 238000006467 substitution reaction Methods 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000004364 calculation method Methods 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- 239000000356 contaminant Substances 0.000 description 2

- 238000007796 conventional method Methods 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 238000007872 degassing Methods 0.000 description 2

- 238000003113 dilution method Methods 0.000 description 2

- 238000004090 dissolution Methods 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 230000006870 function Effects 0.000 description 2

- 230000002209 hydrophobic effect Effects 0.000 description 2

- -1 hydroxyl ions Chemical class 0.000 description 2

- 150000002500 ions Chemical class 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 239000013307 optical fiber Substances 0.000 description 2

- 230000001105 regulatory effect Effects 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 238000005507 spraying Methods 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- 229910021642 ultra pure water Inorganic materials 0.000 description 2

- 239000012498 ultrapure water Substances 0.000 description 2

- 239000006096 absorbing agent Substances 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 230000005465 channeling Effects 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 238000004587 chromatography analysis Methods 0.000 description 1

- 230000000052 comparative effect Effects 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 230000001934 delay Effects 0.000 description 1

- 239000002274 desiccant Substances 0.000 description 1

- 230000001066 destructive effect Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000010494 dissociation reaction Methods 0.000 description 1

- 230000005593 dissociations Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 230000003631 expected effect Effects 0.000 description 1

- 238000004817 gas chromatography Methods 0.000 description 1

- 210000003127 knee Anatomy 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000006386 neutralization reaction Methods 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 238000000206 photolithography Methods 0.000 description 1

- 229920002120 photoresistant polymer Polymers 0.000 description 1

- 230000035479 physiological effects, processes and functions Effects 0.000 description 1

- 238000005498 polishing Methods 0.000 description 1

- 238000007517 polishing process Methods 0.000 description 1

- 238000004886 process control Methods 0.000 description 1

- 239000000047 product Substances 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- 238000011084 recovery Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 239000000523 sample Substances 0.000 description 1

- 239000002002 slurry Substances 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

- 239000008400 supply water Substances 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

- 238000010998 test method Methods 0.000 description 1

- 238000010257 thawing Methods 0.000 description 1

- 230000001052 transient effect Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000009849 vacuum degassing Methods 0.000 description 1

- 238000013022 venting Methods 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

- 238000001039 wet etching Methods 0.000 description 1

- 238000009736 wetting Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/20—Mixing gases with liquids

- B01F23/23—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids

- B01F23/2319—Methods of introducing gases into liquid media

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/20—Mixing gases with liquids

- B01F23/23—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids

- B01F23/231—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids by bubbling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/20—Mixing gases with liquids

- B01F23/29—Mixing systems, i.e. flow charts or diagrams

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F35/00—Accessories for mixers; Auxiliary operations or auxiliary devices; Parts or details of general application

- B01F35/20—Measuring; Control or regulation

- B01F35/21—Measuring

- B01F35/213—Measuring of the properties of the mixtures, e.g. temperature, density or colour

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/20—Mixing gases with liquids

- B01F23/23—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids

- B01F23/231—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids by bubbling

- B01F23/23105—Arrangement or manipulation of the gas bubbling devices

- B01F23/2312—Diffusers

- B01F23/23124—Diffusers consisting of flexible porous or perforated material, e.g. fabric

- B01F23/231244—Dissolving, hollow fiber membranes

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/0318—Processes

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Degasification And Air Bubble Elimination (AREA)

- Separation Using Semi-Permeable Membranes (AREA)

- Accessories For Mixers (AREA)

Applications Claiming Priority (8)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US5422308P | 2008-05-19 | 2008-05-19 | |

| US61/054,223 | 2008-05-19 | ||

| US8253508P | 2008-07-22 | 2008-07-22 | |

| US61/082,535 | 2008-07-22 | ||

| US9523008P | 2008-09-08 | 2008-09-08 | |

| US61/095,230 | 2008-09-08 | ||

| US10150108P | 2008-09-30 | 2008-09-30 | |

| US61/101,501 | 2008-09-30 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20110008319A true KR20110008319A (ko) | 2011-01-26 |

Family

ID=41340494

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020107027647A Ceased KR20110008319A (ko) | 2008-05-19 | 2009-05-18 | 액체 내에 가스의 무기포 용액을 제조하기 위한 기화 시스템 및 방법 |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US8844909B2 (enExample) |

| JP (1) | JP2011520609A (enExample) |

| KR (1) | KR20110008319A (enExample) |

| CN (2) | CN104722239A (enExample) |

| DE (1) | DE112009001233T5 (enExample) |

| TW (1) | TW201004707A (enExample) |

| WO (1) | WO2009143056A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20200139630A (ko) * | 2019-06-04 | 2020-12-14 | 가부시키가이샤 에바라 세이사꾸쇼 | 가스 용해액 공급 장치 및 가스 용해액 공급 방법 |

Families Citing this family (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010234298A (ja) * | 2009-03-31 | 2010-10-21 | Kurita Water Ind Ltd | ガス溶解水供給装置及びガス溶解水の製造方法 |

| US8438969B2 (en) * | 2010-05-06 | 2013-05-14 | Dr Pepper/Seven Up, Inc. | Apparatus and method for dissolving gases in a beverage |

| US9403102B2 (en) * | 2012-02-13 | 2016-08-02 | United Technologies Corporation | Heat exchange system configured with a membrane contactor |

| JP5914037B2 (ja) * | 2012-02-23 | 2016-05-11 | 東京エレクトロン株式会社 | 冷却システム、冷却システムを備える基板処理装置及び冷却方法 |

| CN102692926B (zh) * | 2012-06-05 | 2014-10-22 | 哈尔滨工程大学 | 基于tms320c6713的船舶航向模糊pid融合控制器及控制方法 |

| GB2506689A (en) * | 2012-10-08 | 2014-04-09 | Odour Services Internat Ltd | Air pollution control apparatus and method of use |

| CA2902061C (en) * | 2013-02-28 | 2023-08-08 | New Health Sciences, Inc. | Gas depletion and gas addition devices for blood treatment |

| WO2015175790A1 (en) * | 2014-05-15 | 2015-11-19 | Tokyo Electron Limited | Method and apparatus for increased recirculation and filtration in a photoresist dispense system |

| AU2015100137A4 (en) * | 2015-01-12 | 2015-03-05 | Macau University Of Science And Technology | Optimization of Start-up Transient Processes for Dual-Armed Cluster Tools with Wafer Revisiting |

| JP6993626B2 (ja) * | 2015-04-10 | 2022-01-13 | タカラベルモント株式会社 | 炭酸水生成装置 |

| EP3284530A4 (en) * | 2015-04-13 | 2018-12-19 | DIC Corporation | Device for adjusting specific resistance value and method for adjusting specific resistance value |

| FR3036629B1 (fr) | 2015-05-29 | 2019-06-21 | Nicolas POURTAUD | Dispositif de regulation de la concentration d'un gaz dans un liquide |

| JP6761431B2 (ja) * | 2016-01-06 | 2020-09-23 | 国立大学法人徳島大学 | レーザ光を用いたガス分析装置及びガス分析方法 |

| US10228355B2 (en) | 2016-05-06 | 2019-03-12 | Board Of Regents, The University Of Texas System | Volatile eluent preparation |

| CN106474768B (zh) * | 2016-09-12 | 2019-01-29 | 华中科技大学 | 一种高精度耐腐蚀的自动配液换液装置 |

| WO2018085892A1 (en) * | 2016-11-11 | 2018-05-17 | PTI Pacific Pty Ltd | Modular system for gassing and degassing liquids |

| CN110168713B (zh) * | 2016-11-11 | 2023-08-08 | Mks仪器有限公司 | 用于产生包括其中溶解有氨气的去离子水的导电液体的系统和方法 |

| EP3601147A4 (en) * | 2017-03-28 | 2021-01-06 | Flow Control LLC. | Gas/liquid infusion system with intelligent level management and adjustable absorption output |

| CN108854609B (zh) * | 2017-05-10 | 2025-08-12 | 青岛经济技术开发区海尔热水器有限公司 | 一种微气泡水生产装置 |

| JP7052423B2 (ja) * | 2018-03-02 | 2022-04-12 | 栗田工業株式会社 | オゾン溶解水の製造装置及びこれを用いたオゾン溶解水の製造方法 |

| WO2020210243A1 (en) | 2019-04-08 | 2020-10-15 | Mks Instruments, Inc. | Systems and methods for generating a dissolved ammonia solution with reduced dissolved carrier gas and oxygen content |

| CN110773012A (zh) * | 2019-12-02 | 2020-02-11 | 杭州老板电器股份有限公司 | 微纳米气泡制备装置及其制备方法 |

| JP2024546262A (ja) * | 2021-12-14 | 2024-12-19 | エムケーエス インストゥルメンツ,インコーポレイテッド | 溶解アンモニアデリバリシステム及び使用方法 |

| CN118893499B (zh) * | 2024-09-12 | 2025-11-14 | 福建理工大学 | 一种基于pid控制气体辅助抛光系统的设计方法 |

Family Cites Families (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3751879A (en) * | 1971-04-26 | 1973-08-14 | Instrumentation Specialties Co | Apparatus for reducing the dissolved gas concentration in a liquid |

| DE68926421T2 (de) * | 1988-08-20 | 1996-09-12 | Nitto Denko Corp | Verfahren zur Entfernung von gelösten Gasen aus einer Flüssigkeit |

| US5565149A (en) | 1995-03-15 | 1996-10-15 | Permea, Inc. | Control of dissolved gases in liquids |

| US5766479A (en) | 1995-08-07 | 1998-06-16 | Zenon Environmental Inc. | Production of high purity water using reverse osmosis |

| JPH10324502A (ja) | 1997-05-21 | 1998-12-08 | Dainippon Ink & Chem Inc | 超純水の炭酸ガス付加装置及び付加方法 |

| US6582496B1 (en) | 2000-01-28 | 2003-06-24 | Mykrolis Corporation | Hollow fiber membrane contactor |

| US6328905B1 (en) | 1999-08-12 | 2001-12-11 | Advanced Micro Devices, Inc. | Residue removal by CO2 water rinse in conjunction with post metal etch plasma strip |

| US6982006B1 (en) * | 1999-10-19 | 2006-01-03 | Boyers David G | Method and apparatus for treating a substrate with an ozone-solvent solution |

| US6805791B2 (en) | 2000-09-01 | 2004-10-19 | Applied Science And Technology, Inc. | Ozonated water flow and concentration control apparatus |

| US6884359B2 (en) | 2000-09-27 | 2005-04-26 | Dainippon Ink And Chemicals, Inc. | Apparatus and method for controlling resistivity of ultra pure water |

| JP2002233878A (ja) * | 2001-02-06 | 2002-08-20 | Roki Techno Co Ltd | 給水配管の殺菌洗浄方法 |

| CN100469425C (zh) * | 2001-08-28 | 2009-03-18 | 三菱丽阳株式会社 | 碳酸泉和碳酸水的制造装置及制造方法、及其应用的气体浓度控制方法和膜组件 |

| JP2003154242A (ja) * | 2001-11-26 | 2003-05-27 | Texas Instr Japan Ltd | 流体混合装置 |

| CN1642628B (zh) * | 2002-03-19 | 2010-06-16 | 安格斯公司 | 中空纤维膜接触装置及方法 |

| JP4319445B2 (ja) | 2002-06-20 | 2009-08-26 | 大日本スクリーン製造株式会社 | 基板処理装置 |

| JP2004130205A (ja) * | 2002-10-10 | 2004-04-30 | Fuji Electric Systems Co Ltd | オゾン含有水を用いたろ過膜の逆洗方法および逆洗装置 |

| JP2006524133A (ja) | 2003-04-22 | 2006-10-26 | インテグリス・インコーポレーテッド | 気体移送薄膜をもたらすためのプリ−ツ形構造 |

| JP4330959B2 (ja) | 2003-09-05 | 2009-09-16 | 株式会社東芝 | 半導体基板の洗浄方法および洗浄装置、半導体基板、ならびに半導体装置 |

| US7273549B2 (en) | 2004-01-23 | 2007-09-25 | Geoscience Support Services Inc. | Membrane contactor apparatus including a module having hollow fiber membranes |

| CN1913946A (zh) | 2004-01-27 | 2007-02-14 | 安格斯公司 | 由液体中除去微气泡的方法 |

| JP4470101B2 (ja) | 2004-03-24 | 2010-06-02 | 栗田工業株式会社 | 窒素溶解超純水の製造方法 |

| US20050279207A1 (en) | 2004-06-16 | 2005-12-22 | Advanced Technology Materials, Inc. | Liquid delivery system |

| AU2007247895A1 (en) * | 2006-05-05 | 2007-11-15 | Plascoenergy Ip Holdings, S.L., Bilbao, Schaffhausen Branch | A gas homogenization system |

| CN101479365A (zh) * | 2006-05-05 | 2009-07-08 | 普拉斯科能源Ip控股公司毕尔巴鄂-沙夫豪森分公司 | 用于与气化器一起使用的热量回收系统 |

| US7641795B2 (en) * | 2006-06-05 | 2010-01-05 | Celgard Llc | Membrane contactor |

| JP2007319843A (ja) | 2006-06-05 | 2007-12-13 | Kurita Water Ind Ltd | 気体溶解モジュール |

| JP2009545136A (ja) * | 2006-07-21 | 2009-12-17 | インテグリス・インコーポレーテッド | 浸漬流体を調整するための装置および方法 |

| JP4931201B2 (ja) | 2006-10-13 | 2012-05-16 | 独立行政法人産業技術総合研究所 | 極微小気泡を含む水の製造方法および極微小気泡を含む水 |

| EP2104648B1 (en) | 2006-10-17 | 2013-04-17 | MKS Instruments, Inc. | System and method for carbonation of deionized water |

| JP2008155186A (ja) * | 2006-12-26 | 2008-07-10 | Nomura Micro Sci Co Ltd | オゾン水の製造方法及び製造装置 |

-

2009

- 2009-05-18 CN CN201510020227.7A patent/CN104722239A/zh active Pending

- 2009-05-18 CN CN200980118387.8A patent/CN102036742B/zh not_active Expired - Fee Related

- 2009-05-18 WO PCT/US2009/044343 patent/WO2009143056A1/en not_active Ceased

- 2009-05-18 DE DE112009001233T patent/DE112009001233T5/de not_active Withdrawn

- 2009-05-18 JP JP2011510619A patent/JP2011520609A/ja active Pending

- 2009-05-18 KR KR1020107027647A patent/KR20110008319A/ko not_active Ceased

- 2009-05-18 TW TW98116469A patent/TW201004707A/zh unknown

- 2009-05-18 US US12/993,791 patent/US8844909B2/en not_active Expired - Fee Related

-

2014

- 2014-08-19 US US14/462,950 patent/US20140357734A1/en not_active Abandoned

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20200139630A (ko) * | 2019-06-04 | 2020-12-14 | 가부시키가이샤 에바라 세이사꾸쇼 | 가스 용해액 공급 장치 및 가스 용해액 공급 방법 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE112009001233T5 (de) | 2011-07-21 |

| JP2011520609A (ja) | 2011-07-21 |

| US8844909B2 (en) | 2014-09-30 |

| CN102036742A (zh) | 2011-04-27 |

| US20140357734A1 (en) | 2014-12-04 |

| CN104722239A (zh) | 2015-06-24 |

| CN102036742B (zh) | 2015-02-11 |

| TW201004707A (en) | 2010-02-01 |

| WO2009143056A1 (en) | 2009-11-26 |

| US20110180148A1 (en) | 2011-07-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20110008319A (ko) | 액체 내에 가스의 무기포 용액을 제조하기 위한 기화 시스템 및 방법 | |

| JP7371169B2 (ja) | アンモニアガスをその中に溶解した脱イオン水を含む導電性液体を生成するためのシステム及び方法 | |

| JP2011520609A5 (enExample) | ||

| US8882885B2 (en) | System to remove dissolved gases selectively from liquids | |

| KR101406411B1 (ko) | 탈이온수의 탄화 시스템 및 방법 | |

| CN104203381B (zh) | 从多组分溶液输送工艺气体的方法 | |

| CN102986008B (zh) | 用于去离子水的碳酸化的装置、系统及方法 | |

| WO1997014180A1 (en) | Semiconductor processing using vapor mixtures | |

| KR102192990B1 (ko) | 고농도 과산화수소 가스 스트림의 공급 | |

| US6928750B2 (en) | Membrane dryer | |

| KR102662465B1 (ko) | 기판 처리 장치 및 기판 처리 방법 | |

| TWI842869B (zh) | 用於供應包括超純水及氨氣之沖洗液體之系統以及用於供應包括其中溶解有所期望濃度之氨氣之超純水之沖洗液體之方法 | |

| CN117916860A (zh) | 半导体制造用液体供给装置 | |

| Xia et al. | Controlled DI Water Gasification System for Advanced Semiconductor Cleaning Processes |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20101208 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20140408 Comment text: Request for Examination of Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20150615 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20151001 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20150615 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |