JP7090481B2 - 静電チャック及びその製造方法 - Google Patents

静電チャック及びその製造方法 Download PDFInfo

- Publication number

- JP7090481B2 JP7090481B2 JP2018114381A JP2018114381A JP7090481B2 JP 7090481 B2 JP7090481 B2 JP 7090481B2 JP 2018114381 A JP2018114381 A JP 2018114381A JP 2018114381 A JP2018114381 A JP 2018114381A JP 7090481 B2 JP7090481 B2 JP 7090481B2

- Authority

- JP

- Japan

- Prior art keywords

- primer

- electrostatic chuck

- insulating component

- adhesive layer

- tubular insulating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67098—Apparatus for thermal treatment

- H01L21/67103—Apparatus for thermal treatment mainly by conduction

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23Q—DETAILS, COMPONENTS, OR ACCESSORIES FOR MACHINE TOOLS, e.g. ARRANGEMENTS FOR COPYING OR CONTROLLING; MACHINE TOOLS IN GENERAL CHARACTERISED BY THE CONSTRUCTION OF PARTICULAR DETAILS OR COMPONENTS; COMBINATIONS OR ASSOCIATIONS OF METAL-WORKING MACHINES, NOT DIRECTED TO A PARTICULAR RESULT

- B23Q3/00—Devices holding, supporting, or positioning work or tools, of a kind normally removable from the machine

- B23Q3/15—Devices for holding work using magnetic or electric force acting directly on the work

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/6831—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using electrostatic chucks

- H01L21/6833—Details of electrostatic chucks

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/6835—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using temporarily an auxiliary support

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02N—ELECTRIC MACHINES NOT OTHERWISE PROVIDED FOR

- H02N13/00—Clutches or holding devices using electrostatic attraction, e.g. using Johnson-Rahbek effect

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Mechanical Engineering (AREA)

- Container, Conveyance, Adherence, Positioning, Of Wafer (AREA)

- Drying Of Semiconductors (AREA)

Description

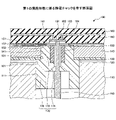

先ず、第1の実施形態について説明する。第1の実施形態は静電チャックに関する。図3は、第1の実施形態に係る静電チャックを示す断面図である。

次に、第2の実施形態について説明する。第2の実施形態は静電チャックに関する。図10は、第2の実施形態に係る静電チャックを示す断面図である。

110 ベースプレート

120 第1接着層

130 絶縁フィルム

140 ヒータ

150 第2接着層

152 第2のプライマー

153 第1のプライマー

160 載置台

162 接続電極

163 ビア導体

164 静電電極

170 第1筒状絶縁部品

180 第2筒状絶縁部品

190 コネクタ

191 給電ピン

Claims (7)

- 電極を備えた載置台と、

前記電極に当接した給電ピンと、

前記給電ピンの周囲に設けられた筒状絶縁部品と、

前記筒状絶縁部品の前記載置台に対向する面に設けられた第1のプライマーと、

前記筒状絶縁部品の外側に設けられた金属部品と、

前記載置台と前記筒状絶縁部品及び前記金属部品の各々とを互いに接着する接着層と、

を有し、

前記第1のプライマーは、前記筒状絶縁部品と前記接着層とに間に設けられ、

前記接着層は、前記第1のプライマーを介さずに前記金属部品に直接接することを特徴とする静電チャック。 - 前記載置台の前記接着層側の面に設けられた第2のプライマーを有することを特徴とする請求項1に記載の静電チャック。

- 前記金属部品はヒータであることを特徴とする請求項1又は2に記載の静電チャック。

- 前記金属部品はベースプレートであることを特徴とする請求項1又は2に記載の静電チャック。

- 開口部が設けられた金属部品の前記開口部内に、給電ピンと、前記給電ピンの周囲に設けられた筒状絶縁部品とを挿入する工程と、

前記筒状絶縁部品に第1のプライマーを塗布する工程と、

接着剤を用いて、前記筒状絶縁部品の前記第1のプライマーを塗布した面に、電極を備えた載置台を、前記電極に前記給電ピンを当接させながら接着するともに、前記載置台を前記金属部品に接着する工程と、

を有し、

前記接着剤は、前記第1のプライマーを介さずに前記金属部品に直接接することを特徴とする静電チャックの製造方法。 - 前記接着剤を用いて前記載置台を接着する工程は、

スクリーン印刷により、前記筒状絶縁部品の前記第1のプライマーを塗布した面に前記接着剤の層を形成する工程を有することを特徴とする請求項5に記載の静電チャックの製造方法。 - 前記接着剤を用いて前記載置台を接着する工程は、

前記載置台の前記筒状絶縁部品に接着される面に第2のプライマーを塗布する工程を有することを特徴とする請求項5又は6に記載の静電チャックの製造方法。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018114381A JP7090481B2 (ja) | 2018-06-15 | 2018-06-15 | 静電チャック及びその製造方法 |

| US16/430,569 US11088006B2 (en) | 2018-06-15 | 2019-06-04 | Electrostatic chuck |

| KR1020190066516A KR20190142215A (ko) | 2018-06-15 | 2019-06-05 | 정전 척 및 그 제조 방법 |

| TW108119861A TWI820147B (zh) | 2018-06-15 | 2019-06-10 | 靜電夾盤及其製造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018114381A JP7090481B2 (ja) | 2018-06-15 | 2018-06-15 | 静電チャック及びその製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2019220503A JP2019220503A (ja) | 2019-12-26 |

| JP2019220503A5 JP2019220503A5 (ja) | 2021-04-22 |

| JP7090481B2 true JP7090481B2 (ja) | 2022-06-24 |

Family

ID=68840316

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2018114381A Active JP7090481B2 (ja) | 2018-06-15 | 2018-06-15 | 静電チャック及びその製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US11088006B2 (ja) |

| JP (1) | JP7090481B2 (ja) |

| KR (1) | KR20190142215A (ja) |

| TW (1) | TWI820147B (ja) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7014821B2 (ja) * | 2018-01-29 | 2022-02-01 | 京セラ株式会社 | 試料保持具 |

| CN115244678A (zh) * | 2020-03-26 | 2022-10-25 | 株式会社巴川制纸所 | 静电吸盘装置、静电吸盘装置用套筒 |

| WO2024058183A1 (ja) * | 2022-09-14 | 2024-03-21 | 京セラ株式会社 | 吸着基板 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011508419A (ja) | 2007-12-19 | 2011-03-10 | ラム リサーチ コーポレーション | 半導体真空処理装置用のフィルム接着剤 |

| JP2012512953A (ja) | 2008-12-19 | 2012-06-07 | アプライド マテリアルズ インコーポレイテッド | 高温静電チャック接着剤 |

| JP2013229464A (ja) | 2012-04-26 | 2013-11-07 | Shinko Electric Ind Co Ltd | 静電チャック |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6071630A (en) * | 1996-03-04 | 2000-06-06 | Shin-Etsu Chemical Co., Ltd. | Electrostatic chuck |

| US20050042881A1 (en) * | 2003-05-12 | 2005-02-24 | Tokyo Electron Limited | Processing apparatus |

| JP5053696B2 (ja) * | 2007-04-26 | 2012-10-17 | 信越化学工業株式会社 | 静電チャック |

| JP6162428B2 (ja) | 2013-02-27 | 2017-07-12 | 日本特殊陶業株式会社 | 支持装置 |

| US10923381B2 (en) * | 2016-01-19 | 2021-02-16 | Sumitomo Osaka Cement Co., Ltd. | Electrostatic chuck device |

| CN111512428A (zh) * | 2017-12-28 | 2020-08-07 | 住友大阪水泥股份有限公司 | 静电卡盘装置 |

-

2018

- 2018-06-15 JP JP2018114381A patent/JP7090481B2/ja active Active

-

2019

- 2019-06-04 US US16/430,569 patent/US11088006B2/en active Active

- 2019-06-05 KR KR1020190066516A patent/KR20190142215A/ko not_active Application Discontinuation

- 2019-06-10 TW TW108119861A patent/TWI820147B/zh active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011508419A (ja) | 2007-12-19 | 2011-03-10 | ラム リサーチ コーポレーション | 半導体真空処理装置用のフィルム接着剤 |

| JP2012512953A (ja) | 2008-12-19 | 2012-06-07 | アプライド マテリアルズ インコーポレイテッド | 高温静電チャック接着剤 |

| JP2013229464A (ja) | 2012-04-26 | 2013-11-07 | Shinko Electric Ind Co Ltd | 静電チャック |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20190142215A (ko) | 2019-12-26 |

| TWI820147B (zh) | 2023-11-01 |

| TW202002154A (zh) | 2020-01-01 |

| US11088006B2 (en) | 2021-08-10 |

| US20190385883A1 (en) | 2019-12-19 |

| JP2019220503A (ja) | 2019-12-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR102166737B1 (ko) | 정전 척 및 반도체·액정 제조 장치 | |

| JP7090481B2 (ja) | 静電チャック及びその製造方法 | |

| KR102501916B1 (ko) | 웨이퍼 유지체 | |

| JP6292977B2 (ja) | 静電チャック及び半導体・液晶製造装置 | |

| JP5816454B2 (ja) | 基板温調固定装置 | |

| TWI423378B (zh) | 靜電夾盤 | |

| JP2017228360A (ja) | 加熱部材及び静電チャック | |

| JP6317183B2 (ja) | 半導体製造装置用部品 | |

| JP6758175B2 (ja) | 静電チャック | |

| US10381253B2 (en) | Electrostatic chuck | |

| JP6699765B2 (ja) | ウェハ保持体 | |

| KR20190083746A (ko) | 정전척용 dc 포트 및 이를 구비한 정전척 | |

| JP6464071B2 (ja) | 基板保持装置 | |

| CN115719725A (zh) | 基板固定装置 | |

| US11735459B2 (en) | Electrostatic chuck | |

| JP2020004809A (ja) | 保持装置 | |

| JP2018181866A (ja) | 保持装置の製造方法 | |

| JP6979375B2 (ja) | 保持装置および保持装置の製造方法 | |

| JP6882040B2 (ja) | 保持装置 | |

| JP2024139669A (ja) | 静電チャック | |

| CN115116921A (zh) | 静电吸盘和基板固定装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20210303 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20210303 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20220224 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20220308 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20220426 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20220531 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20220614 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7090481 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |