JP6139545B2 - ニッケルを含みかつal203表面コーティングを有する超硬炭化タングステンから作られる摩擦撹拌接合工具 - Google Patents

ニッケルを含みかつal203表面コーティングを有する超硬炭化タングステンから作られる摩擦撹拌接合工具 Download PDFInfo

- Publication number

- JP6139545B2 JP6139545B2 JP2014540355A JP2014540355A JP6139545B2 JP 6139545 B2 JP6139545 B2 JP 6139545B2 JP 2014540355 A JP2014540355 A JP 2014540355A JP 2014540355 A JP2014540355 A JP 2014540355A JP 6139545 B2 JP6139545 B2 JP 6139545B2

- Authority

- JP

- Japan

- Prior art keywords

- stir welding

- friction stir

- surface coating

- welding tool

- cemented carbide

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000003466 welding Methods 0.000 title claims description 81

- 238000003756 stirring Methods 0.000 title claims description 65

- 238000000576 coating method Methods 0.000 title claims description 49

- 239000011248 coating agent Substances 0.000 title claims description 48

- 229910052759 nickel Inorganic materials 0.000 title description 11

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 title 2

- UONOETXJSWQNOL-UHFFFAOYSA-N tungsten carbide Chemical compound [W+]#[C-] UONOETXJSWQNOL-UHFFFAOYSA-N 0.000 title 1

- 239000000523 sample Substances 0.000 claims description 55

- 239000002245 particle Substances 0.000 claims description 24

- 238000000034 method Methods 0.000 claims description 23

- 229910018072 Al 2 O 3 Inorganic materials 0.000 claims description 20

- 230000008569 process Effects 0.000 claims description 16

- 239000011230 binding agent Substances 0.000 claims description 13

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 claims description 9

- 239000000463 material Substances 0.000 claims description 8

- 150000001875 compounds Chemical class 0.000 claims description 4

- 150000004767 nitrides Chemical class 0.000 claims description 4

- 238000012360 testing method Methods 0.000 description 28

- 230000003647 oxidation Effects 0.000 description 19

- 238000007254 oxidation reaction Methods 0.000 description 19

- 239000012071 phase Substances 0.000 description 17

- 229910000831 Steel Inorganic materials 0.000 description 12

- 239000010959 steel Substances 0.000 description 12

- 229910001209 Low-carbon steel Inorganic materials 0.000 description 9

- 229910052782 aluminium Inorganic materials 0.000 description 7

- 238000005229 chemical vapour deposition Methods 0.000 description 7

- 229910052802 copper Inorganic materials 0.000 description 5

- 239000010949 copper Substances 0.000 description 5

- 238000005266 casting Methods 0.000 description 4

- 229910052804 chromium Inorganic materials 0.000 description 4

- 239000007769 metal material Substances 0.000 description 4

- 239000000203 mixture Substances 0.000 description 4

- 238000005245 sintering Methods 0.000 description 4

- 239000000126 substance Substances 0.000 description 4

- 238000004441 surface measurement Methods 0.000 description 4

- 229910045601 alloy Inorganic materials 0.000 description 3

- 239000000956 alloy Substances 0.000 description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 229910000851 Alloy steel Inorganic materials 0.000 description 2

- 229910001369 Brass Inorganic materials 0.000 description 2

- 229910000906 Bronze Inorganic materials 0.000 description 2

- 239000010951 brass Substances 0.000 description 2

- 239000010974 bronze Substances 0.000 description 2

- KUNSUQLRTQLHQQ-UHFFFAOYSA-N copper tin Chemical compound [Cu].[Sn] KUNSUQLRTQLHQQ-UHFFFAOYSA-N 0.000 description 2

- 229910052742 iron Inorganic materials 0.000 description 2

- 238000005304 joining Methods 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 238000005240 physical vapour deposition Methods 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229910010037 TiAlN Inorganic materials 0.000 description 1

- -1 TiCN Chemical compound 0.000 description 1

- 229910009043 WC-Co Inorganic materials 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000011362 coarse particle Substances 0.000 description 1

- 238000005261 decarburization Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 230000004927 fusion Effects 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 150000001247 metal acetylides Chemical class 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000012768 molten material Substances 0.000 description 1

- 229910052758 niobium Inorganic materials 0.000 description 1

- 238000005498 polishing Methods 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 238000007712 rapid solidification Methods 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- 239000007790 solid phase Substances 0.000 description 1

- 238000001694 spray drying Methods 0.000 description 1

- 229910052715 tantalum Inorganic materials 0.000 description 1

- 238000005050 thermomechanical fatigue Methods 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/12—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding

- B23K20/122—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding

- B23K20/1245—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding characterised by the apparatus

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/12—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding

- B23K20/122—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding

- B23K20/1245—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding characterised by the apparatus

- B23K20/1255—Tools therefor, e.g. characterised by the shape of the probe

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/14—Preventing or minimising gas access, or using protective gases or vacuum during welding

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C29/00—Alloys based on carbides, oxides, nitrides, borides, or silicides, e.g. cermets, or other metal compounds, e.g. oxynitrides, sulfides

- C22C29/02—Alloys based on carbides, oxides, nitrides, borides, or silicides, e.g. cermets, or other metal compounds, e.g. oxynitrides, sulfides based on carbides or carbonitrides

- C22C29/06—Alloys based on carbides, oxides, nitrides, borides, or silicides, e.g. cermets, or other metal compounds, e.g. oxynitrides, sulfides based on carbides or carbonitrides based on carbides, but not containing other metal compounds

- C22C29/08—Alloys based on carbides, oxides, nitrides, borides, or silicides, e.g. cermets, or other metal compounds, e.g. oxynitrides, sulfides based on carbides or carbonitrides based on carbides, but not containing other metal compounds based on tungsten carbide

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/40—Oxides

- C23C16/403—Oxides of aluminium, magnesium or beryllium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/18—Sheet panels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/02—Iron or ferrous alloys

- B23K2103/04—Steel or steel alloys

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Inorganic Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Pressure Welding/Diffusion-Bonding (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

Description

試料A、B、C、及びDを、試料を低炭素鋼中に部分的に投ずる鋳造試験においてそれらの耐化学性に関して評価した。

試料E、F、及びGを調製し、それらの耐酸化性に関して試料を炉中で空気中で熱処理する酸化試験で評価した。

摩擦撹拌接合試験を3種類の異なるプローブ、すなわちプローブH、プローブI、及びプローブJを用いて行った。すべてのプローブは超硬合金から作られ、先細のピンを有する円柱状の段部を有し、ピンの直径は約5mm、段部の直径は16mmである。溶接試験は、Al、Cu、又は低炭素鋼(C:0.2%、Si:0.3%、P:0.04%、S:0.05%、Fe:残分、硬さ30HRCを有する)の厚さ4mmの2枚の板間の接合部で行った。試験は、溶接速度150mm/分、最大ダウンフォース230kN、回転速度300rpm、及び傾斜角1.5oで行った。

Claims (12)

- バインダー相中にWC粒子を含む超硬合金から作られる摩擦撹拌接合工具(1)であって、前記接合工具が、Ti炭化物層、Ti窒化物層、Ti炭窒化物層、Tiオキシ炭化物層、Tiオキシ炭窒化物層、Zr炭化物層、Zr窒化物層、Zr炭窒化物層、Zrオキシ炭化物層、及びZrオキシ炭窒化物層のうちの少なくとも1層を含むTi化合物及びZr化合物のうちの少なくとも1種類から作られる内層である第1の表面コーティングと、Al2O3を含む外層である第2の表面コーティングの2層から構成される表面コーティングで完全にコーティングされ、かつ前記超硬合金が3wt%〜10wt%のNiを含み、前記表面コーティングがCVDコーティングであることを特徴とする、摩擦撹拌接合工具(1)。

- 前記第2の表面コーティングが最も外側のAl2O3の表面コーティングであり、かつ前記第1の表面コーティングがTiNである、請求項1に記載の摩擦撹拌接合工具(1)。

- 前記第2の表面コーティングが、5μmを超える平均厚さを有するAl2O3表面コーティングである、請求項1又は2に記載の摩擦撹拌接合工具(1)。

- 前記第1の表面コーティングの厚さが、0.3μmを超え、6μm未満である、請求項1〜3のいずれか1項に記載の摩擦撹拌接合工具(1)。

- 前記超硬合金が4〜5wt%のNiを含む、請求項1〜4のいずれか1項に記載の摩擦撹拌接合工具(1)。

- 前記超硬合金が3〜10wt%のCoを含む、請求項1〜5のいずれか1項に記載の摩擦撹拌接合工具(1)。

- 前記超硬合金が4〜5wt%のCoを含む、請求項1〜6のいずれか1項に記載の摩擦撹拌接合工具(1)。

- 前記超硬合金が0.8〜1.2wt%のCr及び/又はMoを含む、請求項1〜7のいずれか1項に記載の摩擦撹拌接合工具(1)。

- 前記超硬合金が0.01〜0.4wt%のFeを含む、請求項1〜8のいずれか1項に記載の摩擦撹拌接合工具(1)。

- 前記超硬合金が、2〜25μmの平均WC粒子サイズを有する85〜95wt%のWCを含む、請求項1〜9のいずれか1項に記載の摩擦撹拌接合工具(1)。

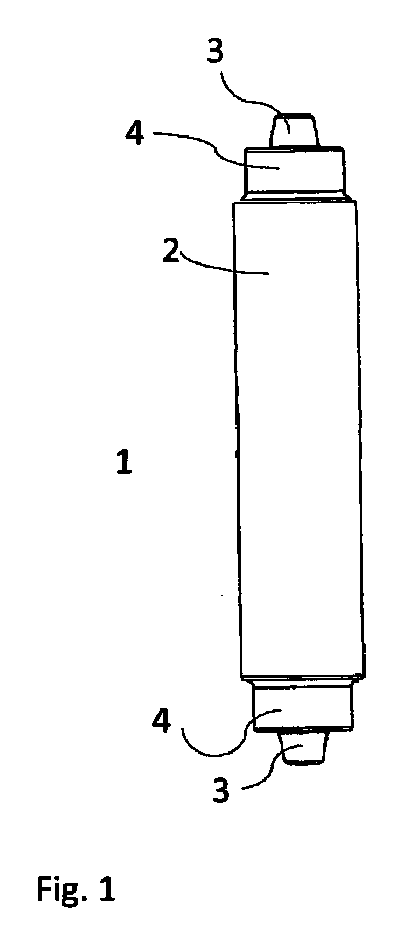

- 前記工具(1)が2個のプローブ(3)を備え、各プローブ(3)は摩擦撹拌接合工程の間、溶接される材料と接触させるためのものであり、前記プローブ(3)は、摩擦撹拌接合工程において第1のプローブ(3)が活動状態であるとき、第2のプローブ(3)が非活動状態であるように互いに反対側に配置され、前記表面コーティングがCVDにより塗布される、請求項1〜10のいずれか1項に記載の摩擦撹拌接合工具(1)。

- 請求項1〜11のいずれか1項に記載の摩擦撹拌接合工具の摩擦撹拌接合工程における使用であって、前記工程がN2又はArの溶接雰囲気中で行われる、使用。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP11188809.5A EP2591874B1 (en) | 2011-11-11 | 2011-11-11 | Friction stir welding tool made of cemented tungsten carbid with Nickel and with a Al2O3 surface coating |

| EP11188809.5 | 2011-11-11 | ||

| PCT/EP2012/004661 WO2013068122A1 (en) | 2011-11-11 | 2012-11-09 | Friction stir welding tool made of cemented tungsten carbid with nickel and with a al203 surface coating |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2015502257A JP2015502257A (ja) | 2015-01-22 |

| JP6139545B2 true JP6139545B2 (ja) | 2017-05-31 |

Family

ID=47358075

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014540355A Expired - Fee Related JP6139545B2 (ja) | 2011-11-11 | 2012-11-09 | ニッケルを含みかつal203表面コーティングを有する超硬炭化タングステンから作られる摩擦撹拌接合工具 |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US9656345B2 (ja) |

| EP (2) | EP2591874B1 (ja) |

| JP (1) | JP6139545B2 (ja) |

| KR (1) | KR101963472B1 (ja) |

| CN (1) | CN103930234B (ja) |

| BR (1) | BR112014011207B1 (ja) |

| CA (1) | CA2853870C (ja) |

| DK (2) | DK2591874T3 (ja) |

| ES (2) | ES2675907T3 (ja) |

| MX (1) | MX356920B (ja) |

| WO (1) | WO2013068122A1 (ja) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012130948A (ja) * | 2010-12-22 | 2012-07-12 | Sumitomo Electric Ind Ltd | 回転ツール |

| JP2012130947A (ja) * | 2010-12-22 | 2012-07-12 | Sumitomo Electric Ind Ltd | 回転ツール |

| US8833633B2 (en) * | 2010-12-22 | 2014-09-16 | Sumitomo Electric Industries, Ltd. | Rotary tool |

| USD762253S1 (en) * | 2011-07-29 | 2016-07-26 | Japan Transport Engineering Company | Friction stir welding tool |

| AT517894B1 (de) * | 2015-10-30 | 2018-06-15 | Univ Wien Tech | Rührreibschweißwerkzeug |

| CN105436697A (zh) * | 2015-12-02 | 2016-03-30 | 浙江理工大学 | 高效、隔热的搅拌摩擦焊搅拌头及方法 |

| RU184619U1 (ru) * | 2018-07-06 | 2018-11-01 | Федеральное государственное автономное образовательное учреждение высшего образования "Белгородский государственный национальный исследовательский университет" (НИУ "БелГУ") | Твердосплавный инструмент для сварки трением с перемешиванием |

| CN109822208B (zh) * | 2019-03-20 | 2021-03-09 | 北京赛福斯特技术有限公司 | 一种双机头双面高效率搅拌摩擦焊设备及其焊接方法 |

| US12311461B2 (en) * | 2021-04-08 | 2025-05-27 | Ntk Cutting Tools Co., Ltd. | Friction stir welding tool and friction stir welding method |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61110771A (ja) | 1984-11-06 | 1986-05-29 | Hitachi Metals Ltd | 表面被覆超硬合金 |

| JPH06170611A (ja) * | 1986-01-27 | 1994-06-21 | Mitsubishi Materials Corp | 表面被覆炭化タングステン基超硬合金製切削工具 |

| JPH06262407A (ja) | 1993-03-16 | 1994-09-20 | Mitsubishi Materials Corp | 耐欠損性のすぐれた表面被覆炭化タングステン基超硬合金製切削工具 |

| SE502223C2 (sv) | 1994-01-14 | 1995-09-18 | Sandvik Ab | Sätt och alster vid beläggning av ett skärande verktyg med ett aluminiumoxidskikt |

| JP3127708B2 (ja) | 1994-03-11 | 2001-01-29 | 住友電気工業株式会社 | 切削工具用の被覆超硬合金 |

| US6022175A (en) * | 1997-08-27 | 2000-02-08 | Kennametal Inc. | Elongate rotary tool comprising a cermet having a Co-Ni-Fe binder |

| US6911063B2 (en) * | 2003-01-13 | 2005-06-28 | Genius Metal, Inc. | Compositions and fabrication methods for hardmetals |

| DE602004031919D1 (de) * | 2003-12-22 | 2011-05-05 | Mitsubishi Materials Corp | Beschichtetes Cermet Schneidwerkzeug mit harter Überzugsschicht mit hervorragender Schlagbeständigkeit. |

| US7198189B2 (en) * | 2004-09-28 | 2007-04-03 | Alcoa Inc. | Multi-shouldered fixed bobbin tools for simultaneous friction stir welding of multiple parallel walls between parts |

| SE528673C2 (sv) * | 2005-01-03 | 2007-01-16 | Sandvik Intellectual Property | Belagt hårdmetallskär för torrfräsning i höglegerat grått gjutjärn samt sätt och användning |

| US7357292B2 (en) * | 2005-02-01 | 2008-04-15 | Battelle Energy Alliance, Llc | Friction stir welding tool |

| SE529015C2 (sv) * | 2005-09-09 | 2007-04-10 | Sandvik Intellectual Property | PVD-belagt skärverktygsskär tillverkat av hårdmetall |

| JP2007268605A (ja) * | 2006-03-31 | 2007-10-18 | Kawasaki Heavy Ind Ltd | 摩擦撹拌接合装置 |

| JP4869817B2 (ja) * | 2006-07-28 | 2012-02-08 | 川崎重工業株式会社 | 摩擦撹拌接合装置 |

| AT506133B1 (de) * | 2007-11-16 | 2009-11-15 | Boehlerit Gmbh & Co Kg | Reibrührschweisswerkzeug |

| JP5326096B2 (ja) * | 2008-03-12 | 2013-10-30 | アイセル株式会社 | 摩擦攪拌加工用ツール |

| JP5441028B2 (ja) * | 2009-04-30 | 2014-03-12 | 国立大学法人大阪大学 | 回転ツール |

| KR101344170B1 (ko) | 2009-12-17 | 2013-12-20 | 스미토모덴키고교가부시키가이샤 | 피복 회전 툴 |

| EP2439300A1 (en) * | 2010-10-08 | 2012-04-11 | Sandvik Intellectual Property AB | Cemented carbide |

| JP2012130948A (ja) * | 2010-12-22 | 2012-07-12 | Sumitomo Electric Ind Ltd | 回転ツール |

| JP2012130947A (ja) * | 2010-12-22 | 2012-07-12 | Sumitomo Electric Ind Ltd | 回転ツール |

-

2011

- 2011-11-11 EP EP11188809.5A patent/EP2591874B1/en not_active Not-in-force

- 2011-11-11 ES ES11188809.5T patent/ES2675907T3/es active Active

- 2011-11-11 DK DK11188809.5T patent/DK2591874T3/en active

-

2012

- 2012-11-09 ES ES12801448T patent/ES2737676T3/es active Active

- 2012-11-09 CA CA2853870A patent/CA2853870C/en not_active Expired - Fee Related

- 2012-11-09 DK DK12801448.7T patent/DK2776204T3/da active

- 2012-11-09 KR KR1020147014351A patent/KR101963472B1/ko active Active

- 2012-11-09 WO PCT/EP2012/004661 patent/WO2013068122A1/en not_active Ceased

- 2012-11-09 BR BR112014011207-0A patent/BR112014011207B1/pt not_active IP Right Cessation

- 2012-11-09 CN CN201280055350.7A patent/CN103930234B/zh not_active Expired - Fee Related

- 2012-11-09 MX MX2014005506A patent/MX356920B/es active IP Right Grant

- 2012-11-09 US US14/357,257 patent/US9656345B2/en active Active

- 2012-11-09 EP EP12801448.7A patent/EP2776204B1/en not_active Not-in-force

- 2012-11-09 JP JP2014540355A patent/JP6139545B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN103930234A (zh) | 2014-07-16 |

| US9656345B2 (en) | 2017-05-23 |

| CA2853870A1 (en) | 2013-05-16 |

| EP2591874B1 (en) | 2018-05-16 |

| DK2776204T3 (da) | 2019-07-15 |

| KR20140098758A (ko) | 2014-08-08 |

| MX2014005506A (es) | 2014-06-05 |

| BR112014011207A2 (pt) | 2017-05-09 |

| KR101963472B1 (ko) | 2019-03-28 |

| ES2737676T3 (es) | 2020-01-15 |

| EP2591874A1 (en) | 2013-05-15 |

| DK2591874T3 (en) | 2018-07-23 |

| US20140312099A1 (en) | 2014-10-23 |

| WO2013068122A1 (en) | 2013-05-16 |

| CN103930234B (zh) | 2017-05-10 |

| EP2776204B1 (en) | 2019-05-08 |

| CA2853870C (en) | 2020-03-24 |

| EP2776204A1 (en) | 2014-09-17 |

| ES2675907T3 (es) | 2018-07-13 |

| MX356920B (es) | 2018-06-20 |

| JP2015502257A (ja) | 2015-01-22 |

| BR112014011207B1 (pt) | 2019-09-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6139545B2 (ja) | ニッケルを含みかつal203表面コーティングを有する超硬炭化タングステンから作られる摩擦撹拌接合工具 | |

| TWI470088B (zh) | Hard alloy and cutting tools using it | |

| KR101361986B1 (ko) | 회전 툴 | |

| EP2493685A1 (en) | Glass forming hardbanding material | |

| JP4517008B1 (ja) | 高温材搬送用部材 | |

| WO2012086488A1 (ja) | 回転ツール | |

| WO2012086490A1 (ja) | 回転ツール | |

| WO2012086489A1 (ja) | 回転ツール | |

| TWI302949B (ja) | ||

| JP2012139694A (ja) | 被覆回転ツール | |

| JP4412563B2 (ja) | 高温材搬送用部材 | |

| JP2019183201A (ja) | 焼結体および回転ツール | |

| JP5708105B2 (ja) | 回転ツール | |

| JP6036795B2 (ja) | 回転ツール | |

| JP6578532B2 (ja) | 被覆層を有する耐熱合金製工具および加工装置 | |

| JP2015107525A (ja) | 回転ツール | |

| JP6039004B2 (ja) | 回転ツール | |

| Lisiecka et al. | ATMOSPHERIC PLASMA SPRAYING (APS) AND ALLOYING AS METHODS TO MODIFY PROPERTIES OF THE SSS SURFACE LAYERS. | |

| Yao et al. | A Hybrid Thermal Spray and Sinter Fusion Process to Apply Wear and Corrosion Resistant Coatings | |

| JP2012166219A (ja) | 回転ツール | |

| Chen et al. | Wear resistance of SK3 carbon tool steel coated a thin layer of cobalt base alloy and poly crystalline diamond by laser brazing |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20150909 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20160606 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160719 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20160720 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20161011 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170209 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20170224 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170411 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170427 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6139545 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |