JP6068979B2 - 有機ポリマー粒子、紙コーティング組成物、および方法 - Google Patents

有機ポリマー粒子、紙コーティング組成物、および方法 Download PDFInfo

- Publication number

- JP6068979B2 JP6068979B2 JP2012505877A JP2012505877A JP6068979B2 JP 6068979 B2 JP6068979 B2 JP 6068979B2 JP 2012505877 A JP2012505877 A JP 2012505877A JP 2012505877 A JP2012505877 A JP 2012505877A JP 6068979 B2 JP6068979 B2 JP 6068979B2

- Authority

- JP

- Japan

- Prior art keywords

- organic polymer

- paper

- polymer particles

- shell

- particles

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000002245 particle Substances 0.000 title claims description 178

- 229920000620 organic polymer Polymers 0.000 title claims description 120

- 238000000034 method Methods 0.000 title claims description 47

- 239000008199 coating composition Substances 0.000 title description 73

- 239000011148 porous material Substances 0.000 claims description 47

- 239000002253 acid Substances 0.000 claims description 46

- 239000000178 monomer Substances 0.000 claims description 44

- 229920001477 hydrophilic polymer Polymers 0.000 claims description 34

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 claims description 27

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical group C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 claims description 20

- 230000007062 hydrolysis Effects 0.000 claims description 5

- 238000006460 hydrolysis reaction Methods 0.000 claims description 5

- 230000000379 polymerizing effect Effects 0.000 claims 2

- 238000004132 cross linking Methods 0.000 claims 1

- 125000004185 ester group Chemical group 0.000 claims 1

- 238000010438 heat treatment Methods 0.000 claims 1

- 230000003301 hydrolyzing effect Effects 0.000 claims 1

- 239000000123 paper Substances 0.000 description 194

- 238000000576 coating method Methods 0.000 description 63

- 239000011248 coating agent Substances 0.000 description 49

- 239000000976 ink Substances 0.000 description 45

- 229920000642 polymer Polymers 0.000 description 38

- 239000000203 mixture Substances 0.000 description 35

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 33

- 239000011230 binding agent Substances 0.000 description 30

- 239000004816 latex Substances 0.000 description 27

- 229920000126 latex Polymers 0.000 description 27

- 239000002585 base Substances 0.000 description 25

- 239000010410 layer Substances 0.000 description 25

- 238000003490 calendering Methods 0.000 description 21

- 239000000049 pigment Substances 0.000 description 20

- 238000007720 emulsion polymerization reaction Methods 0.000 description 19

- 239000003973 paint Substances 0.000 description 18

- 125000002091 cationic group Chemical group 0.000 description 17

- 238000009472 formulation Methods 0.000 description 17

- BAPJBEWLBFYGME-UHFFFAOYSA-N Methyl acrylate Chemical compound COC(=O)C=C BAPJBEWLBFYGME-UHFFFAOYSA-N 0.000 description 16

- 239000007787 solid Substances 0.000 description 15

- 239000003086 colorant Substances 0.000 description 14

- 239000003795 chemical substances by application Substances 0.000 description 13

- -1 hydroxide ions Chemical class 0.000 description 13

- 238000007639 printing Methods 0.000 description 12

- 239000000377 silicon dioxide Substances 0.000 description 12

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 12

- 238000006243 chemical reaction Methods 0.000 description 11

- 239000011087 paperboard Substances 0.000 description 11

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 10

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 10

- VZCYOOQTPOCHFL-OWOJBTEDSA-N Fumaric acid Chemical compound OC(=O)\C=C\C(O)=O VZCYOOQTPOCHFL-OWOJBTEDSA-N 0.000 description 10

- CERQOIWHTDAKMF-UHFFFAOYSA-N Methacrylic acid Chemical compound CC(=C)C(O)=O CERQOIWHTDAKMF-UHFFFAOYSA-N 0.000 description 9

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 9

- 239000006185 dispersion Substances 0.000 description 9

- 238000004519 manufacturing process Methods 0.000 description 9

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 description 8

- 229910052739 hydrogen Inorganic materials 0.000 description 8

- 239000001257 hydrogen Substances 0.000 description 8

- 239000000463 material Substances 0.000 description 8

- 238000001878 scanning electron micrograph Methods 0.000 description 8

- 239000000126 substance Substances 0.000 description 8

- NLHHRLWOUZZQLW-UHFFFAOYSA-N Acrylonitrile Chemical compound C=CC#N NLHHRLWOUZZQLW-UHFFFAOYSA-N 0.000 description 7

- VVQNEPGJFQJSBK-UHFFFAOYSA-N Methyl methacrylate Chemical compound COC(=O)C(C)=C VVQNEPGJFQJSBK-UHFFFAOYSA-N 0.000 description 7

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 7

- 238000001035 drying Methods 0.000 description 7

- 239000003995 emulsifying agent Substances 0.000 description 7

- 238000012360 testing method Methods 0.000 description 7

- VZCYOOQTPOCHFL-UHFFFAOYSA-N trans-butenedioic acid Natural products OC(=O)C=CC(O)=O VZCYOOQTPOCHFL-UHFFFAOYSA-N 0.000 description 7

- 239000002250 absorbent Substances 0.000 description 6

- 230000002745 absorbent Effects 0.000 description 6

- 239000004927 clay Substances 0.000 description 6

- 239000010954 inorganic particle Substances 0.000 description 6

- XTXRWKRVRITETP-UHFFFAOYSA-N Vinyl acetate Chemical compound CC(=O)OC=C XTXRWKRVRITETP-UHFFFAOYSA-N 0.000 description 5

- 239000012736 aqueous medium Substances 0.000 description 5

- 238000006664 bond formation reaction Methods 0.000 description 5

- 150000001875 compounds Chemical class 0.000 description 5

- 239000013256 coordination polymer Substances 0.000 description 5

- 150000002148 esters Chemical class 0.000 description 5

- 239000001530 fumaric acid Substances 0.000 description 5

- 238000005259 measurement Methods 0.000 description 5

- 239000000047 product Substances 0.000 description 5

- KAKZBPTYRLMSJV-UHFFFAOYSA-N Butadiene Chemical compound C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 description 4

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 4

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical compound [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 description 4

- 238000010521 absorption reaction Methods 0.000 description 4

- 125000000129 anionic group Chemical group 0.000 description 4

- TZCXTZWJZNENPQ-UHFFFAOYSA-L barium sulfate Chemical compound [Ba+2].[O-]S([O-])(=O)=O TZCXTZWJZNENPQ-UHFFFAOYSA-L 0.000 description 4

- 229920001577 copolymer Polymers 0.000 description 4

- 239000012530 fluid Substances 0.000 description 4

- 239000007788 liquid Substances 0.000 description 4

- 238000006116 polymerization reaction Methods 0.000 description 4

- 239000006228 supernatant Substances 0.000 description 4

- 239000004094 surface-active agent Substances 0.000 description 4

- JAHNSTQSQJOJLO-UHFFFAOYSA-N 2-(3-fluorophenyl)-1h-imidazole Chemical compound FC1=CC=CC(C=2NC=CN=2)=C1 JAHNSTQSQJOJLO-UHFFFAOYSA-N 0.000 description 3

- HRPVXLWXLXDGHG-UHFFFAOYSA-N Acrylamide Chemical compound NC(=O)C=C HRPVXLWXLXDGHG-UHFFFAOYSA-N 0.000 description 3

- 239000005995 Aluminium silicate Substances 0.000 description 3

- 239000004908 Emulsion polymer Substances 0.000 description 3

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 3

- 239000005977 Ethylene Substances 0.000 description 3

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 3

- 235000012211 aluminium silicate Nutrition 0.000 description 3

- NKWPZUCBCARRDP-UHFFFAOYSA-L calcium bicarbonate Chemical compound [Ca+2].OC([O-])=O.OC([O-])=O NKWPZUCBCARRDP-UHFFFAOYSA-L 0.000 description 3

- 229910000020 calcium bicarbonate Inorganic materials 0.000 description 3

- 150000001732 carboxylic acid derivatives Chemical class 0.000 description 3

- 239000008119 colloidal silica Substances 0.000 description 3

- 239000000839 emulsion Substances 0.000 description 3

- 239000000835 fiber Substances 0.000 description 3

- 239000000834 fixative Substances 0.000 description 3

- NKHAVTQWNUWKEO-UHFFFAOYSA-N fumaric acid monomethyl ester Natural products COC(=O)C=CC(O)=O NKHAVTQWNUWKEO-UHFFFAOYSA-N 0.000 description 3

- 239000003517 fume Substances 0.000 description 3

- NLYAJNPCOHFWQQ-UHFFFAOYSA-N kaolin Chemical compound O.O.O=[Al]O[Si](=O)O[Si](=O)O[Al]=O NLYAJNPCOHFWQQ-UHFFFAOYSA-N 0.000 description 3

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 3

- LVHBHZANLOWSRM-UHFFFAOYSA-N methylenebutanedioic acid Natural products OC(=O)CC(=C)C(O)=O LVHBHZANLOWSRM-UHFFFAOYSA-N 0.000 description 3

- 150000002825 nitriles Chemical class 0.000 description 3

- 239000011146 organic particle Substances 0.000 description 3

- 238000012856 packing Methods 0.000 description 3

- 229920003023 plastic Polymers 0.000 description 3

- 239000004033 plastic Substances 0.000 description 3

- 239000011164 primary particle Substances 0.000 description 3

- 239000000741 silica gel Substances 0.000 description 3

- 229910002027 silica gel Inorganic materials 0.000 description 3

- 229910052708 sodium Inorganic materials 0.000 description 3

- 239000011734 sodium Substances 0.000 description 3

- 239000011115 styrene butadiene Substances 0.000 description 3

- BDHFUVZGWQCTTF-UHFFFAOYSA-M sulfonate Chemical compound [O-]S(=O)=O BDHFUVZGWQCTTF-UHFFFAOYSA-M 0.000 description 3

- 239000011800 void material Substances 0.000 description 3

- 150000007934 α,β-unsaturated carboxylic acids Chemical class 0.000 description 3

- 239000001124 (E)-prop-1-ene-1,2,3-tricarboxylic acid Substances 0.000 description 2

- LCPVQAHEFVXVKT-UHFFFAOYSA-N 2-(2,4-difluorophenoxy)pyridin-3-amine Chemical compound NC1=CC=CN=C1OC1=CC=C(F)C=C1F LCPVQAHEFVXVKT-UHFFFAOYSA-N 0.000 description 2

- OEPOKWHJYJXUGD-UHFFFAOYSA-N 2-(3-phenylmethoxyphenyl)-1,3-thiazole-4-carbaldehyde Chemical compound O=CC1=CSC(C=2C=C(OCC=3C=CC=CC=3)C=CC=2)=N1 OEPOKWHJYJXUGD-UHFFFAOYSA-N 0.000 description 2

- ZNQVEEAIQZEUHB-UHFFFAOYSA-N 2-ethoxyethanol Chemical compound CCOCCO ZNQVEEAIQZEUHB-UHFFFAOYSA-N 0.000 description 2

- CUTWSDAQYCQTGD-UHFFFAOYSA-N 2-prop-2-enoyloxypropanoic acid Chemical compound OC(=O)C(C)OC(=O)C=C CUTWSDAQYCQTGD-UHFFFAOYSA-N 0.000 description 2

- OIYTYGOUZOARSH-UHFFFAOYSA-N 4-methoxy-2-methylidene-4-oxobutanoic acid Chemical compound COC(=O)CC(=C)C(O)=O OIYTYGOUZOARSH-UHFFFAOYSA-N 0.000 description 2

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 2

- GAWIXWVDTYZWAW-UHFFFAOYSA-N C[CH]O Chemical group C[CH]O GAWIXWVDTYZWAW-UHFFFAOYSA-N 0.000 description 2

- MHAJPDPJQMAIIY-UHFFFAOYSA-N Hydrogen peroxide Chemical compound OO MHAJPDPJQMAIIY-UHFFFAOYSA-N 0.000 description 2

- MXRIRQGCELJRSN-UHFFFAOYSA-N O.O.O.[Al] Chemical compound O.O.O.[Al] MXRIRQGCELJRSN-UHFFFAOYSA-N 0.000 description 2

- 239000004372 Polyvinyl alcohol Substances 0.000 description 2

- OFOBLEOULBTSOW-UHFFFAOYSA-N Propanedioic acid Natural products OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 description 2

- UIIMBOGNXHQVGW-UHFFFAOYSA-M Sodium bicarbonate Chemical compound [Na+].OC([O-])=O UIIMBOGNXHQVGW-UHFFFAOYSA-M 0.000 description 2

- 229920002472 Starch Polymers 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- 239000002174 Styrene-butadiene Substances 0.000 description 2

- BZHJMEDXRYGGRV-UHFFFAOYSA-N Vinyl chloride Chemical compound ClC=C BZHJMEDXRYGGRV-UHFFFAOYSA-N 0.000 description 2

- NJSSICCENMLTKO-HRCBOCMUSA-N [(1r,2s,4r,5r)-3-hydroxy-4-(4-methylphenyl)sulfonyloxy-6,8-dioxabicyclo[3.2.1]octan-2-yl] 4-methylbenzenesulfonate Chemical compound C1=CC(C)=CC=C1S(=O)(=O)O[C@H]1C(O)[C@@H](OS(=O)(=O)C=2C=CC(C)=CC=2)[C@@H]2OC[C@H]1O2 NJSSICCENMLTKO-HRCBOCMUSA-N 0.000 description 2

- 150000007513 acids Chemical class 0.000 description 2

- 229940091181 aconitic acid Drugs 0.000 description 2

- 125000003342 alkenyl group Chemical group 0.000 description 2

- 150000004996 alkyl benzenes Chemical class 0.000 description 2

- VSCWAEJMTAWNJL-UHFFFAOYSA-K aluminium trichloride Chemical compound Cl[Al](Cl)Cl VSCWAEJMTAWNJL-UHFFFAOYSA-K 0.000 description 2

- ROOXNKNUYICQNP-UHFFFAOYSA-N ammonium persulfate Chemical compound [NH4+].[NH4+].[O-]S(=O)(=O)OOS([O-])(=O)=O ROOXNKNUYICQNP-UHFFFAOYSA-N 0.000 description 2

- 238000000149 argon plasma sintering Methods 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 125000001797 benzyl group Chemical group [H]C1=C([H])C([H])=C(C([H])=C1[H])C([H])([H])* 0.000 description 2

- 230000002902 bimodal effect Effects 0.000 description 2

- 230000000740 bleeding effect Effects 0.000 description 2

- MTAZNLWOLGHBHU-UHFFFAOYSA-N butadiene-styrene rubber Chemical compound C=CC=C.C=CC1=CC=CC=C1 MTAZNLWOLGHBHU-UHFFFAOYSA-N 0.000 description 2

- CQEYYJKEWSMYFG-UHFFFAOYSA-N butyl acrylate Chemical compound CCCCOC(=O)C=C CQEYYJKEWSMYFG-UHFFFAOYSA-N 0.000 description 2

- 125000000484 butyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 2

- 229910000019 calcium carbonate Inorganic materials 0.000 description 2

- 150000001768 cations Chemical class 0.000 description 2

- 238000004587 chromatography analysis Methods 0.000 description 2

- GTZCVFVGUGFEME-IWQZZHSRSA-N cis-aconitic acid Chemical compound OC(=O)C\C(C(O)=O)=C\C(O)=O GTZCVFVGUGFEME-IWQZZHSRSA-N 0.000 description 2

- LDHQCZJRKDOVOX-NSCUHMNNSA-N crotonic acid Chemical compound C\C=C\C(O)=O LDHQCZJRKDOVOX-NSCUHMNNSA-N 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 125000003438 dodecyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 2

- 239000000975 dye Substances 0.000 description 2

- 239000001041 dye based ink Substances 0.000 description 2

- 238000002296 dynamic light scattering Methods 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 2

- 229920001519 homopolymer Polymers 0.000 description 2

- 239000003999 initiator Substances 0.000 description 2

- 239000002655 kraft paper Substances 0.000 description 2

- 230000014759 maintenance of location Effects 0.000 description 2

- VZCYOOQTPOCHFL-UPHRSURJSA-N maleic acid Chemical compound OC(=O)\C=C/C(O)=O VZCYOOQTPOCHFL-UPHRSURJSA-N 0.000 description 2

- 239000011976 maleic acid Substances 0.000 description 2

- FPYJFEHAWHCUMM-UHFFFAOYSA-N maleic anhydride Chemical compound O=C1OC(=O)C=C1 FPYJFEHAWHCUMM-UHFFFAOYSA-N 0.000 description 2

- NKHAVTQWNUWKEO-NSCUHMNNSA-N monomethyl fumarate Chemical compound COC(=O)\C=C\C(O)=O NKHAVTQWNUWKEO-NSCUHMNNSA-N 0.000 description 2

- 229940005650 monomethyl fumarate Drugs 0.000 description 2

- 125000001117 oleyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])/C([H])=C([H])\C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 2

- 125000000913 palmityl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 2

- 229920002451 polyvinyl alcohol Polymers 0.000 description 2

- 229940088417 precipitated calcium carbonate Drugs 0.000 description 2

- 239000002243 precursor Substances 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- HJWLCRVIBGQPNF-UHFFFAOYSA-N prop-2-enylbenzene Chemical compound C=CCC1=CC=CC=C1 HJWLCRVIBGQPNF-UHFFFAOYSA-N 0.000 description 2

- 239000012429 reaction media Substances 0.000 description 2

- CHQMHPLRPQMAMX-UHFFFAOYSA-L sodium persulfate Substances [Na+].[Na+].[O-]S(=O)(=O)OOS([O-])(=O)=O CHQMHPLRPQMAMX-UHFFFAOYSA-L 0.000 description 2

- 239000008107 starch Substances 0.000 description 2

- 235000019698 starch Nutrition 0.000 description 2

- 125000004079 stearyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 229920003048 styrene butadiene rubber Polymers 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- 239000000454 talc Substances 0.000 description 2

- 229910052623 talc Inorganic materials 0.000 description 2

- 238000010998 test method Methods 0.000 description 2

- 239000002562 thickening agent Substances 0.000 description 2

- 239000004408 titanium dioxide Substances 0.000 description 2

- GTZCVFVGUGFEME-UHFFFAOYSA-N trans-aconitic acid Natural products OC(=O)CC(C(O)=O)=CC(O)=O GTZCVFVGUGFEME-UHFFFAOYSA-N 0.000 description 2

- LDHQCZJRKDOVOX-UHFFFAOYSA-N trans-crotonic acid Natural products CC=CC(O)=O LDHQCZJRKDOVOX-UHFFFAOYSA-N 0.000 description 2

- 239000011787 zinc oxide Substances 0.000 description 2

- 125000003837 (C1-C20) alkyl group Chemical group 0.000 description 1

- URDCARMUOSMFFI-UHFFFAOYSA-N 2-[2-[bis(carboxymethyl)amino]ethyl-(2-hydroxyethyl)amino]acetic acid Chemical compound OCCN(CC(O)=O)CCN(CC(O)=O)CC(O)=O URDCARMUOSMFFI-UHFFFAOYSA-N 0.000 description 1

- 102000009027 Albumins Human genes 0.000 description 1

- 108010088751 Albumins Proteins 0.000 description 1

- UXVMQQNJUSDDNG-UHFFFAOYSA-L Calcium chloride Chemical compound [Cl-].[Cl-].[Ca+2] UXVMQQNJUSDDNG-UHFFFAOYSA-L 0.000 description 1

- 229920002134 Carboxymethyl cellulose Polymers 0.000 description 1

- 229920000742 Cotton Polymers 0.000 description 1

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 1

- 229920002488 Hemicellulose Polymers 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 1

- 108050003409 Mediator of RNA polymerase II transcription subunit 22 Proteins 0.000 description 1

- 102100030223 Mediator of RNA polymerase II transcription subunit 22 Human genes 0.000 description 1

- 241000282341 Mustela putorius furo Species 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 229920002873 Polyethylenimine Polymers 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 description 1

- 229910003902 SiCl 4 Inorganic materials 0.000 description 1

- DBMJMQXJHONAFJ-UHFFFAOYSA-M Sodium laurylsulphate Chemical compound [Na+].CCCCCCCCCCCCOS([O-])(=O)=O DBMJMQXJHONAFJ-UHFFFAOYSA-M 0.000 description 1

- 229920002125 Sokalan® Polymers 0.000 description 1

- 229920002522 Wood fibre Polymers 0.000 description 1

- 239000011358 absorbing material Substances 0.000 description 1

- 150000001252 acrylic acid derivatives Chemical class 0.000 description 1

- 150000001253 acrylic acids Chemical class 0.000 description 1

- XECAHXYUAAWDEL-UHFFFAOYSA-N acrylonitrile butadiene styrene Chemical compound C=CC=C.C=CC#N.C=CC1=CC=CC=C1 XECAHXYUAAWDEL-UHFFFAOYSA-N 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 229910052783 alkali metal Inorganic materials 0.000 description 1

- 150000001340 alkali metals Chemical class 0.000 description 1

- 125000005907 alkyl ester group Chemical group 0.000 description 1

- 125000000217 alkyl group Chemical group 0.000 description 1

- XYLMUPLGERFSHI-UHFFFAOYSA-N alpha-Methylstyrene Chemical compound CC(=C)C1=CC=CC=C1 XYLMUPLGERFSHI-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 150000001408 amides Chemical class 0.000 description 1

- 150000001412 amines Chemical class 0.000 description 1

- 229910021529 ammonia Inorganic materials 0.000 description 1

- 229910001870 ammonium persulfate Inorganic materials 0.000 description 1

- 229920006318 anionic polymer Polymers 0.000 description 1

- 239000012298 atmosphere Substances 0.000 description 1

- 239000003139 biocide Substances 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000001110 calcium chloride Substances 0.000 description 1

- 229910001628 calcium chloride Inorganic materials 0.000 description 1

- 239000001768 carboxy methyl cellulose Substances 0.000 description 1

- 235000010948 carboxy methyl cellulose Nutrition 0.000 description 1

- 125000002843 carboxylic acid group Chemical group 0.000 description 1

- 239000008112 carboxymethyl-cellulose Substances 0.000 description 1

- 239000005018 casein Substances 0.000 description 1

- BECPQYXYKAMYBN-UHFFFAOYSA-N casein, tech. Chemical compound NCCCCC(C(O)=O)N=C(O)C(CC(O)=O)N=C(O)C(CCC(O)=N)N=C(O)C(CC(C)C)N=C(O)C(CCC(O)=O)N=C(O)C(CC(O)=O)N=C(O)C(CCC(O)=O)N=C(O)C(C(C)O)N=C(O)C(CCC(O)=N)N=C(O)C(CCC(O)=N)N=C(O)C(CCC(O)=N)N=C(O)C(CCC(O)=O)N=C(O)C(CCC(O)=O)N=C(O)C(COP(O)(O)=O)N=C(O)C(CCC(O)=N)N=C(O)C(N)CC1=CC=CC=C1 BECPQYXYKAMYBN-UHFFFAOYSA-N 0.000 description 1

- 235000021240 caseins Nutrition 0.000 description 1

- 239000001913 cellulose Substances 0.000 description 1

- 229920002678 cellulose Polymers 0.000 description 1

- 239000002738 chelating agent Substances 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 239000011247 coating layer Substances 0.000 description 1

- 239000000084 colloidal system Substances 0.000 description 1

- 230000003750 conditioning effect Effects 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- 238000007334 copolymerization reaction Methods 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 239000003431 cross linking reagent Substances 0.000 description 1

- 238000007766 curtain coating Methods 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- LSXWFXONGKSEMY-UHFFFAOYSA-N di-tert-butyl peroxide Chemical compound CC(C)(C)OOC(C)(C)C LSXWFXONGKSEMY-UHFFFAOYSA-N 0.000 description 1

- 239000002270 dispersing agent Substances 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- GVGUFUZHNYFZLC-UHFFFAOYSA-N dodecyl benzenesulfonate;sodium Chemical compound [Na].CCCCCCCCCCCCOS(=O)(=O)C1=CC=CC=C1 GVGUFUZHNYFZLC-UHFFFAOYSA-N 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 229940079593 drug Drugs 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000003623 enhancer Substances 0.000 description 1

- FHJUNZDWQYDDNJ-UHFFFAOYSA-N ethoxy ethyl sulfate Chemical compound CCOOS(=O)(=O)OCC FHJUNZDWQYDDNJ-UHFFFAOYSA-N 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 238000005188 flotation Methods 0.000 description 1

- 239000006081 fluorescent whitening agent Substances 0.000 description 1

- PTCGDEVVHUXTMP-UHFFFAOYSA-N flutolanil Chemical compound CC(C)OC1=CC=CC(NC(=O)C=2C(=CC=CC=2)C(F)(F)F)=C1 PTCGDEVVHUXTMP-UHFFFAOYSA-N 0.000 description 1

- 239000006260 foam Substances 0.000 description 1

- 229910021485 fumed silica Inorganic materials 0.000 description 1

- 239000013538 functional additive Substances 0.000 description 1

- 230000004927 fusion Effects 0.000 description 1

- 230000009477 glass transition Effects 0.000 description 1

- 239000011796 hollow space material Substances 0.000 description 1

- GPRLSGONYQIRFK-UHFFFAOYSA-N hydron Chemical compound [H+] GPRLSGONYQIRFK-UHFFFAOYSA-N 0.000 description 1

- 229920003063 hydroxymethyl cellulose Polymers 0.000 description 1

- 229940031574 hydroxymethyl cellulose Drugs 0.000 description 1

- 230000008595 infiltration Effects 0.000 description 1

- 238000001764 infiltration Methods 0.000 description 1

- 238000007603 infrared drying Methods 0.000 description 1

- 239000004615 ingredient Substances 0.000 description 1

- 239000003112 inhibitor Substances 0.000 description 1

- 229920005610 lignin Polymers 0.000 description 1

- 238000012886 linear function Methods 0.000 description 1

- 229910052744 lithium Inorganic materials 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- NKHAVTQWNUWKEO-IHWYPQMZSA-N methyl hydrogen fumarate Chemical compound COC(=O)\C=C/C(O)=O NKHAVTQWNUWKEO-IHWYPQMZSA-N 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 239000005022 packaging material Substances 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- JRKICGRDRMAZLK-UHFFFAOYSA-L peroxydisulfate Chemical compound [O-]S(=O)(=O)OOS([O-])(=O)=O JRKICGRDRMAZLK-UHFFFAOYSA-L 0.000 description 1

- 239000003348 petrochemical agent Substances 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 229920000058 polyacrylate Polymers 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 239000013047 polymeric layer Substances 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 229920000036 polyvinylpyrrolidone Polymers 0.000 description 1

- 239000001267 polyvinylpyrrolidone Substances 0.000 description 1

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 description 1

- 229910052700 potassium Inorganic materials 0.000 description 1

- 239000011591 potassium Substances 0.000 description 1

- 239000003755 preservative agent Substances 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 235000018102 proteins Nutrition 0.000 description 1

- 102000004169 proteins and genes Human genes 0.000 description 1

- 108090000623 proteins and genes Proteins 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 238000010526 radical polymerization reaction Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 239000011541 reaction mixture Substances 0.000 description 1

- 238000002310 reflectometry Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 238000000518 rheometry Methods 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 238000010112 shell-mould casting Methods 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 238000004513 sizing Methods 0.000 description 1

- 235000017557 sodium bicarbonate Nutrition 0.000 description 1

- 229910000030 sodium bicarbonate Inorganic materials 0.000 description 1

- 229940080264 sodium dodecylbenzenesulfonate Drugs 0.000 description 1

- 235000019333 sodium laurylsulphate Nutrition 0.000 description 1

- 159000000000 sodium salts Chemical class 0.000 description 1

- 238000001179 sorption measurement Methods 0.000 description 1

- 239000012798 spherical particle Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 229920001909 styrene-acrylic polymer Polymers 0.000 description 1

- 230000003746 surface roughness Effects 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

- 230000008961 swelling Effects 0.000 description 1

- 239000012209 synthetic fiber Substances 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 239000011882 ultra-fine particle Substances 0.000 description 1

- 235000013311 vegetables Nutrition 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- 239000002025 wood fiber Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J3/00—Processes of treating or compounding macromolecular substances

- C08J3/12—Powdering or granulating

- C08J3/126—Polymer particles coated by polymer, e.g. core shell structures

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F212/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an aromatic carbocyclic ring

- C08F212/02—Monomers containing only one unsaturated aliphatic radical

- C08F212/04—Monomers containing only one unsaturated aliphatic radical containing one ring

- C08F212/06—Hydrocarbons

- C08F212/08—Styrene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F265/00—Macromolecular compounds obtained by polymerising monomers on to polymers of unsaturated monocarboxylic acids or derivatives thereof as defined in group C08F20/00

- C08F265/02—Macromolecular compounds obtained by polymerising monomers on to polymers of unsaturated monocarboxylic acids or derivatives thereof as defined in group C08F20/00 on to polymers of acids, salts or anhydrides

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F265/00—Macromolecular compounds obtained by polymerising monomers on to polymers of unsaturated monocarboxylic acids or derivatives thereof as defined in group C08F20/00

- C08F265/04—Macromolecular compounds obtained by polymerising monomers on to polymers of unsaturated monocarboxylic acids or derivatives thereof as defined in group C08F20/00 on to polymers of esters

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J3/00—Processes of treating or compounding macromolecular substances

- C08J3/12—Powdering or granulating

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/0061—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof characterized by the use of several polymeric components

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/16—Making expandable particles

- C08J9/18—Making expandable particles by impregnating polymer particles with the blowing agent

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/22—After-treatment of expandable particles; Forming foamed products

- C08J9/224—Surface treatment

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/26—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof by elimination of a solid phase from a macromolecular composition or article, e.g. leaching out

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D151/00—Coating compositions based on graft polymers in which the grafted component is obtained by reactions only involving carbon-to-carbon unsaturated bonds; Coating compositions based on derivatives of such polymers

- C09D151/003—Coating compositions based on graft polymers in which the grafted component is obtained by reactions only involving carbon-to-carbon unsaturated bonds; Coating compositions based on derivatives of such polymers grafted on to macromolecular compounds obtained by reactions only involving unsaturated carbon-to-carbon bonds

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H19/00—Coated paper; Coating material

- D21H19/10—Coatings without pigments

- D21H19/14—Coatings without pigments applied in a form other than the aqueous solution defined in group D21H19/12

- D21H19/20—Coatings without pigments applied in a form other than the aqueous solution defined in group D21H19/12 comprising macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H19/00—Coated paper; Coating material

- D21H19/10—Coatings without pigments

- D21H19/14—Coatings without pigments applied in a form other than the aqueous solution defined in group D21H19/12

- D21H19/20—Coatings without pigments applied in a form other than the aqueous solution defined in group D21H19/12 comprising macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- D21H19/22—Polyalkenes, e.g. polystyrene

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H19/00—Coated paper; Coating material

- D21H19/36—Coatings with pigments

- D21H19/38—Coatings with pigments characterised by the pigments

- D21H19/42—Coatings with pigments characterised by the pigments at least partly organic

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H21/00—Non-fibrous material added to the pulp, characterised by its function, form or properties; Paper-impregnating or coating material, characterised by its function, form or properties

- D21H21/50—Non-fibrous material added to the pulp, characterised by its function, form or properties; Paper-impregnating or coating material, characterised by its function, form or properties characterised by form

- D21H21/52—Additives of definite length or shape

- D21H21/54—Additives of definite length or shape being spherical, e.g. microcapsules, beads

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2325/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an aromatic carbocyclic ring; Derivatives of such polymers

- C08J2325/02—Homopolymers or copolymers of hydrocarbons

- C08J2325/04—Homopolymers or copolymers of styrene

- C08J2325/08—Copolymers of styrene

- C08J2325/14—Copolymers of styrene with unsaturated esters

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2333/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers

- C08J2333/02—Homopolymers or copolymers of acids; Metal or ammonium salts thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2333/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers

- C08J2333/04—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters

- C08J2333/06—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters of esters containing only carbon, hydrogen, and oxygen, the oxygen atom being present only as part of the carboxyl radical

- C08J2333/08—Homopolymers or copolymers of acrylic acid esters

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2333/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers

- C08J2333/04—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters

- C08J2333/06—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters of esters containing only carbon, hydrogen, and oxygen, the oxygen atom being present only as part of the carboxyl radical

- C08J2333/10—Homopolymers or copolymers of methacrylic acid esters

- C08J2333/12—Homopolymers or copolymers of methyl methacrylate

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2425/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an aromatic carbocyclic ring; Derivatives of such polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2425/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an aromatic carbocyclic ring; Derivatives of such polymers

- C08J2425/02—Homopolymers or copolymers of hydrocarbons

- C08J2425/04—Homopolymers or copolymers of styrene

- C08J2425/08—Copolymers of styrene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2433/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/29—Coated or structually defined flake, particle, cell, strand, strand portion, rod, filament, macroscopic fiber or mass thereof

- Y10T428/2982—Particulate matter [e.g., sphere, flake, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/29—Coated or structually defined flake, particle, cell, strand, strand portion, rod, filament, macroscopic fiber or mass thereof

- Y10T428/2982—Particulate matter [e.g., sphere, flake, etc.]

- Y10T428/2989—Microcapsule with solid core [includes liposome]

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Organic Chemistry (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Health & Medical Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Crystallography & Structural Chemistry (AREA)

- Life Sciences & Earth Sciences (AREA)

- Wood Science & Technology (AREA)

- Paper (AREA)

- Graft Or Block Polymers (AREA)

Description

本出願は、米国仮出願番号61/212,638(代理人整理番号67020、2009年4月14日出願)および米国仮出願番号61/214,093(代理人整理番号67020(US−0206.03)、2009年4月20日出願)の両者に関連する出願であり、これらに対して優先権を主張する。これらの開示は本明細書中に参考として援用される。

本明細書の開示は有機ポリマー粒子、該有機ポリマー粒子を含む紙コーティング組成物、該紙コーティング組成物を使用して形成されたコート紙および/または板紙、有機ポリマー粒子を形成する方法、該紙コーティング組成物を使用してコート紙および/または板紙を製造する方法に関する。

印刷されたテキストおよび/または紙上のイメージの外観は、紙の上のコーティングの存在により影響を受けることができる。コーティングはクレー、顔料、およびバインダーの混合物を含むことができる。インクがコーティングしていない紙に適用されるとき、それは紙によって吸収される。インクがコーティングの上に配置された時には、コーティングされた紙の上に保持される。この特性により、コート紙上に印刷されたインクは、くっきりしたエッジを保有できる。その結果、コート紙は、一般に、より鋭くて、より明るいイメージを形成して、コーティングしていない紙より良い反射性を有している。

本明細書に議論するように、有機ポリマー粒子の実施態様は水素結合形成のためのユニットを有する有機親水性ポリマーと、少なくとも部分的に有機親水性ポリマーを取り囲む有機ポリマーの中空ポーラス構造体(hollow porous structure)を含み;該中空ポーラス構造体が理論的な総外表面積の1パーセント以上のポア表面積を持ち、そして、該有機親水性ポリマーと該中空ポーラス構造体が、40パーセントから85パーセントの範囲内の空隙率(void volume fraction)を該有機ポリマー粒子に与える。

本明細書において使用される時、「紙」は野菜および/または木材繊維、たとえばセルロースなどのような、ヘミセルロース、リグニンおよび/または合成繊維を少なくとも一部含むことができるファイバーの融合体に基づく基紙をいう。理解されるように、紙の基紙組成物に他の成分を含むことができる。さらに、「紙」という用語は紙および/または板紙を含む様に意味される。本明細書において使用される時、紙および/または板紙はそれらの厚さ、強度および/または重量において異なることができるが、コート紙および/または板紙を形成するために本明細書に提供された紙コーティング組成物および方法の実施態様によって両方が変成されることが意図される。改良された読み易さのために、「紙および/または板紙」という句は「紙」という用語に置き換えられる。用語の使用されている文脈から明確にそうではないことが明らかでない限り、用語「紙」は「紙および/または板紙」の両者を包含する。

したがって、例えば、バインダーを含む反応混合物は、バインダーが「1種以上の」バインダーを含んでいることを意味すると解釈できる。

実施例

ボリュームメディアン直径

有機ポリマー粒子のボリュームメディアン直径は流体力学クロマトグラフィーで測定される。流体力学クロマトグラフィーを使用することでボリュームメディアン直径を決定する方法は、「一体化された高速コンピューターによる流体力学的なクロマトグラフの発達と用途”Development and application of an integrated, high-speed, computerized hydrodynamic chromatograph"」、Journal of Colloid and Interface Science, Vol. 89, Issue I. September 1982, Pgs.94-106, Gerald R. McGowan and Martin A. Langhorstに提示される。この文献は全体が参照のため援用される。

紙の光沢は、75°(度)の入射角でTechnidyne GlossmeterモデルT480Aを使用して測定される。光沢はコート紙のサンプルの複数点で測定される。それぞれのコート紙のサンプルを横切る直線上の5カ所(すなわち、左端、中心の左側、中心、中心の右側、右端)を決め、2回測定した。報告された光沢値は、10回の読みの平均である。

コート重量は、10分間、コート紙のサンプルを熱オーブンで130−140℃で乾燥した後に、コート紙のサンプルの質量からコーティングしていない紙のサンプルの質量を引き算することによって測定した。標本のサンプルは、基紙とそれぞれのコーティングについて100cm2で12枚、切断型で切られた。報告されたコート重量値は、12個のサンプルの平均である。

平滑性

空隙率は、以下の手順を用いて測定される。50mlのポリプロピレン遠心分離機チューブ(半球の下部を有する)に、有機ポリマー粒子を含む40グラムのラテックスが加えられた。チューブは、遠心分離機に置かれて、180分間1万9500rpmで回転される。上澄みはデカントされ、秤量される。ラテックス質量、個体パーセント、および上澄み質量から、空隙率(fvoid)は、以下の方程式を使用することで決定される:

fvoid=((VT−SH2O)*(FR−VP))/((VT−SH2O)*FR)

ここで:

VPはポリマー容積(ポリマー質量/ポリマー密度)である。コポリマーの密度は、それぞれのモノマーのホモポリマーの密度の文献値を使用して、コポリマーの密度がコポリマーの組成物の一次関数であると仮定して計算された。Peter A. Lovell and Mohamed S.El-Aasser,「エマルション重合とエマルションポリマー」"Emulsion Polymerization and Emulsion Polymers";p. 624, John Wiley and Sons:New York (1997)を参照。これは、本明細書中に参考として援用される。

VT=チューブ内の合計容積(ラテックスの質量/ラテックスの密度)

SH2O=上澄みの容積=上澄みの重量

FR=本質的に単分散球のランダム充填では0.64である充填効率

充填効率は固いパック内の固体の容積分率に対応する修正である。

ポア表面積は、有機ポリマー粒子のSEM画像を使用して決定する。ポア表面積を決定するために、データからのいくつかの推論が使用されている。最初に、信頼性良く示され測定できるポア面積は有機ポリマー粒子の中空ポーラス構造体の表面にのみ存在し、これはイメージで見られる投射直径のミドルサード(middle third)に過ぎない。これは有機ポリマー粒子の側面に向くポアは、角度があり、ポアの投射断面積は新のポアの断面積よりも小さい。2番目に、走査型電子顕微鏡は球のまっすぐな下方向への投射であり、測定される有機ポリマー粒子の中空ポーラス構造体の「面積」は係数2だけ小さくなる。ポアの最も大きい10パーセントの加重平均がポア径として使用される。

S=2πrh、

ここでSはキャップの表面積である。rは球体の有機ポリマー粒子の半径である。hは交差平面上のキャップの高さである。

以下の材料が塗料に使用される:

コート紙のための基紙は58lb/3300ft2の、着色されたサイズ剤(Appleton PapersからのUtopia)で予備被覆された、木材を含まない、クラフト繊維シートである。塗料配合は以下の通りである:55重量部の炭酸水素カルシウム(オムヤからのHydrocarb60)と、45部の表2に記載された粒子により、合計で100部の粒子を与えた。すべての塗料配合物が10重量部のカルボキシル化 SBラテックス接着剤CP 615MA、および合成増粘剤(AKZO NOBELからのAlcogum L−229)の1部を含んでいた。コーティング配合および物理的性質を以下の表2に示す。

ダウ実験室用コーターを使用して、塗料配合物を基紙に適用する。15フィート/分の被覆速度でブレード−メータリング(blade-metering)法を利用して、ウェブ形状の基紙をコーティングする。メータリングブレードとペーパー・ウェブの間に形成されたギャップにコーティングをシリンジで適用する。ウェブ速度とメータリングブレードに加えられるチューブ圧の組み合わせにより、目標コーティング量(グラム/m2)を達成する。いったん適用されると、2つの赤外線乾燥ゾーンと250℃で操作される2つの熱気浮揚乾燥帯で、コーティングを乾燥する。速度と乾燥温度の組み合わせでコート紙の最終的な湿り気を変えることができる。

実験室用カレンダリング処理の前に、コート紙を所定のシートサイズ(8.5 × 11インチ)に切断する。カレンダー加工はBeloit Wheeler Model753研究所用カレンダーで実行される。150°Fの鉄鋼ロール温度、3ニップ、およびリニアインチ当たり200、400,および60ポンド(pli)の圧力で全ての実験が行われた。

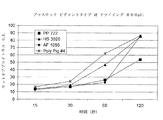

コート紙に関するウイックおよびブリード

ウイック(wick)とブリードテストは、コート紙のための吸水率の良い定量的な尺度を提供する。実施例1において、コート紙のサンプルの上の印字行における染料ベースのインクのウイックとブリードの特性が評価された。染料ベースのインクは、HP78トリカラーインクジェット(Tri-ColorInkJet)プリント・カートリッジとHP45の黒色インクジェットプリント・カートリッジである。HPデスクジェット932Cは、印字行をコート紙に作成するために使用された。

この実施例では、実施例3に記載されるような、有機ポリマー粒子4を含む塗料配合物を有するコート紙が、Staples(登録商標)で購入されたさまざまな写真用高級紙に、HPプリンタで印刷され比較される。テストされた写真用高級紙としては、エプソン(Epson(登録商標)) カラーライフ 半−光沢(ColorLife Semi-Gloss)、Staples(登録商標) フォトスーパーつや消し仕上げ(Photo Supreme Matte-finish)、エプソン(Epson)、つや消し重量写真紙( Matte Heavyweight photo paper)、およびHP プレミアム プラス(Premium Plus)が含まれる。実施例3に記載されるような有機ポリマー粒子4を含む塗料配合物を有するコート紙を、実施例1で記載されていた手順で調製した。また、実施例1のように、色留め剤溶液が0.5重量%で適用された。

材料

H P78トリカラーインクジェットプリント・カートリッジを備えたヒュレットパッカード デクスジェット(Hewlett Packard Deskjet) 932C プリンタ、およびHP45の黒色インクジェットプリント・カートリッジ

この実施例では、上記の方法により、本発明の有機ポリマー粒子4とHS3200のポア表面積を決定する。

Claims (6)

- 以下を含む、有機ポリマー粒子を形成する方法;

酸基、潜在性酸基、またはそれらの組み合わせを含むモノマーを重合することにより有機親水性ポリマーのコアを形成すること、ここで潜在性酸基を含むモノマーは必ず含まれる;

スチレンモノマーと潜在性酸基を含むモノマーを重合することにより有機ポリマーを含むシェルを形成し、該コアを取り囲むこと、ここで該シェルは当初の大きさを有する;

該コアを膨張させ、該シェルを当初のシェルのサイズより大きなサイズに膨張させること;および

該潜在性酸基を加水分解し、40パーセントから85パーセントの空隙率、および理論上の総外側表面積の1パーセント以上のポア表面積を有する中空ポーラス構造体を得ること。 - 該シェルの有機ポリマーを形成する際に使用される潜在性酸基の量を調整することによって、該中空ポーラス構造体におけるポアのサイズを調整することを含む、請求項1記載の方法。

- 該コアの有機親水性ポリマーを架橋することを含む、請求項1または2記載の方法。

- 該シェルを形成することが、シェルを形成するモノマーの合計重量に基づいてアクリレートモノマーの5から10重量部と、スチレンモノマーの95から90重量部からシェルを形成することを含む、請求項1から3のいずれか1項記載の方法。

- 該潜在性酸基がエステル基である、請求項1または2記載の方法。

- 加水分解が加圧下で140℃まで加熱することにより行われる、請求項5記載の方法。

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US21263809P | 2009-04-14 | 2009-04-14 | |

| US61/212,638 | 2009-04-14 | ||

| US21409309P | 2009-04-20 | 2009-04-20 | |

| US61/214,093 | 2009-04-20 | ||

| PCT/US2010/000978 WO2010120344A1 (en) | 2009-04-14 | 2010-04-01 | Organic polymeric particles, paper coating compositions, and methods |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2012524150A JP2012524150A (ja) | 2012-10-11 |

| JP2012524150A5 JP2012524150A5 (ja) | 2013-04-11 |

| JP6068979B2 true JP6068979B2 (ja) | 2017-01-25 |

Family

ID=42227603

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012505877A Active JP6068979B2 (ja) | 2009-04-14 | 2010-04-01 | 有機ポリマー粒子、紙コーティング組成物、および方法 |

Country Status (6)

| Country | Link |

|---|---|

| US (5) | US20120136078A1 (ja) |

| EP (1) | EP2419463B1 (ja) |

| JP (1) | JP6068979B2 (ja) |

| BR (1) | BRPI1006579B8 (ja) |

| CA (1) | CA2758241C (ja) |

| WO (1) | WO2010120344A1 (ja) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2419463B1 (en) | 2009-04-14 | 2022-07-20 | Dow Global Technologies LLC | Organic polymeric particles, paper coating compositions, and methods |

| US10634612B2 (en) | 2016-07-19 | 2020-04-28 | Hp Indigo B.V. | Assessment of primer content on a print substrate |

| US10730334B1 (en) | 2017-04-21 | 2020-08-04 | Omnova Solutions Inc. | Thermosensitive recording material |

| WO2018216784A1 (ja) * | 2017-05-24 | 2018-11-29 | 積水化学工業株式会社 | 測定試薬用ラテックス粒子、感作ラテックス粒子及び免疫比濁法用測定試薬 |

| JP2020158638A (ja) * | 2019-03-27 | 2020-10-01 | 日本ゼオン株式会社 | 中空重合体粒子の製造方法 |

| CN110041741B (zh) * | 2019-04-04 | 2021-03-02 | 东南大学 | 一种高效集水自清洁超双疏涂层及其制备方法 |

| WO2024129692A1 (en) * | 2022-12-16 | 2024-06-20 | Rohm And Haas Company | Hollow sphere pigments disposed on a substrate |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA1180474A (en) * | 1979-06-26 | 1985-01-02 | Alexander Kowalski | Sequential heteropolymer dispersion and a particulate material obtainable therefrom useful in coating compositions as a thickening and/or opacifying agent |

| JPS5917636B2 (ja) | 1979-07-13 | 1984-04-23 | 東洋電機製造株式会社 | Pwmインバ−タ装置 |

| JP2728910B2 (ja) * | 1988-12-27 | 1998-03-18 | 三井東圧化学株式会社 | 小孔を有する合成樹脂粒子の製造法 |

| JP2872710B2 (ja) * | 1989-10-27 | 1999-03-24 | 三井化学株式会社 | 合成樹脂エマルション及びその製造方法 |

| EP0467646B2 (en) * | 1990-07-16 | 2006-05-17 | Mitsui Chemicals, Inc. | Process for the preparation of multi-shell emulsion particles |

| JP2999594B2 (ja) * | 1990-07-16 | 2000-01-17 | 三井化学株式会社 | 多層構造エマルション粒子 |

| US5157084A (en) | 1990-10-12 | 1992-10-20 | The Dow Chemical Company | Process of making hollow polymer latex particles |

| US5521253A (en) * | 1990-10-12 | 1996-05-28 | The Dow Chemical Company | Hollow polymer latex particles |

| SG84480A1 (en) * | 1992-04-10 | 2001-11-20 | Rohm & Haas | Polymeric particles |

| AU666332B2 (en) * | 1992-08-19 | 1996-02-08 | Omnova Solutions Inc. | Hollow polymer latex particles |

| ID18920A (id) * | 1996-11-15 | 1998-05-20 | Rohm & Haas | Komposisi lapisan dengan gloss rendah |

| AU2002317533A1 (en) * | 2002-01-07 | 2003-07-24 | Rohm And Haas Company | Process for preparing emulsion polymers and polymers formed therefrom |

| CN100427543C (zh) * | 2003-01-21 | 2008-10-22 | 株式会社可乐丽 | 丙烯酸类聚合物粉末、丙烯酸溶胶以及成形物 |

| CA2488981C (en) * | 2003-12-15 | 2008-06-17 | Rohm And Haas Company | Oil absorbing composition and process |

| CA2577549C (en) | 2004-08-25 | 2017-02-21 | John Tsavalas | Paper manufacturing using agglomerated hollow particle latex |

| US8236431B2 (en) * | 2006-10-03 | 2012-08-07 | Rohm And Haas Company | Hollow organic pigment core binder coated paper and paperboard articles and methods for making the same |

| JPWO2008126521A1 (ja) * | 2007-03-30 | 2010-07-22 | 綜研化学株式会社 | アクリル中空粒子、アクリル中空粒子の製造方法、およびこの粒子を含有する化粧料 |

| CN102677538B (zh) | 2007-06-18 | 2014-12-31 | 欧美诺华解决方案公司 | 纸涂布组合物、涂布纸和方法 |

| EP2419463B1 (en) | 2009-04-14 | 2022-07-20 | Dow Global Technologies LLC | Organic polymeric particles, paper coating compositions, and methods |

-

2010

- 2010-04-01 EP EP10714118.6A patent/EP2419463B1/en active Active

- 2010-04-01 US US13/264,521 patent/US20120136078A1/en not_active Abandoned

- 2010-04-01 JP JP2012505877A patent/JP6068979B2/ja active Active

- 2010-04-01 CA CA2758241A patent/CA2758241C/en active Active

- 2010-04-01 WO PCT/US2010/000978 patent/WO2010120344A1/en active Application Filing

- 2010-04-01 BR BRPI1006579A patent/BRPI1006579B8/pt active IP Right Grant

-

2014

- 2014-11-14 US US14/541,776 patent/US20150072147A1/en not_active Abandoned

-

2015

- 2015-11-17 US US14/943,321 patent/US10351678B2/en active Active

-

2017

- 2017-10-24 US US15/791,558 patent/US10189958B2/en active Active

-

2019

- 2019-01-25 US US16/258,003 patent/US10774187B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP2419463B1 (en) | 2022-07-20 |

| US20190153172A1 (en) | 2019-05-23 |

| CA2758241A1 (en) | 2010-10-21 |

| CA2758241C (en) | 2018-08-28 |

| WO2010120344A1 (en) | 2010-10-21 |

| US10774187B2 (en) | 2020-09-15 |

| BRPI1006579B8 (pt) | 2023-04-25 |

| BRPI1006579B1 (pt) | 2019-12-31 |

| US20160068640A1 (en) | 2016-03-10 |

| US20120136078A1 (en) | 2012-05-31 |

| US10189958B2 (en) | 2019-01-29 |

| US20150072147A1 (en) | 2015-03-12 |

| JP2012524150A (ja) | 2012-10-11 |

| EP2419463A1 (en) | 2012-02-22 |

| BRPI1006579A2 (pt) | 2017-05-02 |

| US10351678B2 (en) | 2019-07-16 |

| US20180072854A1 (en) | 2018-03-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10774187B2 (en) | Organic polymeric particles, paper coating compositions, and methods | |

| JP5064616B2 (ja) | 改良された印刷品質を有する紙 | |

| US8334047B2 (en) | Paper coating compositions, coated papers, and methods | |

| KR940003956B1 (ko) | 유심다층구조 에멀션 입자 | |

| JP5841659B2 (ja) | 記録媒体 | |

| JPH11348416A (ja) | インクジェット記録用シート及びその製造方法 | |

| WO2011115167A1 (ja) | 印刷用塗工紙およびその製造方法 | |

| WO2001083232A1 (fr) | Feuille support d'impression et procede de production correspondant | |

| JP2012197545A (ja) | 印刷用塗工紙およびその製造方法 | |

| JP2940851B2 (ja) | 印刷用塗被紙 | |

| JPWO2003097370A1 (ja) | インクジェット記録用紙 | |

| JP2006111980A (ja) | 塗被組成物及び塗被紙 | |

| JP4310527B2 (ja) | インクジェット用光沢記録紙、並びにその製造方法 | |

| EP3458276B1 (en) | Printable recording medium | |

| JP4171863B2 (ja) | 記録シート用バインダー及び記録シートの製造方法 | |

| JPS6321636B2 (ja) | ||

| JP2010163708A (ja) | 紙塗工用組成物及びそれを用いて得られた塗工紙 | |

| JP3976258B2 (ja) | 普通紙タイプのインクジェット記録媒体 | |

| JP2005290579A (ja) | 塗工紙の製造方法 | |

| JP3900701B2 (ja) | 塗工板紙および塗工用組成物 | |

| JP2006240257A (ja) | インクジェット記録媒体用有機粒子の分散系およびこれを用いたインクジェット記録媒体 | |

| JP2016166443A (ja) | オフセット印刷用紙 | |

| JP2004358736A (ja) | 光沢インクジェット記録媒体およびその製造方法 | |

| JP2005281886A (ja) | キャスト塗工紙及びその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130221 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130221 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130725 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130819 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20131118 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20131125 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20131213 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20140609 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20141007 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20141121 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20141201 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20150116 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160817 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20161226 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6068979 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |