JP6066760B2 - 成膜方法 - Google Patents

成膜方法 Download PDFInfo

- Publication number

- JP6066760B2 JP6066760B2 JP2013030404A JP2013030404A JP6066760B2 JP 6066760 B2 JP6066760 B2 JP 6066760B2 JP 2013030404 A JP2013030404 A JP 2013030404A JP 2013030404 A JP2013030404 A JP 2013030404A JP 6066760 B2 JP6066760 B2 JP 6066760B2

- Authority

- JP

- Japan

- Prior art keywords

- film

- layer

- combustion chamber

- film formation

- manufacturing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000151 deposition Methods 0.000 title description 11

- 238000000034 method Methods 0.000 claims description 125

- 230000015572 biosynthetic process Effects 0.000 claims description 63

- 239000007921 spray Substances 0.000 claims description 56

- 238000002485 combustion reaction Methods 0.000 claims description 30

- 238000010438 heat treatment Methods 0.000 claims description 29

- 238000004519 manufacturing process Methods 0.000 claims description 25

- 238000005323 electroforming Methods 0.000 claims description 13

- 239000000945 filler Substances 0.000 claims description 11

- 239000002184 metal Substances 0.000 claims description 11

- 229910052751 metal Inorganic materials 0.000 claims description 11

- 238000001816 cooling Methods 0.000 claims description 10

- 239000007789 gas Substances 0.000 description 18

- 230000008021 deposition Effects 0.000 description 10

- 239000000463 material Substances 0.000 description 10

- 230000001590 oxidative effect Effects 0.000 description 10

- 239000000843 powder Substances 0.000 description 9

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 8

- 229910052802 copper Inorganic materials 0.000 description 7

- 239000010949 copper Substances 0.000 description 7

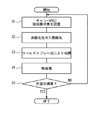

- 238000010586 diagram Methods 0.000 description 6

- 230000000694 effects Effects 0.000 description 5

- 230000000052 comparative effect Effects 0.000 description 4

- 239000000758 substrate Substances 0.000 description 4

- 229910052734 helium Inorganic materials 0.000 description 3

- 230000003647 oxidation Effects 0.000 description 3

- 238000007254 oxidation reaction Methods 0.000 description 3

- 238000005507 spraying Methods 0.000 description 3

- 238000011282 treatment Methods 0.000 description 3

- 229910052786 argon Inorganic materials 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 238000002474 experimental method Methods 0.000 description 2

- 239000012530 fluid Substances 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 239000012528 membrane Substances 0.000 description 2

- 229910052757 nitrogen Inorganic materials 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 239000003507 refrigerant Substances 0.000 description 2

- 230000008719 thickening Effects 0.000 description 2

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- CMPNPRUFRJFQIB-UHFFFAOYSA-N [N].[Cu] Chemical compound [N].[Cu] CMPNPRUFRJFQIB-UHFFFAOYSA-N 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 238000010288 cold spraying Methods 0.000 description 1

- 230000006837 decompression Effects 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 239000001307 helium Substances 0.000 description 1

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 238000005554 pickling Methods 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 230000003252 repetitive effect Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C24/00—Coating starting from inorganic powder

- C23C24/02—Coating starting from inorganic powder by application of pressure only

- C23C24/04—Impact or kinetic deposition of particles

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C4/00—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge

- C23C4/04—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge characterised by the coating material

- C23C4/06—Metallic material

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C4/00—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge

- C23C4/12—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge characterised by the method of spraying

- C23C4/137—Spraying in vacuum or in an inert atmosphere

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013030404A JP6066760B2 (ja) | 2013-02-19 | 2013-02-19 | 成膜方法 |

| PCT/JP2013/063896 WO2014128983A1 (ja) | 2013-02-19 | 2013-05-20 | 成膜方法 |

| US14/764,766 US9951426B2 (en) | 2013-02-19 | 2013-05-20 | Method for depositing layer |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013030404A JP6066760B2 (ja) | 2013-02-19 | 2013-02-19 | 成膜方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2014159613A JP2014159613A (ja) | 2014-09-04 |

| JP2014159613A5 JP2014159613A5 (enExample) | 2015-12-17 |

| JP6066760B2 true JP6066760B2 (ja) | 2017-01-25 |

Family

ID=51390802

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013030404A Active JP6066760B2 (ja) | 2013-02-19 | 2013-02-19 | 成膜方法 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US9951426B2 (enExample) |

| JP (1) | JP6066760B2 (enExample) |

| WO (1) | WO2014128983A1 (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2021080943A1 (en) * | 2019-10-21 | 2021-04-29 | Westinghouse Electric Company Llc | Multiple nozzle design in a cold spray system and associated method |

| US20220331914A1 (en) * | 2021-04-15 | 2022-10-20 | General Electric Company | Methods of coating components with cold spray and brazing coated components |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060121187A1 (en) | 2004-12-03 | 2006-06-08 | Haynes Jeffrey D | Vacuum cold spray process |

| US20060269685A1 (en) * | 2005-05-31 | 2006-11-30 | Honeywell International, Inc. | Method for coating turbine engine components with high velocity particles |

| JP2008127676A (ja) * | 2006-11-24 | 2008-06-05 | Toyohashi Univ Of Technology | 金属皮膜の形成方法 |

| JP2009191349A (ja) * | 2008-02-18 | 2009-08-27 | Honda Motor Co Ltd | 強化皮膜の接合界面の改質方法 |

| JP5017675B2 (ja) | 2008-04-01 | 2012-09-05 | 富士岐工産株式会社 | 皮膜の製造方法 |

| JP2010047825A (ja) | 2008-08-25 | 2010-03-04 | Mitsubishi Heavy Ind Ltd | 金属皮膜の形成方法及び航空宇宙構造部材 |

| US20100170937A1 (en) | 2009-01-07 | 2010-07-08 | General Electric Company | System and Method of Joining Metallic Parts Using Cold Spray Technique |

| JP5642461B2 (ja) * | 2010-09-07 | 2014-12-17 | 三菱重工業株式会社 | ロケットエンジンの燃焼室及び中空構造体の製造方法 |

-

2013

- 2013-02-19 JP JP2013030404A patent/JP6066760B2/ja active Active

- 2013-05-20 WO PCT/JP2013/063896 patent/WO2014128983A1/ja not_active Ceased

- 2013-05-20 US US14/764,766 patent/US9951426B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2014159613A (ja) | 2014-09-04 |

| WO2014128983A1 (ja) | 2014-08-28 |

| US9951426B2 (en) | 2018-04-24 |

| US20150368807A1 (en) | 2015-12-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6066759B2 (ja) | 成膜方法 | |

| KR102540252B1 (ko) | 반도체 소자의 제조 방법 | |

| WO2012128327A1 (ja) | 積層体、導電材料および積層体の製造方法 | |

| JP6066760B2 (ja) | 成膜方法 | |

| KR102412911B1 (ko) | 실린더 타겟의 제조방법 | |

| JP2017008379A (ja) | クラッドパイプ及びクラッドパイプの製造方法 | |

| TWI667364B (zh) | 包括SiC蒸鍍層的半導體製造用部件及其製造方法 | |

| JP2006144061A (ja) | 遮熱コーティング部材およびその形成方法 | |

| US9963772B2 (en) | Interior material for thin film deposition device and method for manufacturing same | |

| JP5642461B2 (ja) | ロケットエンジンの燃焼室及び中空構造体の製造方法 | |

| JP5830660B2 (ja) | スパッタリング方法 | |

| KR20210007339A (ko) | 내식성 보호막 증착 방법 | |

| JP6037885B2 (ja) | 成膜方法 | |

| WO2018066392A1 (ja) | タービン翼の製造方法 | |

| US11123820B2 (en) | Process of forming a metal additive manufactured part with a smooth surface | |

| JP5628231B2 (ja) | 積層体 | |

| JP6206159B2 (ja) | 半導体装置の製造方法 | |

| JP6131701B2 (ja) | 半導体基板の製造方法 | |

| JP2020083734A (ja) | SiC部材の製造方法 | |

| JP5490927B2 (ja) | クロス・カップリング反応によるアルミニウム硬化材の製造方法 | |

| TWI716184B (zh) | 金屬層的形成方法 | |

| KR20170072624A (ko) | 금속 및 세라믹 복합재 형성 방법 | |

| JP2023116088A (ja) | 金属材料及びプラズマ発生装置 | |

| CN106925484B (zh) | 一种带有封孔结构的阳极氧化层结构及封孔方法 | |

| KR20220170095A (ko) | 플라즈마 나노질화층이 형성된 프로펠러의 제조방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20151029 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20151029 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160831 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20161031 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20161122 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20161220 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 6066760 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |