WO2014128983A1 - 成膜方法 - Google Patents

成膜方法 Download PDFInfo

- Publication number

- WO2014128983A1 WO2014128983A1 PCT/JP2013/063896 JP2013063896W WO2014128983A1 WO 2014128983 A1 WO2014128983 A1 WO 2014128983A1 JP 2013063896 W JP2013063896 W JP 2013063896W WO 2014128983 A1 WO2014128983 A1 WO 2014128983A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- film

- cold spray

- film forming

- film formation

- thickness

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C24/00—Coating starting from inorganic powder

- C23C24/02—Coating starting from inorganic powder by application of pressure only

- C23C24/04—Impact or kinetic deposition of particles

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C4/00—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge

- C23C4/04—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge characterised by the coating material

- C23C4/06—Metallic material

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C4/00—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge

- C23C4/12—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge characterised by the method of spraying

- C23C4/137—Spraying in vacuum or in an inert atmosphere

Definitions

- the present invention relates to a film forming technique using cold spray.

- such a structure includes a combustion chamber of an aerospace rocket engine.

- a combustion chamber of a rocket engine for example, it is necessary to form a copper film of 10 mm or more on a copper base material.

- One method for forming such a thick metal film is “electroforming”.

- the film growth rate by the electroforming method is extremely slow, and it takes several months to achieve a target film thickness of about 10 mm, for example.

- Patent Document 1 a technique for forming a thick metal film by using a “cold spray method” in Patent Document 1.

- a gas whose temperature is lower than the melting point or softening temperature of the material powder is made to flow at high speed, and the material particles are injected into the gas flow to accelerate it and collide with the substrate in the solid state to form a film. It is a method to do.

- the film formation rate by this cold spray method is extremely high compared to the case of the electroforming method. Therefore, by using the cold spray method, it is possible to significantly reduce the time required for manufacturing the structure.

- peeling limit The limit at which such peeling of the generated film occurs is hereinafter referred to as “peeling limit”.

- peeling limit In order to prevent peeling of the generated film, it is necessary to remove the residual stress by performing heat treatment before the peeling limit, as described in Patent Document 1.

- FIG. 1 conceptually shows the relationship between the thickness of the generated film and the residual stress (internal stress).

- the film thickness increases with time, and the residual stress also increases accordingly.

- the residual stress exceeds the peeling limit line, the produced film is peeled off, so that the film forming process by cold spray is temporarily stopped before that.

- “heat treatment” is separately performed on the deposition target. By this heat treatment, the residual stress of the generated film is removed. Thereafter, the film formation process by cold spray starts again.

- the unit film forming process includes (1) a process of forming a film by cold spray so that the residual stress does not exceed the peeling limit line, and (2) a process of performing a heat treatment to remove the residual stress. .

- Patent Document 2 discloses a method of forming a film having a thickness of about 400 ⁇ m by a cold spray method.

- the method includes (A) a step of reducing or removing oxide on the surface of the film raw material powder on which the oxide is formed on the surface of the metal powder by hydrogen reduction treatment or pickling treatment, and (B) the oxide.

- Patent Document 3 discloses a method of forming a film of about 1.5 mm by a cold spray method.

- the method includes a step of projecting non-spherical irregularly shaped particles made of metal onto the substrate surface by a cold spray method to form a metal film on the substrate surface.

- the inventors of the present application focused on the following points. As described above, in order to realize a thick film using the cold spray method, it is necessary to perform a heat treatment during the film formation. However, as the number of heat treatments increases, the film formation time as a whole also increases. This is not only because the heat treatment itself requires a certain amount of time, but also because it is necessary to stop and restart the cold spray device every time the heat treatment is performed and restart and adjust the cold spray device every time the film forming process is restarted. That is, as the number of heat treatments increases, the film formation cost increases. Therefore, the smaller the number of heat treatments (unit film formation treatment), the better.

- One object of the present invention is to provide a technique capable of reducing the number of heat treatments (unit film forming processes) in thickening using a cold spray.

- a film forming method includes a step of repeatedly executing the unit film forming process until the thickness of the film formed on the film formation target reaches a desired film thickness.

- the unit film forming process includes (A) a step of forming a film on the film formation target by a cold spray method while heating the film formation target with a heater, and (B) a process on the film formation target after film formation. Applying heat treatment.

- a film forming method in another aspect of the present invention, includes a step of forming a film with a thickness of 1 mm or more on the film formation target by forming a film on the film formation target by a cold spray method while heating the film formation target with a heater. .

- the present invention it is possible to reduce the number of heat treatments (unit film forming processes) in thickening using cold spray. As a result, the film formation cost is reduced.

- FIG. 1 is a diagram conceptually showing the relationship between the thickness of a generated film and the residual stress (internal stress) when forming a thick film by cold spray.

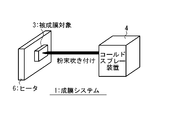

- FIG. 2 is a schematic diagram showing the configuration of the film forming system according to the first embodiment of the present invention.

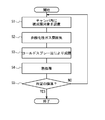

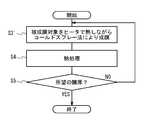

- FIG. 3 is a flowchart showing a film forming method according to the first embodiment of the present invention.

- FIG. 4 is a conceptual diagram for explaining the effect of the first embodiment of the present invention.

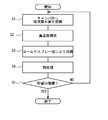

- FIG. 5 is a flowchart showing a film forming method according to the second embodiment of the present invention.

- FIG. 6 is a schematic diagram showing a configuration of a film forming system according to the third embodiment of the present invention.

- FIG. 1 is a diagram conceptually showing the relationship between the thickness of a generated film and the residual stress (internal stress) when forming a thick film by cold spray.

- FIG. 2 is a schematic diagram showing the configuration of the film forming system according to the first embodiment of the present invention.

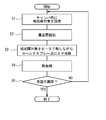

- FIG. 7 is a flowchart showing a film forming method according to the third embodiment of the present invention.

- FIG. 8 is a conceptual diagram for explaining the effect of the third embodiment of the present invention.

- FIG. 9 is a schematic diagram showing the configuration of a film forming system according to the fourth embodiment of the present invention.

- FIG. 10 is a flowchart showing a film forming method according to the fourth embodiment of the present invention.

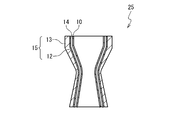

- FIG. 11 is a schematic cross-sectional view showing the configuration of the combustion chamber of the rocket engine in the fifth embodiment of the present invention.

- FIG. 12 is a schematic diagram showing the configuration of the combustion chamber of the rocket engine in the fifth embodiment of the present invention.

- FIG. 2 schematically shows a configuration of a film forming system 1 according to a first embodiment.

- the film forming system 1 includes a chamber 2, a cold spray device 4, and an atmosphere control device 5.

- a deposition target 3 is installed in the chamber 2 (deposition chamber).

- the cold spray device 4 is installed so that the film formation target 3 can be formed by a cold spray method.

- the atmosphere control device 5 is provided to control the atmosphere in the chamber 2.

- the atmosphere control device 5 is a gas supply device that supplies “non-oxidizing gas” to the chamber 2.

- the non-oxidizing gas include rare gases such as Ar and He, N 2 and the like.

- FIG. 3 is a flowchart showing the film forming method according to the first embodiment. With reference to FIG.2 and FIG.3, the film-forming method based on 1st Embodiment is demonstrated.

- Step S1 First, the deposition target 3 is installed in the chamber 2.

- Step S2 Subsequently, the atmosphere control device 5 operates to supply a non-oxidizing gas into the chamber 2. As a result, the atmosphere in the chamber 2 is set to a non-oxidizing gas atmosphere.

- the non-oxidizing gas include rare gases such as Ar and He, N 2 and the like.

- Step S3 Next, the cold spray device 4 is operated to form a film on the film formation target 3 by the cold spray method.

- the film forming process is performed in the non-oxidizing gas atmosphere set in step S2. Therefore, oxidation during the film forming process is prevented.

- a metal film is typically formed by spraying metal material powder.

- an example of cold spray conditions when forming a copper film by spraying copper powder is as follows.

- Cold spray working gas helium, nitrogen Copper powder supply: 20g / min-300g / min

- Gas pressure 2MPa-10MPa Powder and gas temperature in heating furnace before film formation: 200 ° C-950 ° C

- Step S4 When one film formation process is completed, the film formation target 3 after film formation is taken out of the chamber 2 and placed in a heat treatment apparatus (not shown). Then, heat treatment is performed on the deposition target 3. As a result, the residual stress of the generated film is removed.

- Step S5 Steps S1 to S4 described above are “unit film forming processes”.

- the unit film forming process is completed once, if the generated film thickness does not reach the desired film thickness (step S5; No), the process returns to step S1.

- the process ends. That is, the unit film formation process is repeatedly performed until the thickness of the film formed on the film formation target 3 reaches a desired film thickness.

- the desired film thickness is typically 1 mm or more.

- the desired film thickness is typically 10 mm or more. Even such a thick film can be formed using a cold spray method by performing a heat treatment to remove residual stress.

- the film formation process by cold spray is performed in a non-oxidizing gas atmosphere.

- a comparative example let us consider performing a film forming process by cold spray in the atmosphere as in the past.

- the oxide formed in the middle of the film forming process became obvious by the heat treatment, and cracks were generated in the generated film. Such cracks in the generated film reduce the adhesion of the generated film.

- the film forming process is performed in a non-oxidizing gas atmosphere, oxidation during the film forming process is prevented. As a result, generation of cracks in the generated film is prevented. This has been confirmed through experiments by the present inventors.

- the prevention of cracks means that the generated film becomes dense and the adhesion of the generated film increases. Since the peeling limit line is determined from the adhesion force and residual stress of the generated film, the peeling limit line increases as the adhesion force increases.

- the film thickness that can be formed by one unit film forming process increases. Accordingly, the number of repetitions of the unit film forming process necessary for obtaining a desired film thickness is reduced. That is, the number of heat treatments to be performed is reduced. As a result, the film formation cost is reduced.

- the present embodiment capable of suppressing the generation of cracks is suitable for increasing the thickness of the metal film of the structure.

- the atmosphere in the chamber 2 is set to a non-oxidizing gas atmosphere.

- the atmosphere is not limited thereto.

- a vacuum atmosphere is used instead of the non-oxidizing gas atmosphere.

- the atmosphere control device 5 is a decompression device that puts the chamber 2 in a vacuum state.

- the vacuum is in a state where the pressure is 1 ⁇ 10 ⁇ 3 Pa or less.

- FIG. 5 is a flowchart showing a film forming method according to the second embodiment.

- step S2 ' is executed instead of step S2 described above.

- the atmosphere control device 5 is activated to set the atmosphere in the chamber 2 to a vacuum atmosphere. Others are the same as those in the first embodiment.

- FIG. 6 schematically shows a configuration of a film forming system 1 according to a third embodiment.

- the film forming system 1 includes a cold spray device 4 and a heater 6.

- the heater 6 is provided so as to heat the film formation target 3, and is typically provided so as to contact the film formation target 3.

- the cold spray device 4 is installed so that the film formation target 3 can be formed by a cold spray method.

- FIG. 7 is a flowchart showing a film forming method according to the first embodiment.

- the film-forming method which concerns on 3rd Embodiment is demonstrated.

- the description which overlaps with 1st Embodiment is abbreviate

- Step S3 ′ The heater 6 operates to heat the film formation target 3. As a result, the temperature of the deposition target 3 becomes higher than room temperature.

- the cold spray device 4 is operated to form a film on the film formation target 3 by the cold spray method. That is, film formation is performed on the film formation target 3 while the film formation target 3 is heated by the heater 6.

- the cold spray conditions are the same as in the first embodiment.

- Step S4 When one film formation process is completed, a heat treatment is performed on the film formation target 3 as in the case of the first embodiment. As a result, the residual stress of the generated film is removed.

- Step S5 Steps S3 ′ to S4 described above are “unit film forming processes”.

- the process returns to step S3 ′.

- the process ends. That is, the unit film formation process is repeatedly performed until the thickness of the film formed on the film formation target 3 reaches a desired film thickness.

- the desired film thickness is typically 1 mm or more.

- the desired film thickness is typically 10 mm or more. Even such a thick film can be formed using a cold spray method by performing a heat treatment to remove residual stress.

- the film forming process by cold spray is performed while the film formation target 3 is heated by the heater 6. The effect of this will be described with reference to FIG.

- the cold spray method is a method of forming a film by colliding a material powder with an exposed surface. Due to such properties, as the film forming process is repeated, the exposed surface is heated more and more (the surface temperature reaches about 200 ° C.). That is, as the film thickness increases, a new film is formed in a heated state. Conversely, in the initial stage of film formation, a new film is formed at about room temperature.

- the inventor of the present application considered that such a temperature difference during film formation affects the adhesion of the generated film. That is, on the side closest to the film formation target 3, since the temperature at the time of film formation is substantially room temperature, it was considered that the adhesion of the generated film is weak and peeling is likely to occur.

- the deposition target 3 is “positively” heated by using the heater 6, and the temperature is set higher than the room temperature.

- the heating temperature is set to about 200 ° C., which is the temperature at which the surface temperature is reached by cold spray, for example.

- the adhesion of the generated film increases, and thereby the peeling limit line also increases. Therefore, as in the case of the first embodiment, the number of repetitions of the unit film forming process necessary for obtaining a desired film thickness is reduced (see FIG. 4). That is, the number of heat treatments to be performed is reduced. As a result, the film formation cost is reduced.

- the fourth embodiment is a combination of the first or second embodiment and the third embodiment.

- FIG. 9 schematically shows a configuration of a film forming system 1 according to the fourth embodiment.

- the film forming system 1 includes a heater 6 shown in FIG. 6 in addition to the configuration shown in FIG.

- FIG. 10 is a flowchart showing a film forming method according to the fourth embodiment.

- step S3 is replaced with step S3 'in the third embodiment.

- the effect of the combination of the first or second embodiment and the third embodiment can be obtained.

- a further increase in the adhesion of the resulting film is expected and suitable.

- FIG. 11 schematically shows the combustion chamber 25 of the rocket engine.

- a high-temperature and high-pressure fluid burns and circulates during use.

- the combustion chamber 25 has a plurality of cooling channels 14 through which the refrigerant passes, and the temperature of the combustion chamber 25 can be suppressed by cooling with the refrigerant.

- the combustion chamber 25 includes an inner cylinder 10 and an outer cylinder 15 arranged concentrically, and a cooling channel 14 is formed between the inner cylinder 10 and the outer cylinder 15. .

- copper or an alloy containing copper as a main component is preferable in terms of cooling efficiency, strength, and extension.

- FIG. 12 shows the relationship between the inner cylinder 10, the cooling flow path 14, and the outer cylinder 15.

- a plurality of cooling channels 14 are formed in the inner cylinder 10.

- An outer cylinder 15 is formed on the inner cylinder 10 as a base material. More specifically, the outer cylinder 15 has a laminated structure of the first layer 12 and the second layer 13. The first layer 12 is formed in layers on the inner cylinder 10 on the inner cylinder 10 side. The second layer 13 is formed in a layered manner on the outer surface of the first layer 12.

- the manufacturing method of the “structure” as shown in FIG. 12 is as follows. First, a plurality of grooves are formed on the surface of the inner cylinder 10 as the base material portion. The groove finally becomes the fluid flow path 14. Subsequently, a plurality of grooves are filled with a filler such as wax. Here, the filler is filled so that the exposed surface and the surface (exposed surface) of the base material portion form substantially the same plane.

- a conductive layer such as silver powder is formed on the exposed surface of the filler and the inner cylinder 10 (base material portion). That is, in the electroforming method, a conductive process is performed on a region where an electroformed film is formed. And the 1st layer 12 is formed as an electroforming film

- the second layer 13 is formed as a cold spray film on the first layer 12 by the method described in the above embodiment.

- a cold spray film of copper is laminated about 10 mm.

- the total thickness of the first layer 12 and the second layer 13 is set to a desired thickness for the outer cylinder 15.

- the filler is removed from the plurality of grooves by a method such as melting. Thereby, a structure having a plurality of cooling channels 14 surrounded by the outer cylinder 15 and the inner cylinder 10 can be manufactured.

- the outer cylinder 15 is formed by combining the electroforming method and the cold spray method.

- the film formation rate of the cold spray method is extremely high as compared with the film formation rate of the electroforming method. Therefore, the case where the film of the outer cylinder 15 (eg, copper film) is formed by combining the electroforming method and the cold spray method is much shorter than the case where the film is formed only by the electroforming method. The film formation can be terminated. Thereby, the manufacturing time of the structure can be shortened while maintaining the mechanical properties such as the strength and elongation of the film.

- the first layer 12 is formed by electroforming and the second layer 13 is formed by cold spraying, it is preferable that the first layer 12 is relatively thin and the second layer 13 is relatively thick. . As a result, it is possible to shorten the manufacturing period, reduce manufacturing costs, and manufacturing labor.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14/764,766 US9951426B2 (en) | 2013-02-19 | 2013-05-20 | Method for depositing layer |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013-030404 | 2013-02-19 | ||

| JP2013030404A JP6066760B2 (ja) | 2013-02-19 | 2013-02-19 | 成膜方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2014128983A1 true WO2014128983A1 (ja) | 2014-08-28 |

Family

ID=51390802

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2013/063896 Ceased WO2014128983A1 (ja) | 2013-02-19 | 2013-05-20 | 成膜方法 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US9951426B2 (enExample) |

| JP (1) | JP6066760B2 (enExample) |

| WO (1) | WO2014128983A1 (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2021080943A1 (en) * | 2019-10-21 | 2021-04-29 | Westinghouse Electric Company Llc | Multiple nozzle design in a cold spray system and associated method |

| US20220331914A1 (en) * | 2021-04-15 | 2022-10-20 | General Electric Company | Methods of coating components with cold spray and brazing coated components |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006161161A (ja) * | 2004-12-03 | 2006-06-22 | United Technol Corp <Utc> | 真空コールドスプレープロセス |

| JP2008127676A (ja) * | 2006-11-24 | 2008-06-05 | Toyohashi Univ Of Technology | 金属皮膜の形成方法 |

| JP2009191349A (ja) * | 2008-02-18 | 2009-08-27 | Honda Motor Co Ltd | 強化皮膜の接合界面の改質方法 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060269685A1 (en) * | 2005-05-31 | 2006-11-30 | Honeywell International, Inc. | Method for coating turbine engine components with high velocity particles |

| JP5017675B2 (ja) | 2008-04-01 | 2012-09-05 | 富士岐工産株式会社 | 皮膜の製造方法 |

| JP2010047825A (ja) | 2008-08-25 | 2010-03-04 | Mitsubishi Heavy Ind Ltd | 金属皮膜の形成方法及び航空宇宙構造部材 |

| US20100170937A1 (en) | 2009-01-07 | 2010-07-08 | General Electric Company | System and Method of Joining Metallic Parts Using Cold Spray Technique |

| JP5642461B2 (ja) * | 2010-09-07 | 2014-12-17 | 三菱重工業株式会社 | ロケットエンジンの燃焼室及び中空構造体の製造方法 |

-

2013

- 2013-02-19 JP JP2013030404A patent/JP6066760B2/ja active Active

- 2013-05-20 WO PCT/JP2013/063896 patent/WO2014128983A1/ja not_active Ceased

- 2013-05-20 US US14/764,766 patent/US9951426B2/en active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006161161A (ja) * | 2004-12-03 | 2006-06-22 | United Technol Corp <Utc> | 真空コールドスプレープロセス |

| JP2008127676A (ja) * | 2006-11-24 | 2008-06-05 | Toyohashi Univ Of Technology | 金属皮膜の形成方法 |

| JP2009191349A (ja) * | 2008-02-18 | 2009-08-27 | Honda Motor Co Ltd | 強化皮膜の接合界面の改質方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2014159613A (ja) | 2014-09-04 |

| US9951426B2 (en) | 2018-04-24 |

| JP6066760B2 (ja) | 2017-01-25 |

| US20150368807A1 (en) | 2015-12-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6066759B2 (ja) | 成膜方法 | |

| KR102540252B1 (ko) | 반도체 소자의 제조 방법 | |

| CN107492481A (zh) | 用于在较低温度下使用远程等离子体源进行选择性氧化的设备和方法 | |

| KR102094304B1 (ko) | 표면 처리 방법 및 이를 이용한 세라믹 구조물 | |

| JP6066760B2 (ja) | 成膜方法 | |

| TWI667364B (zh) | 包括SiC蒸鍍層的半導體製造用部件及其製造方法 | |

| JP2006144061A (ja) | 遮熱コーティング部材およびその形成方法 | |

| JP5642461B2 (ja) | ロケットエンジンの燃焼室及び中空構造体の製造方法 | |

| JP5830660B2 (ja) | スパッタリング方法 | |

| KR102182690B1 (ko) | 플라즈마 처리 장치용 내부재 및 이의 제조 방법 | |

| US20150235855A1 (en) | Metal Deposition with Reduced Stress | |

| WO2018066392A1 (ja) | タービン翼の製造方法 | |

| JP6037885B2 (ja) | 成膜方法 | |

| US11123820B2 (en) | Process of forming a metal additive manufactured part with a smooth surface | |

| JP5628231B2 (ja) | 積層体 | |

| JP5449045B2 (ja) | シャフト付きヒータユニットおよびシャフト付きヒータユニット製造方法 | |

| JP6206159B2 (ja) | 半導体装置の製造方法 | |

| CN116065118B (zh) | 一种钛合金离子渗氧的方法 | |

| TWI827089B (zh) | 用於擴散接合的氣體淬火 | |

| KR20170072624A (ko) | 금속 및 세라믹 복합재 형성 방법 | |

| RU2700437C1 (ru) | Способ химико-термической обработки деталей из титановых сплавов | |

| JP2020083734A (ja) | SiC部材の製造方法 | |

| JP2013091856A (ja) | クロス・カップリング反応によるアルミニウム硬化材の製造方法 | |

| CN119551910A (zh) | 玻璃盖板的ag处理工艺 | |

| KR20190096134A (ko) | 합금 박막 및 그 제조 방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 13875546 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 14764766 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 13875546 Country of ref document: EP Kind code of ref document: A1 |