JP6027227B2 - 亜酸化窒素の、再生可能な室温浄化装置及び方法 - Google Patents

亜酸化窒素の、再生可能な室温浄化装置及び方法 Download PDFInfo

- Publication number

- JP6027227B2 JP6027227B2 JP2015507616A JP2015507616A JP6027227B2 JP 6027227 B2 JP6027227 B2 JP 6027227B2 JP 2015507616 A JP2015507616 A JP 2015507616A JP 2015507616 A JP2015507616 A JP 2015507616A JP 6027227 B2 JP6027227 B2 JP 6027227B2

- Authority

- JP

- Japan

- Prior art keywords

- renewable

- room temperature

- purification

- nickel

- purification device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000746 purification Methods 0.000 title claims description 61

- GQPLMRYTRLFLPF-UHFFFAOYSA-N Nitrous Oxide Chemical compound [O-][N+]#N GQPLMRYTRLFLPF-UHFFFAOYSA-N 0.000 title description 16

- 238000000034 method Methods 0.000 title description 16

- 239000001272 nitrous oxide Substances 0.000 title description 8

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 claims description 58

- 229910052759 nickel Inorganic materials 0.000 claims description 26

- 239000000463 material Substances 0.000 claims description 25

- 229910000480 nickel oxide Inorganic materials 0.000 claims description 11

- GNRSAWUEBMWBQH-UHFFFAOYSA-N oxonickel Chemical compound [Ni]=O GNRSAWUEBMWBQH-UHFFFAOYSA-N 0.000 claims description 11

- 239000011538 cleaning material Substances 0.000 claims description 6

- 229910052751 metal Inorganic materials 0.000 claims description 6

- 239000002184 metal Substances 0.000 claims description 6

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 4

- 239000000395 magnesium oxide Substances 0.000 claims description 4

- CPLXHLVBOLITMK-UHFFFAOYSA-N magnesium oxide Inorganic materials [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 claims description 4

- AXZKOIWUVFPNLO-UHFFFAOYSA-N magnesium;oxygen(2-) Chemical compound [O-2].[Mg+2] AXZKOIWUVFPNLO-UHFFFAOYSA-N 0.000 claims description 4

- 239000002253 acid Substances 0.000 claims 1

- 239000007789 gas Substances 0.000 description 20

- 230000008569 process Effects 0.000 description 10

- 230000008929 regeneration Effects 0.000 description 9

- 238000011069 regeneration method Methods 0.000 description 9

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 8

- 238000001994 activation Methods 0.000 description 8

- 239000012535 impurity Substances 0.000 description 8

- 239000002245 particle Substances 0.000 description 6

- 239000011159 matrix material Substances 0.000 description 4

- 229910052757 nitrogen Inorganic materials 0.000 description 4

- 230000009471 action Effects 0.000 description 3

- 230000004913 activation Effects 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 229910001220 stainless steel Inorganic materials 0.000 description 3

- 239000010935 stainless steel Substances 0.000 description 3

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 2

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 2

- 229910002091 carbon monoxide Inorganic materials 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 230000001627 detrimental effect Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000004821 distillation Methods 0.000 description 2

- 239000001257 hydrogen Substances 0.000 description 2

- 229910052739 hydrogen Inorganic materials 0.000 description 2

- 239000002808 molecular sieve Substances 0.000 description 2

- 230000007420 reactivation Effects 0.000 description 2

- 239000004065 semiconductor Substances 0.000 description 2

- URGAHOPLAPQHLN-UHFFFAOYSA-N sodium aluminosilicate Chemical compound [Na+].[Al+3].[O-][Si]([O-])=O.[O-][Si]([O-])=O URGAHOPLAPQHLN-UHFFFAOYSA-N 0.000 description 2

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 1

- 101150035080 RGA5 gene Proteins 0.000 description 1

- 239000003990 capacitor Substances 0.000 description 1

- 229910002092 carbon dioxide Inorganic materials 0.000 description 1

- 239000001569 carbon dioxide Substances 0.000 description 1

- 238000005229 chemical vapour deposition Methods 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 230000000593 degrading effect Effects 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 230000002452 interceptive effect Effects 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B21/00—Nitrogen; Compounds thereof

- C01B21/20—Nitrogen oxides; Oxyacids of nitrogen; Salts thereof

- C01B21/22—Nitrous oxide (N2O)

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/02—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols by adsorption, e.g. preparative gas chromatography

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/02—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols by adsorption, e.g. preparative gas chromatography

- B01D53/04—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols by adsorption, e.g. preparative gas chromatography with stationary adsorbents

- B01D53/0462—Temperature swing adsorption

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/46—Removing components of defined structure

- B01D53/62—Carbon oxides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2253/00—Adsorbents used in seperation treatment of gases and vapours

- B01D2253/10—Inorganic adsorbents

- B01D2253/112—Metals or metal compounds not provided for in B01D2253/104 or B01D2253/106

- B01D2253/1122—Metals

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2253/00—Adsorbents used in seperation treatment of gases and vapours

- B01D2253/10—Inorganic adsorbents

- B01D2253/112—Metals or metal compounds not provided for in B01D2253/104 or B01D2253/106

- B01D2253/1124—Metal oxides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2257/00—Components to be removed

- B01D2257/50—Carbon oxides

- B01D2257/504—Carbon dioxide

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2257/00—Components to be removed

- B01D2257/80—Water

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/96—Regeneration, reactivation or recycling of reactants

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B2210/00—Purification or separation of specific gases

- C01B2210/0001—Separation or purification processing

- C01B2210/0009—Physical processing

- C01B2210/0014—Physical processing by adsorption in solids

- C01B2210/0015—Physical processing by adsorption in solids characterised by the adsorbent

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B2210/00—Purification or separation of specific gases

- C01B2210/0043—Impurity removed

- C01B2210/005—Carbon monoxide

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B2210/00—Purification or separation of specific gases

- C01B2210/0043—Impurity removed

- C01B2210/0051—Carbon dioxide

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B2210/00—Purification or separation of specific gases

- C01B2210/0043—Impurity removed

- C01B2210/0062—Water

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02C—CAPTURE, STORAGE, SEQUESTRATION OR DISPOSAL OF GREENHOUSE GASES [GHG]

- Y02C20/00—Capture or disposal of greenhouse gases

- Y02C20/10—Capture or disposal of greenhouse gases of nitrous oxide (N2O)

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02C—CAPTURE, STORAGE, SEQUESTRATION OR DISPOSAL OF GREENHOUSE GASES [GHG]

- Y02C20/00—Capture or disposal of greenhouse gases

- Y02C20/40—Capture or disposal of greenhouse gases of CO2

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/151—Reduction of greenhouse gas [GHG] emissions, e.g. CO2

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Analytical Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Emergency Medicine (AREA)

- Inorganic Chemistry (AREA)

- Environmental & Geological Engineering (AREA)

- Biomedical Technology (AREA)

- Solid-Sorbent Or Filter-Aiding Compositions (AREA)

- Catalysts (AREA)

- Inorganic Compounds Of Heavy Metals (AREA)

- Separation Of Gases By Adsorption (AREA)

- Gas Separation By Absorption (AREA)

- Treating Waste Gases (AREA)

Description

長さ4.8cm、直径1.04cmの、体積が4ccである円柱状の浄化装置導管が、異なる浄化材料で充填され、表1のスキームに従う活性化プロセスの対象となり、表1は活性化プロセス中の材料及び平衡温度を示す。表1において、全てのサンプルに共通のパラメータは省略された。すなわち、活性化中にフローされたガスの種類(窒素)、フロー(0.5L/分)、及び活性化プロセスの全体にわたる長さ(21時間)である。

ある例示的な実施形態に従ってつくられたサンプルS1が再活性化プロセスの対象とされた。すなわち、導管中のメディアが、その容量を使い果たした(下流に接続された分析装置が0.5ppmに到達した)後で、表1に記述された活性化プロセスが繰り返された。再活性化の後で、材料が完全に再生可能であり、応用と相性がよいことの証明として、サンプルS1の容量が測定され、同一の値を得た。

ニッケル浄化メディアは、10%の水素を含む窒素気流をフローさせることによって、ニッケルへの還元を引き起こす活性化処理の対象とされた。室温にされた後で、材料を条件づけるために、浄化装置は一連の制御されたサイクル中のN2Oに露出された。これほど用心したにも関わらず、システム温度は250℃を超え、安全の観点から重大な問題を提起した。このテストは、上述の特許文献3で開示されたメディアは、工業スケールのプロセスで亜酸化窒素の浄化に使用されるのに適していないことを示している。

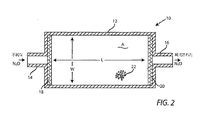

12 浄化装置導管

14 入口

16 出口

18 第一粒子フィルター

20 第二粒子フィルター

22 浄化材料

24 浄化装置システム

26 マニホールド

28 コントローラ

30 管

32 弁

34 ヒーター

36 温度センサ

Claims (10)

- 入口及び出口を有する導管を備え、活性部分が少なくとも部分的に、酸化ニッケルからなる浄化材料で充填され、前記酸化ニッケルの表面積は50m 2 /gと等しいか、50m 2 /gより大きい、再生可能室温N 2 O浄化装置。

- 入口及び出口を有する導管を備え、活性部分が少なくとも部分的に、酸化ニッケル及びニッケル金属を含む浄化材料で充填され、酸化ニッケルに対するニッケル金属の重量比が5%未満であり、酸化ニッケル及びニッケル金属の表面積は50m2/gと等しいか、50m2/gより大きい、再生可能室温N2O浄化装置。

- 酸化ニッケル及びニッケル金属の表面積が100m2/gと等しいか、100m2/gより大きい、請求項2に記載の再生可能室温N2O浄化装置。

- 前記浄化材料がサポートされる、請求項1または2に記載の再生可能室温N2O浄化装置。

- 前記浄化材料が、アモルファスシリカ及び酸化マグネシウムの少なくとも一つの上にサポートされる、請求項4に記載の再生可能室温N2O浄化装置。

- 浄化材料の再生を実行するためのヒーター及び温度制御を備える、請求項1または2に記載の再生可能室温N2O浄化装置。

- 前記活性部分が、長さL、幅Wを有する体積を区切り、長さと幅との間の比L/Wが、1から15の間である、請求項1または2に記載の再生可能室温N2O浄化装置。

- 前記活性部分の体積の少なくとも30%が前記浄化材料で充填される、請求項1、2または4に記載の再生可能室温N2O浄化装置。

- 前記活性部分の体積が、実質的に完全に前記浄化材料で充填される、請求項8に記載の再生可能室温N2O浄化装置。

- ガスマニホールドと、その自動制御と、少なくとも二つの、請求項1または2に記載の再生可能N2O浄化装置とを備える、再生可能室温N2O浄化装置システム。

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT000676A ITMI20120676A1 (it) | 2012-04-24 | 2012-04-24 | Metodo e dispositivo rigenerabile di purificazione a temperatura ambiente per monossido di diazoto |

| ITMI2012A000676 | 2012-04-24 | ||

| US13/866,875 | 2013-04-19 | ||

| US13/866,875 US20140000456A1 (en) | 2012-04-24 | 2013-04-19 | Nitrous oxide regenerable room temperature purifier and method |

| PCT/IB2013/000753 WO2013160746A1 (en) | 2012-04-24 | 2013-04-23 | Nitrous oxide regenerable room temperature purifier and method |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015519192A JP2015519192A (ja) | 2015-07-09 |

| JP2015519192A5 JP2015519192A5 (ja) | 2016-03-31 |

| JP6027227B2 true JP6027227B2 (ja) | 2016-11-16 |

Family

ID=46262175

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015507616A Active JP6027227B2 (ja) | 2012-04-24 | 2013-04-23 | 亜酸化窒素の、再生可能な室温浄化装置及び方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US20140000456A1 (ja) |

| EP (1) | EP2841377B1 (ja) |

| JP (1) | JP6027227B2 (ja) |

| KR (1) | KR101866918B1 (ja) |

| CN (1) | CN104245574B (ja) |

| IT (1) | ITMI20120676A1 (ja) |

| WO (1) | WO2013160746A1 (ja) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3862067A1 (en) * | 2020-02-10 | 2021-08-11 | Clariant Catalysts (Japan) K.K. | Co2 and o2 remover |

| GB202103659D0 (en) * | 2021-03-17 | 2021-04-28 | Johnson Matthey Plc | Getter activation and use |

Family Cites Families (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1596425A (ja) * | 1968-12-27 | 1970-06-15 | ||

| DE3149672C2 (de) * | 1981-12-15 | 1986-11-13 | Didier-Werke Ag, 6200 Wiesbaden | Verfahren zum Klimatisieren unter Anwendung von mittels Wassersorption arbeitenden Speichermedien |

| US4713224A (en) * | 1986-03-31 | 1987-12-15 | The Boc Group, Inc. | One-step process for purifying an inert gas |

| US5268021A (en) * | 1989-11-20 | 1993-12-07 | Dynotec Corporation | Fluid fractionator |

| JP3359928B2 (ja) * | 1991-11-06 | 2002-12-24 | 日本パイオニクス株式会社 | アンモニアの精製方法 |

| IT1270875B (it) * | 1993-04-29 | 1997-05-13 | Getters Spa | Procedimento di purificazione dell'idrogeno e purificatore relativo |

| US5547648A (en) * | 1992-04-15 | 1996-08-20 | Mobil Oil Corporation | Removing SOx, NOX and CO from flue gases |

| JP3260826B2 (ja) * | 1992-06-26 | 2002-02-25 | 日本パイオニクス株式会社 | 亜酸化窒素の精製方法 |

| US6436352B1 (en) * | 1993-04-29 | 2002-08-20 | Saes Getter, S.P.A. | Hydrogen purification |

| RU2123971C1 (ru) * | 1993-04-29 | 1998-12-27 | Саес Геттерс С.П.А. | Способ удаления газообразных примесей из потока водорода и устройство для его осуществления |

| JP3294390B2 (ja) * | 1993-07-26 | 2002-06-24 | 日本エア・リキード株式会社 | 超高純度亜酸化窒素製造方法及び装置 |

| DE69309680T2 (de) * | 1993-09-20 | 1997-08-21 | Fina Research | Verfahren zur Entfernung von Arsien und Carbonylsulfid aus leichten Olefinen enthaltender Kohlenwasserstoffbeschickungen |

| JP3582141B2 (ja) * | 1995-03-06 | 2004-10-27 | 堺化学工業株式会社 | 窒素酸化物除去法 |

| US6517797B1 (en) * | 1997-02-26 | 2003-02-11 | Calgon Carbon Corporation | Process for separation of NOx from N2O in a mixture |

| US5983667A (en) * | 1997-10-31 | 1999-11-16 | Praxair Technology, Inc. | Cryogenic system for producing ultra-high purity nitrogen |

| US6080226A (en) * | 1998-09-30 | 2000-06-27 | Uop Llc | Nitrous oxide purification by pressure swing adsorption |

| US7070746B1 (en) * | 1999-05-26 | 2006-07-04 | Solutia Inc. | Process for nitrous oxide purification |

| US6521192B1 (en) * | 1999-08-06 | 2003-02-18 | Saes Pure Gas, Inc. | Rejuvenable ambient temperature purifier |

| JP3934885B2 (ja) * | 2000-09-27 | 2007-06-20 | 昭和電工株式会社 | 余剰麻酔ガスの処理装置 |

| US6511526B2 (en) * | 2001-01-12 | 2003-01-28 | Vbox, Incorporated | Pressure swing adsorption gas separation method and apparatus |

| US20030064014A1 (en) * | 2001-08-03 | 2003-04-03 | Ravi Kumar | Purification of gases by pressure swing adsorption |

| US6824589B2 (en) * | 2001-10-31 | 2004-11-30 | Matheson Tri-Gas | Materials and methods for the purification of inert, nonreactive, and reactive gases |

| US7101415B2 (en) * | 2002-08-30 | 2006-09-05 | Matheson Tri-Gas, Inc. | Methods for regenerating process gas purifier materials |

| EP1417995A1 (en) * | 2002-10-30 | 2004-05-12 | Air Products And Chemicals, Inc. | Process and device for adsorption of nitrous oxide from a feed gas stream |

| US7201841B2 (en) * | 2003-02-05 | 2007-04-10 | Water Visions International, Inc. | Composite materials for fluid treatment |

| US7314506B2 (en) | 2004-10-25 | 2008-01-01 | Matheson Tri-Gas, Inc. | Fluid purification system with low temperature purifier |

| JP5103757B2 (ja) * | 2006-03-08 | 2012-12-19 | トヨタ自動車株式会社 | 燃料電池の酸化剤ガス浄化装置 |

| JP5002230B2 (ja) * | 2006-10-05 | 2012-08-15 | 日本パイオニクス株式会社 | 不活性ガスの精製方法 |

-

2012

- 2012-04-24 IT IT000676A patent/ITMI20120676A1/it unknown

-

2013

- 2013-04-19 US US13/866,875 patent/US20140000456A1/en not_active Abandoned

- 2013-04-23 CN CN201380021354.8A patent/CN104245574B/zh active Active

- 2013-04-23 WO PCT/IB2013/000753 patent/WO2013160746A1/en active Application Filing

- 2013-04-23 EP EP13726862.9A patent/EP2841377B1/en not_active Not-in-force

- 2013-04-23 KR KR1020147028597A patent/KR101866918B1/ko active IP Right Grant

- 2013-04-23 JP JP2015507616A patent/JP6027227B2/ja active Active

-

2016

- 2016-10-17 US US15/295,978 patent/US9643845B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| EP2841377B1 (en) | 2016-02-24 |

| US20140000456A1 (en) | 2014-01-02 |

| US20170029273A1 (en) | 2017-02-02 |

| CN104245574A (zh) | 2014-12-24 |

| JP2015519192A (ja) | 2015-07-09 |

| KR20150013450A (ko) | 2015-02-05 |

| US9643845B2 (en) | 2017-05-09 |

| ITMI20120676A1 (it) | 2013-10-25 |

| EP2841377A1 (en) | 2015-03-04 |

| CN104245574B (zh) | 2016-07-06 |

| WO2013160746A1 (en) | 2013-10-31 |

| KR101866918B1 (ko) | 2018-06-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5566815B2 (ja) | ガスの精製方法およびガス精製装置 | |

| JP5013633B2 (ja) | 亜酸化窒素精製方法 | |

| SE463511B (sv) | Superreningsanordning och saett foer superrening av argongas | |

| KR19980087318A (ko) | 가스정제방법 및 장치 | |

| JPS62269728A (ja) | 不活性ガスを精製する1工程方法 | |

| NL192104C (nl) | Inrichting en werkwijze voor het zuiveren van stikstof. | |

| CN107362683A (zh) | 一种超高纯气体纯化装置及纯化方法 | |

| Hsu et al. | Binary VOCs absorption in a rotating packed bed with blade packings | |

| JP2010195616A (ja) | ガスの精製方法および精製装置 | |

| JP6027227B2 (ja) | 亜酸化窒素の、再生可能な室温浄化装置及び方法 | |

| Lin et al. | Mass transfer performance of a rotating packed bed equipped with blade packings in removing methanol and 1-butanol from gaseous streams | |

| EP3406318A1 (en) | Carbon dioxide separation/recovery device, combustion system using same, thermal power generation system using same, and method for separating and recovering carbon dioxide | |

| CN1970133A (zh) | 超高纯度惰性气体纯化装置及纯化方法 | |

| Lin et al. | Mass transfer performance of rotating packed beds with blade packings in carbon dioxide absorption into sodium hydroxide solution | |

| JP2000233117A (ja) | 排ガスの浄化方法及び浄化装置 | |

| KR20020047114A (ko) | 재생할 수 있는 주변 온도 정제기 | |

| JP2016188153A (ja) | ヘリウムガス精製装置およびヘリウムガス精製方法 | |

| Chattopadhyaya et al. | Adsorptive removal of sulfur dioxide by Saskatchewan lignite and its derivatives | |

| CN207271059U (zh) | 一种超高纯气体纯化装置 | |

| JP6450405B2 (ja) | 超高純度(uhp)二酸化炭素浄化のためのシステム及び方法 | |

| JP4733960B2 (ja) | 熱スイング吸着方式による不純物含有アルゴンガスの精製方法および精製装置 | |

| EP3254746B1 (en) | Gas purification apparatus comprising an adsorbent and a cooling device | |

| JP2753106B2 (ja) | 排オゾン分解装置 | |

| JP4101955B2 (ja) | アンモニアの精製方法 | |

| JP5782137B2 (ja) | Co変成装置及び変成方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160208 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160208 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20160208 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20160610 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20160613 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160620 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160812 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20160916 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20161013 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6027227 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: R3D03 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |