JP6012732B2 - 液体還元剤のための調量システム - Google Patents

液体還元剤のための調量システム Download PDFInfo

- Publication number

- JP6012732B2 JP6012732B2 JP2014526428A JP2014526428A JP6012732B2 JP 6012732 B2 JP6012732 B2 JP 6012732B2 JP 2014526428 A JP2014526428 A JP 2014526428A JP 2014526428 A JP2014526428 A JP 2014526428A JP 6012732 B2 JP6012732 B2 JP 6012732B2

- Authority

- JP

- Japan

- Prior art keywords

- pump

- ventilation

- diaphragm

- metering system

- valve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000003638 chemical reducing agent Substances 0.000 title description 32

- 239000007788 liquid Substances 0.000 title description 24

- 238000009423 ventilation Methods 0.000 claims description 155

- XSQUKJJJFZCRTK-UHFFFAOYSA-N Urea Chemical compound NC(N)=O XSQUKJJJFZCRTK-UHFFFAOYSA-N 0.000 claims description 11

- 239000004202 carbamide Substances 0.000 claims description 11

- 238000007789 sealing Methods 0.000 claims description 11

- 230000000903 blocking effect Effects 0.000 claims description 8

- 239000003990 capacitor Substances 0.000 claims description 7

- 238000001125 extrusion Methods 0.000 claims description 2

- 239000000463 material Substances 0.000 claims description 2

- 239000007789 gas Substances 0.000 description 10

- 239000007864 aqueous solution Substances 0.000 description 7

- 238000002485 combustion reaction Methods 0.000 description 6

- 238000010586 diagram Methods 0.000 description 6

- 230000008901 benefit Effects 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 5

- 238000000034 method Methods 0.000 description 4

- 230000008569 process Effects 0.000 description 4

- 239000003054 catalyst Substances 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 230000005489 elastic deformation Effects 0.000 description 2

- 238000005265 energy consumption Methods 0.000 description 2

- 230000008014 freezing Effects 0.000 description 2

- 238000007710 freezing Methods 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 230000035939 shock Effects 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 230000009471 action Effects 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 239000013013 elastic material Substances 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 238000010348 incorporation Methods 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 230000008092 positive effect Effects 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B23/00—Pumping installations or systems

- F04B23/04—Combinations of two or more pumps

- F04B23/08—Combinations of two or more pumps the pumps being of different types

- F04B23/12—Combinations of two or more pumps the pumps being of different types at least one pump being of the rotary-piston positive-displacement type

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/18—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control

- F01N3/20—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control specially adapted for catalytic conversion ; Methods of operation or control of catalytic converters

- F01N3/2066—Selective catalytic reduction [SCR]

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/18—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control

- F01N3/20—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control specially adapted for catalytic conversion ; Methods of operation or control of catalytic converters

- F01N3/2066—Selective catalytic reduction [SCR]

- F01N3/208—Control of selective catalytic reduction [SCR], e.g. dosing of reducing agent

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/24—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by constructional aspects of converting apparatus

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2610/00—Adding substances to exhaust gases

- F01N2610/02—Adding substances to exhaust gases the substance being ammonia or urea

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2610/00—Adding substances to exhaust gases

- F01N2610/14—Arrangements for the supply of substances, e.g. conduits

- F01N2610/1433—Pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2610/00—Adding substances to exhaust gases

- F01N2610/14—Arrangements for the supply of substances, e.g. conduits

- F01N2610/1466—Means for venting air out of conduits or tanks

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2610/00—Adding substances to exhaust gases

- F01N2610/14—Arrangements for the supply of substances, e.g. conduits

- F01N2610/1473—Overflow or return means for the substances, e.g. conduits or valves for the return path

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2610/00—Adding substances to exhaust gases

- F01N2610/14—Arrangements for the supply of substances, e.g. conduits

- F01N2610/1493—Purging the reducing agent out of the conduits or nozzle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B23/00—Pumping installations or systems

- F04B23/04—Combinations of two or more pumps

- F04B23/08—Combinations of two or more pumps the pumps being of different types

- F04B23/10—Combinations of two or more pumps the pumps being of different types at least one pump being of the reciprocating positive-displacement type

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Toxicology (AREA)

- Combustion & Propulsion (AREA)

- Reciprocating Pumps (AREA)

- Exhaust Gas After Treatment (AREA)

Description

このことは、穴71と送出室45の圧力差が十分に大きいとき、還元剤が矢印59の方向でバルブプレート57の穴69を通って流れることができることを意味している。

3 吸込配管

5 送出ポンプ

7 圧力配管

9 調量モジュール

15 換気ポンプ

Claims (17)

- 尿素水溶液のための調量システムにおいて、送出ポンプ(5)と、調量モジュール(9)と、タンク(1)とを備える送出モジュールを含んでおり、前記送出ポンプ(5)と前記タンク(1)は吸込配管(3)を介して相互に接続されており、前記送出ポンプ(5)と前記調量モジュール(9)は圧力配管(7)を介して相互に接続されている、そのような調量システムにおいて、前記送出ポンプ(5)と並列に換気ポンプ(15)が配置されており、前記換気ポンプ(15)は吸込側で前記調量モジュール(9)と接続されるとともに圧力側で前記タンク(1)と接続されていて、

前記送出ポンプ(5)および/または前記換気ポンプ(15)の吸込側と送出側にはそれぞれ第1の逆止め弁(17,19,21,23)が設けられていて、

前記換気ポンプ(15)の圧力側(25.2)には前記第1の逆止め弁(23)と並列にスロットル(33)または絞りが設けられていることを特徴とする(図8)調量システム。 - 前記送出ポンプ(5)および/または前記換気ポンプ(15)はダイヤフラムポンプとして構成されていることを特徴とする、請求項1に記載の調量システム。

- 前記送出ポンプ(5)および/または前記換気ポンプ(15)は電磁式のアクチュエータ(35)により駆動されることを特徴とする、請求項1または2に記載の調量システム。

- 前記送出ポンプ(5)および/または前記換気ポンプ(15)の吸込側にはスロットル(27)または絞りが設けられていることを特徴とする、請求項3に記載の調量システム。

- 前記換気ポンプ(15)の吸込側には前記第1の逆止め弁(21)と並列に第2の逆止め弁(31)が設けられており、前記第2の逆止め弁(31)の阻止方向は前記第1の逆止め弁(21)の阻止方向と反対向きであり、前記第2の逆止め弁(31)の開放圧力は前記第1の逆止め弁(21)の開放圧力よりも高いことを特徴とする(図7)、請求項4に記載の調量システム。

- 前記送出ポンプ(5)および/または前記換気ポンプ(15)の前記アクチュエータ(35)が無通電のときにダイヤフラム(43)が前記圧力配管(7)、前記吸込配管(3)、または前記換気配管(25)を閉止することを特徴とする、請求項3から5のいずれか1項に記載の調量システム。

- 前記スロットル(27)または絞りは、前記アクチュエータ(35)が無通電のときに前記ダイヤフラム(43)によって閉止される、前記圧力配管(7)、前記吸込配管(3)、または前記換気配管(25)の端部に配置されていることを特徴とする、請求項6に記載の調量システム。

- 前記アクチュエータ(35)が無通電のときに前記ダイヤフラム(43)によって閉止される、前記圧力配管(7)、前記吸込配管(3)、または前記換気配管(25)の前記端部はシールシート(49,65,81)で取り囲まれていることを特徴とする、請求項6に記載の調量システム。

- 前記送出ポンプ(5)および/または前記換気ポンプ(15)の前記アクチュエータ(35)が無通電のとき前記ダイヤフラム(43)は前記逆止め弁(17,19,21,23)の弁体に対して閉止力を直接的または間接的に及ぼすことを特徴とする、請求項6から8のいずれか1項に記載の調量システム。

- 前記換気ポンプ(15)は前記送出ポンプ(5)に統合されていることを特徴とする、請求項1から9のうちのいずれか1項に記載の調量システム。

- 少なくとも1つのコンデンサが存在しており、前記コンデンサに蓄えられた前記コンデンサの電荷を前記換気ポンプ(15)の電気式の前記アクチュエータ(35)への通電のために利用可能であることを特徴とする、請求項3から9のうちのいずれか1項に記載の調量システム。

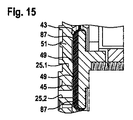

- 前記送出ポンプ(5)および/または前記換気ポンプ(15)は、磁石(37)および電機子(39)を備える電気式のアクチュエータ(35)と、ダイヤフラム(43)と、バルブ・ダイヤフラム・プレート(51)と、バルブプレート(57)とを含んでおり、前記バルブ・ダイヤフラム・プレート(51)と前記バルブプレート(57)との間にはゴムプレート(55)がバルブ部材および密閉部材として存在していることを特徴とする、請求項1または2に記載の調量システム。

- 前記バルブ・ダイヤフラム・プレート(51)と前記換気ポンプ(15)の前記ダイヤフラム(43)は制御可能な方向制御弁または逆止め弁(26)を形成することを特徴とする(図9から16)、請求項12に記載の調量システム。

- 前記バルブ・ダイヤフラム・プレート(51)、前記ゴムプレート(55)、および前記バルブプレート(57)は、第1の吸込側の逆止め弁(21)、第2の吸込側の逆止め弁(31)、圧力側の逆止め弁(23)、および/またはスロットル(27,29,33)を形成することを特徴とする(図4,5,7および8)、請求項12または13に記載の調量システム。

- 前記電機子(39)には弁皿(53)が構成されており、前記弁皿(53)は前記ダイヤフラム(43)の素材で押出被覆されており、前記ダイヤフラム(43)は前記電機子(39)の前記弁皿(53)に対してストローク方向で段差を有するように配置されていることを特徴とする、請求項12から14のいずれか1項に記載の調量システム。

- 前記ダイヤフラム(43)は断面で見て波形に構成されていることを特徴とする、請求項6から9または12から15のうちのいずれか1項に記載の調量システム。

- 前記電機子(39)は前記ダイヤフラム(43)の経路をストローク方向で制限していることを特徴とする、請求項12から16のうちのいずれか1項に記載の調量システム。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102011081628A DE102011081628A1 (de) | 2011-08-26 | 2011-08-26 | Dosiersystem für ein flüssiges Reduktionsmittel |

| DE102011081628.3 | 2011-08-26 | ||

| PCT/EP2012/063342 WO2013029849A1 (de) | 2011-08-26 | 2012-07-09 | Dosiersystem für ein flüssiges reduktionsmittel |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2014524542A JP2014524542A (ja) | 2014-09-22 |

| JP2014524542A5 JP2014524542A5 (ja) | 2015-10-29 |

| JP6012732B2 true JP6012732B2 (ja) | 2016-10-25 |

Family

ID=46466558

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014526428A Active JP6012732B2 (ja) | 2011-08-26 | 2012-07-09 | 液体還元剤のための調量システム |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US9562455B2 (ja) |

| EP (1) | EP2748439B1 (ja) |

| JP (1) | JP6012732B2 (ja) |

| CN (1) | CN103782002B (ja) |

| DE (1) | DE102011081628A1 (ja) |

| WO (1) | WO2013029849A1 (ja) |

Families Citing this family (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105804837B (zh) * | 2011-08-22 | 2018-12-14 | 康明斯排放处理公司 | 具有泄漏旁路的尿素溶液泵 |

| DE102011088221A1 (de) | 2011-12-12 | 2013-06-13 | Robert Bosch Gmbh | Dosieranordnung für ein flüssiges Abgasnachbehandlungsmittel und Dosierverfahren |

| DE102011088217A1 (de) | 2011-12-12 | 2013-06-13 | Robert Bosch Gmbh | Dosieranordnung für ein flüssiges Abgasnachbehandlungsmittel und Dosierverfahren |

| DE102011089516B4 (de) | 2011-12-22 | 2021-08-12 | Robert Bosch Gmbh | Pumpe zum Rücksaugen für ein flüssiges Abgasnachbehandlungsmittel, Dosieranordnung und Verfahren zum Dosieren und Rücksaugen |

| DE102011090070A1 (de) | 2011-12-29 | 2013-07-04 | Robert Bosch Gmbh | Abgasnachbehandlungsanordnung und Verfahren zur Abgasnachbehandlung |

| DE102012004726A1 (de) | 2012-03-07 | 2013-09-12 | Emitec Gesellschaft Für Emissionstechnologie Mbh | Fördereinheit für ein flüssiges Additiv |

| DE102012212562B4 (de) * | 2012-07-18 | 2020-11-26 | Robert Bosch Gmbh | Verfahren zum Betreiben eines Pumpensystems |

| DE102013211234A1 (de) | 2013-06-17 | 2014-12-18 | Robert Bosch Gmbh | Einstellbarer Magnetkreis für Druckindizierung |

| DE102014211057A1 (de) | 2013-06-19 | 2014-12-24 | Robert Bosch Gmbh | Rücksaugpumpe mit Anschlagdämpfung |

| SE539369C2 (sv) * | 2014-06-12 | 2017-08-15 | Scania Cv Ab | System och metod för överföring och evakuering av fluid frånen sekundärtank till en huvudtank i ett fordon |

| CN106150618B (zh) * | 2015-04-01 | 2023-08-15 | 天纳克(苏州)排放系统有限公司 | 尿素喷射组件 |

| DE102015118147A1 (de) | 2015-10-23 | 2017-04-27 | Eberspächer Exhaust Technology GmbH & Co. KG | Vorrichtung und Verfahren zur Abgabe von Reaktionsmittel in den Abgasstrom einer Brennkraftmaschine |

| DE102015226463A1 (de) * | 2015-12-22 | 2017-06-22 | Robert Bosch Gmbh | Magnetaktor für ein Förderaggregat |

| CN107246302A (zh) * | 2017-08-09 | 2017-10-13 | 华中科技大学无锡研究院 | 一种尿素泵送系统 |

| DE102017213958A1 (de) | 2017-08-10 | 2019-02-14 | Robert Bosch Gmbh | Magnetaktor für ein Förderaggregat |

| DE102017214481A1 (de) * | 2017-08-21 | 2019-02-21 | Robert Bosch Gmbh | Wassereinspritzvorrichtung für eine Brennkraftmaschine |

| DE102017215658A1 (de) | 2017-09-06 | 2019-03-07 | Robert Bosch Gmbh | Vorrichtung zur Verbindung von metallischen Komponenten mit Kunststoffkomponenten in einem Förderaggregat |

| DE102017217891A1 (de) * | 2017-10-09 | 2019-04-11 | Robert Bosch Gmbh | Fördermodul zur Förderung eines Fluids |

| DE102017218452A1 (de) | 2017-10-16 | 2019-04-18 | Robert Bosch Gmbh | Magnetaktor für ein Förderaggregat |

| DE102017220535A1 (de) * | 2017-11-17 | 2019-05-23 | Robert Bosch Gmbh | Verfahren zum Betreiben eines Reagenzmittel-Dosiersystems, Vorrichtung und Leitungsnetz zur Durchführung des Verfahrens |

| DE102017222448A1 (de) | 2017-12-12 | 2019-06-13 | Robert Bosch Gmbh | Pumpe mit Anschlagdämpfung |

| DE102018200572A1 (de) * | 2018-01-15 | 2019-07-18 | Robert Bosch Gmbh | Verfahren zur Überprüfung eines SCR-Systems mit zumindest zwei Dosierventilen |

| CN111482067A (zh) * | 2020-03-05 | 2020-08-04 | 华电电力科学研究院有限公司 | 一种sncr脱硝技术活性物质添加提效的方法 |

| CN111828139A (zh) * | 2020-08-26 | 2020-10-27 | 山东艾泰克环保科技股份有限公司 | 一种尿素泵集成流道块 |

Family Cites Families (41)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59517A (ja) | 1982-06-23 | 1984-01-05 | Mazda Motor Corp | デイ−ゼルエンジンの排気浄化装置 |

| JPS59144106U (ja) * | 1983-03-18 | 1984-09-26 | 日産自動車株式会社 | 排気微粒子捕集用トラツプの再生用バ−ナ− |

| JPH059517A (ja) * | 1991-06-28 | 1993-01-19 | Sumitomo Metal Ind Ltd | 高炉操業方法 |

| US5433238A (en) * | 1992-12-18 | 1995-07-18 | Vlsi Technology, Inc. | Pumping system for evacuating reactor chambers |

| US5522218A (en) * | 1994-08-23 | 1996-06-04 | Caterpillar Inc. | Combustion exhaust purification system and method |

| DE19726392A1 (de) * | 1997-06-21 | 1998-12-24 | Bosch Gmbh Robert | Gemischabgabevorrichtung |

| DE19738859A1 (de) * | 1997-09-05 | 1999-03-11 | Bosch Gmbh Robert | Gemischabgabevorrichtung |

| DE19819579C1 (de) * | 1998-04-30 | 1999-09-30 | Siemens Ag | Verfahren und Vorrichtung zur Abgasnachbehandlung für eine mit einem SCR-Katalysator ausgestattete Brennkraftmaschine |

| JP2000325754A (ja) | 1999-05-17 | 2000-11-28 | Osaka Gas Co Ltd | コージェネレーションの排気ガス脱硝システム |

| DE19956493C1 (de) * | 1999-11-24 | 2001-01-04 | Siemens Ag | Vorrichtung und Verfahren zum Entsticken von Abgas einer Brennkraftmaschine |

| US6470673B1 (en) * | 2000-02-22 | 2002-10-29 | Ford Global Technologies, Inc. | Control of a NOX reductant delivery system |

| DE10047516A1 (de) * | 2000-09-22 | 2002-04-18 | Bosch Gmbh Robert | Verfahren und Vorrichtung zur Dosierung eines Reduktionsmittels zur Entfernung von Stickoxiden aus Abgasen |

| JP2003003962A (ja) | 2001-06-20 | 2003-01-08 | Nikki Co Ltd | ダイヤフラムポンプ |

| DE10139142A1 (de) * | 2001-08-09 | 2003-02-20 | Bosch Gmbh Robert | Abgasbehandlungseinheit und Messvorrichtung zur Ermittlung einer Konzentration einer Harnstoff-Wasser-Lösung |

| DE10161132A1 (de) * | 2001-12-12 | 2003-06-26 | Siemens Ag | Membranpumpe mit integriertem Drucksensor |

| US6810661B2 (en) * | 2002-08-09 | 2004-11-02 | Ford Global Technologies, Llc | Method and system for freeze protecting liquid NOx reductants for vehicle application |

| DE10254981A1 (de) * | 2002-11-26 | 2004-06-03 | Robert Bosch Gmbh | Vorrichtung zur Entfernung eines Reduktionsmittels aus einer Apparatur zum Nachbehandeln von Abgasen einer Brennkraftmaschine |

| JP2004346808A (ja) | 2003-05-21 | 2004-12-09 | Denso Corp | 電磁弁駆動装置 |

| EP2426329B1 (en) * | 2003-09-19 | 2013-05-01 | Nissan Diesel Motor Co., Ltd. | Exhaust gas purification device of engine |

| US20050252201A1 (en) * | 2004-05-17 | 2005-11-17 | Lecea Oscar A | Method and apparatus for reducing NOx emissions |

| US7594393B2 (en) * | 2004-09-07 | 2009-09-29 | Robert Bosch Gmbh | Apparatus for introducing a reducing agent into the exhaust of an internal combustion engine |

| DE102004046881A1 (de) * | 2004-09-28 | 2006-04-13 | Robert Bosch Gmbh | Zuführsystem für ein Medium, insbesondere zur Behandlung von Abgasen einer Brennkraftmaschine, Abgasreinigungsvorrichtung und Verfahren zum Betreiben eines Zuführsystems |

| DE102004050023A1 (de) * | 2004-10-13 | 2006-04-27 | L'orange Gmbh | Einrichtung zur dosierten Einspritzung eines Reduktionsmittels in den Abgastrakt einer Brennkraftmaschine |

| DE102004054238A1 (de) * | 2004-11-10 | 2006-05-11 | Robert Bosch Gmbh | Dosiersystem sowie Verfahren zum Betreiben eines Dosiersystems |

| FR2879239A1 (fr) * | 2004-12-15 | 2006-06-16 | Inergy Automotive Systems Res | Systeme de stockage et d'injection d'un additif dans des gaz d'echappement d'un moteur |

| US7836684B2 (en) * | 2005-06-04 | 2010-11-23 | Eichenauer Heizelemente Gmbh & Co. Kg | Urea supply system for a waste gas cleaning catalyst and heating insert suitable therefor |

| JP2007056741A (ja) * | 2005-08-24 | 2007-03-08 | Nissan Diesel Motor Co Ltd | エンジンの排気浄化装置 |

| DE102006027487A1 (de) * | 2005-09-12 | 2007-03-15 | Robert Bosch Gmbh | Fahrzeugtank für ein flüssiges Reduktionsmittel, insbesondere für eine Harnstofflösung |

| WO2008006840A1 (en) * | 2006-07-13 | 2008-01-17 | Inergy Automotive Systems Research (Société Anonyme) | System and process for storing an additive and injecting it into the exhaust gases of an engine |

| FR2921911A3 (fr) * | 2007-09-21 | 2009-04-10 | Inergy Automotive Systems Res | Systeme de stockage et d'injection d'une solution d'additif dans des gaz d'echappement d'un moteur. |

| US20090194604A1 (en) * | 2008-01-19 | 2009-08-06 | Clyde Meriwether Smith | Pulsed spray system of reduced power consumption |

| JP5475243B2 (ja) * | 2008-03-07 | 2014-04-16 | ボッシュ株式会社 | 還元剤供給装置の制御装置及び還元剤の回収方法並びに排気浄化装置 |

| DE102008022991A1 (de) * | 2008-05-09 | 2009-11-12 | Emitec Gesellschaft Für Emissionstechnologie Mbh | Vorrichtung zur Förderung eines Reduktionsmittels und Verfahren zur Herstellung eines Kraftfahrzeuges |

| DE102008040463A1 (de) | 2008-07-16 | 2010-01-21 | Robert Bosch Gmbh | Vorrichtung zur Eindosierung von Kraftstoff |

| US8459012B2 (en) * | 2008-11-19 | 2013-06-11 | Caterpillar Inc. | Method for purging a dosing system |

| WO2010119116A2 (en) * | 2009-04-16 | 2010-10-21 | Inergy Automotive Systems Research (Société Anonyme) | System and process for storing an additive and injecting it into the exhaust gases of an engine |

| JP5388286B2 (ja) * | 2009-06-19 | 2014-01-15 | ボッシュ株式会社 | 排気浄化装置及びその制御方法 |

| DE102009037564B4 (de) * | 2009-08-14 | 2013-08-29 | Continental Automotive Gmbh | Vorrichtung und Verfahren zur Dosierung eines Reduktionsmittels in einen Abgastrakt einer Brennkraftmaschine |

| DE102009029408B4 (de) | 2009-09-14 | 2023-10-19 | Robert Bosch Gmbh | Verfahren zur Überwachung der Funktion eines SCR-Katalysatorsystems |

| DE102010039102B4 (de) * | 2010-08-09 | 2013-10-31 | Mtu Friedrichshafen Gmbh | Versorgungsvorrichtung, Brennkraftmaschine, Generatoreinheit, Verfahren zur Versorgung eines Abgassystems einer Brennkraftmaschine mit einer Reduktionsmittel enthaltenden Lösung und Steuereinrichtung |

| DE102011002425A1 (de) * | 2011-01-04 | 2012-07-05 | Robert Bosch Gmbh | Fördervorrichtung zur Versorgung eines Abgasnachbehandlungssytems einer Brennkraftmaschine mit einem Reduktionsmittel sowie Verfahren |

-

2011

- 2011-08-26 DE DE102011081628A patent/DE102011081628A1/de not_active Withdrawn

-

2012

- 2012-07-09 EP EP12733139.5A patent/EP2748439B1/de active Active

- 2012-07-09 US US14/241,360 patent/US9562455B2/en active Active

- 2012-07-09 JP JP2014526428A patent/JP6012732B2/ja active Active

- 2012-07-09 WO PCT/EP2012/063342 patent/WO2013029849A1/de active Application Filing

- 2012-07-09 CN CN201280041092.7A patent/CN103782002B/zh active Active

Also Published As

| Publication number | Publication date |

|---|---|

| EP2748439A1 (de) | 2014-07-02 |

| CN103782002A (zh) | 2014-05-07 |

| CN103782002B (zh) | 2017-03-22 |

| US9562455B2 (en) | 2017-02-07 |

| JP2014524542A (ja) | 2014-09-22 |

| DE102011081628A1 (de) | 2013-02-28 |

| WO2013029849A1 (de) | 2013-03-07 |

| EP2748439B1 (de) | 2017-10-04 |

| US20140227120A1 (en) | 2014-08-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6012732B2 (ja) | 液体還元剤のための調量システム | |

| JP4415929B2 (ja) | 高圧燃料供給ポンプ | |

| JP4595996B2 (ja) | 内燃機関の高圧燃料供給装置 | |

| CN101029695B (zh) | 可快速响应的电磁促动器 | |

| US8882475B2 (en) | Electromagnetic flow rate control valve and high-pressure fuel supply pump using the same | |

| JP4701227B2 (ja) | プランジャ式高圧燃料ポンプ | |

| JP2014524542A5 (ja) | ||

| JP2009535562A (ja) | エマージェンシおよびベンチレーション機能を備える圧力制御弁 | |

| JP2002115622A (ja) | 高圧燃料供給装置 | |

| JPWO2017203861A1 (ja) | 高圧燃料供給ポンプ | |

| JP2008309016A (ja) | 油圧制御装置 | |

| JP4585977B2 (ja) | 高圧燃料供給ポンプ及びその組立方法 | |

| JP4728389B2 (ja) | 燃料を噴射するための装置 | |

| US7543568B1 (en) | Fuel pressure amplifier for improved cranking performance | |

| US20180245489A1 (en) | Solenoid-actuated pressure-relief valve | |

| CN106414967A (zh) | 用于操作用于内燃机的燃料供应系统的方法 | |

| JP5030381B2 (ja) | 圧力パルス発生装置及び圧力パルス発生方法 | |

| JP4775488B2 (ja) | 内燃機関の高圧燃料供給装置 | |

| JP5514564B2 (ja) | 燃料供給装置 | |

| US6520156B2 (en) | High-pressure fuel supply system | |

| JP2004518845A (ja) | 内燃機関用のガス交換弁装置 | |

| JP4552834B2 (ja) | 燃料噴射装置 | |

| JP5780581B2 (ja) | コモンレール式燃料噴射制御装置用圧力制御弁 | |

| JP6355756B2 (ja) | 内燃機関の燃料噴射システム用の弁装置および高圧ポンプ | |

| US20030091445A1 (en) | Variable-flow high pressure pump |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20150219 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150302 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20150602 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20150901 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160210 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160419 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20160825 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20160920 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6012732 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |