JP4662716B2 - 接合用取付具から燃料電池アセンブリを分離する装置および方法 - Google Patents

接合用取付具から燃料電池アセンブリを分離する装置および方法 Download PDFInfo

- Publication number

- JP4662716B2 JP4662716B2 JP2003582849A JP2003582849A JP4662716B2 JP 4662716 B2 JP4662716 B2 JP 4662716B2 JP 2003582849 A JP2003582849 A JP 2003582849A JP 2003582849 A JP2003582849 A JP 2003582849A JP 4662716 B2 JP4662716 B2 JP 4662716B2

- Authority

- JP

- Japan

- Prior art keywords

- fixture

- mea

- assembly

- port

- fuel cell

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000000034 method Methods 0.000 title claims abstract description 21

- 239000000446 fuel Substances 0.000 title description 47

- 238000005304 joining Methods 0.000 title description 27

- 239000012528 membrane Substances 0.000 claims abstract description 23

- 230000000087 stabilizing effect Effects 0.000 claims abstract 7

- 239000012530 fluid Substances 0.000 claims description 14

- 238000004891 communication Methods 0.000 claims description 6

- 238000003825 pressing Methods 0.000 claims 1

- 238000000926 separation method Methods 0.000 description 33

- 239000000463 material Substances 0.000 description 18

- 239000001257 hydrogen Substances 0.000 description 14

- 229910052739 hydrogen Inorganic materials 0.000 description 14

- 230000032258 transport Effects 0.000 description 14

- 238000012545 processing Methods 0.000 description 12

- 239000003054 catalyst Substances 0.000 description 11

- 238000005520 cutting process Methods 0.000 description 10

- 239000003792 electrolyte Substances 0.000 description 10

- 239000011248 coating agent Substances 0.000 description 8

- 238000000576 coating method Methods 0.000 description 8

- 230000008569 process Effects 0.000 description 8

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 7

- -1 hydrogen ions Chemical class 0.000 description 7

- 239000001301 oxygen Substances 0.000 description 7

- 229910052760 oxygen Inorganic materials 0.000 description 7

- 239000011148 porous material Substances 0.000 description 7

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 6

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- 230000007246 mechanism Effects 0.000 description 5

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 4

- 238000010586 diagram Methods 0.000 description 3

- 238000011143 downstream manufacturing Methods 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 3

- 238000012986 modification Methods 0.000 description 3

- 230000004048 modification Effects 0.000 description 3

- 239000000047 product Substances 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 2

- ATUOYWHBWRKTHZ-UHFFFAOYSA-N Propane Chemical compound CCC ATUOYWHBWRKTHZ-UHFFFAOYSA-N 0.000 description 2

- CDBYLPFSWZWCQE-UHFFFAOYSA-L Sodium Carbonate Chemical compound [Na+].[Na+].[O-]C([O-])=O CDBYLPFSWZWCQE-UHFFFAOYSA-L 0.000 description 2

- 230000002411 adverse Effects 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 2

- 238000009792 diffusion process Methods 0.000 description 2

- 239000007789 gas Substances 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 229910052697 platinum Inorganic materials 0.000 description 2

- BWHMMNNQKKPAPP-UHFFFAOYSA-L potassium carbonate Chemical compound [K+].[K+].[O-]C([O-])=O BWHMMNNQKKPAPP-UHFFFAOYSA-L 0.000 description 2

- 230000001172 regenerating effect Effects 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 229920000049 Carbon (fiber) Polymers 0.000 description 1

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 1

- BVKZGUZCCUSVTD-UHFFFAOYSA-L Carbonate Chemical compound [O-]C([O-])=O BVKZGUZCCUSVTD-UHFFFAOYSA-L 0.000 description 1

- KJTLSVCANCCWHF-UHFFFAOYSA-N Ruthenium Chemical compound [Ru] KJTLSVCANCCWHF-UHFFFAOYSA-N 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 239000001569 carbon dioxide Substances 0.000 description 1

- 229910002092 carbon dioxide Inorganic materials 0.000 description 1

- 239000004917 carbon fiber Substances 0.000 description 1

- 229910002091 carbon monoxide Inorganic materials 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 229910021525 ceramic electrolyte Inorganic materials 0.000 description 1

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 239000003245 coal Substances 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 239000002283 diesel fuel Substances 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 239000002001 electrolyte material Substances 0.000 description 1

- 238000006056 electrooxidation reaction Methods 0.000 description 1

- 238000004146 energy storage Methods 0.000 description 1

- UQSQSQZYBQSBJZ-UHFFFAOYSA-N fluorosulfonic acid Chemical compound OS(F)(=O)=O UQSQSQZYBQSBJZ-UHFFFAOYSA-N 0.000 description 1

- 239000002803 fossil fuel Substances 0.000 description 1

- 238000002309 gasification Methods 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 150000002431 hydrogen Chemical class 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 238000003475 lamination Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000011244 liquid electrolyte Substances 0.000 description 1

- 239000006193 liquid solution Substances 0.000 description 1

- XGZVUEUWXADBQD-UHFFFAOYSA-L lithium carbonate Chemical compound [Li+].[Li+].[O-]C([O-])=O XGZVUEUWXADBQD-UHFFFAOYSA-L 0.000 description 1

- 229910052808 lithium carbonate Inorganic materials 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 229910001092 metal group alloy Inorganic materials 0.000 description 1

- 239000002923 metal particle Substances 0.000 description 1

- 239000003345 natural gas Substances 0.000 description 1

- 229910000510 noble metal Inorganic materials 0.000 description 1

- 229920000620 organic polymer Polymers 0.000 description 1

- RVTZCBVAJQQJTK-UHFFFAOYSA-N oxygen(2-);zirconium(4+) Chemical compound [O-2].[O-2].[Zr+4] RVTZCBVAJQQJTK-UHFFFAOYSA-N 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 229920005597 polymer membrane Polymers 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 229910000027 potassium carbonate Inorganic materials 0.000 description 1

- 238000010248 power generation Methods 0.000 description 1

- 239000001294 propane Substances 0.000 description 1

- 238000011946 reduction process Methods 0.000 description 1

- 229910052707 ruthenium Inorganic materials 0.000 description 1

- 229910000029 sodium carbonate Inorganic materials 0.000 description 1

- 239000007784 solid electrolyte Substances 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 238000009966 trimming Methods 0.000 description 1

- 229910001928 zirconium oxide Inorganic materials 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/24—Grouping of fuel cells, e.g. stacking of fuel cells

- H01M8/2465—Details of groupings of fuel cells

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/24—Grouping of fuel cells, e.g. stacking of fuel cells

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/10—Fuel cells with solid electrolytes

- H01M8/1004—Fuel cells with solid electrolytes characterised by membrane-electrode assemblies [MEA]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/02—Details

- H01M8/0271—Sealing or supporting means around electrodes, matrices or membranes

- H01M8/0273—Sealing or supporting means around electrodes, matrices or membranes with sealing or supporting means in the form of a frame

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/30—Hydrogen technology

- Y02E60/50—Fuel cells

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10S156/934—Apparatus having delaminating means adapted for delaminating a specified article

- Y10S156/935—Delaminating means in preparation for post consumer recycling

- Y10S156/937—Means for delaminating specified electronic component in preparation for recycling

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/11—Methods of delaminating, per se; i.e., separating at bonding face

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/11—Methods of delaminating, per se; i.e., separating at bonding face

- Y10T156/1126—Using direct fluid current against work during delaminating

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/19—Delaminating means

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49815—Disassembling

- Y10T29/49822—Disassembling by applying force

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/53—Means to assemble or disassemble

- Y10T29/53096—Means to assemble or disassemble including means to provide a controlled environment

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/53—Means to assemble or disassemble

- Y10T29/53274—Means to disassemble electrical device

- Y10T29/53278—Storage cell or battery

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/53—Means to assemble or disassemble

- Y10T29/53683—Spreading parts apart or separating them from face to face engagement

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/53—Means to assemble or disassemble

- Y10T29/53978—Means to assemble or disassemble including means to relatively position plural work parts

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Fuel Cell (AREA)

Description

Claims (3)

- 取付具アセンブリから膜電極アセンブリ(MEA)を、該取付具アセンブリ内でのMEA接合の後に分離する方法であって、該取付具アセンブリが、該MEAの第1表面に接触する第1取付具と該MEAの第2表面に接触する第2取付具とを備え、該第1および第2取付具がそれぞれ多孔性領域を備えてなる、方法において、

前記取付具アセンブリの前記第1取付具の位置を安定させ、

前記取付具アセンブリの前記第2取付具の位置を安定させ、

前記第2取付具の位置が安定させられている間に、前記第1取付具と前記MEAの前記第1表面とに圧力を加えて、前記MEAの前記第1表面を前記第1取付具から分離させ、

続いて、前記第1取付具の位置が安定させられている間に、前記第2取付具と前記MEAの前記第2表面とに圧力を加えて、前記MEAの前記第2表面を前記第2取付具から分離させ、

続いて、前記第1取付具から離れるように前記第2取付具を移動させて、前記第1取付具からの前記MEAの取出しを可能にすること、

を特徴とする方法。 - 前記第1取付具と前記MEAの前記第1表面とに圧力が加えられている間に、前記第2取付具と前記MEAの前記第2表面とに真空を与え、続いて、前記第2取付具と前記MEAの前記第2表面とに圧力が加えられている間に、前記第1取付具と前記MEAの前記第1表面とに真空を与え、

前記第1取付具の位置を安定させることは、前記第1取付具をつかんで該第1取付具の位置を安定させることを含み、

前記第2取付具の位置を安定させることは、真空を用いて前記第2取付具の位置を安定させることを含む、

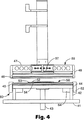

請求項1に記載の方法。 - 取付具アセンブリから膜電極アセンブリ(MEA)を、該取付具アセンブリ内でのMEA接合の後に分離する装置であって、該取付具アセンブリが、該MEAの第1表面に接触する第1取付具と該MEAの第2表面に接触する第2取付具とを備え、該第1および第2取付具がそれぞれ多孔性領域を備えてなる、装置において、

第1ポートと下部グリッパアセンブリとを有するベースであって、該第1ポートが前記第1取付具の前記多孔性領域を介して前記MEAの前記第1表面と流体連通するように、前記取付具アセンブリを受容するとともに、該下部グリッパアセンブリが、前記第1取付具をつかんで前記第1取付具の位置を安定させるようになっているベースと、

支持体上に移動可能に取付けられる上部グリッパアセンブリであって、グリッパフィンガと第2ポートとを有し、該第2ポートが、前記第2取付具の前記多孔性領域を介して前記MEAの前記第2表面と流体連通するとともに、前記第2取付具の位置を安定させる真空を形成するようになっている上部グリッパアセンブリと、を具備し、

前記第1および第2ポートが、選択的に加圧かつ排気されて、それぞれ前記第1および第2取付具から前記MEAの前記第1および第2表面を分離し、

前記上部グリッパアセンブリが、前記第2取付具の一対の両縁を解放可能につかんで、前記第1取付具から離れるように前記第2取付具を移動させるようになっていること、

を特徴とする装置。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/115,731 US6749713B2 (en) | 2002-04-03 | 2002-04-03 | Apparatus and method for separating a fuel cell assembly from a bonding fixture |

| PCT/US2003/004276 WO2003085770A2 (en) | 2002-04-03 | 2003-02-11 | Apparatus and method for separating a fuel cell assembly from a bonding fixture |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006504229A JP2006504229A (ja) | 2006-02-02 |

| JP2006504229A5 JP2006504229A5 (ja) | 2006-03-30 |

| JP4662716B2 true JP4662716B2 (ja) | 2011-03-30 |

Family

ID=28673826

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003582849A Expired - Fee Related JP4662716B2 (ja) | 2002-04-03 | 2003-02-11 | 接合用取付具から燃料電池アセンブリを分離する装置および方法 |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US6749713B2 (ja) |

| EP (1) | EP1516385B1 (ja) |

| JP (1) | JP4662716B2 (ja) |

| KR (1) | KR20040094899A (ja) |

| CN (1) | CN100356625C (ja) |

| AT (1) | ATE498212T1 (ja) |

| AU (1) | AU2003213036A1 (ja) |

| CA (1) | CA2480967A1 (ja) |

| DE (1) | DE60335986D1 (ja) |

| WO (1) | WO2003085770A2 (ja) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6740131B2 (en) | 2002-04-03 | 2004-05-25 | 3M Innovative Properties Company | Apparatus for automatically fabricating fuel cell |

| US6868890B2 (en) * | 2002-04-03 | 2005-03-22 | 3M Innovative Properties Company | Method and apparatus for peeling a thin film from a liner |

| US20030188615A1 (en) * | 2002-04-03 | 2003-10-09 | 3M Innovative Properties Company | Angled product transfer conveyor |

| US7432009B2 (en) | 2002-04-03 | 2008-10-07 | 3M Innovative Properties Company | Lamination apparatus and methods |

| US20030190226A1 (en) * | 2002-04-03 | 2003-10-09 | 3M Innovative Properties Company | Apparatus and method for singulating porous fuel cell layers using adhesive tape pick head |

| US7195690B2 (en) | 2003-05-28 | 2007-03-27 | 3M Innovative Properties Company | Roll-good fuel cell fabrication processes, equipment, and articles produced from same |

| WO2008076137A2 (en) * | 2006-02-15 | 2008-06-26 | 3M Innovative Properties Company | Selective oxidation of carbon monoxide relative to hydrogen using catalytically active gold |

| US8137750B2 (en) * | 2006-02-15 | 2012-03-20 | 3M Innovative Properties Company | Catalytically active gold supported on thermally treated nanoporous supports |

| US7641801B2 (en) * | 2007-02-28 | 2010-01-05 | Vale Inco Limited | Method for removing manganese from nickel laterite waste liquors |

| JP2009154407A (ja) * | 2007-12-27 | 2009-07-16 | Tdk Corp | 剥離装置、剥離方法および情報記録媒体製造方法 |

| KR101869922B1 (ko) * | 2011-11-28 | 2018-06-22 | 삼성디스플레이 주식회사 | 진공 필링 장치 및 진공 필링 방법 |

| CA2878828C (en) | 2012-07-10 | 2016-10-04 | Nissan Motor Co., Ltd. | Holding apparatus for fuel cell electrolyte membrane |

| KR102331334B1 (ko) * | 2017-09-25 | 2021-11-24 | 주식회사 엘지에너지솔루션 | 배터리용 커넥터 탈착 기구 |

| CN109687008B (zh) * | 2019-01-15 | 2023-08-25 | 安徽明天氢能科技股份有限公司 | 一种燃料电池电堆系统组装托盘 |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5598040A (en) * | 1979-01-23 | 1980-07-25 | Toppan Printing Co Ltd | Paper feeder by adhesive tape |

| JPS5793854A (en) * | 1980-11-29 | 1982-06-11 | Matsushita Electric Works Ltd | Single-plate piling method and apparatus therefor |

| JPS62244830A (ja) * | 1986-04-14 | 1987-10-26 | Yoshiyuki Kobayashi | 布等の移送方法及びその装置 |

| JPH08335462A (ja) * | 1995-06-08 | 1996-12-17 | Fuji Electric Co Ltd | 燃料電池電極の膜合わせ装置 |

| JPH11292327A (ja) * | 1998-04-10 | 1999-10-26 | Takeshi Tanaka | 布片採取器 |

| JP2001520445A (ja) * | 1997-10-10 | 2001-10-30 | ミネソタ マイニング アンド マニュファクチャリング カンパニー | 膜電極アセンブリ |

| WO2001086738A1 (en) * | 2000-04-26 | 2001-11-15 | Kukil Inntot Industries Co., Ltd. | Fixture for fuel cell of proton exchange membrane type |

| JP2001319666A (ja) * | 2000-05-02 | 2001-11-16 | Honda Motor Co Ltd | 燃料電池及びその製造方法 |

Family Cites Families (61)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2710234A (en) * | 1950-05-22 | 1955-06-07 | Hughes Aircraft Co | Fluid-bearing mount |

| US3178041A (en) * | 1961-10-23 | 1965-04-13 | Libbey Owens Ford Glass Co | Sheet handling apparatus |

| US3285112A (en) * | 1964-08-03 | 1966-11-15 | Lamb Grays Harbor Co Inc | Vacuum controlling of sheet delivery |

| IL23954A (en) | 1964-08-04 | 1969-06-25 | Ibm | Apparatus for guiding and feeding a continuous web |

| US3380788A (en) * | 1964-12-28 | 1968-04-30 | Gen Electric | Hydrostatic bearing |

| US3359046A (en) * | 1965-10-22 | 1967-12-19 | Hugh L Dryden | Bismuth-lead coatings for gas bearings used in atmospheric environments and vacuum chambers |

| US3477558A (en) * | 1966-10-27 | 1969-11-11 | Fred J Fleischauer | Air lift and vacuum conveyors and foraminous belt means therefor |

| DE1928110A1 (de) | 1969-06-03 | 1970-12-10 | Viktor Prochaska | Vorrichtung zum Beschicken,Foerdern,Sortieren und Stapeln von Materialien wie z.B. Bleche,Furniere,Kunststoffe,Pappe und Platten jeder Art |

| AT314323B (de) | 1970-10-09 | 1974-03-25 | Malew Eng Ltd | Preß- bzw. Stanzwerkzeug od.dgl. und Verfahren zu dessen Herstellung |

| US3861259A (en) * | 1973-06-04 | 1975-01-21 | Harris Intertype Corp | Sheet delivery system |

| US3946920A (en) * | 1974-02-22 | 1976-03-30 | Xerox Corporation | Vacuum system control |

| US4168772A (en) * | 1974-10-01 | 1979-09-25 | General Battery Corporation | Apparatus and method for stacking battery plates and separators |

| DE2610628C3 (de) | 1976-03-13 | 1979-09-27 | Dornier Gmbh, 7990 Friedrichshafen | Vorrichtung zum Ausschneiden von plattenförmigen Kernwerkstoffen für Sandwichbauteile |

| CA1069949A (en) * | 1976-07-01 | 1980-01-15 | Hubert Blessing | Facing ply separator |

| DE2900663C2 (de) * | 1979-01-10 | 1982-12-16 | FAG Kugelfischer Georg Schäfer & Co, 8720 Schweinfurt | Verfahren zum Herstellen und Prüfen von Wälzkörpern |

| FR2456613A1 (fr) | 1979-05-16 | 1980-12-12 | Reine Yvan | Procede pour fabriquer des emballages pliants a partir d'une feuille de matiere plastique souple, outillage utilise et emballage obtenu |

| US4236814A (en) * | 1979-06-13 | 1980-12-02 | A. B. Dick Company | Transport system for advancing copy sheets through tandem duplicating system |

| US4381596A (en) * | 1981-02-04 | 1983-05-03 | Mac Engineering & Equip. Co., Inc. | Method and apparatus for battery plate stacking |

| IT1138810B (it) | 1981-06-23 | 1986-09-17 | Rockwell Rimoldi Spa | Prelevatore di pezzi impilati con mezzi di presa provvisti di nastro adesivo |

| US4360260A (en) | 1981-10-05 | 1982-11-23 | Polaroid Corporation | Spreader roller system having adjustable roller gap |

| US4534549A (en) * | 1982-06-22 | 1985-08-13 | General Battery Corporation | Automatic battery stacker |

| US4728093A (en) * | 1982-06-22 | 1988-03-01 | General Battery Corporation | Automatic battery stacker |

| US4784380A (en) * | 1982-06-22 | 1988-11-15 | General Battery Corporation | Automatic battery stacker |

| DE3336426A1 (de) * | 1983-10-06 | 1985-04-18 | Maschinenfabrik Herbert Meyer KG, 8000 München | Vorrichtung zum aufnehmen flaechiger werkstuecke |

| DE3343811A1 (de) | 1983-12-03 | 1985-06-13 | Babcock-BSH AG vormals Büttner-Schilde-Haas AG, 4150 Krefeld | Saugriemenfoerderer |

| DE3420409A1 (de) | 1984-06-01 | 1985-12-05 | ELTI Apparatebau und Elektronik GmbH, 6106 Erzhausen | Laminierstation |

| US5048182A (en) | 1988-02-22 | 1991-09-17 | Robbins Edward S Iii | Methods for fabricating pattern rolls |

| US4819928A (en) * | 1987-09-21 | 1989-04-11 | Mobil Oil Corporation | Plastic film air table conveyor |

| IT1213837B (it) * | 1987-10-14 | 1990-01-05 | Solis Srl | Dispositivo di presa temporanea di manufatti tessili a maglia, specialmente tubolari |

| EP0313088B1 (en) * | 1987-10-23 | 1995-01-04 | Fujitsu Limited | A suction-type sheet-carrying mechanism for an image-forming apparatus |

| GB8822328D0 (en) * | 1988-09-22 | 1988-10-26 | Stoddard Sekers Int | Pressure roller assembly |

| US5063415A (en) * | 1989-10-13 | 1991-11-05 | Minolta Camera Kabushiki Kaisha | Image forming apparatus |

| JPH03128851A (ja) | 1989-10-13 | 1991-05-31 | Minolta Camera Co Ltd | 画像形成装置 |

| JP2676947B2 (ja) | 1989-10-13 | 1997-11-17 | ミノルタ株式会社 | 画像形成装置 |

| US5000697A (en) * | 1990-03-27 | 1991-03-19 | R.H. Murphy Co., Inc. | Carrier system for PGA electrical components |

| DE4013302A1 (de) * | 1990-04-26 | 1991-10-31 | Koenig & Bauer Ag | Vorrichtung zum foerdern eines insbesondere geschuppten stroms von bogen |

| US5078375A (en) * | 1990-12-06 | 1992-01-07 | Tamarack Products, Inc. | Method of superposing webs |

| JP3254714B2 (ja) * | 1992-03-10 | 2002-02-12 | 石川島播磨重工業株式会社 | カレンダーのロールギャップ制御方法及びその装置 |

| CA2079721C (en) * | 1992-10-02 | 2002-08-20 | Ernest R. Bodnar | Rotary apparatus with moveable die |

| BE1007774A3 (nl) | 1993-11-19 | 1995-10-17 | Agfa Gevaert Nv | Delaminator voor een droog verwerkbaar thermisch beeld. |

| EP0654347A1 (en) | 1993-11-19 | 1995-05-24 | Agfa-Gevaert N.V. | Device for producing an imaging element |

| DE9400890U1 (de) | 1994-01-20 | 1994-03-17 | Naumann Spezialwerkzeugfabrik GmbH, 51381 Leverkusen | Werkzeuganordnung zum Bandstahlschneiden |

| US5556499A (en) * | 1994-12-01 | 1996-09-17 | Polaroid Corporation | Delaminating method and apparatus |

| US5596897A (en) * | 1995-09-12 | 1997-01-28 | Reynolds Metals Company | Mechanism for controlling form roll movement in spin flow necking machine |

| US6159327A (en) * | 1996-04-12 | 2000-12-12 | Polaroid Corporation | Apparatus and method for applying heat bondable lamina to a substrate |

| US5783024A (en) * | 1996-04-12 | 1998-07-21 | Nbs Imaging Systems, Inc. | Apparatus for applying heat bondable lamina to a substrate |

| US5989747A (en) * | 1996-07-10 | 1999-11-23 | Fuji Photo Film Co., Ltd. | Cell electrode with thick tip portions |

| US5993582A (en) * | 1996-08-13 | 1999-11-30 | Canon Kabushiki Kaisha | Continuous vacuum lamination treatment system and vacuum lamination apparatus |

| JP3272619B2 (ja) | 1996-12-05 | 2002-04-08 | 三菱重工業株式会社 | 2段タンデム圧延機及び該圧延機を備えた熱間圧延設備 |

| DE19723749A1 (de) * | 1997-06-06 | 1998-12-10 | Koenig & Bauer Albert Ag | Verfahren und Vorrichtung zum Quertrennen von laufenden Bedruckstoffbahnen |

| EP1018177B1 (en) * | 1997-07-16 | 2002-04-10 | Ballard Power Systems Inc. | Resilient seal for membrane electrode assembly (mea) in an electrochemical fuel cell and method of making same |

| JPH11273663A (ja) | 1998-03-25 | 1999-10-08 | Fuji Photo Film Co Ltd | 間欠塗布品の切断位置検出方法および装置 |

| JPH11297314A (ja) | 1998-04-07 | 1999-10-29 | Mitsubishi Heavy Ind Ltd | 電池製造用切断装置 |

| US6059003A (en) * | 1998-07-29 | 2000-05-09 | Integrated Design Corporation | Web heating and pressing apparatus |

| US6347585B1 (en) * | 1998-08-04 | 2002-02-19 | Goss Graphic Systems, Inc. | Variable gap stabilizer |

| US6224203B1 (en) * | 1999-05-13 | 2001-05-01 | Hewlett-Packard Company | Hard copy print media path for reducing cockle |

| JP4275254B2 (ja) * | 1999-06-17 | 2009-06-10 | リンテック株式会社 | 両面粘着シートに固定された物品の剥離方法および剥離装置 |

| CA2345852C (en) * | 2000-05-02 | 2008-11-18 | Honda Giken Kogyo Kabushiki Kaisha | Fuel cell having sealant for sealing a solid polymer electrolyte membrane |

| JP3429739B2 (ja) * | 2000-07-28 | 2003-07-22 | 株式会社東京機械製作所 | ニッピングローラーの間隙調整装置 |

| US6470946B2 (en) * | 2001-02-06 | 2002-10-29 | Anadigics, Inc. | Wafer demount gas distribution tool |

| US6491083B2 (en) * | 2001-02-06 | 2002-12-10 | Anadigics, Inc. | Wafer demount receptacle for separation of thinned wafer from mounting carrier |

-

2002

- 2002-04-03 US US10/115,731 patent/US6749713B2/en not_active Expired - Lifetime

-

2003

- 2003-02-11 DE DE60335986T patent/DE60335986D1/de not_active Expired - Lifetime

- 2003-02-11 AT AT03709078T patent/ATE498212T1/de not_active IP Right Cessation

- 2003-02-11 EP EP03709078A patent/EP1516385B1/en not_active Expired - Lifetime

- 2003-02-11 CA CA002480967A patent/CA2480967A1/en not_active Abandoned

- 2003-02-11 CN CNB038102501A patent/CN100356625C/zh not_active Expired - Fee Related

- 2003-02-11 AU AU2003213036A patent/AU2003213036A1/en not_active Abandoned

- 2003-02-11 KR KR10-2004-7015577A patent/KR20040094899A/ko not_active Application Discontinuation

- 2003-02-11 JP JP2003582849A patent/JP4662716B2/ja not_active Expired - Fee Related

- 2003-02-11 WO PCT/US2003/004276 patent/WO2003085770A2/en active Application Filing

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5598040A (en) * | 1979-01-23 | 1980-07-25 | Toppan Printing Co Ltd | Paper feeder by adhesive tape |

| JPS5793854A (en) * | 1980-11-29 | 1982-06-11 | Matsushita Electric Works Ltd | Single-plate piling method and apparatus therefor |

| JPS62244830A (ja) * | 1986-04-14 | 1987-10-26 | Yoshiyuki Kobayashi | 布等の移送方法及びその装置 |

| JPH08335462A (ja) * | 1995-06-08 | 1996-12-17 | Fuji Electric Co Ltd | 燃料電池電極の膜合わせ装置 |

| JP2001520445A (ja) * | 1997-10-10 | 2001-10-30 | ミネソタ マイニング アンド マニュファクチャリング カンパニー | 膜電極アセンブリ |

| JPH11292327A (ja) * | 1998-04-10 | 1999-10-26 | Takeshi Tanaka | 布片採取器 |

| WO2001086738A1 (en) * | 2000-04-26 | 2001-11-15 | Kukil Inntot Industries Co., Ltd. | Fixture for fuel cell of proton exchange membrane type |

| JP2001319666A (ja) * | 2000-05-02 | 2001-11-16 | Honda Motor Co Ltd | 燃料電池及びその製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE498212T1 (de) | 2011-02-15 |

| CN100356625C (zh) | 2007-12-19 |

| CA2480967A1 (en) | 2003-10-16 |

| EP1516385B1 (en) | 2011-02-09 |

| WO2003085770A2 (en) | 2003-10-16 |

| KR20040094899A (ko) | 2004-11-10 |

| DE60335986D1 (de) | 2011-03-24 |

| AU2003213036A1 (en) | 2003-10-20 |

| CN1653639A (zh) | 2005-08-10 |

| EP1516385A2 (en) | 2005-03-23 |

| US20030188418A1 (en) | 2003-10-09 |

| WO2003085770A3 (en) | 2005-01-27 |

| US6749713B2 (en) | 2004-06-15 |

| AU2003213036A8 (en) | 2003-10-20 |

| JP2006504229A (ja) | 2006-02-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6756146B2 (en) | Apparatus and method for automatically stacking fuel cell material layers | |

| JP4662716B2 (ja) | 接合用取付具から燃料電池アセンブリを分離する装置および方法 | |

| JP4584590B2 (ja) | 燃料電池膜ウェブを精密に位置決めされた膜シートに加工する装置および方法 | |

| JP4584591B2 (ja) | 燃料電池材料層の自動組立て用取付パレット装置 | |

| US7681304B2 (en) | Membrane electrode assembly and method of manufacturing a membrane electrode assembly | |

| US7018500B2 (en) | Apparatus and method for singulating porous fuel cell layers using adhesive tape pick head | |

| KR20120022145A (ko) | 막 전극 접합체 및 가스확산층 상호 간의 적층 정밀도 향상을 통해 개선된 품질을 갖는 연료전지 제조 장치 및 그 제조 방법 | |

| US20240297321A1 (en) | Method for producing an electrochemical cell unit | |

| CN117501482A (zh) | 用于制造电化学电池单元的方法 | |

| KR20190106057A (ko) | 다중작업이 가능한 연료전지제작용 카트리지 및 연료전지 소재에 부착된 간지제거방법 | |

| Micro | PEMFC system operated with conventional compressors while maintaining cold-start capability |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060210 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060210 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20091006 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20100105 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20100113 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100406 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100803 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101102 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20101130 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110104 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4662716 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140114 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |