JP4656344B2 - ウェブ搬送方法及び装置 - Google Patents

ウェブ搬送方法及び装置 Download PDFInfo

- Publication number

- JP4656344B2 JP4656344B2 JP2008218225A JP2008218225A JP4656344B2 JP 4656344 B2 JP4656344 B2 JP 4656344B2 JP 2008218225 A JP2008218225 A JP 2008218225A JP 2008218225 A JP2008218225 A JP 2008218225A JP 4656344 B2 JP4656344 B2 JP 4656344B2

- Authority

- JP

- Japan

- Prior art keywords

- web

- roller

- nip

- conveyance

- expansion angle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims description 14

- 230000006837 decompression Effects 0.000 claims description 10

- 239000012788 optical film Substances 0.000 claims description 7

- 230000003287 optical effect Effects 0.000 claims description 5

- 238000000576 coating method Methods 0.000 description 24

- 239000011248 coating agent Substances 0.000 description 21

- 230000037303 wrinkles Effects 0.000 description 19

- 238000011156 evaluation Methods 0.000 description 13

- 238000004519 manufacturing process Methods 0.000 description 10

- 239000010408 film Substances 0.000 description 9

- 239000000463 material Substances 0.000 description 9

- 238000004804 winding Methods 0.000 description 5

- 230000000694 effects Effects 0.000 description 4

- 230000007613 environmental effect Effects 0.000 description 4

- 238000001035 drying Methods 0.000 description 3

- 210000005069 ears Anatomy 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 238000007665 sagging Methods 0.000 description 3

- 238000011144 upstream manufacturing Methods 0.000 description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 238000007664 blowing Methods 0.000 description 2

- 238000007765 extrusion coating Methods 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 238000003892 spreading Methods 0.000 description 2

- 239000004809 Teflon Substances 0.000 description 1

- 229920006362 Teflon® Polymers 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000009501 film coating Methods 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000007756 gravure coating Methods 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 230000002452 interceptive effect Effects 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- -1 polytetrafluoroethylene Polymers 0.000 description 1

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 1

- 239000004810 polytetrafluoroethylene Substances 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H23/00—Registering, tensioning, smoothing or guiding webs

- B65H23/02—Registering, tensioning, smoothing or guiding webs transversely

- B65H23/022—Registering, tensioning, smoothing or guiding webs transversely by tentering devices

- B65H23/025—Registering, tensioning, smoothing or guiding webs transversely by tentering devices by rollers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H23/00—Registering, tensioning, smoothing or guiding webs

- B65H23/02—Registering, tensioning, smoothing or guiding webs transversely

- B65H23/022—Registering, tensioning, smoothing or guiding webs transversely by tentering devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/14—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers

- B32B37/24—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers with at least one layer not being coherent before laminating, e.g. made up from granular material sprinkled onto a substrate

- B32B2037/243—Coating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/40—Properties of the layers or laminate having particular optical properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/16—Drying; Softening; Cleaning

- B32B38/164—Drying

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/50—Auxiliary process performed during handling process

- B65H2301/51—Modifying a characteristic of handled material

- B65H2301/512—Changing form of handled material

- B65H2301/5124—Stretching; Tentering

- B65H2301/51242—Stretching transversely; Tentering

- B65H2301/512422—Stretching transversely; Tentering involving roller pair acting on edge of web

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/10—Handled articles or webs

- B65H2701/17—Nature of material

- B65H2701/172—Composite material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/10—Handled articles or webs

- B65H2701/17—Nature of material

- B65H2701/175—Plastic

- B65H2701/1752—Polymer film

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2801/00—Application field

- B65H2801/61—Display device manufacture, e.g. liquid crystal displays

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03G—ELECTROGRAPHY; ELECTROPHOTOGRAPHY; MAGNETOGRAPHY

- G03G2215/00—Apparatus for electrophotographic processes

- G03G2215/00135—Handling of parts of the apparatus

- G03G2215/00139—Belt

- G03G2215/00143—Meandering prevention

Landscapes

- Advancing Webs (AREA)

- Registering, Tensioning, Guiding Webs, And Rollers Therefor (AREA)

Description

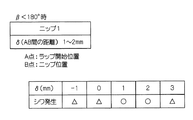

また、請求項1に従属する請求項2のように、ニップローラの拡張角はウェブの搬送テンションが100Nを境に異なる傾向にあり、ウェブの搬送テンションが100N以下の場合には1°以上〜3°以下で、そのときのニップ圧を10Pa以上30Pa以下に設定すると、ウェブの幅方向外側への拡張効果が良くなる。また、ウェブの搬送テンションが100Nを超えて150N以下の場合には、ニップローラの拡張角を3°を超えて30°未満に設定し、そのときのニップ圧を30Paを超えて60Pa以下に設定すると、ウェブの幅方向外側への拡張効果が良くなる。

Claims (7)

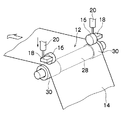

- 帯状のウェブを搬送するウェブ搬送において、

前記ウェブはローラ両端部がローラ中央部より大径に形成された段差ローラに対して所定のラップ角度を有してラップされ、

前記段差ローラにラップされたウェブの両端部を、前記段差ローラの前記ローラ両端部と、前記ラップの開始位置の直前に配置された一対のニップローラとでニップすると共に、該一対のニップローラの向きを前記ウェブの搬送方向に対して逆ハの字状に拡張することを特徴とするウェブ搬送方法。 - 前記逆ハの字状に拡張するニップローラの拡張角は、ウェブの搬送テンションが100N以下の場合には、ニップローラの拡張角を1°以上〜3°以下に設定し、そのときのニップ圧を10Pa以上30Pa以下に設定すると共に、

ウェブの搬送テンションが100Nを超えて150N以下の場合には、ニップローラの拡張角を3°を超えて30°未満に設定し、そのときのニップ圧を30Paを超えて60Pa以下に設定することを特徴とする請求項1に記載のウェブ搬送方法。 - 前記ラップの開始位置からラップ終了位置の間の任意位置に配置した更に別のニップローラで前記ウェブをニップすることを特徴とする請求項1又は2に記載のウェブ搬送方法。

- 前記ウェブは光学フィルムであって、光学特性を有する機能面が前記段差ローラ側に面していることを特徴とする請求項1〜3のいずれか1に記載のウェブ搬送方法。

- 帯状のウェブを減圧室内で搬送するウェブ搬送において、

前記ウェブが所定のラップ角度を有してラップされると共に、ローラ両端部がローラ中央部より大径に形成された段差ローラと、

前記ラップの開始位置の直前に配置され、前記ウェブの両端部を、前記段差ローラの前記ローラ両端部とでニップすると共に、前記ウェブの搬送方向に対して逆ハの字状の拡張角を有して配置された一対のニップローラと、を備えたことを特徴とするウェブ搬送装置。 - 前記ニップローラは、並列配置された複数個のローラで構成されることを特徴とする請求項5に記載のウェブ搬送装置。

- 前記複数個配列されたローラの拡張角は、内側に配置されたローラよりも外側に配置されたローラの方が大きいことを特徴とする請求項6に記載のウェブ搬送装置。

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008218225A JP4656344B2 (ja) | 2008-08-27 | 2008-08-27 | ウェブ搬送方法及び装置 |

| US12/545,349 US20100054826A1 (en) | 2008-08-27 | 2009-08-21 | Web transfer method and apparatus |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008218225A JP4656344B2 (ja) | 2008-08-27 | 2008-08-27 | ウェブ搬送方法及び装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010052872A JP2010052872A (ja) | 2010-03-11 |

| JP2010052872A5 JP2010052872A5 (ja) | 2010-04-30 |

| JP4656344B2 true JP4656344B2 (ja) | 2011-03-23 |

Family

ID=41725669

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008218225A Active JP4656344B2 (ja) | 2008-08-27 | 2008-08-27 | ウェブ搬送方法及び装置 |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US20100054826A1 (ja) |

| JP (1) | JP4656344B2 (ja) |

Families Citing this family (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5206908B2 (ja) * | 2011-03-29 | 2013-06-12 | 凸版印刷株式会社 | 巻き取り成膜装置 |

| KR101788171B1 (ko) | 2011-08-16 | 2017-10-20 | 삼성전자주식회사 | 롤투롤 인쇄 시스템 |

| JP5752559B2 (ja) * | 2011-10-27 | 2015-07-22 | 株式会社ヒラノテクシード | 塗工装置 |

| US9428359B2 (en) * | 2011-11-30 | 2016-08-30 | Corning Incorporated | Methods and apparatuses for conveying flexible glass substrates |

| JP5895487B2 (ja) * | 2011-12-02 | 2016-03-30 | 大日本印刷株式会社 | 機能性フィルムの移送装置とそれを用いた細胞培養容器の製造方法 |

| EP2860280A4 (en) * | 2012-05-31 | 2016-03-23 | Toppan Printing Co Ltd | DEVICE FOR FORMING A ROLLED FILM |

| US20140064812A1 (en) * | 2012-09-05 | 2014-03-06 | Xerox Corporation | Bowed and non-parallel rollers forming nip |

| US9182698B2 (en) * | 2013-02-01 | 2015-11-10 | Ricoh Company, Ltd. | Method of transferring image and image transferring system and image forming apparatus with same |

| JP6048243B2 (ja) * | 2013-03-19 | 2016-12-21 | セイコーエプソン株式会社 | 液体吐出装置、及び、媒体搬送装置 |

| JP5688858B2 (ja) * | 2013-03-28 | 2015-03-25 | 富士フイルム株式会社 | 機能性フィルムの製造方法、及びウエブ搬送装置 |

| JP5922613B2 (ja) * | 2013-05-08 | 2016-05-24 | 富士フイルム株式会社 | ナーリング装置及び方法並びにフィルムロール製造方法 |

| JP6301156B2 (ja) * | 2014-02-25 | 2018-03-28 | セーレン株式会社 | 記録装置 |

| US9108817B1 (en) | 2014-03-24 | 2015-08-18 | Eastman Kodak Company | Web guiding structure with continuous smooth recesses |

| US9090424B1 (en) | 2014-04-02 | 2015-07-28 | Eastman Kodak Company | Drive roller configuration providing reduced web wrinkling |

| CN103950773A (zh) * | 2014-04-30 | 2014-07-30 | 长兴志恒服装辅料有限公司 | 一种布边调整装置 |

| JP6254070B2 (ja) * | 2014-11-20 | 2017-12-27 | 株式会社ノリタケカンパニーリミテド | フィルム送り装置、フィルム巻取装置およびフィルム巻出装置 |

| SG11201704746TA (en) | 2014-12-23 | 2017-07-28 | 3M Innovative Properties Co | Edge contact substrate transport method and apparatus |

| US9623678B1 (en) * | 2015-10-30 | 2017-04-18 | Hewlett—Packard Development Company, L.P. | Movement of a medium |

| JP6674774B2 (ja) * | 2015-12-18 | 2020-04-01 | 株式会社アルバック | フィルム搬送装置 |

| US20200189870A1 (en) * | 2017-04-28 | 2020-06-18 | 3M Innovative Properties Company | Passive edge guiding method and apparatus |

| DE102017215110B4 (de) * | 2017-08-30 | 2020-05-14 | Koenig & Bauer Ag | Vorrichtung zur Kompensation von Fanout |

| KR102616738B1 (ko) * | 2018-05-17 | 2023-12-21 | 주식회사 엘지화학 | 필름 주름 제거용 롤러 |

| JP7507039B2 (ja) | 2020-08-21 | 2024-06-27 | 日東電工株式会社 | 光学フィルムの製造方法 |

| CN113928898B (zh) * | 2021-11-16 | 2024-06-18 | 中国航发北京航空材料研究院 | 一种结构胶膜内柔性载体展开机构 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0312840U (ja) * | 1989-06-20 | 1991-02-08 | ||

| JP2000118815A (ja) * | 1998-10-16 | 2000-04-25 | Kokusai Gijutsu Kaihatsu Kk | フィルム移送装置 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2979829A (en) * | 1958-07-15 | 1961-04-18 | Nat Steel Corp | Roller and apparatus for transporting strip material |

| JPS4944155B1 (ja) * | 1967-07-26 | 1974-11-26 | ||

| US3561659A (en) * | 1968-06-19 | 1971-02-09 | Dresser Ind | Transport system |

| US3750924A (en) * | 1972-01-17 | 1973-08-07 | O Pepper | Web tensioner and guide system |

| JPS6098630U (ja) * | 1983-12-13 | 1985-07-05 | 三菱重工業株式会社 | 横延伸機 |

| JPS63310432A (ja) * | 1987-06-11 | 1988-12-19 | Yokohama Rubber Co Ltd:The | シ−ト部材のセンタリングガイド装置 |

| US6104907A (en) * | 1997-04-28 | 2000-08-15 | Hitachi, Ltd. | Image recording apparatus which prevents variation in speed of a recording medium and reduces shift values thereof |

| US6170727B1 (en) * | 1997-11-03 | 2001-01-09 | Gerber Scientific Products, Inc. | Web having alignment indicia and an associated web feeding and working apparatus |

| JP3956264B2 (ja) * | 1999-10-08 | 2007-08-08 | 富士フイルム株式会社 | ウェブ搬送方法及び装置 |

| US6352188B1 (en) * | 2000-08-03 | 2002-03-05 | Eastman Kodak Company | Edge drive for photosensitive media |

| US20060175372A1 (en) * | 2005-02-07 | 2006-08-10 | Eastman Kodak Company | Web conveyance system for protecting web patterns |

-

2008

- 2008-08-27 JP JP2008218225A patent/JP4656344B2/ja active Active

-

2009

- 2009-08-21 US US12/545,349 patent/US20100054826A1/en not_active Abandoned

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0312840U (ja) * | 1989-06-20 | 1991-02-08 | ||

| JP2000118815A (ja) * | 1998-10-16 | 2000-04-25 | Kokusai Gijutsu Kaihatsu Kk | フィルム移送装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20100054826A1 (en) | 2010-03-04 |

| JP2010052872A (ja) | 2010-03-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4656344B2 (ja) | ウェブ搬送方法及び装置 | |

| JP2010052872A5 (ja) | ||

| KR20140118781A (ko) | 기능성 필름의 제조 방법 및 웨브 반송 장치 | |

| US5803398A (en) | Multiple durometer pressure roller | |

| JP2012166896A (ja) | ウェブ巻取装置 | |

| JP2010143704A (ja) | ニップローラー | |

| KR20090064276A (ko) | 웹의 사행 수정 장치 | |

| JP2009298496A (ja) | 搬送ローラおよび膜電極接合体の製造装置、製造方法 | |

| US4830303A (en) | Process and device for winding a film web | |

| JP5710552B2 (ja) | ウエブの異物除去方法及び異物除去装置 | |

| WO2011158584A1 (ja) | 薄膜ガラスの搬送装置、及び薄膜ガラスの搬送方法 | |

| WO2005040018A1 (ja) | ウェブのシワ伸ばし用ローラ、ならびに、ウェブロールの製造装置、および、製造方法 | |

| JP2016108075A (ja) | シート巻取装置及びシート巻取方法 | |

| JP5759501B2 (ja) | ガイドロール及びウェブ搬送装置 | |

| JPS6397565A (ja) | 帯状搬送物の蛇行防止方法 | |

| JP2003171044A (ja) | テンション調節装置 | |

| JP2001063883A (ja) | シートロール体の製造方法 | |

| KR100644511B1 (ko) | 극박 압연재 주름 방지용 댄서롤을 구비한 압연 장치 | |

| JP2020132412A (ja) | フィルム搬送装置 | |

| JP5816219B2 (ja) | ガイドロール及びウェブ搬送装置 | |

| JP2000086031A (ja) | シート状物の搬送装置およびシート状物の製造方法 | |

| JP2004277168A (ja) | 圧接ローラ、該圧接ローラを用いたウェブロール体の製造方法および製造装置 | |

| JP2001066205A (ja) | シート張力検出計 | |

| US20240158195A1 (en) | Conveyor adapted for battery manufacturing process | |

| US20200189870A1 (en) | Passive edge guiding method and apparatus |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100223 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100312 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20100312 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20100622 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100624 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100706 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100906 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20101201 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20101214 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140107 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4656344 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |