JP4485696B2 - 交換可能な金型キャビティ及び金型キャビティインサート - Google Patents

交換可能な金型キャビティ及び金型キャビティインサート Download PDFInfo

- Publication number

- JP4485696B2 JP4485696B2 JP2000618059A JP2000618059A JP4485696B2 JP 4485696 B2 JP4485696 B2 JP 4485696B2 JP 2000618059 A JP2000618059 A JP 2000618059A JP 2000618059 A JP2000618059 A JP 2000618059A JP 4485696 B2 JP4485696 B2 JP 4485696B2

- Authority

- JP

- Japan

- Prior art keywords

- plastic

- mold

- mold cavity

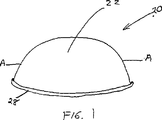

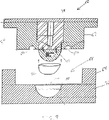

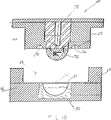

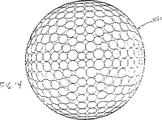

- golf ball

- insert

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000004033 plastic Substances 0.000 claims description 86

- 229920003023 plastic Polymers 0.000 claims description 86

- 229910052751 metal Inorganic materials 0.000 claims description 84

- 239000002184 metal Substances 0.000 claims description 84

- 239000012778 molding material Substances 0.000 claims description 40

- 238000010137 moulding (plastic) Methods 0.000 claims description 39

- 238000000465 moulding Methods 0.000 claims description 37

- 238000004519 manufacturing process Methods 0.000 claims description 32

- 238000007373 indentation Methods 0.000 claims description 6

- 238000000034 method Methods 0.000 description 42

- 239000000463 material Substances 0.000 description 16

- 238000000748 compression moulding Methods 0.000 description 12

- 239000000853 adhesive Substances 0.000 description 11

- 230000001070 adhesive effect Effects 0.000 description 11

- 239000010935 stainless steel Substances 0.000 description 10

- 229910001220 stainless steel Inorganic materials 0.000 description 10

- 150000002739 metals Chemical class 0.000 description 7

- 239000000126 substance Substances 0.000 description 7

- 238000000576 coating method Methods 0.000 description 6

- 238000007906 compression Methods 0.000 description 6

- 238000012360 testing method Methods 0.000 description 6

- 229910000831 Steel Inorganic materials 0.000 description 5

- 239000003795 chemical substances by application Substances 0.000 description 5

- 239000011248 coating agent Substances 0.000 description 5

- 150000001875 compounds Chemical class 0.000 description 5

- 238000013461 design Methods 0.000 description 5

- 238000001746 injection moulding Methods 0.000 description 5

- 239000005011 phenolic resin Substances 0.000 description 5

- 229920001568 phenolic resin Polymers 0.000 description 5

- 229920005989 resin Polymers 0.000 description 5

- 239000011347 resin Substances 0.000 description 5

- 239000010959 steel Substances 0.000 description 5

- 229920001187 thermosetting polymer Polymers 0.000 description 5

- KXGFMDJXCMQABM-UHFFFAOYSA-N 2-methoxy-6-methylphenol Chemical compound [CH]OC1=CC=CC([CH])=C1O KXGFMDJXCMQABM-UHFFFAOYSA-N 0.000 description 4

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 4

- 239000004809 Teflon Substances 0.000 description 4

- 229920006362 Teflon® Polymers 0.000 description 4

- 238000005266 casting Methods 0.000 description 4

- 230000006835 compression Effects 0.000 description 4

- 238000004070 electrodeposition Methods 0.000 description 4

- 239000000945 filler Substances 0.000 description 4

- 230000007246 mechanism Effects 0.000 description 4

- 239000007787 solid Substances 0.000 description 4

- 229920005992 thermoplastic resin Polymers 0.000 description 4

- 238000007740 vapor deposition Methods 0.000 description 4

- 239000011230 binding agent Substances 0.000 description 3

- 239000011521 glass Substances 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 2

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 2

- 229910045601 alloy Inorganic materials 0.000 description 2

- 239000000956 alloy Substances 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 239000011651 chromium Substances 0.000 description 2

- 229910052804 chromium Inorganic materials 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 238000004512 die casting Methods 0.000 description 2

- 229910052500 inorganic mineral Inorganic materials 0.000 description 2

- 238000003754 machining Methods 0.000 description 2

- 229910052749 magnesium Inorganic materials 0.000 description 2

- 239000011777 magnesium Substances 0.000 description 2

- 239000011707 mineral Substances 0.000 description 2

- 239000012764 mineral filler Substances 0.000 description 2

- 239000006082 mold release agent Substances 0.000 description 2

- 239000002991 molded plastic Substances 0.000 description 2

- 229910052759 nickel Inorganic materials 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 239000000843 powder Substances 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 230000010076 replication Effects 0.000 description 2

- 239000011701 zinc Substances 0.000 description 2

- 229910052725 zinc Inorganic materials 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 239000004696 Poly ether ether ketone Substances 0.000 description 1

- 239000004962 Polyamide-imide Substances 0.000 description 1

- 239000004695 Polyether sulfone Substances 0.000 description 1

- 239000004697 Polyetherimide Substances 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- 239000000443 aerosol Substances 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 238000005219 brazing Methods 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 238000004132 cross linking Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 229910003460 diamond Inorganic materials 0.000 description 1

- 239000010432 diamond Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000001747 exhibiting effect Effects 0.000 description 1

- 238000007730 finishing process Methods 0.000 description 1

- 238000007429 general method Methods 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 239000002923 metal particle Substances 0.000 description 1

- 238000011056 performance test Methods 0.000 description 1

- 238000005498 polishing Methods 0.000 description 1

- 238000007517 polishing process Methods 0.000 description 1

- 229920001643 poly(ether ketone) Polymers 0.000 description 1

- 229920002312 polyamide-imide Polymers 0.000 description 1

- 229920001225 polyester resin Polymers 0.000 description 1

- 239000004645 polyester resin Substances 0.000 description 1

- 229920006393 polyether sulfone Polymers 0.000 description 1

- 229920002530 polyetherether ketone Polymers 0.000 description 1

- 229920001601 polyetherimide Polymers 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 238000012552 review Methods 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 238000009966 trimming Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/30—Mounting, exchanging or centering

- B29C33/306—Exchangeable mould parts, e.g. cassette moulds, mould inserts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/42—Moulds or cores; Details thereof or accessories therefor characterised by the shape of the moulding surface, e.g. ribs or grooves

- B29C33/424—Moulding surfaces provided with means for marking or patterning

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/56—Coatings, e.g. enameled or galvanised; Releasing, lubricating or separating agents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/02—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles

- B29C43/021—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles characterised by the shape of the surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/54—Balls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/54—Balls

- B29L2031/545—Football balls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/757—Moulds, cores, dies

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/4998—Combined manufacture including applying or shaping of fluent material

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/4998—Combined manufacture including applying or shaping of fluent material

- Y10T29/49982—Coating

- Y10T29/49984—Coating and casting

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US09/310,785 US6171091B1 (en) | 1999-05-12 | 1999-05-12 | Replaceable mold cavities and mold cavity inserts |

| US09/310,785 | 1999-05-12 | ||

| PCT/US2000/012248 WO2000069612A1 (en) | 1999-05-12 | 2000-05-03 | Replaceable mold cavities and mold cavity inserts |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002544016A JP2002544016A (ja) | 2002-12-24 |

| JP2002544016A5 JP2002544016A5 (enExample) | 2007-06-28 |

| JP4485696B2 true JP4485696B2 (ja) | 2010-06-23 |

Family

ID=23204099

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2000618059A Expired - Fee Related JP4485696B2 (ja) | 1999-05-12 | 2000-05-03 | 交換可能な金型キャビティ及び金型キャビティインサート |

Country Status (4)

| Country | Link |

|---|---|

| US (2) | US6171091B1 (enExample) |

| JP (1) | JP4485696B2 (enExample) |

| AU (1) | AU4986500A (enExample) |

| WO (1) | WO2000069612A1 (enExample) |

Families Citing this family (33)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3649902B2 (ja) * | 1998-04-08 | 2005-05-18 | 松下電器産業株式会社 | ドームカバーの製造方法 |

| JP2000254254A (ja) * | 1999-03-05 | 2000-09-19 | Bridgestone Sports Co Ltd | ゴルフボール用成形金型及びゴルフボール |

| US6408567B1 (en) * | 2001-03-12 | 2002-06-25 | Knight Manufacturing Co., Inc. | Fishing lures and methods and molds for making same |

| US6644948B2 (en) * | 2001-06-18 | 2003-11-11 | Acushnet Company | Mold-half |

| JP4317375B2 (ja) * | 2003-03-20 | 2009-08-19 | 株式会社日立製作所 | ナノプリント装置、及び微細構造転写方法 |

| ITMI20030853A1 (it) * | 2003-04-29 | 2004-10-30 | Intercos Italia S P A Ora Intercos S P A | Macchina per la fabbricazione di stampi flessibili, in particolare per l'ottenimento di rossetti o simili. |

| US7204685B1 (en) | 2003-09-08 | 2007-04-17 | Crain Enterprises, Inc. | Modular mold |

| US7497677B1 (en) | 2003-09-08 | 2009-03-03 | Crain Enterprises, Inc. | Mold having modular submold |

| US7241405B1 (en) | 2003-09-08 | 2007-07-10 | Crain Enterprises, Inc. | Method of renewing a mold block |

| USRE45998E1 (en) * | 2004-04-02 | 2016-05-10 | Cosmetic Group USA, Inc. | Methods and molds for producing customized hot pour products |

| US20050266114A1 (en) * | 2004-05-12 | 2005-12-01 | Meidenbauer Russel L | Paintball rounder tray |

| US7500843B2 (en) * | 2004-09-08 | 2009-03-10 | Crain Enterprises, Inc. | Mold system kit |

| US20070031595A1 (en) * | 2005-08-03 | 2007-02-08 | Fox Richard B | Process for 360 degree soft touch molding on an object core and product made therewith |

| WO2007092091A2 (en) * | 2005-12-23 | 2007-08-16 | Polyworks, Inc. | Methods of making polymeric articles and the polymeric articles formed thereby |

| WO2007100922A2 (en) * | 2006-02-28 | 2007-09-07 | Polyworks, Inc. | Methods of making polymeric articles and polymeric articles formed thereby |

| EP1834748A1 (en) * | 2006-03-14 | 2007-09-19 | Electrovac AG | Mould and method of producing a mould |

| EP1834749A1 (en) * | 2006-03-14 | 2007-09-19 | Electrovac AG | Mould and method of producing a mould |

| US7520741B2 (en) * | 2006-07-21 | 2009-04-21 | Acushnet Company | Replaceable mold cavities |

| US20080194362A1 (en) * | 2007-02-08 | 2008-08-14 | Paul HELMER | Resilient baseball and method of manufacture |

| US8871328B2 (en) | 2007-04-13 | 2014-10-28 | Daniel M. Wyner | Impact and vibration absorbing body-contacting medallions, methods of using and methods of making |

| WO2008128206A1 (en) * | 2007-04-13 | 2008-10-23 | Polyworks, Inc. | Cushioning medallions, methods of making and methods of using |

| US8021590B2 (en) * | 2007-12-26 | 2011-09-20 | Taylor Made Golf Company, Inc. | Golf-ball-cover casting molds with self-centering mold-cavity inserts |

| CN105495850A (zh) * | 2008-04-14 | 2016-04-20 | 宝立沃克斯公司 | 制造冲击和振动吸收物品的深冲压方法及由此形成的物品 |

| US20100003357A1 (en) * | 2008-07-07 | 2010-01-07 | Ajay Vora | Golf ball mold |

| JP2013506585A (ja) * | 2009-10-05 | 2013-02-28 | ジャスト・アッド・テクノロジー・ソリューションズ・リミテッド・ライアビリティ・カンパニー | ゴルフボールの製造のための断熱金型キャビティアセンブリ及び方法 |

| US8283603B2 (en) * | 2009-10-23 | 2012-10-09 | Nike, Inc. | Device for heating a golf ball |

| US20110162701A1 (en) * | 2010-01-03 | 2011-07-07 | Claudio Truzzi | Photovoltaic Cells |

| US8663512B2 (en) * | 2010-08-02 | 2014-03-04 | Nike, Inc. | Kit and method for customization of golf balls |

| US8550941B2 (en) | 2010-12-02 | 2013-10-08 | Nike, Inc. | Systems and methods for evaluating a golf ball design |

| US8550940B2 (en) | 2010-12-02 | 2013-10-08 | Nike, Inc. | Systems and methods for evaluating a golf ball design |

| DE102013226753A1 (de) * | 2013-12-19 | 2015-06-25 | Airbus Operations Gmbh | Vorrichtung und Verfahren zur kontinuierlichen Fertigung von Strukturbauteilen aus faserverstärkten Verbundmaterialien sowie Formwerkzeugset |

| USD744156S1 (en) * | 2014-06-25 | 2015-11-24 | Martin Professional Aps | Light lens |

| US20230242965A1 (en) | 2020-05-28 | 2023-08-03 | Charm Sciences, Inc. | Methods and assemblies for sample analysis |

Family Cites Families (42)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US791648A (en) | 1902-06-12 | 1905-06-06 | Francis H Richards | Apparatus for making golf-balls. |

| US2388776A (en) * | 1942-01-10 | 1945-11-13 | Us Rubber Co | Method of making molds |

| US3018520A (en) | 1959-02-12 | 1962-01-30 | Ren Plastics Inc | Method of molding by spraying molten metal and heat-reactive bonding agent |

| US3188370A (en) | 1960-11-14 | 1965-06-08 | Andrew A Halacsy | Method of incapsulating an object |

| US3308223A (en) * | 1963-11-18 | 1967-03-07 | Nat Latex Prod Co | Method of making molds for elastomeric articles having surface details |

| US3405212A (en) | 1966-02-17 | 1968-10-08 | Weyerhaeuser Co | Method of making metal clad tools |

| US3616101A (en) | 1969-12-05 | 1971-10-26 | Brunswick Corp | Ball or other article of manufacture having a liquid center |

| US3867078A (en) * | 1971-10-12 | 1975-02-18 | Fried E Victor | Apparatus for forming a golf ball mold |

| US3772008A (en) | 1971-10-12 | 1973-11-13 | Freid E | Golf ball mold production |

| US3871060A (en) | 1971-12-29 | 1975-03-18 | Ladney M Jr | Method of constructing mold for forming plastic foam parts |

| US4231982A (en) | 1975-05-20 | 1980-11-04 | Ab Volvo | Method for the production of tools for deep drawing, moulding, extruding and the like |

| US4225109A (en) | 1978-07-06 | 1980-09-30 | Osaka City & Taiyo Manufacturing Works Co., Ltd. | Insulated metal mold |

| JPS5534950A (en) * | 1978-09-04 | 1980-03-11 | Mitsubishi Electric Corp | Metal mold manufacturing method |

| US4414731A (en) * | 1980-03-31 | 1983-11-15 | Replogle Globes, Inc. | Method of manufacture of raised relief illuminated globe |

| SE433321B (sv) | 1982-04-30 | 1984-05-21 | Lindskog K J E | Sett vid tillverkning av ett formset avsett for formning av skalformade foremal av plast |

| DE3304073A1 (de) | 1983-02-07 | 1984-08-09 | Alban 5456 Rheinbrohl Pütz | Verfahren zur erstellung von formen fuer das spritzgiessen, insbesondere von werkzeugen fuer das spritzgiessen von kunststoff |

| US4552004A (en) | 1983-12-01 | 1985-11-12 | Gilbert Barfield | Apparatus for forming golf ball molds |

| US4509358A (en) | 1984-03-26 | 1985-04-09 | Chrysler Corporation | Urethane dies |

| GB8411550D0 (en) | 1984-05-04 | 1984-06-13 | Stylo Matchmakers Int | Injection moulding apparatus |

| GB8722668D0 (en) | 1987-09-26 | 1987-11-04 | Games Workshop Ltd | Injection moulding process |

| JPS6478811A (en) * | 1987-09-22 | 1989-03-24 | Shigeru Kogyo Kk | Mold for injection molding and manufacture thereof |

| JP2569657B2 (ja) * | 1987-12-23 | 1997-01-08 | ブリヂストンスポーツ株式会社 | 金 型 |

| JPH01196311A (ja) * | 1988-02-01 | 1989-08-08 | Alps Electric Co Ltd | 射出成形用金型の製造方法 |

| JPH01196312A (ja) * | 1988-02-01 | 1989-08-08 | Alps Electric Co Ltd | 射出成形用金型の製造方法 |

| US4980112A (en) | 1988-06-24 | 1990-12-25 | Masters William E | Method for rotational molding |

| US5039469A (en) | 1989-06-16 | 1991-08-13 | General Motors Corporation | Method of making plastic tooling with compression adjustment |

| US4959000A (en) | 1989-10-31 | 1990-09-25 | Acushnet Company | Retractable pin mold |

| JPH0469216A (ja) * | 1990-07-11 | 1992-03-04 | Kuniaki Itou | 熱硬化性樹脂製の成形型及びその製造方法 |

| US5198172A (en) | 1990-07-23 | 1993-03-30 | Phillips Petroleum Company | Method of pultruding utilizing a die with changeable die insects |

| JP2725447B2 (ja) | 1990-07-26 | 1998-03-11 | ブリヂストンスポーツ株式会社 | ゴルフボールの製造方法 |

| US5530227A (en) * | 1991-04-05 | 1996-06-25 | The Boeing Company | Method and apparatus for consolidating organic matrix composites using induction heating |

| US5213747A (en) | 1991-08-27 | 1993-05-25 | William Lippert | Methods of making fiber-reinforced resin molds |

| US5271875A (en) * | 1991-09-12 | 1993-12-21 | Bausch & Lomb Incorporated | Method for molding lenses |

| US5247861A (en) | 1992-04-08 | 1993-09-28 | Rohr, Inc. | Method of manufacturing laminated plastic tooling and tooling produced thereby |

| US5362429A (en) | 1993-03-08 | 1994-11-08 | Magnum Manufacturing, Inc. | Rubber molding method using a frangible foam core |

| US5523038A (en) * | 1993-03-26 | 1996-06-04 | Ngk Insulators, Ltd. | Process and an apparatus for producing insulators |

| JPH0732369A (ja) * | 1993-07-22 | 1995-02-03 | Ikegami Kanagata Kogyo Kk | 樹脂型の製造方法 |

| US5435959A (en) | 1993-12-17 | 1995-07-25 | Nike, Inc. | Method of making a mold and parts from the mold |

| US5514320A (en) | 1995-04-25 | 1996-05-07 | Akemi, Inc. | Method of making a hollow tool |

| JPH1067032A (ja) * | 1996-08-28 | 1998-03-10 | Mitsubishi Chem Corp | 中空射出成形品の製造方法 |

| JPH11138557A (ja) * | 1997-11-13 | 1999-05-25 | Komatsu Ltd | 射出成形用金型 |

| US5984807A (en) * | 1998-08-20 | 1999-11-16 | Callaway Golf Company | Golf ball |

-

1999

- 1999-05-12 US US09/310,785 patent/US6171091B1/en not_active Expired - Lifetime

-

2000

- 2000-05-03 AU AU49865/00A patent/AU4986500A/en not_active Abandoned

- 2000-05-03 WO PCT/US2000/012248 patent/WO2000069612A1/en not_active Ceased

- 2000-05-03 JP JP2000618059A patent/JP4485696B2/ja not_active Expired - Fee Related

- 2000-10-23 US US09/695,796 patent/US6319446B1/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| AU4986500A (en) | 2000-12-05 |

| JP2002544016A (ja) | 2002-12-24 |

| WO2000069612A1 (en) | 2000-11-23 |

| US6171091B1 (en) | 2001-01-09 |

| US6319446B1 (en) | 2001-11-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4485696B2 (ja) | 交換可能な金型キャビティ及び金型キャビティインサート | |

| US4560607A (en) | Method of joining materials by mechanical interlock and article | |

| JP4975021B2 (ja) | 熱可塑性樹脂成形用金型、キャビティ型及びそのキャビティ型の製造方法 | |

| JP2013506585A5 (enExample) | ||

| US3548050A (en) | Method of making resin faced metal molding dies | |

| US3088174A (en) | Method of producing a reinforced plastic die | |

| JP2725447B2 (ja) | ゴルフボールの製造方法 | |

| US6439873B1 (en) | Golf ball casting mold assembly | |

| JPH01120315A (ja) | 金型及び射出成形方法 | |

| KR102100198B1 (ko) | 압축 성형용 금형 및 이를 이용한 차량용 부품의 제조 방법 | |

| US6119763A (en) | Method for preparing golf ball mold | |

| JP2937084B2 (ja) | ゴルフボール用金型の製造方法 | |

| JPH0114848B2 (enExample) | ||

| JPS63199615A (ja) | ゴルフボ−ル用金型 | |

| CA2410534C (en) | Moulding tooling | |

| JPH0839574A (ja) | 中空プラスチック品の製造方法 | |

| JP3779148B2 (ja) | 樹脂金型およびその製造方法 | |

| CN100556659C (zh) | 制造鞋底的模具和方法 | |

| JP5574496B2 (ja) | 転写成形用金型及び微細構造体製造方法 | |

| CN111451949A (zh) | 树脂砂轮模具及其压制方法 | |

| JPS5831292B2 (ja) | 熱硬化性樹脂成形金型 | |

| JP3393557B2 (ja) | 成形型及びその製造方法 | |

| JP2025007032A (ja) | 浴槽及びその製造方法 | |

| US20150091205A1 (en) | Mold and associated methods | |

| JPH07232332A (ja) | 樹脂製成形用型 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070501 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070501 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20091023 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20091027 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100126 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100316 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100325 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130402 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |