JP3657944B2 - 等速ジョイント用樹脂製ブーツの製造方法等速ジョイント用樹脂製ブーツの製造装置 - Google Patents

等速ジョイント用樹脂製ブーツの製造方法等速ジョイント用樹脂製ブーツの製造装置 Download PDFInfo

- Publication number

- JP3657944B2 JP3657944B2 JP2003041317A JP2003041317A JP3657944B2 JP 3657944 B2 JP3657944 B2 JP 3657944B2 JP 2003041317 A JP2003041317 A JP 2003041317A JP 2003041317 A JP2003041317 A JP 2003041317A JP 3657944 B2 JP3657944 B2 JP 3657944B2

- Authority

- JP

- Japan

- Prior art keywords

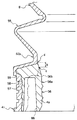

- resin

- bellows

- diameter side

- side end

- molding space

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/14—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D3/00—Yielding couplings, i.e. with means permitting movement between the connected parts during the drive

- F16D3/84—Shrouds, e.g. casings, covers; Sealing means specially adapted therefor

- F16D3/843—Shrouds, e.g. casings, covers; Sealing means specially adapted therefor enclosed covers

- F16D3/845—Shrouds, e.g. casings, covers; Sealing means specially adapted therefor enclosed covers allowing relative movement of joint parts due to the flexing of the cover

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/14—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles

- B29C45/14336—Coating a portion of the article, e.g. the edge of the article

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2023/00—Tubular articles

- B29L2023/18—Pleated or corrugated hoses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/703—Bellows

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Diaphragms And Bellows (AREA)

- Injection Moulding Of Plastics Or The Like (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Sealing Devices (AREA)

Priority Applications (11)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003041317A JP3657944B2 (ja) | 2003-02-19 | 2003-02-19 | 等速ジョイント用樹脂製ブーツの製造方法等速ジョイント用樹脂製ブーツの製造装置 |

| US10/396,520 US7588713B2 (en) | 2003-02-19 | 2003-03-26 | Method of manufacturing resin boots for constant velocity universal joint |

| CA2423624A CA2423624C (en) | 2003-02-19 | 2003-03-27 | Method of manufacturing resin boots for constant velocity universal joint and apparatus for manufacturing resin boots for constant velocity universal joint |

| CNB031286429A CN100467257C (zh) | 2003-02-19 | 2003-03-28 | 制造等速万向节的树脂防尘罩的方法及装置 |

| KR1020030019485A KR100994200B1 (ko) | 2003-02-19 | 2003-03-28 | 등속 조인트용 수지제 부트의 제조방법 및 제조장치 |

| EP03252148.6A EP1450060B1 (en) | 2003-02-19 | 2003-04-04 | Method of manufacturing boots for constant velocity universal joint and apparatus for manufacturing boots for constant velocity universal joint |

| MXPA03003016A MXPA03003016A (es) | 2003-02-19 | 2003-04-07 | Metodo para fabricar cubiertas para junta universal de velocidad constante, de resina y aparato para fabricar cubiertas para junta universal de velocidad constante, de resina. |

| US11/220,726 US20060049584A1 (en) | 2003-02-19 | 2005-09-08 | Method of manufacturing resin boots for constant velocity universal joint and resin boots for constant velocity universal joint |

| US11/220,727 US7488259B2 (en) | 2003-02-19 | 2005-09-08 | Resin boots for constant velocity universal joint |

| US12/335,113 US20090194953A1 (en) | 2003-02-19 | 2009-01-13 | Resin boots for constant velocity universal joint |

| US12/805,614 US20110024029A1 (en) | 2003-02-19 | 2010-08-10 | Resin boots for constant velocity universal joint |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003041317A JP3657944B2 (ja) | 2003-02-19 | 2003-02-19 | 等速ジョイント用樹脂製ブーツの製造方法等速ジョイント用樹脂製ブーツの製造装置 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004217244A Division JP2004353872A (ja) | 2004-07-26 | 2004-07-26 | 樹脂製等速ジョイント用ブーツ |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2004249545A JP2004249545A (ja) | 2004-09-09 |

| JP2004249545A5 JP2004249545A5 (enExample) | 2005-05-26 |

| JP3657944B2 true JP3657944B2 (ja) | 2005-06-08 |

Family

ID=32732943

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003041317A Expired - Fee Related JP3657944B2 (ja) | 2003-02-19 | 2003-02-19 | 等速ジョイント用樹脂製ブーツの製造方法等速ジョイント用樹脂製ブーツの製造装置 |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US7588713B2 (enExample) |

| EP (1) | EP1450060B1 (enExample) |

| JP (1) | JP3657944B2 (enExample) |

| KR (1) | KR100994200B1 (enExample) |

| CN (1) | CN100467257C (enExample) |

| CA (1) | CA2423624C (enExample) |

| MX (1) | MXPA03003016A (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3323581A1 (en) | 2016-11-16 | 2018-05-23 | Yong Hoon Hur | Injection apparatus for molding combined member of constantvelocity joint boot, injection method of combined member of constant-velocity joint boot, and constant-velocity joint boot manufactured by injection method of combined member |

Families Citing this family (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4317784B2 (ja) * | 2003-08-29 | 2009-08-19 | 株式会社フコク | 等速ジョイント用ブーツの製造方法並びにその方法に用いられる製造装置 |

| JP4359532B2 (ja) * | 2003-09-02 | 2009-11-04 | 株式会社フコク | 等速ジョイント用ブーツの製造方法並びにその方法に用いられる製造装置等速ジョイント用ブーツ |

| US7775891B2 (en) * | 2004-11-19 | 2010-08-17 | Honda Motor Co., Ltd. | Boot for joint |

| JP3956015B2 (ja) * | 2004-11-29 | 2007-08-08 | 東洋ゴム工業株式会社 | 樹脂製ジョイントブーツ |

| FR2879279B1 (fr) * | 2004-12-15 | 2007-01-26 | Trelleborg Prodyn Soc Par Acti | Manchon polylobe de protection de transmission de vehicule |

| DE602004006526T2 (de) * | 2004-12-31 | 2008-01-24 | Fukoku Co. Ltd., Ageo | Dichtungsmanschette für Gleichlaufgelenk |

| WO2007034844A1 (ja) * | 2005-09-20 | 2007-03-29 | Fukoku Co., Ltd. | 等速ジョイント用ブーツ、等速ジョイント用ブーツの製造方法、等速ジョイント用ブーツの製造装置 |

| DE102006008558B3 (de) * | 2006-02-22 | 2007-08-02 | Gkn Driveline International Gmbh | Faltenbalganordnung für eine Tripodegelenkeinheit |

| JP4926584B2 (ja) * | 2006-07-18 | 2012-05-09 | Ntn株式会社 | トリポード型等速自在継手 |

| KR200452587Y1 (ko) * | 2007-06-29 | 2011-03-07 | 윤지한 | 자동차 제동장치에 사용되는 부츠 벨로즈 자동 이형장치 |

| US9651096B2 (en) * | 2008-11-14 | 2017-05-16 | Gkn Driveline North America, Inc. | Tripod seal feature |

| JP5312580B2 (ja) * | 2009-05-19 | 2013-10-09 | 三菱電機株式会社 | カバー及びアクチュエータ |

| CN103797260A (zh) * | 2011-09-21 | 2014-05-14 | Gkn动力传动系统北美有限公司 | 外滚动隔膜包覆模制高速恒速接头罩 |

| US20130154153A1 (en) * | 2011-12-20 | 2013-06-20 | Shape Corp. | Multi-shot molding method with pressure activated expansion locks |

| KR101405187B1 (ko) * | 2012-11-08 | 2014-06-10 | 현대자동차주식회사 | 부트 유닛 및 이의 제조방법 |

| JP2014144589A (ja) * | 2013-01-29 | 2014-08-14 | Jtekt Corp | 等速ジョイント用ブーツの製造装置及びその製造方法 |

| JP5964934B2 (ja) * | 2014-01-08 | 2016-08-03 | 豊田合成株式会社 | 可変圧縮比エンジン用ブーツシール及びその製造方法 |

| JP6448201B2 (ja) * | 2014-03-18 | 2019-01-09 | 株式会社ショーワ | ステアリング装置 |

| US10156268B2 (en) * | 2014-09-03 | 2018-12-18 | Gkn Driveline North America, Inc. | Boot with insert |

| CN105422674A (zh) * | 2015-12-15 | 2016-03-23 | 天津市环宇橡塑股份有限公司 | 一种带有18波峰结构的转向齿条防尘罩 |

| WO2018177519A1 (en) * | 2017-03-29 | 2018-10-04 | Essity Hygiene And Health Aktiebolag | Plastomer spring with captive valve |

| JP6823546B2 (ja) * | 2017-06-02 | 2021-02-03 | 株式会社ブリヂストン | 射出成形金型、樹脂部材、及び、樹脂製品の製造方法 |

| CN107322843B (zh) * | 2017-08-31 | 2023-10-03 | 重庆鲜宇机械制造有限公司 | 一种简易联轴器制造设备 |

| KR102070024B1 (ko) * | 2018-07-27 | 2020-01-29 | 현대트랜시스(주) | 차량 시트의 통풍기구 및 이를 이용한 가변형 통풍시트 |

| KR102299584B1 (ko) * | 2019-04-26 | 2021-09-10 | 현대트랜시스(주) | 통풍 시트용 주름관의 제조방법 및 통풍 시트용 주름관 |

| CN110541899B (zh) * | 2019-09-09 | 2021-09-07 | 中车青岛四方车辆研究所有限公司 | 一种液压制动夹钳 |

| KR102184948B1 (ko) * | 2020-06-03 | 2020-12-01 | 주식회사 건화이엔지 | 등속조인트의 부트 결합부 이중 사출 성형방법 |

| CN114619601B (zh) * | 2021-12-30 | 2024-11-08 | 浙江国泰萧星密封材料股份有限公司 | 一种密封大尺寸联轴器用油包的制备方法 |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4341317A (en) * | 1980-05-09 | 1982-07-27 | Yoshino Kogyosho Co., Ltd. | Biaxially oriented bottle of saturated polyester resin |

| GB2195167B (en) * | 1986-09-17 | 1990-03-21 | Ntn Toyo Bearing Co Ltd | Homokinetic universal joint |

| JPH0222463A (ja) | 1988-07-12 | 1990-01-25 | Matsushita Electric Ind Co Ltd | 金属薄膜の製造法 |

| JP3037988B2 (ja) * | 1990-09-29 | 2000-05-08 | キーパー株式会社 | 合成樹脂製蛇腹製品の射出ブロー成形方法 |

| GB2273678B (en) * | 1992-01-15 | 1995-05-03 | Patrick Arthur Leach | Method and apparatus for making a loudspeaker cone and surround assembly |

| US5529538A (en) * | 1993-04-01 | 1996-06-25 | General Motors Corporation | Boot bushing for constant velocity universal joint |

| WO1994029622A1 (en) * | 1993-06-04 | 1994-12-22 | Nok Corporation | Seal structure and method of manufacturing the same |

| US6041824A (en) | 1994-06-30 | 2000-03-28 | Steere Enterprises, Inc. | Clean air ducts and methods for the manufacture thereof |

| US5851471A (en) * | 1996-05-16 | 1998-12-22 | The Coca-Cola Company | Method for injection molding a multi-layer preform for use in blow molding a plastic bottle |

| US5900205A (en) * | 1996-08-08 | 1999-05-04 | Salflex Polymers Ltd. | Method for blow molding a CVJ boot |

| US6099788A (en) | 1997-12-19 | 2000-08-08 | Salflex Polymers Ltd. | Method of making a protective boot for an automotive component |

| US6099785A (en) * | 1998-03-17 | 2000-08-08 | Schweigert; Lothar | Method for injection molding plastic closures |

| GB2366338B (en) * | 2000-08-22 | 2003-11-19 | Draftex Ind Ltd | Protective bellows |

| US20020160074A1 (en) * | 2001-03-07 | 2002-10-31 | Katsushi Saito | Apparatus for manufacturing resin bellows |

| JP2002286048A (ja) | 2001-03-26 | 2002-10-03 | Toyoda Gosei Co Ltd | 等速ジョイント用ブーツ |

| JP2003113858A (ja) * | 2001-10-04 | 2003-04-18 | Toyoda Gosei Co Ltd | 等速ジョイント用ブーツ |

| US6682678B2 (en) * | 2002-02-04 | 2004-01-27 | Arrow Innovations, Llc | Method of making translational spout closure for a container |

| JP4317784B2 (ja) * | 2003-08-29 | 2009-08-19 | 株式会社フコク | 等速ジョイント用ブーツの製造方法並びにその方法に用いられる製造装置 |

| JP4359532B2 (ja) * | 2003-09-02 | 2009-11-04 | 株式会社フコク | 等速ジョイント用ブーツの製造方法並びにその方法に用いられる製造装置等速ジョイント用ブーツ |

-

2003

- 2003-02-19 JP JP2003041317A patent/JP3657944B2/ja not_active Expired - Fee Related

- 2003-03-26 US US10/396,520 patent/US7588713B2/en not_active Expired - Fee Related

- 2003-03-27 CA CA2423624A patent/CA2423624C/en not_active Expired - Fee Related

- 2003-03-28 CN CNB031286429A patent/CN100467257C/zh not_active Expired - Lifetime

- 2003-03-28 KR KR1020030019485A patent/KR100994200B1/ko not_active Expired - Lifetime

- 2003-04-04 EP EP03252148.6A patent/EP1450060B1/en not_active Expired - Lifetime

- 2003-04-07 MX MXPA03003016A patent/MXPA03003016A/es active IP Right Grant

-

2005

- 2005-09-08 US US11/220,726 patent/US20060049584A1/en not_active Abandoned

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3323581A1 (en) | 2016-11-16 | 2018-05-23 | Yong Hoon Hur | Injection apparatus for molding combined member of constantvelocity joint boot, injection method of combined member of constant-velocity joint boot, and constant-velocity joint boot manufactured by injection method of combined member |

| US10663007B2 (en) | 2016-11-16 | 2020-05-26 | Yong-Hoon Hur | Injection apparatus for molding combined member of constant-velocity joint boot, injection method of combined member of constant-velocity joint boot, and constant-velocity joint boot manufactured by injection method of combined member |

Also Published As

| Publication number | Publication date |

|---|---|

| KR100994200B1 (ko) | 2010-11-12 |

| MXPA03003016A (es) | 2005-11-08 |

| US20060049584A1 (en) | 2006-03-09 |

| CN1522848A (zh) | 2004-08-25 |

| CA2423624C (en) | 2010-10-19 |

| CA2423624A1 (en) | 2004-08-19 |

| CN100467257C (zh) | 2009-03-11 |

| US7588713B2 (en) | 2009-09-15 |

| US20040159976A1 (en) | 2004-08-19 |

| KR20040074571A (ko) | 2004-08-25 |

| EP1450060B1 (en) | 2013-06-19 |

| JP2004249545A (ja) | 2004-09-09 |

| EP1450060A1 (en) | 2004-08-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3657944B2 (ja) | 等速ジョイント用樹脂製ブーツの製造方法等速ジョイント用樹脂製ブーツの製造装置 | |

| JP2004249545A5 (enExample) | ||

| US20090194953A1 (en) | Resin boots for constant velocity universal joint | |

| KR101110146B1 (ko) | 등속 조인트용 부트의 제조방법과 그 방법에 사용되는 제조장치 | |

| JP4420279B2 (ja) | 樹脂製等速ジョイント用ブーツの製造装置樹脂製等速ジョイント用ブーツの製造方法樹脂製等速ジョイント用ブーツ | |

| JP2004353872A5 (enExample) | ||

| JP2004353872A (ja) | 樹脂製等速ジョイント用ブーツ | |

| JP4192765B2 (ja) | 等速ジョイント用ブーツ | |

| JP2005315303A (ja) | 樹脂製等速ジョイント用ブーツ | |

| JP4446081B2 (ja) | 樹脂製等速ジョイント用ブーツの製造方法 | |

| JP2009156409A (ja) | 等速ジョイント用ブーツ | |

| JP4269309B2 (ja) | 等速ジョイント用樹脂ブーツの製造方法 | |

| JP3563466B2 (ja) | 樹脂成形品 | |

| JP2002266991A (ja) | 樹脂プーリ付き軸受 | |

| JP4914837B2 (ja) | 等速ジョイント用ブーツ、等速ジョイント用ブーツの製造方法、等速ジョイント用ブーツの製造装置 | |

| JP3124185U (ja) | 軸スリーブ | |

| JP2004001553A (ja) | 樹脂成形品 | |

| JP2006312962A (ja) | 等速ジョイント用ブーツ、等速ジョイント用ブーツの製造方法、等速ジョイント用ブーツの製造装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20040726 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20041112 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20041124 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050121 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20050215 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20050310 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 3657944 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20080318 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100318 Year of fee payment: 5 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100318 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110318 Year of fee payment: 6 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130318 Year of fee payment: 8 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130318 Year of fee payment: 8 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140318 Year of fee payment: 9 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: R3D02 |

|

| LAPS | Cancellation because of no payment of annual fees |