JP2017190940A - 熱交換器 - Google Patents

熱交換器 Download PDFInfo

- Publication number

- JP2017190940A JP2017190940A JP2016234961A JP2016234961A JP2017190940A JP 2017190940 A JP2017190940 A JP 2017190940A JP 2016234961 A JP2016234961 A JP 2016234961A JP 2016234961 A JP2016234961 A JP 2016234961A JP 2017190940 A JP2017190940 A JP 2017190940A

- Authority

- JP

- Japan

- Prior art keywords

- liquid

- heat exchanger

- reservoir

- refrigerant

- phase refrigerant

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000007788 liquid Substances 0.000 claims abstract description 224

- 239000003507 refrigerant Substances 0.000 claims abstract description 224

- 239000007791 liquid phase Substances 0.000 claims abstract description 95

- 239000012071 phase Substances 0.000 claims abstract description 89

- 238000005192 partition Methods 0.000 claims description 28

- 238000005057 refrigeration Methods 0.000 claims description 15

- 239000002826 coolant Substances 0.000 claims description 8

- 238000000926 separation method Methods 0.000 abstract description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 38

- 239000007789 gas Substances 0.000 description 28

- 238000011144 upstream manufacturing Methods 0.000 description 12

- 238000001816 cooling Methods 0.000 description 9

- 238000004378 air conditioning Methods 0.000 description 8

- 238000010438 heat treatment Methods 0.000 description 8

- 238000012986 modification Methods 0.000 description 7

- 230000004048 modification Effects 0.000 description 7

- 238000004891 communication Methods 0.000 description 6

- 238000010586 diagram Methods 0.000 description 4

- 238000010521 absorption reaction Methods 0.000 description 3

- 230000032683 aging Effects 0.000 description 2

- 238000007664 blowing Methods 0.000 description 2

- 230000001143 conditioned effect Effects 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 239000007792 gaseous phase Substances 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 238000000638 solvent extraction Methods 0.000 description 2

- 239000003990 capacitor Substances 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 230000006837 decompression Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000001050 lubricating effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B43/00—Arrangements for separating or purifying gases or liquids; Arrangements for vaporising the residuum of liquid refrigerant, e.g. by heat

- F25B43/006—Accumulators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00321—Heat exchangers for air-conditioning devices

- B60H1/00335—Heat exchangers for air-conditioning devices of the gas-air type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H1/3204—Cooling devices using compression

- B60H1/3228—Cooling devices using compression characterised by refrigerant circuit configurations

- B60H1/32281—Cooling devices using compression characterised by refrigerant circuit configurations comprising a single secondary circuit, e.g. at evaporator or condenser side

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B39/00—Evaporators; Condensers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B40/00—Subcoolers, desuperheaters or superheaters

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B5/00—Compression machines, plants or systems, with several evaporator circuits, e.g. for varying refrigerating capacity

- F25B5/04—Compression machines, plants or systems, with several evaporator circuits, e.g. for varying refrigerating capacity arranged in series

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B6/00—Compression machines, plants or systems, with several condenser circuits

- F25B6/04—Compression machines, plants or systems, with several condenser circuits arranged in series

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D1/00—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators

- F28D1/02—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid

- F28D1/04—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with tubular conduits

- F28D1/053—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with tubular conduits the conduits being straight

- F28D1/0535—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with tubular conduits the conduits being straight the conduits having a non-circular cross-section

- F28D1/05366—Assemblies of conduits connected to common headers, e.g. core type radiators

- F28D1/05391—Assemblies of conduits connected to common headers, e.g. core type radiators with multiple rows of conduits or with multi-channel conduits combined with a particular flow pattern, e.g. multi-row multi-stage radiators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2339/00—Details of evaporators; Details of condensers

- F25B2339/04—Details of condensers

- F25B2339/047—Water-cooled condensers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2400/00—General features or devices for refrigeration machines, plants or systems, combined heating and refrigeration systems or heat-pump systems, i.e. not limited to a particular subgroup of F25B

- F25B2400/16—Receivers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2400/00—General features or devices for refrigeration machines, plants or systems, combined heating and refrigeration systems or heat-pump systems, i.e. not limited to a particular subgroup of F25B

- F25B2400/23—Separators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2500/00—Problems to be solved

- F25B2500/18—Optimization, e.g. high integration of refrigeration components

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B39/00—Evaporators; Condensers

- F25B39/04—Condensers

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Power Engineering (AREA)

- Air-Conditioning For Vehicles (AREA)

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

Abstract

Description

このように構成することで、流入する気液二相冷媒を、貯液器36Fの内壁面816に確実に当ててから落下させることができる。

36,36A,36B,36C,36D,36E,36F,36G:貯液器

12:流入流路

13:気相流出流路

14:液相流出流路

81a:流入口

81b:気相流出口

81c:液相流出口

Claims (12)

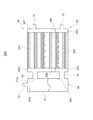

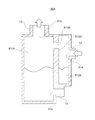

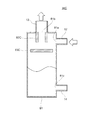

- 冷凍サイクルを構成する熱交換器であって、

内部を通過する冷媒と空気とを熱交換させる熱交換部(34)と、

前記熱交換部から流出した気液二相冷媒を気相冷媒と液相冷媒とに気液分離し、液相冷媒を溜める貯液器(36,36A,36B,36C,36D,36E,36F,36G)と、

前記熱交換部から流出する気液二相冷媒を前記貯液器に流入させる流入流路(12,12D,12E,12F,12G)と、

前記貯液器から気相冷媒を流出させる気相流出流路(13)と、

前記貯液器から液相冷媒を流出させる液相流出流路(14)と、

を備え、

前記流入流路は、前記貯液器に溜められた液相冷媒の液面よりも上方に設けられてなる流入口(81a)に連通するように繋がれ、前記気相流出流路は、前記貯液器に溜められた液相冷媒の液面よりも上方に設けられてなる気相流出口(81b)に連通するように繋がれ、前記液相流出流路は、前記貯液器に溜められた液相冷媒の液面よりも下方に設けられてなる液相流出口(81c)に連通するように繋がれている、熱交換器。 - 請求項1記載の熱交換器であって、

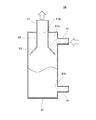

前記貯液器は、前記流入口と前記気相流出口の間に仕切部(82,82B,82C)を有する、熱交換器。 - 請求項2記載の熱交換器であって、

前記仕切部は、その少なくとも一部が前記流入口に対向するように配置されている、熱交換器。 - 請求項1又は2記載の熱交換器であって、

前記流入口と液相冷媒の液面との間に緩衝部(83,83B,83C)を有する、熱交換器。 - 請求項4記載の熱交換器であって、

前記緩衝部は、その少なくとも一部が前記流入口から前記液相流出口の間であって、前記流入口よりも液面側に配置されている、熱交換器。 - 請求項5記載の熱交換器であって、

前記貯液器は、その内部に液相冷媒を貯液可能な略円筒状の本体部(81)を有しており、

前記緩衝部から前記本体部の内壁までの平均距離が、前記本体部の半径の3分の1以下である、熱交換器。 - 請求項1記載の熱交換器であって、

前記貯液器(36A)は、その内部に液相冷媒を貯液可能な略円筒状の本体部(81A)を有しており、

前記本体部は、主液溜め空間(811A)と、前記主液溜め空間よりも液面面積が小さくなる副液溜め空間(812A)と、が形成されている、熱交換器。 - 請求項1記載の熱交換器であって、

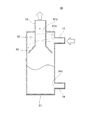

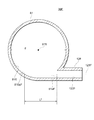

前記流入流路(12D,12E,12F,12G)は、その中心線を延伸すると、前記貯液器(36D,36E,36F,36G)の中央(815,812Ga)を通らずに前記貯液器の内壁面(816,812Gb)に至るように設けられている、熱交換器。 - 請求項8記載の熱交換器であって、

前記流入流路は、前記流入流路を通り前記流入口から流入する気液二相冷媒が、前記貯液器の内壁面に衝突してから前記貯液器に溜められた液相冷媒に落ちるように設けられている、熱交換器。 - 請求項8又は9に記載の熱交換器であって、

前記流入口から前記流入口に対向する前記貯液器の内壁面部分(816aD,816aE,816aG,811Gd,812Gc)までの距離(Ld,Le,Lf,Lg1,Lg2)が、前記貯液器の内壁面において最も離れた部分間の距離(d,d1,d2)よりも短くなるように設けられている、熱交換器。 - 請求項10記載の熱交換器であって、

前記貯液器の内壁面は断面が略円形を成しており、

前記流入口から前記流入口に対向する前記貯液器の内壁面部分までの距離(Ld,Le,Lf,Lg1)が、前記貯液器の内壁面の直径(d,d1)よりも短くなるように設けられている、熱交換器。 - 請求項11記載の熱交換器であって、

前記流入流路の内壁面の一部が前記貯液器の内壁面の接線に沿うように設けられている、熱交換器。

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/091,138 US20190128577A1 (en) | 2016-04-08 | 2017-04-03 | Heat exchanger |

| PCT/JP2017/013975 WO2017175724A1 (ja) | 2016-04-08 | 2017-04-03 | 熱交換器 |

| US17/098,487 US11656014B2 (en) | 2016-04-08 | 2020-11-16 | Heat exchanger |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016078224 | 2016-04-08 | ||

| JP2016078224 | 2016-04-08 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2017190940A true JP2017190940A (ja) | 2017-10-19 |

| JP2017190940A5 JP2017190940A5 (ja) | 2018-08-30 |

| JP6631489B2 JP6631489B2 (ja) | 2020-01-15 |

Family

ID=60085769

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016234961A Expired - Fee Related JP6631489B2 (ja) | 2016-04-08 | 2016-12-02 | 熱交換器 |

Country Status (2)

| Country | Link |

|---|---|

| US (2) | US20190128577A1 (ja) |

| JP (1) | JP6631489B2 (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118107281A (zh) * | 2022-11-29 | 2024-05-31 | 株式会社理光 | 喷头模块、图像形成装置及液体喷出装置 |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110945299A (zh) * | 2017-08-03 | 2020-03-31 | 三菱电机株式会社 | 热交换器及制冷循环装置 |

| CN110945300B (zh) * | 2017-08-03 | 2022-07-22 | 三菱电机株式会社 | 制冷剂分配器、热交换器及制冷循环装置 |

| CN115200268B (zh) * | 2022-06-10 | 2024-10-18 | 智己汽车科技有限公司 | 一种换热循环系统、空调及车辆 |

| EP4378695A1 (en) * | 2022-11-29 | 2024-06-05 | Ricoh Company, Ltd. | Head module, image forming apparatus, and liquid discharge apparatus |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0367874U (ja) * | 1989-10-26 | 1991-07-03 | ||

| JP2001289539A (ja) * | 1999-05-24 | 2001-10-19 | Denso Corp | アキュムレータ |

| JP2004069272A (ja) * | 2002-08-09 | 2004-03-04 | Denso Corp | 冷凍サイクル装置 |

| JP2011152827A (ja) * | 2010-01-26 | 2011-08-11 | Honda Motor Co Ltd | 車両用空調システムの冷媒体貯留構造 |

| JP2012241962A (ja) * | 2011-05-18 | 2012-12-10 | Fuji Electric Co Ltd | 気液分離器 |

| JP2014149123A (ja) * | 2013-02-01 | 2014-08-21 | Denso Corp | 冷凍サイクル装置 |

| WO2016103599A1 (ja) * | 2014-12-25 | 2016-06-30 | 株式会社デンソー | 冷凍サイクル装置 |

| JP2017190943A (ja) * | 2016-04-08 | 2017-10-19 | 株式会社デンソー | 冷凍サイクル装置及び熱交換器 |

| JP2017190944A (ja) * | 2016-04-08 | 2017-10-19 | 株式会社デンソー | 熱交換器 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4199960A (en) * | 1978-10-26 | 1980-04-29 | Parker-Hannifin Corporation | Accumulator for air conditioning systems |

| US4187695A (en) * | 1978-11-07 | 1980-02-12 | Virginia Chemicals Inc. | Air-conditioning system having recirculating and flow-control means |

| US5787729A (en) * | 1997-06-04 | 1998-08-04 | Automotive Fluid Systems, Inc. | Accumulator deflector |

| JPH1130445A (ja) * | 1997-07-10 | 1999-02-02 | Denso Corp | 冷凍サイクル装置 |

| JP4032548B2 (ja) | 1999-01-22 | 2008-01-16 | 株式会社デンソー | 受液器一体型冷媒凝縮器 |

| JP2004116938A (ja) * | 2002-09-27 | 2004-04-15 | Denso Corp | エジェクタサイクル |

| US20050081559A1 (en) * | 2003-10-20 | 2005-04-21 | Mcgregor Ian A.N. | Accumulator with pickup tube |

| US7461519B2 (en) * | 2005-02-03 | 2008-12-09 | Halla Climate Control Canada, Inc. | Accumulator with deflector |

| JP4626586B2 (ja) * | 2006-08-03 | 2011-02-09 | トヨタ紡織株式会社 | 気液分離器 |

| JP5395358B2 (ja) | 2008-01-23 | 2014-01-22 | 日冷工業株式会社 | 気液分離装置および気液分離装置を備えた冷凍装置。 |

| JP4803199B2 (ja) * | 2008-03-27 | 2011-10-26 | 株式会社デンソー | 冷凍サイクル装置 |

| US8147575B2 (en) * | 2009-09-09 | 2012-04-03 | Ingersoll-Rand Company | Multi-stage oil separation system including a cyclonic separation stage |

| WO2015128807A2 (en) | 2014-02-26 | 2015-09-03 | Denso Thermal Systems S.P.A. | Horizontal condenser with coolant accumulator |

| US10391839B2 (en) * | 2015-08-03 | 2019-08-27 | Denso Corporation | Refrigeration cycle device |

-

2016

- 2016-12-02 JP JP2016234961A patent/JP6631489B2/ja not_active Expired - Fee Related

-

2017

- 2017-04-03 US US16/091,138 patent/US20190128577A1/en not_active Abandoned

-

2020

- 2020-11-16 US US17/098,487 patent/US11656014B2/en active Active

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0367874U (ja) * | 1989-10-26 | 1991-07-03 | ||

| JP2001289539A (ja) * | 1999-05-24 | 2001-10-19 | Denso Corp | アキュムレータ |

| JP2004069272A (ja) * | 2002-08-09 | 2004-03-04 | Denso Corp | 冷凍サイクル装置 |

| JP2011152827A (ja) * | 2010-01-26 | 2011-08-11 | Honda Motor Co Ltd | 車両用空調システムの冷媒体貯留構造 |

| JP2012241962A (ja) * | 2011-05-18 | 2012-12-10 | Fuji Electric Co Ltd | 気液分離器 |

| JP2014149123A (ja) * | 2013-02-01 | 2014-08-21 | Denso Corp | 冷凍サイクル装置 |

| WO2016103599A1 (ja) * | 2014-12-25 | 2016-06-30 | 株式会社デンソー | 冷凍サイクル装置 |

| JP2017190943A (ja) * | 2016-04-08 | 2017-10-19 | 株式会社デンソー | 冷凍サイクル装置及び熱交換器 |

| JP2017190944A (ja) * | 2016-04-08 | 2017-10-19 | 株式会社デンソー | 熱交換器 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118107281A (zh) * | 2022-11-29 | 2024-05-31 | 株式会社理光 | 喷头模块、图像形成装置及液体喷出装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| US11656014B2 (en) | 2023-05-23 |

| US20190128577A1 (en) | 2019-05-02 |

| US20210063067A1 (en) | 2021-03-04 |

| JP6631489B2 (ja) | 2020-01-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US11656014B2 (en) | Heat exchanger | |

| CN101545690B (zh) | 制冷剂循环装置 | |

| KR101462176B1 (ko) | 열교환기 | |

| KR101929910B1 (ko) | 축냉 열교환기 | |

| US9951996B2 (en) | Refrigerant evaporator | |

| EP1860390A2 (en) | Vapor compression refrigerating cycle | |

| US11512903B2 (en) | Heat exchanger | |

| WO2018173356A1 (ja) | 熱交換器、および、それを用いた空気調和機 | |

| JP6562025B2 (ja) | 熱交換器 | |

| KR101766617B1 (ko) | 냉매 회로용 열교환기 | |

| JPH109713A (ja) | 冷媒凝縮装置、および冷媒凝縮器 | |

| JP6927353B1 (ja) | 熱交換器 | |

| JP2001174103A (ja) | 冷媒凝縮器 | |

| WO2017175724A1 (ja) | 熱交換器 | |

| US20140166256A1 (en) | Sub-Cooled Condenser Having a Receiver Tank with a Refrigerant Diverter for Improved Filling Efficiency | |

| JP6780516B2 (ja) | 貯液器 | |

| WO2017175726A1 (ja) | 熱交換器 | |

| JP2018048766A (ja) | パラレルフロー熱交換器、及び冷凍サイクル装置 | |

| JP4577291B2 (ja) | 冷媒蒸発器 | |

| JP2008281254A (ja) | 冷凍サイクル装置、および車両用空調装置 | |

| CN111213020B (zh) | 热交换器 | |

| JP2019163893A (ja) | 熱交換器および冷凍サイクル装置 | |

| CN117308415A (zh) | 用于冷媒循环系统的换热装置、冷媒循环系统 | |

| JP2016125767A (ja) | アキュームレータ及び空気調和装置 | |

| KR20170084787A (ko) | 공기조화기 및 공기조화기에 포함되는 팽창모듈 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180713 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20180713 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190416 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190612 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190820 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20191021 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20191112 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20191125 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 6631489 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |

|

| LAPS | Cancellation because of no payment of annual fees |