JP2007334357A - 光学素子並びにマッピング部品 - Google Patents

光学素子並びにマッピング部品 Download PDFInfo

- Publication number

- JP2007334357A JP2007334357A JP2007156063A JP2007156063A JP2007334357A JP 2007334357 A JP2007334357 A JP 2007334357A JP 2007156063 A JP2007156063 A JP 2007156063A JP 2007156063 A JP2007156063 A JP 2007156063A JP 2007334357 A JP2007334357 A JP 2007334357A

- Authority

- JP

- Japan

- Prior art keywords

- lens

- optical

- glass

- optical element

- ceramic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 230000003287 optical effect Effects 0.000 title claims abstract description 88

- 238000013507 mapping Methods 0.000 title claims description 37

- 239000000919 ceramic Substances 0.000 claims abstract description 51

- 239000011521 glass Substances 0.000 claims abstract description 38

- 239000006185 dispersion Substances 0.000 claims abstract description 28

- 239000013078 crystal Substances 0.000 claims abstract description 18

- 229910021193 La 2 O 3 Inorganic materials 0.000 claims description 12

- 239000012780 transparent material Substances 0.000 claims description 6

- 229910052747 lanthanoid Inorganic materials 0.000 claims description 5

- 150000002602 lanthanoids Chemical class 0.000 claims description 5

- 229910052765 Lutetium Inorganic materials 0.000 claims description 4

- 239000012535 impurity Substances 0.000 claims description 4

- 229910052688 Gadolinium Inorganic materials 0.000 claims description 3

- 229910052769 Ytterbium Inorganic materials 0.000 claims description 3

- 229910052746 lanthanum Inorganic materials 0.000 claims description 3

- 229910017493 Nd 2 O 3 Inorganic materials 0.000 claims description 2

- 229910052738 indium Inorganic materials 0.000 claims description 2

- 229910052706 scandium Inorganic materials 0.000 claims description 2

- 229910052727 yttrium Inorganic materials 0.000 claims description 2

- 101100018566 Neurospora crassa (strain ATCC 24698 / 74-OR23-1A / CBS 708.71 / DSM 1257 / FGSC 987) tif-1 gene Proteins 0.000 claims 1

- 239000000463 material Substances 0.000 abstract description 38

- 238000000034 method Methods 0.000 description 26

- 239000000843 powder Substances 0.000 description 22

- 238000005245 sintering Methods 0.000 description 18

- 239000000203 mixture Substances 0.000 description 16

- 238000004519 manufacturing process Methods 0.000 description 14

- 230000008569 process Effects 0.000 description 12

- 238000001556 precipitation Methods 0.000 description 10

- 238000010586 diagram Methods 0.000 description 9

- 238000010521 absorption reaction Methods 0.000 description 8

- 238000005516 engineering process Methods 0.000 description 8

- 238000002834 transmittance Methods 0.000 description 8

- MUBZPKHOEPUJKR-UHFFFAOYSA-N Oxalic acid Chemical compound OC(=O)C(O)=O MUBZPKHOEPUJKR-UHFFFAOYSA-N 0.000 description 6

- 238000000465 moulding Methods 0.000 description 6

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 5

- 239000000654 additive Substances 0.000 description 5

- 230000000694 effects Effects 0.000 description 5

- 230000007246 mechanism Effects 0.000 description 5

- 239000012071 phase Substances 0.000 description 5

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 4

- 230000004075 alteration Effects 0.000 description 4

- 239000011230 binding agent Substances 0.000 description 4

- 230000005540 biological transmission Effects 0.000 description 4

- 230000015572 biosynthetic process Effects 0.000 description 4

- 238000001514 detection method Methods 0.000 description 4

- 150000002500 ions Chemical class 0.000 description 4

- 239000002245 particle Substances 0.000 description 4

- 239000011148 porous material Substances 0.000 description 4

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 3

- 150000001768 cations Chemical class 0.000 description 3

- 230000007123 defense Effects 0.000 description 3

- 238000001035 drying Methods 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 238000002844 melting Methods 0.000 description 3

- 230000008018 melting Effects 0.000 description 3

- 239000013081 microcrystal Substances 0.000 description 3

- 230000003595 spectral effect Effects 0.000 description 3

- 238000001694 spray drying Methods 0.000 description 3

- 229910052692 Dysprosium Inorganic materials 0.000 description 2

- 229910052691 Erbium Inorganic materials 0.000 description 2

- 229910052693 Europium Inorganic materials 0.000 description 2

- 229910052689 Holmium Inorganic materials 0.000 description 2

- IMNFDUFMRHMDMM-UHFFFAOYSA-N N-Heptane Chemical compound CCCCCCC IMNFDUFMRHMDMM-UHFFFAOYSA-N 0.000 description 2

- 229910052779 Neodymium Inorganic materials 0.000 description 2

- 229910052777 Praseodymium Inorganic materials 0.000 description 2

- 229910052772 Samarium Inorganic materials 0.000 description 2

- 229910052771 Terbium Inorganic materials 0.000 description 2

- 229910052775 Thulium Inorganic materials 0.000 description 2

- 230000000996 additive effect Effects 0.000 description 2

- 229910052786 argon Inorganic materials 0.000 description 2

- 238000000149 argon plasma sintering Methods 0.000 description 2

- QVQLCTNNEUAWMS-UHFFFAOYSA-N barium oxide Chemical compound [Ba]=O QVQLCTNNEUAWMS-UHFFFAOYSA-N 0.000 description 2

- 238000001354 calcination Methods 0.000 description 2

- 238000005266 casting Methods 0.000 description 2

- 230000003750 conditioning effect Effects 0.000 description 2

- 239000006059 cover glass Substances 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 238000002845 discoloration Methods 0.000 description 2

- 238000004108 freeze drying Methods 0.000 description 2

- 238000007496 glass forming Methods 0.000 description 2

- 239000002241 glass-ceramic Substances 0.000 description 2

- 239000010410 layer Substances 0.000 description 2

- 239000002105 nanoparticle Substances 0.000 description 2

- 239000011858 nanopowder Substances 0.000 description 2

- 150000004767 nitrides Chemical class 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- 239000011164 primary particle Substances 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 239000000047 product Substances 0.000 description 2

- 230000005855 radiation Effects 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 238000007569 slipcasting Methods 0.000 description 2

- 239000000725 suspension Substances 0.000 description 2

- 238000005496 tempering Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- RUDFQVOCFDJEEF-UHFFFAOYSA-N yttrium(III) oxide Inorganic materials [O-2].[O-2].[O-2].[Y+3].[Y+3] RUDFQVOCFDJEEF-UHFFFAOYSA-N 0.000 description 2

- OBOSXEWFRARQPU-UHFFFAOYSA-N 2-n,2-n-dimethylpyridine-2,5-diamine Chemical compound CN(C)C1=CC=C(N)C=N1 OBOSXEWFRARQPU-UHFFFAOYSA-N 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- BVKZGUZCCUSVTD-UHFFFAOYSA-L Carbonate Chemical compound [O-]C([O-])=O BVKZGUZCCUSVTD-UHFFFAOYSA-L 0.000 description 1

- VEXZGXHMUGYJMC-UHFFFAOYSA-M Chloride anion Chemical compound [Cl-] VEXZGXHMUGYJMC-UHFFFAOYSA-M 0.000 description 1

- FBPFZTCFMRRESA-JGWLITMVSA-N D-glucitol Chemical compound OC[C@H](O)[C@@H](O)[C@H](O)[C@H](O)CO FBPFZTCFMRRESA-JGWLITMVSA-N 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- 229920002125 Sokalan® Polymers 0.000 description 1

- 238000005411 Van der Waals force Methods 0.000 description 1

- QCWXUUIWCKQGHC-UHFFFAOYSA-N Zirconium Chemical compound [Zr] QCWXUUIWCKQGHC-UHFFFAOYSA-N 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 238000000137 annealing Methods 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 238000000889 atomisation Methods 0.000 description 1

- MSMNVXKYCPHLLN-UHFFFAOYSA-N azane;oxalic acid;hydrate Chemical compound N.N.O.OC(=O)C(O)=O MSMNVXKYCPHLLN-UHFFFAOYSA-N 0.000 description 1

- 238000010533 azeotropic distillation Methods 0.000 description 1

- 229910052788 barium Inorganic materials 0.000 description 1

- DSAJWYNOEDNPEQ-UHFFFAOYSA-N barium atom Chemical compound [Ba] DSAJWYNOEDNPEQ-UHFFFAOYSA-N 0.000 description 1

- 238000004523 catalytic cracking Methods 0.000 description 1

- 238000009750 centrifugal casting Methods 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000009388 chemical precipitation Methods 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000003153 chemical reaction reagent Substances 0.000 description 1

- 238000000975 co-precipitation Methods 0.000 description 1

- 238000009841 combustion method Methods 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 238000013500 data storage Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 239000012065 filter cake Substances 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- WIHZLLGSGQNAGK-UHFFFAOYSA-N hafnium(4+);oxygen(2-) Chemical class [O-2].[O-2].[Hf+4] WIHZLLGSGQNAGK-UHFFFAOYSA-N 0.000 description 1

- 238000001513 hot isostatic pressing Methods 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 230000007062 hydrolysis Effects 0.000 description 1

- 238000006460 hydrolysis reaction Methods 0.000 description 1

- 238000001027 hydrothermal synthesis Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-M hydroxide Chemical compound [OH-] XLYOFNOQVPJJNP-UHFFFAOYSA-M 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 238000000608 laser ablation Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000007791 liquid phase Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000001393 microlithography Methods 0.000 description 1

- 229910052750 molybdenum Inorganic materials 0.000 description 1

- 238000012544 monitoring process Methods 0.000 description 1

- 238000010137 moulding (plastic) Methods 0.000 description 1

- 238000009828 non-uniform distribution Methods 0.000 description 1

- 239000005304 optical glass Substances 0.000 description 1

- 235000006408 oxalic acid Nutrition 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 239000011505 plaster Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004584 polyacrylic acid Substances 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 238000012805 post-processing Methods 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 230000002285 radioactive effect Effects 0.000 description 1

- 229910052761 rare earth metal Inorganic materials 0.000 description 1

- 150000002910 rare earth metals Chemical group 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 238000010583 slow cooling Methods 0.000 description 1

- 239000002002 slurry Substances 0.000 description 1

- 238000003980 solgel method Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000003786 synthesis reaction Methods 0.000 description 1

- 231100000331 toxic Toxicity 0.000 description 1

- 230000002588 toxic effect Effects 0.000 description 1

- 231100000419 toxicity Toxicity 0.000 description 1

- 230000001988 toxicity Effects 0.000 description 1

- 229910052723 transition metal Chemical group 0.000 description 1

- 150000003624 transition metals Chemical group 0.000 description 1

- YWYZEGXAUVWDED-UHFFFAOYSA-N triammonium citrate Chemical compound [NH4+].[NH4+].[NH4+].[O-]C(=O)CC(O)(CC([O-])=O)C([O-])=O YWYZEGXAUVWDED-UHFFFAOYSA-N 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

- 229910052726 zirconium Inorganic materials 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/50—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on rare-earth compounds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y30/00—Nanotechnology for materials or surface science, e.g. nanocomposites

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/01—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/01—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics

- C04B35/48—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics based on zirconium or hafnium oxides, zirconates, zircon or hafnates

- C04B35/486—Fine ceramics

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/50—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on rare-earth compounds

- C04B35/505—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on rare-earth compounds based on yttrium oxide

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/622—Forming processes; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/626—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B

- C04B35/62605—Treating the starting powders individually or as mixtures

- C04B35/62645—Thermal treatment of powders or mixtures thereof other than sintering

- C04B35/62655—Drying, e.g. freeze-drying, spray-drying, microwave or supercritical drying

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/622—Forming processes; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/626—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B

- C04B35/62605—Treating the starting powders individually or as mixtures

- C04B35/62695—Granulation or pelletising

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/622—Forming processes; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/64—Burning or sintering processes

- C04B35/645—Pressure sintering

- C04B35/6455—Hot isostatic pressing

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

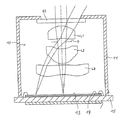

- G02B1/00—Optical elements characterised by the material of which they are made; Optical coatings for optical elements

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

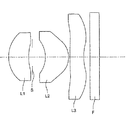

- G02B13/00—Optical objectives specially designed for the purposes specified below

- G02B13/001—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras

- G02B13/0015—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras characterised by the lens design

- G02B13/002—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras characterised by the lens design having at least one aspherical surface

- G02B13/0035—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras characterised by the lens design having at least one aspherical surface having three lenses

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B13/00—Optical objectives specially designed for the purposes specified below

- G02B13/001—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras

- G02B13/008—Miniaturised objectives for electronic devices, e.g. portable telephones, webcams, PDAs, small digital cameras designed for infrared light

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3224—Rare earth oxide or oxide forming salts thereof, e.g. scandium oxide

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3224—Rare earth oxide or oxide forming salts thereof, e.g. scandium oxide

- C04B2235/3227—Lanthanum oxide or oxide-forming salts thereof

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3231—Refractory metal oxides, their mixed metal oxides, or oxide-forming salts thereof

- C04B2235/3244—Zirconium oxides, zirconates, hafnium oxides, hafnates, or oxide-forming salts thereof

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/50—Constituents or additives of the starting mixture chosen for their shape or used because of their shape or their physical appearance

- C04B2235/54—Particle size related information

- C04B2235/5418—Particle size related information expressed by the size of the particles or aggregates thereof

- C04B2235/5454—Particle size related information expressed by the size of the particles or aggregates thereof nanometer sized, i.e. below 100 nm

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/70—Aspects relating to sintered or melt-casted ceramic products

- C04B2235/74—Physical characteristics

- C04B2235/76—Crystal structural characteristics, e.g. symmetry

- C04B2235/762—Cubic symmetry, e.g. beta-SiC

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/70—Aspects relating to sintered or melt-casted ceramic products

- C04B2235/96—Properties of ceramic products, e.g. mechanical properties such as strength, toughness, wear resistance

- C04B2235/9646—Optical properties

- C04B2235/9653—Translucent or transparent ceramics other than alumina

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S501/00—Compositions: ceramic

- Y10S501/90—Optical glass, e.g. silent on refractive index and/or ABBE number

- Y10S501/901—Optical glass, e.g. silent on refractive index and/or ABBE number having R.I. at least 1.8

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S501/00—Compositions: ceramic

- Y10S501/90—Optical glass, e.g. silent on refractive index and/or ABBE number

- Y10S501/904—Infrared transmitting or absorbing

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Ceramic Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Physics & Mathematics (AREA)

- Materials Engineering (AREA)

- Structural Engineering (AREA)

- Organic Chemistry (AREA)

- General Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Inorganic Chemistry (AREA)

- Nanotechnology (AREA)

- Composite Materials (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Compositions Of Oxide Ceramics (AREA)

- Glass Compositions (AREA)

- Diffracting Gratings Or Hologram Optical Elements (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102006027957A DE102006027957A1 (de) | 2006-06-14 | 2006-06-14 | Optische Elemente sowie Abbildungsoptiken |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2007334357A true JP2007334357A (ja) | 2007-12-27 |

| JP2007334357A5 JP2007334357A5 (enExample) | 2012-03-01 |

Family

ID=38515440

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007156063A Ceased JP2007334357A (ja) | 2006-06-14 | 2007-06-13 | 光学素子並びにマッピング部品 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US7751123B2 (enExample) |

| EP (1) | EP1867618A1 (enExample) |

| JP (1) | JP2007334357A (enExample) |

| CN (1) | CN101093257B (enExample) |

| DE (1) | DE102006027957A1 (enExample) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2010004861A1 (ja) * | 2008-07-07 | 2010-01-14 | 日鉱金属株式会社 | 酸化ランタン基焼結体、同焼結体からなるスパッタリングターゲット、酸化ランタン基焼結体の製造方法及び同製造方法によるスパッタリングターゲットの製造方法 |

| WO2010004862A1 (ja) * | 2008-07-07 | 2010-01-14 | 日鉱金属株式会社 | 酸化物焼結体、同焼結体からなるスパッタリングターゲット、同焼結体の製造方法及び同焼結体スパッタリングターゲットゲートの製造方法 |

| JP2010285299A (ja) * | 2009-06-09 | 2010-12-24 | Shin-Etsu Chemical Co Ltd | 酸化物及び磁気光学デバイス |

| JP2011121837A (ja) * | 2009-12-14 | 2011-06-23 | Oxide Corp | 磁気光学素子用透光性酸化テルビウム焼結体 |

| JP2013510063A (ja) * | 2009-11-03 | 2013-03-21 | サントル ナスィオナル ド ラ ルシェルシュ スィアンティフィク | 単結晶立方晶系三二酸化物の製造方法及びその使用 |

| EP2716616A1 (en) | 2012-10-03 | 2014-04-09 | Shin-Etsu Chemical Co., Ltd. | Method of Manufacturing Transparent Sesquioxide Sintered Body, and Transparent Sesquioxide Sintered Body Manufactured by the Method |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2898890B1 (fr) * | 2006-03-23 | 2008-05-09 | Saint Gobain Ct Recherches | Produit d'oxyde d'yttrium fritte et dope. |

| DE102006027958A1 (de) * | 2006-06-14 | 2007-12-20 | Schott Ag | Optokeramiken, daraus hergestellte optische Elemente sowie Abbildungsoptiken |

| JP5762715B2 (ja) * | 2010-10-06 | 2015-08-12 | 信越化学工業株式会社 | 磁気光学材料、ファラデー回転子、及び光アイソレータ |

| TWI481562B (zh) * | 2010-10-13 | 2015-04-21 | Shinetsu Chemical Co | Oxide and magnetic optics |

| KR101899587B1 (ko) * | 2011-03-16 | 2018-11-02 | 신에쓰 가가꾸 고교 가부시끼가이샤 | 세라믹스 자기 광학 재료 및 그 선정 방법 |

| US20140098411A1 (en) * | 2011-09-28 | 2014-04-10 | Woohong Kim | RARE EARTH DOPED Lu2O3 POLYCRYSTALLINE CERAMIC LASER GAIN MEDIUM |

| CN102815945B (zh) * | 2012-09-13 | 2014-09-10 | 中国科学院上海硅酸盐研究所 | 锆酸镧钆透明陶瓷材料及其制备方法 |

| JP6052800B2 (ja) * | 2013-07-12 | 2016-12-27 | 信越化学工業株式会社 | 光アイソレータ |

| CN108585853B (zh) * | 2017-12-11 | 2021-12-24 | 上海大学 | 一种铕掺杂氧化钪闪烁体及其制备方法和用途 |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5158409A (enExample) * | 1974-11-20 | 1976-05-21 | Toray Industries | |

| JPS5417911A (en) * | 1977-07-11 | 1979-02-09 | Gte Laboratories Inc | Transparent yttria ceramic and method of making same |

| JPH06211573A (ja) * | 1993-01-18 | 1994-08-02 | Kurosaki Refract Co Ltd | 透明なy2o3焼結体の製造方法 |

| JP2002326862A (ja) * | 2001-05-02 | 2002-11-12 | Kohan Kogyo Kk | 透光性セラミックスおよびその製造方法 |

| JP2004075512A (ja) * | 2001-11-20 | 2004-03-11 | Murata Mfg Co Ltd | 透光性セラミックスならびにそれを用いた光学部品および光学素子 |

| JP2004091271A (ja) * | 2002-08-30 | 2004-03-25 | Rikogaku Shinkokai | 透明もしくは透光性セラミックスおよびその製造方法 |

| WO2006003726A1 (ja) * | 2004-07-02 | 2006-01-12 | Konoshima Chemical Co., Ltd. | 透光性酸化ルテチウム焼結体及びその製造方法 |

| JP2006084887A (ja) * | 2004-09-17 | 2006-03-30 | Casio Comput Co Ltd | レンズ装置 |

| JP2006113287A (ja) * | 2004-10-14 | 2006-04-27 | Olympus Corp | 顕微鏡対物レンズ |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3432314A (en) * | 1966-08-02 | 1969-03-11 | Us Air Force | Transparent zirconia composition and process for making same |

| US3545987A (en) * | 1966-09-28 | 1970-12-08 | Gen Electric | Transparent yttria-based ceramics and method for producing same |

| GB1202032A (en) * | 1966-09-28 | 1970-08-12 | Gen Electric | Improvements in transparent ceramics and method for producing same |

| US3640887A (en) * | 1970-04-06 | 1972-02-08 | Gen Electric | Transparent zirconia- hafnia- and thoria-rare earth ceramics |

| US4098612A (en) * | 1977-07-11 | 1978-07-04 | Gte Laboratories Incorporated | Transparent yttria ceramics and method for producing same |

| US4747973A (en) * | 1982-06-18 | 1988-05-31 | General Electric Company | Rare-earth-doped yttria-gadolina ceramic scintillators |

| US4571312A (en) * | 1982-06-18 | 1986-02-18 | General Electric Company | Preparation of yttria-gadolinia ceramic scintillators by sintering and gas hot isostatic pressing |

| US4755492A (en) * | 1986-10-06 | 1988-07-05 | General Electric Company | Yttrium oxide ceramic body |

| US4761390A (en) * | 1987-02-02 | 1988-08-02 | Raytheon Company | Optically transparent yttrium oxide |

| JP3401553B2 (ja) | 1999-01-14 | 2003-04-28 | 独立行政法人物質・材料研究機構 | 乾式混合法による透明イットリウム・アルミニウム・ガーネット焼結体の製造法 |

| US6908872B2 (en) * | 2000-12-20 | 2005-06-21 | Murata Manufacturing Co. Ltd | Transparent ceramic and method for production thereof, and optical element |

| CN1244096C (zh) * | 2001-10-10 | 2006-03-01 | 索尼公司 | 光学透镜、聚光透镜、光学拾取器和光学记录/再现装置 |

| JP3883106B2 (ja) * | 2001-10-18 | 2007-02-21 | 神島化学工業株式会社 | 透光性酸化スカンジウム焼結体及びその製造方法 |

| US7141523B2 (en) | 2003-09-18 | 2006-11-28 | 3M Innovative Properties Company | Ceramics comprising Al2O3, REO, ZrO2 and/or HfO2, and Nb2O5 and/or Ta2O5 and methods of making the same |

| US7141522B2 (en) * | 2003-09-18 | 2006-11-28 | 3M Innovative Properties Company | Ceramics comprising Al2O3, Y2O3, ZrO2 and/or HfO2, and Nb2O5 and/or Ta2O5 and methods of making the same |

| US7466489B2 (en) * | 2003-12-15 | 2008-12-16 | Susanne Beder | Projection objective having a high aperture and a planar end surface |

| US7148480B2 (en) * | 2004-07-14 | 2006-12-12 | The Regents Of The University Of California | Polycrystalline optical window materials from nanoceramics |

| JP4591757B2 (ja) * | 2004-09-17 | 2010-12-01 | カシオ計算機株式会社 | レンズ装置 |

| JP2006091482A (ja) * | 2004-09-24 | 2006-04-06 | Casio Comput Co Ltd | 光学機器用セラミックスレンズ |

| JP2006091430A (ja) * | 2004-09-24 | 2006-04-06 | Casio Comput Co Ltd | レンズユニット |

| CN100447106C (zh) * | 2005-01-17 | 2008-12-31 | 上海大学 | 掺La3+的Y2O3基透明激光陶瓷的制备方法 |

| CN100336777C (zh) * | 2005-06-28 | 2007-09-12 | 中国科学院上海硅酸盐研究所 | 一种氧化镥基透明陶瓷的制备方法 |

| DE102006027958A1 (de) * | 2006-06-14 | 2007-12-20 | Schott Ag | Optokeramiken, daraus hergestellte optische Elemente sowie Abbildungsoptiken |

-

2006

- 2006-06-14 DE DE102006027957A patent/DE102006027957A1/de not_active Withdrawn

-

2007

- 2007-06-11 EP EP07011365A patent/EP1867618A1/en not_active Withdrawn

- 2007-06-13 JP JP2007156063A patent/JP2007334357A/ja not_active Ceased

- 2007-06-13 US US11/762,124 patent/US7751123B2/en not_active Expired - Fee Related

- 2007-06-14 CN CN2007101086758A patent/CN101093257B/zh not_active Expired - Fee Related

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5158409A (enExample) * | 1974-11-20 | 1976-05-21 | Toray Industries | |

| JPS5417911A (en) * | 1977-07-11 | 1979-02-09 | Gte Laboratories Inc | Transparent yttria ceramic and method of making same |

| JPH06211573A (ja) * | 1993-01-18 | 1994-08-02 | Kurosaki Refract Co Ltd | 透明なy2o3焼結体の製造方法 |

| JP2002326862A (ja) * | 2001-05-02 | 2002-11-12 | Kohan Kogyo Kk | 透光性セラミックスおよびその製造方法 |

| JP2004075512A (ja) * | 2001-11-20 | 2004-03-11 | Murata Mfg Co Ltd | 透光性セラミックスならびにそれを用いた光学部品および光学素子 |

| JP2004091271A (ja) * | 2002-08-30 | 2004-03-25 | Rikogaku Shinkokai | 透明もしくは透光性セラミックスおよびその製造方法 |

| WO2006003726A1 (ja) * | 2004-07-02 | 2006-01-12 | Konoshima Chemical Co., Ltd. | 透光性酸化ルテチウム焼結体及びその製造方法 |

| JP2006084887A (ja) * | 2004-09-17 | 2006-03-30 | Casio Comput Co Ltd | レンズ装置 |

| JP2006113287A (ja) * | 2004-10-14 | 2006-04-27 | Olympus Corp | 顕微鏡対物レンズ |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2010004861A1 (ja) * | 2008-07-07 | 2010-01-14 | 日鉱金属株式会社 | 酸化ランタン基焼結体、同焼結体からなるスパッタリングターゲット、酸化ランタン基焼結体の製造方法及び同製造方法によるスパッタリングターゲットの製造方法 |

| WO2010004862A1 (ja) * | 2008-07-07 | 2010-01-14 | 日鉱金属株式会社 | 酸化物焼結体、同焼結体からなるスパッタリングターゲット、同焼結体の製造方法及び同焼結体スパッタリングターゲットゲートの製造方法 |

| JP2010285299A (ja) * | 2009-06-09 | 2010-12-24 | Shin-Etsu Chemical Co Ltd | 酸化物及び磁気光学デバイス |

| KR20120036342A (ko) * | 2009-06-09 | 2012-04-17 | 신에쓰 가가꾸 고교 가부시끼가이샤 | 산화물 및 자기 광학 디바이스 |

| US8753538B2 (en) | 2009-06-09 | 2014-06-17 | Shin-Etsu Chemical Co., Ltd. | Oxide and magneto-optical device |

| KR101687431B1 (ko) * | 2009-06-09 | 2016-12-19 | 신에쓰 가가꾸 고교 가부시끼가이샤 | 산화물 및 자기 광학 디바이스 |

| JP2013510063A (ja) * | 2009-11-03 | 2013-03-21 | サントル ナスィオナル ド ラ ルシェルシュ スィアンティフィク | 単結晶立方晶系三二酸化物の製造方法及びその使用 |

| JP2011121837A (ja) * | 2009-12-14 | 2011-06-23 | Oxide Corp | 磁気光学素子用透光性酸化テルビウム焼結体 |

| EP2716616A1 (en) | 2012-10-03 | 2014-04-09 | Shin-Etsu Chemical Co., Ltd. | Method of Manufacturing Transparent Sesquioxide Sintered Body, and Transparent Sesquioxide Sintered Body Manufactured by the Method |

| KR20140043874A (ko) | 2012-10-03 | 2014-04-11 | 신에쓰 가가꾸 고교 가부시끼가이샤 | 투명한 세스퀴옥시드 소결체의 제조 방법, 및 이 방법에 의해서 제조된 투명한 세스퀴옥시드 소결체 |

| US9090513B2 (en) | 2012-10-03 | 2015-07-28 | Shin-Etsu Chemical Co., Ltd. | Method of manufacturing transparent sesquioxide sintered body, and transparent sesquioxide sintered body manufactured by the method |

| KR102117992B1 (ko) | 2012-10-03 | 2020-06-02 | 신에쓰 가가꾸 고교 가부시끼가이샤 | 투명한 세스퀴옥시드 소결체의 제조 방법, 및 이 방법에 의해서 제조된 투명한 세스퀴옥시드 소결체 |

Also Published As

| Publication number | Publication date |

|---|---|

| US7751123B2 (en) | 2010-07-06 |

| EP1867618A1 (en) | 2007-12-19 |

| CN101093257B (zh) | 2012-05-23 |

| CN101093257A (zh) | 2007-12-26 |

| DE102006027957A1 (de) | 2007-12-20 |

| US20080094734A1 (en) | 2008-04-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2007334357A (ja) | 光学素子並びにマッピング部品 | |

| US7700510B2 (en) | Opto-ceramics made from In2O3 or oxides Y, Lu, Sc, Yb, In, Gd, and La, optical elements made therefrom, and mapping optics including the optical elements | |

| JP5427368B2 (ja) | オプトセラミックス、それらから製造された光学エレメント、その用途及びイメージング光学素子 | |

| JP5563766B2 (ja) | 透明スピネルセラミックス及びその製造方法ならびにその透明スピネルセラミックスを用いた光学材料 | |

| JP5390454B2 (ja) | 立方晶構造を持つ受動光学セラミックス、同一のものの製造方法およびそれらの使用 | |

| JP5325518B2 (ja) | 透明セラミック及びその製造方法ならびにその透明セラミックスを用いた光学素子 | |

| JP6179731B2 (ja) | スピネルオプトセラミックスを用いた光学素子および製造方法 | |

| US7324285B2 (en) | Optical elements and imaging optics comprising them | |

| US20110143912A1 (en) | Colored spinel optoceramics | |

| JP2014062007A (ja) | 透光性セラミックス、その製造方法、光学素子およびその製造方法 | |

| WO2007122985A1 (ja) | 透光性セラミックおよびその製造方法、ならびに光学部品および光学装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090209 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20100216 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110117 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110119 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110408 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111026 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120113 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20120113 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120509 |

|

| A045 | Written measure of dismissal of application [lapsed due to lack of payment] |

Free format text: JAPANESE INTERMEDIATE CODE: A045 Effective date: 20120926 |