JP2006024751A - 平面多導体の接続方法及び該接続方法で接続される部分を含む電気電子部品 - Google Patents

平面多導体の接続方法及び該接続方法で接続される部分を含む電気電子部品 Download PDFInfo

- Publication number

- JP2006024751A JP2006024751A JP2004201633A JP2004201633A JP2006024751A JP 2006024751 A JP2006024751 A JP 2006024751A JP 2004201633 A JP2004201633 A JP 2004201633A JP 2004201633 A JP2004201633 A JP 2004201633A JP 2006024751 A JP2006024751 A JP 2006024751A

- Authority

- JP

- Japan

- Prior art keywords

- conductor

- adhesive composition

- multiconductor

- planar

- thermosetting adhesive

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 239000004020 conductor Substances 0.000 title claims abstract description 80

- 238000000034 method Methods 0.000 title claims abstract description 42

- 239000000853 adhesive Substances 0.000 claims abstract description 60

- 230000001070 adhesive effect Effects 0.000 claims abstract description 59

- 239000000203 mixture Substances 0.000 claims abstract description 39

- 229920001187 thermosetting polymer Polymers 0.000 claims abstract description 37

- 229910000510 noble metal Inorganic materials 0.000 claims abstract description 16

- 229910052751 metal Inorganic materials 0.000 claims abstract description 7

- 239000002184 metal Substances 0.000 claims abstract description 7

- 239000003822 epoxy resin Substances 0.000 claims description 46

- 229920000647 polyepoxide Polymers 0.000 claims description 46

- ZFSLODLOARCGLH-UHFFFAOYSA-N isocyanuric acid Chemical compound OC1=NC(O)=NC(O)=N1 ZFSLODLOARCGLH-UHFFFAOYSA-N 0.000 claims description 12

- 229920006287 phenoxy resin Polymers 0.000 claims description 11

- 239000013034 phenoxy resin Substances 0.000 claims description 11

- 229920000877 Melamine resin Polymers 0.000 claims description 8

- 239000007790 solid phase Substances 0.000 claims description 7

- JDSHMPZPIAZGSV-UHFFFAOYSA-N melamine Chemical compound NC1=NC(N)=NC(N)=N1 JDSHMPZPIAZGSV-UHFFFAOYSA-N 0.000 claims description 6

- 239000002245 particle Substances 0.000 claims description 5

- 239000000155 melt Substances 0.000 claims description 2

- 238000010438 heat treatment Methods 0.000 abstract description 10

- 238000003466 welding Methods 0.000 abstract description 5

- 239000007787 solid Substances 0.000 abstract description 2

- 239000004065 semiconductor Substances 0.000 abstract 5

- 238000002844 melting Methods 0.000 abstract 1

- 230000008018 melting Effects 0.000 abstract 1

- 239000010410 layer Substances 0.000 description 19

- 238000007747 plating Methods 0.000 description 12

- 229920005989 resin Polymers 0.000 description 10

- 239000011347 resin Substances 0.000 description 10

- 239000000758 substrate Substances 0.000 description 10

- 239000003795 chemical substances by application Substances 0.000 description 9

- 239000000126 substance Substances 0.000 description 8

- 239000012790 adhesive layer Substances 0.000 description 7

- 238000010586 diagram Methods 0.000 description 5

- GYZLOYUZLJXAJU-UHFFFAOYSA-N diglycidyl ether Chemical compound C1OC1COCC1CO1 GYZLOYUZLJXAJU-UHFFFAOYSA-N 0.000 description 5

- 239000004593 Epoxy Substances 0.000 description 4

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 4

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 4

- -1 for example Substances 0.000 description 4

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 4

- 238000005476 soldering Methods 0.000 description 4

- 229910000881 Cu alloy Inorganic materials 0.000 description 3

- IISBACLAFKSPIT-UHFFFAOYSA-N bisphenol A Chemical compound C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 IISBACLAFKSPIT-UHFFFAOYSA-N 0.000 description 3

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 3

- 229910052737 gold Inorganic materials 0.000 description 3

- 239000010931 gold Substances 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 238000003825 pressing Methods 0.000 description 3

- 230000035882 stress Effects 0.000 description 3

- 229920005992 thermoplastic resin Polymers 0.000 description 3

- 239000004925 Acrylic resin Substances 0.000 description 2

- 229920000178 Acrylic resin Polymers 0.000 description 2

- LCFVJGUPQDGYKZ-UHFFFAOYSA-N Bisphenol A diglycidyl ether Chemical compound C=1C=C(OCC2OC2)C=CC=1C(C)(C)C(C=C1)=CC=C1OCC1CO1 LCFVJGUPQDGYKZ-UHFFFAOYSA-N 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 2

- 239000004642 Polyimide Substances 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- PXKLMJQFEQBVLD-UHFFFAOYSA-N bisphenol F Chemical compound C1=CC(O)=CC=C1CC1=CC=C(O)C=C1 PXKLMJQFEQBVLD-UHFFFAOYSA-N 0.000 description 2

- 230000000740 bleeding effect Effects 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- QGBSISYHAICWAH-UHFFFAOYSA-N dicyandiamide Chemical compound NC(N)=NC#N QGBSISYHAICWAH-UHFFFAOYSA-N 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- NIHNNTQXNPWCJQ-UHFFFAOYSA-N fluorene Chemical compound C1=CC=C2CC3=CC=CC=C3C2=C1 NIHNNTQXNPWCJQ-UHFFFAOYSA-N 0.000 description 2

- RAXXELZNTBOGNW-UHFFFAOYSA-N imidazole Natural products C1=CNC=N1 RAXXELZNTBOGNW-UHFFFAOYSA-N 0.000 description 2

- 229910052742 iron Inorganic materials 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 229910052759 nickel Inorganic materials 0.000 description 2

- 229920003986 novolac Polymers 0.000 description 2

- 239000011146 organic particle Substances 0.000 description 2

- 239000012071 phase Substances 0.000 description 2

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 2

- 229920000139 polyethylene terephthalate Polymers 0.000 description 2

- 239000005020 polyethylene terephthalate Substances 0.000 description 2

- 229920001721 polyimide Polymers 0.000 description 2

- 239000010970 precious metal Substances 0.000 description 2

- QTWJRLJHJPIABL-UHFFFAOYSA-N 2-methylphenol;3-methylphenol;4-methylphenol Chemical compound CC1=CC=C(O)C=C1.CC1=CC=CC(O)=C1.CC1=CC=CC=C1O QTWJRLJHJPIABL-UHFFFAOYSA-N 0.000 description 1

- BRLQWZUYTZBJKN-UHFFFAOYSA-N Epichlorohydrin Chemical compound ClCC1CO1 BRLQWZUYTZBJKN-UHFFFAOYSA-N 0.000 description 1

- 229920000106 Liquid crystal polymer Polymers 0.000 description 1

- 239000004977 Liquid-crystal polymers (LCPs) Substances 0.000 description 1

- 239000004640 Melamine resin Substances 0.000 description 1

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 1

- 239000004696 Poly ether ether ketone Substances 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 239000004693 Polybenzimidazole Substances 0.000 description 1

- 239000004695 Polyether sulfone Substances 0.000 description 1

- 239000004697 Polyetherimide Substances 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 239000002174 Styrene-butadiene Substances 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 150000008065 acid anhydrides Chemical class 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 1

- 229920006243 acrylic copolymer Polymers 0.000 description 1

- 239000002313 adhesive film Substances 0.000 description 1

- 238000004220 aggregation Methods 0.000 description 1

- 230000032683 aging Effects 0.000 description 1

- 125000002723 alicyclic group Chemical group 0.000 description 1

- 239000004844 aliphatic epoxy resin Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 150000001412 amines Chemical class 0.000 description 1

- MTAZNLWOLGHBHU-UHFFFAOYSA-N butadiene-styrene rubber Chemical compound C=CC=C.C=CC1=CC=CC=C1 MTAZNLWOLGHBHU-UHFFFAOYSA-N 0.000 description 1

- 238000010538 cationic polymerization reaction Methods 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 229930003836 cresol Natural products 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- 150000007973 cyanuric acids Chemical class 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 238000007772 electroless plating Methods 0.000 description 1

- 238000009713 electroplating Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 238000005187 foaming Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 230000009477 glass transition Effects 0.000 description 1

- 125000003055 glycidyl group Chemical group C(C1CO1)* 0.000 description 1

- 238000007731 hot pressing Methods 0.000 description 1

- OAKJQQAXSVQMHS-UHFFFAOYSA-N hydrazine Substances NN OAKJQQAXSVQMHS-UHFFFAOYSA-N 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 238000003475 lamination Methods 0.000 description 1

- ZQKXQUJXLSSJCH-UHFFFAOYSA-N melamine cyanurate Chemical compound NC1=NC(N)=NC(N)=N1.O=C1NC(=O)NC(=O)N1 ZQKXQUJXLSSJCH-UHFFFAOYSA-N 0.000 description 1

- 150000007974 melamines Chemical class 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 239000003960 organic solvent Substances 0.000 description 1

- AFEQENGXSMURHA-UHFFFAOYSA-N oxiran-2-ylmethanamine Chemical compound NCC1CO1 AFEQENGXSMURHA-UHFFFAOYSA-N 0.000 description 1

- 229910052763 palladium Inorganic materials 0.000 description 1

- 238000011056 performance test Methods 0.000 description 1

- 238000000206 photolithography Methods 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 229920003223 poly(pyromellitimide-1,4-diphenyl ether) Polymers 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920000768 polyamine Polymers 0.000 description 1

- 229920001230 polyarylate Polymers 0.000 description 1

- 229920002480 polybenzimidazole Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920006393 polyether sulfone Polymers 0.000 description 1

- 229920002530 polyetherether ketone Polymers 0.000 description 1

- 229920001601 polyetherimide Polymers 0.000 description 1

- 239000002685 polymerization catalyst Substances 0.000 description 1

- 229920005672 polyolefin resin Polymers 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 229920002050 silicone resin Polymers 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 229910000679 solder Inorganic materials 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 239000011115 styrene butadiene Substances 0.000 description 1

- 229920003048 styrene butadiene rubber Polymers 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J163/00—Adhesives based on epoxy resins; Adhesives based on derivatives of epoxy resins

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

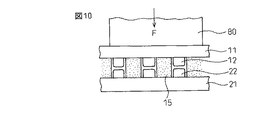

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/70—Coupling devices

- H01R12/77—Coupling devices for flexible printed circuits, flat or ribbon cables or like structures

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/36—Assembling printed circuits with other printed circuits

- H05K3/361—Assembling flexible printed circuits with other printed circuits

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/09—Shape and layout

- H05K2201/09209—Shape and layout details of conductors

- H05K2201/09654—Shape and layout details of conductors covering at least two types of conductors provided for in H05K2201/09218 - H05K2201/095

- H05K2201/09745—Recess in conductor, e.g. in pad or in metallic substrate

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/10—Details of components or other objects attached to or integrated in a printed circuit board

- H05K2201/10613—Details of electrical connections of non-printed components, e.g. special leads

- H05K2201/10954—Other details of electrical connections

- H05K2201/10977—Encapsulated connections

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2203/00—Indexing scheme relating to apparatus or processes for manufacturing printed circuits covered by H05K3/00

- H05K2203/11—Treatments characterised by their effect, e.g. heating, cooling, roughening

- H05K2203/1189—Pressing leads, bumps or a die through an insulating layer

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/30—Assembling printed circuits with electric components, e.g. with resistor

- H05K3/303—Surface mounted components, e.g. affixing before soldering, aligning means, spacing means

- H05K3/305—Affixing by adhesive

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

- Y10T29/49117—Conductor or circuit manufacturing

- Y10T29/49124—On flat or curved insulated base, e.g., printed circuit, etc.

- Y10T29/49126—Assembling bases

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24802—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.]

- Y10T428/24843—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.] with heat sealable or heat releasable adhesive layer

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Adhesives Or Adhesive Processes (AREA)

- Combinations Of Printed Boards (AREA)

- Coupling Device And Connection With Printed Circuit (AREA)

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004201633A JP2006024751A (ja) | 2004-07-08 | 2004-07-08 | 平面多導体の接続方法及び該接続方法で接続される部分を含む電気電子部品 |

| EP05768133A EP1785017A1 (en) | 2004-07-08 | 2005-07-01 | Connection method of conductive articles, and electric or electronic component with parts connected by the connection method |

| PCT/US2005/023373 WO2006017037A1 (en) | 2004-07-08 | 2005-07-01 | Connection method of conductive articles, and electric or electronic component with parts connected by the connection method |

| KR1020077002798A KR20070033016A (ko) | 2004-07-08 | 2005-07-01 | 도전성 물품의 접속 방법, 및 이 접속 방법에 의해 접속된부품을 갖는 전기 또는 전자 성분 |

| US11/571,624 US20070224397A1 (en) | 2004-07-08 | 2005-07-01 | Connection Method of Conductive Articles, and Electric or Electronic Component with Parts Connected By the Connection Method |

| CNA2005800230784A CN1985553A (zh) | 2004-07-08 | 2005-07-01 | 连接导电制品的方法,和具有通过所述连接方法连接的部件的电气或电子元件 |

| TW094123255A TW200618703A (en) | 2004-07-08 | 2005-07-08 | Connection method of conductive articles, and electric or electronic component with parts connected by the connection method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004201633A JP2006024751A (ja) | 2004-07-08 | 2004-07-08 | 平面多導体の接続方法及び該接続方法で接続される部分を含む電気電子部品 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006024751A true JP2006024751A (ja) | 2006-01-26 |

| JP2006024751A5 JP2006024751A5 (enExample) | 2007-08-23 |

Family

ID=35797809

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004201633A Ceased JP2006024751A (ja) | 2004-07-08 | 2004-07-08 | 平面多導体の接続方法及び該接続方法で接続される部分を含む電気電子部品 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20070224397A1 (enExample) |

| EP (1) | EP1785017A1 (enExample) |

| JP (1) | JP2006024751A (enExample) |

| KR (1) | KR20070033016A (enExample) |

| CN (1) | CN1985553A (enExample) |

| TW (1) | TW200618703A (enExample) |

| WO (1) | WO2006017037A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008118091A (ja) * | 2006-10-10 | 2008-05-22 | Sumitomo Electric Ind Ltd | 配線板、配線板接続体および配線板モジュール |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4803350B2 (ja) * | 2005-06-03 | 2011-10-26 | 信越化学工業株式会社 | 圧着性異方導電性樹脂組成物及び微細電極の接続方法 |

| JP5186157B2 (ja) * | 2007-08-24 | 2013-04-17 | デクセリアルズ株式会社 | 異方性導電フィルム及びそれを用いた接続構造体の製造方法 |

| EP2192167A4 (en) * | 2007-09-19 | 2013-07-03 | Toray Industries | ADHESIVE COMPOSITION FOR ELECTRONIC COMPOSITIONS AND ADHESIVE FOR ELECTRONIC COMPOSITIONS THEREWITH |

| JP2009096851A (ja) * | 2007-10-15 | 2009-05-07 | Three M Innovative Properties Co | 非導電性接着剤組成物及び非導電性接着フィルム、並びにそれらの製造方法及び使用方法 |

| KR20090055673A (ko) * | 2007-11-29 | 2009-06-03 | 삼성전자주식회사 | 인쇄회로기판 조립체 및 그 제조방법 |

| JP2009188114A (ja) * | 2008-02-05 | 2009-08-20 | Three M Innovative Properties Co | フレキシブルプリント回路基板の接続方法及び当該方法で得られる電子機器 |

| JP5732631B2 (ja) | 2009-09-18 | 2015-06-10 | ボンドテック株式会社 | 接合装置および接合方法 |

| US20120257343A1 (en) * | 2011-04-08 | 2012-10-11 | Endicott Interconnect Technologies, Inc. | Conductive metal micro-pillars for enhanced electrical interconnection |

| WO2018022379A1 (en) | 2016-07-28 | 2018-02-01 | 3M Innovative Properties Company | Electrical cable |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0289026B1 (en) * | 1987-05-01 | 1994-12-28 | Canon Kabushiki Kaisha | External circuit connecting method and packaging structure |

| JP3231814B2 (ja) * | 1991-07-12 | 2001-11-26 | ミネソタ マイニング アンド マニュファクチャリング カンパニー | 異方性導電膜 |

| JP2937705B2 (ja) * | 1993-08-31 | 1999-08-23 | アルプス電気株式会社 | プリント配線板の接続方法 |

| JP2978390B2 (ja) * | 1993-12-16 | 1999-11-15 | 松下電器産業株式会社 | フレキシブルプリント基板と配線基板との接続体の製造方法 |

| US5936850A (en) * | 1995-03-03 | 1999-08-10 | Canon Kabushiki Kaisha | Circuit board connection structure and method, and liquid crystal device including the connection structure |

| US20010028953A1 (en) * | 1998-11-16 | 2001-10-11 | 3M Innovative Properties Company | Adhesive compositions and methods of use |

| JP2000204332A (ja) * | 1999-01-08 | 2000-07-25 | Minnesota Mining & Mfg Co <3M> | 熱剥離性接着剤組成物および接着構造体 |

| US6228500B1 (en) * | 1999-03-08 | 2001-05-08 | 3M Innovative Properties Company | Adhesive composition and precursor thereof |

| JP4201436B2 (ja) * | 1999-07-14 | 2008-12-24 | 日東電工株式会社 | 多層配線基板の製造方法 |

| JP2001107009A (ja) * | 1999-09-30 | 2001-04-17 | Three M Innovative Properties Co | 熱硬化性接着剤組成物及びそれを用いた接着構造 |

| US6520669B1 (en) * | 2000-06-19 | 2003-02-18 | Light Sciences Corporation | Flexible substrate mounted solid-state light sources for exterior vehicular lighting |

| US20050224978A1 (en) * | 2002-06-24 | 2005-10-13 | Kohichiro Kawate | Heat curable adhesive composition, article, semiconductor apparatus and method |

-

2004

- 2004-07-08 JP JP2004201633A patent/JP2006024751A/ja not_active Ceased

-

2005

- 2005-07-01 KR KR1020077002798A patent/KR20070033016A/ko not_active Withdrawn

- 2005-07-01 WO PCT/US2005/023373 patent/WO2006017037A1/en not_active Ceased

- 2005-07-01 EP EP05768133A patent/EP1785017A1/en not_active Withdrawn

- 2005-07-01 CN CNA2005800230784A patent/CN1985553A/zh active Pending

- 2005-07-01 US US11/571,624 patent/US20070224397A1/en not_active Abandoned

- 2005-07-08 TW TW094123255A patent/TW200618703A/zh unknown

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008118091A (ja) * | 2006-10-10 | 2008-05-22 | Sumitomo Electric Ind Ltd | 配線板、配線板接続体および配線板モジュール |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1985553A (zh) | 2007-06-20 |

| KR20070033016A (ko) | 2007-03-23 |

| EP1785017A1 (en) | 2007-05-16 |

| WO2006017037A1 (en) | 2006-02-16 |

| TW200618703A (en) | 2006-06-01 |

| US20070224397A1 (en) | 2007-09-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7888604B2 (en) | Connection method of a flexible printed circuit board with two printed circuit boards, and electric or electronic component with parts connected by the connection method | |

| JP2006245453A (ja) | フレキシブルプリント回路基板の他の回路基板への接続方法 | |

| KR20100044916A (ko) | 이방성 도전 필름 및 그것을 이용한 접속 구조체의 제조 방법 | |

| KR20100114111A (ko) | 연성 인쇄 회로 기판의 접속 방법 및 이에 의해 얻어진 전자 소자 | |

| WO2010137413A1 (ja) | 電極構造、配線体、接着剤接続構造、電子機器およびその組立方法 | |

| JP2006278014A (ja) | 異方導電性構造体 | |

| KR20190087365A (ko) | 실장체의 제조 방법, 접속 방법 및 이방성 도전막 | |

| JP2006024751A (ja) | 平面多導体の接続方法及び該接続方法で接続される部分を含む電気電子部品 | |

| KR100617410B1 (ko) | 열경화성 전기전도성 접착 시트, 이를 이용한 연결 구조체및 연결 방법 | |

| JP2006216758A (ja) | プリント回路基板の接続方法 | |

| KR102336897B1 (ko) | 실장체의 제조 방법 및 이방성 도전 필름 | |

| JP2008537288A (ja) | ケーブルハーネス体 | |

| JP4152196B2 (ja) | 平面多導体の接続方法、該接続方法で接続される部分を含む電気電子部品、該接続方法で接続される平面多導体、および、平面多導体の接続システム | |

| CN101529662A (zh) | 连接电路板的方法以及连接结构 | |

| CN100596262C (zh) | 用于相互连接电路板的方法 | |

| JP4653726B2 (ja) | フレキシブル配線板の接続構造およびフレキシブル配線板の接続方法 | |

| JP2006140052A (ja) | 熱硬化性接着フィルム付きコネクタ及びそれを用いた接続方法 | |

| JP2007243223A (ja) | 電子部品実装構造体 | |

| JP2009004603A (ja) | 基板の製造方法 | |

| JP2008147380A (ja) | プリント配線板の接続構造およびプリント配線板の接続方法 | |

| JP2008205206A (ja) | 配線板の接続構造および接続方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070706 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070706 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090120 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20090417 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20090422 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20091117 |

|

| A045 | Written measure of dismissal of application [lapsed due to lack of payment] |

Free format text: JAPANESE INTERMEDIATE CODE: A045 Effective date: 20100323 |