EP3257633B1 - Cloueur a air comprime comprenant une chambre de commande de securite - Google Patents

Cloueur a air comprime comprenant une chambre de commande de securite Download PDFInfo

- Publication number

- EP3257633B1 EP3257633B1 EP16174533.6A EP16174533A EP3257633B1 EP 3257633 B1 EP3257633 B1 EP 3257633B1 EP 16174533 A EP16174533 A EP 16174533A EP 3257633 B1 EP3257633 B1 EP 3257633B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- valve

- control

- piston

- nail gun

- control chamber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 claims description 8

- 230000008569 process Effects 0.000 claims description 7

- 230000004913 activation Effects 0.000 claims description 4

- 230000036316 preload Effects 0.000 claims 1

- 230000001960 triggered effect Effects 0.000 description 7

- 230000005540 biological transmission Effects 0.000 description 6

- 239000000523 sample Substances 0.000 description 4

- 238000009423 ventilation Methods 0.000 description 4

- 230000000903 blocking effect Effects 0.000 description 3

- 210000003746 feather Anatomy 0.000 description 3

- 238000013022 venting Methods 0.000 description 3

- 230000000694 effects Effects 0.000 description 2

- 230000000977 initiatory effect Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 101100390736 Danio rerio fign gene Proteins 0.000 description 1

- 101100390738 Mus musculus Fign gene Proteins 0.000 description 1

- 241000283984 Rodentia Species 0.000 description 1

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000001680 brushing effect Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 230000000994 depressogenic effect Effects 0.000 description 1

- 230000004941 influx Effects 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25C—HAND-HELD NAILING OR STAPLING TOOLS; MANUALLY OPERATED PORTABLE STAPLING TOOLS

- B25C1/00—Hand-held nailing tools; Nail feeding devices

- B25C1/008—Safety devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25C—HAND-HELD NAILING OR STAPLING TOOLS; MANUALLY OPERATED PORTABLE STAPLING TOOLS

- B25C1/00—Hand-held nailing tools; Nail feeding devices

- B25C1/04—Hand-held nailing tools; Nail feeding devices operated by fluid pressure, e.g. by air pressure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25C—HAND-HELD NAILING OR STAPLING TOOLS; MANUALLY OPERATED PORTABLE STAPLING TOOLS

- B25C1/00—Hand-held nailing tools; Nail feeding devices

- B25C1/04—Hand-held nailing tools; Nail feeding devices operated by fluid pressure, e.g. by air pressure

- B25C1/041—Hand-held nailing tools; Nail feeding devices operated by fluid pressure, e.g. by air pressure with fixed main cylinder

- B25C1/043—Trigger valve and trigger mechanism

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25C—HAND-HELD NAILING OR STAPLING TOOLS; MANUALLY OPERATED PORTABLE STAPLING TOOLS

- B25C1/00—Hand-held nailing tools; Nail feeding devices

- B25C1/04—Hand-held nailing tools; Nail feeding devices operated by fluid pressure, e.g. by air pressure

- B25C1/047—Mechanical details

Definitions

- the invention relates to a pneumatic nailer with a working piston, which is connected to a driving ram for driving a fastener and is applied to trigger a Eintreibvorgangs with compressed air, a triggering device having a manually actuable trigger and a touch sensor, wherein a joint actuation of trigger and embarksetzr a controls a first control valve and triggers a driving operation, if the pressure in a safety control chamber is above a predetermined pressure threshold, and a second control valve, which is actuated upon actuation of the trigger independently of an actuation of the Aufsetzrylers.

- the Aufsetztler is a mechanical component, which is usually held by a spring in a protruding over a neck tool of Druck Kunststoffnaglers position. If the compressed air bearing is attached to a workpiece, the touch sensor is displaced against the force of the spring until the muzzle tool rests against the workpiece or almost rests. Only with such actuated Aufsetzitchler a driving operation can be triggered. As a result, the known compressed air nailers offer a significantly improved security against unintentional release compared to devices without Aufsetzthler.

- Pneumatic nailer with a triggering device of the type described can be used in two different modes.

- the pneumatic nailer is first attached to a workpiece and thereby actuated the landing sensor. Subsequently, the trigger is actuated by hand, thereby triggering a single drive.

- the user In the so-called contact release, also referred to as touch, the user already holds the trigger while pressing the pneumatic nailer against the workpiece.

- the trigger When attaching to the workpiece of the touch sensor is actuated and thereby initiates a drive-in process.

- the compressed air nailer can be repeatedly set in rapid succession, which allows a very fast working, especially if many fasteners must be driven for a sufficient attachment to the positioning accuracy only small demands are made.

- the contact triggering procedure entails an increased risk of injury. For example, not only does the user depress the hand-operated trigger when he wants to place the pneumatic nailer on one and the same workpiece a few centimeters from the last driven fastener, but also when changing to another remotely located workpiece in an accidental contact of an object or body part with the Aufsetzrler a driving operation are triggered. For example, accidents can occur when a user (in disregard of important safety regulations) climbs a ladder with the pneumatic nailer while holding the trigger and accidentally brushing his leg with the touch probe.

- the pneumatic rodger is used to drive fasteners such as nails, pins or staples.

- the pneumatic nailer can have a magazine for the fastening means, from which in each case a fastening means is supplied to a receptacle of a necking tool of the pneumatic nailer.

- venting is always meant that a connection to a non-pressurized space, in particular to the outside air, is produced.

- ventilation is always meant that a connection is made to a compressed air leading room.

- a working piston of the pneumatic nailer When initiating a driving operation, a working piston of the pneumatic nailer is pressurized with compressed air.

- the working piston drives a Eintreibst Schemeel, which is connected to the working piston.

- the drive ram strikes a rear end of the fastener in the receptacle of the muzzle tool and drives the fastener into the workpiece.

- the triggering device has a hand-operated trigger, for example in the form of a tilt or push button, and a touch sensor.

- the touch sensor may be a mechanical component that projects beyond the front end of the muzzle tool and is held in this position by a spring until the pneumatic nailer is attached to a workpiece. Then the Aufsetzterler is displaced against the direction of the spring force and against the driving direction. If this actuation of the touch probe together with an actuation of the trigger, a first control valve is actuated, whereby a driving operation can be triggered.

- the first control valve With a common actuation of trigger and Aufsetzr the first control valve is activated. If only one of the manually actuable release and the touch sensor is actuated, the first control valve will not be actuated. For a joint actuation of trigger and embarksetzr it is sufficient if both the trigger and the touch sensor at a certain time both at the same time in the actuated state. This can be achieved on the one hand by a simultaneous operation, but also in any order. For example can, as is typical for a single triggering, first the touch sensor be actuated and then the hand-actuated trigger. In contact tripping operation, however, the hand-actuated trigger and then the touch sensor can be operated first.

- the control of the first control valve can be achieved by a mechanical coupling of the manually operated release and the Aufsetzterlers.

- a control pin of the first control valve can only be displaced when the trigger and the touch sensor are actuated together, and the first control valve can thereby be activated.

- the actuation of the first control valve triggers a drive-in operation if the pressure in the safety control chamber is above a predetermined pressure threshold. Otherwise, when driving the first control valve no drive-in process is triggered.

- the second control valve is actuated upon actuation of the manually operable trigger independently of an actuation of the Aufsetzterlers.

- the second control valve is thus activated with each actuation of the trigger.

- a control pin of the second control valve may be arranged so that it is displaced from its rest position with each actuation of the trigger.

- the safety control chamber is vented independently of the position of the second control valve continuously via a throttle and separated when controlling the second control valve of a pressurized housing interior.

- the safety control chamber In an initial state of the pneumatic nailer, the safety control chamber is connected to the pressurized housing interior.

- initial state is always meant a state in which the pneumatic nailer is connected to a compressed air supply and neither the touch sensor nor the trigger are actuated.

- the safety control chamber becomes continuous vented via the throttle.

- the air flow escaping through the throttle is no longer compensated by flowing from the housing interior into the safety control chamber air and the pressure in the safety control chamber falls within a certain time the predetermined pressure threshold, so that further triggering is no longer possible.

- the throttle or a line connecting the throttle with the outside air can be arranged in particular and a flow of air which escapes via the throttle can be dimensioned so that the air escaping via the throttle causes a perceptible operating noise for a user.

- This operating noise indicates the correct functioning of the safety device and the ready-to-fire status of the device: If a malfunction occurs, for example if the throttle is soiled, the operating noise will change or become dull. If the operating sound is silenced when the trigger is depressed as a result of the pressure loss in the safety control chamber, this indicates to a user that further drive-in operations can not be triggered until the pressure in the safety control chamber has been restored by releasing the trigger.

- the safety control chamber is vented when the trigger is not actuated via the second control valve.

- a direct connection between the safety control chamber and a housing interior under pressure is produced via the second control valve, which leads to an instantaneous ventilation of the safety control chamber.

- the pneumatic nailer is located Therefore, after releasing the trigger within a very short time again in a ready shot initial state.

- the throttle is connected to a line which connects the second control valve with the safety control chamber.

- the throttle may be in any connection between the safety control chamber and outside air.

- the arrangement of the provided for the ventilation of the safety control chamber via the second control valve line allows a particularly simple, compact design.

- the first control valve, the second control valve and the throttle are combined in a valve block. This measure also serves a simple and compact construction.

- the pressure in the safety control chamber acts on a safety valve piston of a safety valve which shuts off a line which is vented or vented when the first control valve is actuated.

- the safety control chamber can be connected via a line with a working volume of the safety valve or it can form this working volume.

- the pressure in the safety control chamber can in particular press the safety valve piston in one direction, which corresponds to an open position of the safety valve.

- a spring biases the safety valve piston against the pressure in the safety control chamber.

- the position of the safety valve therefore results from the interaction of the spring force and the pressure exerted by the pressure in the safety control chamber on the safety valve piston force. It can therefore be adjusted by tuning the spring to the effective cross section of the safety valve piston exactly specify up to what pressure in the safety control chamber the safety valve remains in its open position.

- the pneumatic nailer has a pilot valve with a control piston, wherein the control piston and the safety valve piston are arranged along a common longitudinal axis.

- the pilot valve is used to control a main valve of the pneumatic nailer, via which the working piston is ventilated. Said arrangement of control piston and safety valve piston allows a particularly easy to manufacture, compact design of the pneumatic nailer.

- control piston and the safety valve piston are arranged laterally of the working cylinder.

- common axis of the control piston and safety valve piston can be aligned parallel to a longitudinal axis of the working cylinder.

- an opening cross-section of the throttle is dimensioned such that during operation of the pneumatic nailer with a designated operating pressure of the pressure in the safety control chamber falls below the predetermined pressure threshold in a period of 0.1 s to 10 s after activation of the second control valve.

- the pressure threshold can be exceeded in a period between 1 s and 5 s after activation of the second control valve, for example after approximately 4 s.

- the opening cross-section of the throttle can be adjustable, so that the period can be individually regulated. Preferably, this regulation takes place only once by the manufacturer of the pneumatic nailer and can only be changed by impermissible manipulation by a user. In any case, the pneumatic nailer is locked in time to prevent in many typical application situations a driving operation as a result of unintentional actuation of the Aufsetznchlers.

- the pneumatic nailer on a check valve via which the safety control chamber is vented when triggering a Eintreibvorgangs.

- the initial state is restored upon initiation of a driving operation with respect to the pressure in the safety control chamber. This can happen very fast. If, after the drive-in operation, the trigger is still kept pressed, the pressure in the safety control chamber approaches in the previously described manner again the pressure threshold, which is undershot after the predetermined period of time. Until then, a further release by pressing the Aufsetztlers is possible at any time, so that the Druck Kunststoffnagler is suitable without restriction for fast successive Eintreibvor réellen in the contact triggering process.

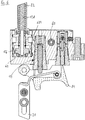

- the pneumatic nailer 10 has a handle 12 which is fixed to a lower housing part 140, which is closed at the top by a housing cap 142.

- the manually operable trigger 14 is pivotally mounted about a pivot axis 16 on the housing of the pneumatic nailer 10 and arranged so that it can be easily operated by a user who holds the pneumatic nailer 10 on the handle 12 with the index finger.

- a button 18 located at the top of the trigger 14 engages a switching pin 20 of a second control valve 22, displaces the switching pin 20 upwardly and thereby controls the second control valve 22. Since this activation of the second control valve 22 is effected directly by the button 18 fixedly arranged on the trigger 14, it takes place independently of the actuation of a touch sensor 24.

- the Aufsetztler 24 is about the mouth 26 of a muzzle tool 28 by a few millimeters down over. If the pneumatic nailer 10 is attached to a workpiece, the Aufsetzmeler 24 is displaced upward against the force of a spring, not shown, until it is flush with the mouth 26 or only slightly beyond the mouth 26.

- the touch sensor 24 is mechanically coupled to a power transmission element 30, which moves with the movement of the Aufsetzmelers 24 upwards.

- the power transmission element 30 is movably guided on the housing of the pneumatic nailer 10 and for this purpose has a slot 32, through which a guide pin 98 is passed.

- the force transmission element 30 moves from the initial position drawn upwards and takes with a fixed to the force transmission element 30 stop pin 34, the free end of a lever 36, the fixed end pivotable about a pivot axis 38 in the interior of the trigger 14th and hinged near its free end.

- the lever 36 is then disposed approximately parallel to a longitudinal direction of the trigger 14 and its upper surface acts as a button 40 which, upon joint actuation of the touch sensor 24 and the trigger 14, displaces a switching pin 42 of a first control valve 44 upwardly and thus drives the first control valve 44 ,

- the mouth tool 28 has a receptacle 46, to which a fastening means is supplied from a magazine 48 in each case. From this position within the receptacle 46, the fastening means - for example, a nail, a pin or a clip - by a driving ram 50, which is connected to a working piston 52 of the pneumatic nailer 10, driven.

- the working piston 52 is guided in a working cylinder 54. Above the working cylinder 54 and this sealingly closing a main valve 56 is arranged, to the right thereof a pilot valve 58 which controls the main valve 56. Details of these elements and the associated function of the device are based on the enlarged detail of the FIG. 2 explained in more detail.

- the pilot valve 58 is best in the FIG. 2 recognizable. It has a control piston 94, which is guided in a guide sleeve 96. The lower end of the control piston 94 is sealed with a lower O-ring 100 opposite the guide sleeve 96.

- a first control line 82 which is connected to a working volume of the pilot valve 58, vented and the control piston 94 is in the lower position shown. In this position, it is held by the force of a spring 102.

- the spool 94 has a middle O-ring 104 and an upper O-ring 106 in addition to the lower O-ring 100.

- the upper O-ring 106 seals the control piston 94 against the guide sleeve 96 and closes a connection to a vent not shown, which is connected to outside air.

- the middle O-ring 104 is not in seal, so that a main control line 110 is connected via a radial bore 112 in the guide sleeve 96 and the annular gap 70 between the control piston 94 and guide sleeve 96 on the middle O-ring 104 past the housing interior 64.

- the main control line 110 is connected via a not visible in the sectional plane shown connection with the space 72, which opens into the radial bore 112.

- the housing interior 64 is in the initial state of the pneumatic nailer 10 ventilated, that is connected to a compressed air connection, not shown, and standing under operating pressure.

- the main control line 110 is connected to a space 114 above a main valve actuator 116 of the main valve 56, so that the main valve actuator 116 is acted upon by a downward force and thereby the upper edge of the working cylinder 54 by means of an O-ring 118 relative to the housing interior 64th seals.

- the main valve actuator 116 is acted upon by a spring 120 with a force in the direction of the shown, the working cylinder 54 occluding position.

- a drive-in operation is initiated by venting the first control line 82 by displacing the control piston 94 upwardly so that the middle O-ring 104 enters the seal and the upper O-ring 106 moves out of the seal.

- the connection of the main control line 110 is shut off to the housing interior 64 and a connection between the main control line 110 and a vent not shown is made.

- the space 114 above the main valve actuator 116 is vented through the vent and the main valve actuator 116 is displaced upward by the pressure prevailing at its lower, outer annular surface 122 in the housing interior 64 against the force of the spring 120.

- compressed air flows from the housing interior 64 into the working cylinder 54 above the working piston 52 and drives the working piston 52 downwards.

- the driving ram 50 connected to the working piston 52 drives a fastening means.

- FIG. 1 Below the pilot valve 58 is a safety valve 124 with a safety valve piston 126 which cooperates with a safety control chamber 62 and a throttle 60. Details of these elements and the associated function of the device are based on the FIGS. 3 to 6 explained in more detail.

- FIG. 3 the manually operated trigger 14 with the lever 36 and the button 18 mounted therein is clearly visible.

- the switching pin 20 of the second control valve 22 is guided in a sleeve 66 of the second control valve 22 which is inserted into the housing and sealed relative thereto.

- a second control line not visible in the sectional planes of the figures, connects a radial bore 68 in the sleeve 66 to the safety control chamber 62.

- An upper O-ring 74 of the second control valve 22 is not in sealing so that the radial bore 68 engages with the Housing interior 64 is connected. Therefore, the safety control chamber 62 is in the in the Fig. 3 vented initial state shown.

- a throttle 60 is connected to the second control line, not shown, which connects the second control line and thus the safety control chamber 62 with outside air. In the initial state, air continuously flows out via the throttle 60, causing an operating noise perceptible to a user.

- the pressure in the safety control chamber 62 acts on the underside of the safety valve piston 126 and holds the safety valve piston 126 against the force of a spring 128 in the upper position shown.

- the safety valve piston 126 is guided in a sleeve 80 and has an upper O-ring 138 which is not in the position shown in seal. Therefore, the first control line 82, within the in the FIG. 3 the spring 128 is arranged, connected via an annular gap 130 and a radial bore 132 in the sleeve 80 with an obliquely arranged, third control line 134.

- the switching pin 42 of the first control valve 44 is guided in a sleeve 76 which has a radial bore 78 connected to the third control line 134.

- An upper O-ring 90 on the valve pin 42 seals against the sleeve 76; a lower O-ring 88 on the valve pin 42 is not in seal. That is why the radial Bore 78 and thus the third control line 134 via an annular gap 84 vented.

- the housing interior 64 is separated from the radial bore 78 by the upper O-ring 90.

- the first control valve 44, the second control valve 22 and the throttle 60 are combined in a common valve block 148.

- FIG. 4 shows the arrangement Fig. 3 immediately after the actuation of the trigger 14.

- the control pin 20 is in an upper position and the second control valve 22 shuts off the connection between the housing interior 64 and the second control line, not shown, because the upper O-ring 74 seals against the sleeve 66 , Thereby, the influx of air into the safety control chamber 62 is shut off and the safety control chamber 62 is vented slowly via the throttle 60.

- the second control valve 22 has two further O-rings 86, which seal the control pin 20 relative to the sleeve 66 in the two end positions of the control pin 20.

- the spaces outside of the two further O-rings 86 are connected to one another via a bypass line 92 running in the interior of the control pin 20.

- the bypass line 92 has two radial bores and an axial bore extending therebetween.

- the ventilation of the first control line 82 also has the effect that air passes through an axial bore 136 and a radial bore 144 in the safety valve piston 126 to the inside of an O-ring 146 which is inserted into a circumferential groove of the control piston 126 and a Forming check valve that leads into the safety control chamber 62.

- the check valve opens so that the safety control chamber 62 is vented due to the driving operation. The time within which further driving operations are possible by means of contact triggering begins again to run.

- FIG. 6 shows a locked state of the Druck Kunststoffnaglers 10, starting from the FIG. 4 , so when pressed trigger 14, automatically after a certain period of inactivity results, for example, after about 4 s.

- the pressure in the safety control chamber 62 has dropped below the predetermined pressure threshold due to the air escaping via the throttle 60, so that the safety valve piston 126 has moved downward due to the force of the spring 128, ie the safety valve 124 is in a blocking position in which the connection between the third control line 134 and the first control line 82 is shut off.

- the touch sensor 24 is actuated and the first control valve 44 is activated, the ventilation of the third control line 134 remains without consequences.

- a drive-in process can only be triggered again when the pressure in the safety control chamber 62 is restored. This is possible at any time by briefly releasing the trigger 14.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Portable Nailing Machines And Staplers (AREA)

Claims (10)

- Cloueur à air comprimé (10) avec• un piston de travail (25), qui est relié à un poussoir (50) pour pousser un moyen de fixation en bas et est pressurisé par air quand un procédé de pousse est enclenché,• un dispositif de déclenchement, qui comporte un déclencheur à main (14) et un capteur de contact (24), dans lequel un actionnement simultané du déclencheur (14) et du capteur de contact (24) commande une première vanne de commande (44) et déclenche un procédé de pousse au cas ou la pression dans une chambre de commande de sécurité (62) est au-dessus d'un seuil de pression donné, et• une deuxième vanne de commande (22), qui est commandée lors d'un actionnement du déclencheur (14), n'importe si le capteur de contact (24) soit actionné ou non,• caractérisé en ce que n'importe quelle soit la position de la deuxième vanne de commande (22), la chambre de commande de sécurité (62) est continûment désaérée à travers un étrangleur (60) et est séparée d'un intérieur de boîtier pressurisé (64) quand la deuxième vanne de commande (22) est commandée.

- Cloueur à air comprimé (10) selon la revendication 1, caractérisé en ce que la chambre de commande de sécurité (62) est désaérée à travers la deuxième vanne de commande (22) quand le déclencheur (14) n'a pas été actionné.

- Cloueur à air comprimé (10) selon la revendication 1 ou 2, caractérisé en ce que l'étrangleur (60) est relié á une ligne qui relie la deuxième vanne de commande (22) et la chambre de commande de sécurité (62).

- Cloueur à air comprimé (10) selon l'une quelconque des revendications 1 à 3, caractérisé en ce que la première vanne de commande (44), la deuxième vanne de commande (22) et l'étrangleur (60) sont combinés dans un bloc de vanne (148).

- Cloueur à air comprimé (10) selon l'une quelconque des revendications 1 à 4, caractérisé en ce que la pression dans la chambre de commande de sécurité (62) agît sur un piston de soupape de sécurité (126) d'une soupape de sécurité (124), qui ferme une ligne qui est aérée ou désaérée quand la première vanne de commande (44) est commandée.

- Cloueur à air comprimé (10) selon la revendication 5, caractérisé par un ressort (128), qui précontraint le piston de la soupape de sécurité (124) contre la pression dans la chambre de commande de sécurité (62).

- Cloueur à air comprimé (10) selon la revendication 6, caractérisé en ce que le cloueur à air comprimé (10) comporte une vanne pilote (58) avec un piston de commande (94), le piston de commande (94) et le piston de la soupape de sécurité (126) étant arrangés le long d'un axe longitudinal commun.

- Cloueur à air comprimé (10) selon la revendication 7, caractérisé en ce que le piston de commande (94) et le piston de la soupape de sécurité (126) sont arrangés latéralement au piston de travail (54).

- Cloueur à air comprimé (10) selon l'une quelconque des revendications 1 à 8, caractérisé en ce que une section d'ouverture de l'étrangleur (60) est dimensionnée tellement que dans l'opération du cloueur à air comprimé (10) avec une pression de travail prévue pour cela, la pression dans la chambre de commande de sécurité (62) devient plus basse que le seuil de pression dans une période de 0,1 s à 10 s après la commande de la deuxième vanne de commande (22).

- Cloueur à air comprimé (10) selon l'une quelconque des revendications 1 à 9, caractérisé par un clapet anti-retour à travers duquel la chambre de commande de sécurité (62) est aérée quand un procédé de pousse est déclenché.

Priority Applications (10)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP16174533.6A EP3257633B1 (fr) | 2016-06-15 | 2016-06-15 | Cloueur a air comprime comprenant une chambre de commande de securite |

| ES16174533T ES2704139T3 (es) | 2016-06-15 | 2016-06-15 | Remachadora de aire comprimido con cámara de control de seguridad |

| PCT/EP2017/061603 WO2017215860A1 (fr) | 2016-06-15 | 2017-05-15 | Cloueuse pneumatique à chambre de commande de sécurité |

| JP2018564360A JP6806802B2 (ja) | 2016-06-15 | 2017-05-15 | 安全制御チャンバ付き空気圧式ネイルガン |

| RU2018145827A RU2706905C1 (ru) | 2016-06-15 | 2017-05-15 | Пневматический гвоздезабивной пистолет с предохранительной камерой |

| CN201780047677.2A CN109843512B (zh) | 2016-06-15 | 2017-05-15 | 具有安全控制腔室的气动钉枪 |

| AU2017284889A AU2017284889B2 (en) | 2016-06-15 | 2017-05-15 | Pneumatic nail gun with safety control chamber |

| BR112018075768-3A BR112018075768A2 (pt) | 2016-06-15 | 2017-05-15 | pistola de pregos pneumática com câmara de controle de segurança |

| US16/310,006 US11103986B2 (en) | 2016-06-15 | 2017-05-15 | Pneumatic nail gun with safety control chamber |

| TW106117028A TWI686274B (zh) | 2016-06-15 | 2017-05-23 | 具有安全控制腔室的氣動釘槍 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP16174533.6A EP3257633B1 (fr) | 2016-06-15 | 2016-06-15 | Cloueur a air comprime comprenant une chambre de commande de securite |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3257633A1 EP3257633A1 (fr) | 2017-12-20 |

| EP3257633B1 true EP3257633B1 (fr) | 2018-10-17 |

Family

ID=56134192

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16174533.6A Active EP3257633B1 (fr) | 2016-06-15 | 2016-06-15 | Cloueur a air comprime comprenant une chambre de commande de securite |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US11103986B2 (fr) |

| EP (1) | EP3257633B1 (fr) |

| JP (1) | JP6806802B2 (fr) |

| CN (1) | CN109843512B (fr) |

| AU (1) | AU2017284889B2 (fr) |

| BR (1) | BR112018075768A2 (fr) |

| ES (1) | ES2704139T3 (fr) |

| RU (1) | RU2706905C1 (fr) |

| TW (1) | TWI686274B (fr) |

| WO (1) | WO2017215860A1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3666469A1 (fr) | 2018-12-12 | 2020-06-17 | Joh. Friedrich Behrens AG | Cloueur pneumatique doté d'un dispositif de sécurité |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| PL3446833T3 (pl) | 2017-08-23 | 2020-10-19 | Joh. Friedrich Behrens Ag | Gwoździarka pneumatyczna z układem zaworu bezpieczeństwa |

| TWI744560B (zh) * | 2017-11-02 | 2021-11-01 | 鑽全實業股份有限公司 | 氣壓式釘槍及其撞針裝置 |

| EP4140651A1 (fr) | 2018-07-18 | 2023-03-01 | Milwaukee Electric Tool Corporation | Pilote d'impulsion |

| TW202007497A (zh) * | 2018-08-06 | 2020-02-16 | 日商工機控股股份有限公司 | 釘打機 |

| TWI808135B (zh) * | 2019-03-06 | 2023-07-11 | 鑽全實業股份有限公司 | 電動釘槍 |

| US11491623B2 (en) | 2019-10-02 | 2022-11-08 | Illinois Tool Works Inc. | Fastener driving tool |

| TWI734418B (zh) * | 2020-03-18 | 2021-07-21 | 力肯實業股份有限公司 | 氣動釘槍的氣路結構 |

| TWI734417B (zh) * | 2020-03-18 | 2021-07-21 | 力肯實業股份有限公司 | 氣動釘槍的氣路結構 |

| WO2022067235A1 (fr) | 2020-09-28 | 2022-03-31 | Milwaukee Electric Tool Corporation | Dispositif d'entraînement à impulsions |

| TWI771006B (zh) * | 2021-05-18 | 2022-07-11 | 力肯實業股份有限公司 | 氣動釘槍的氣路結構 |

| CN114750112B (zh) * | 2022-04-22 | 2023-03-24 | 四川轻化工大学 | 一种双气缸打钉方法 |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1226837A (fr) * | 1967-07-13 | 1971-03-31 | ||

| US3685396A (en) * | 1970-06-15 | 1972-08-22 | Fastener Corp | Fastener driving tool |

| SU895646A2 (ru) * | 1980-04-11 | 1982-01-07 | Всесоюзный Проектно-Технологический Институт По Электробытовым Машинам И Приборам | Пневматический пистолет дл забивки гвоздей |

| DE3142237A1 (de) * | 1981-10-24 | 1983-05-05 | Signode Corp., Glenview, Ill. | Pneumatisch betaetigbares befestigungsmitteleintreibgeraet |

| SU1066798A2 (ru) * | 1982-10-11 | 1984-01-15 | Всесоюзный Проектно-Технологический Институт По Электробытовым Машинам И Приборам | Пневматический пистолет дл забивки гвоздей |

| JPH0632308Y2 (ja) * | 1988-11-17 | 1994-08-24 | マックス株式会社 | 空気圧式釘打機 |

| DE9216386U1 (de) * | 1992-12-02 | 1993-02-11 | Joh. Friedrich Behrens AG, 2070 Ahrensburg | Steuerventileinrichtung |

| US5522532A (en) * | 1995-03-14 | 1996-06-04 | Testo Industry Corp. | Single-shooting/continuous-shooting control switch for penumatic nail guns |

| EP2161103A1 (fr) * | 2008-09-07 | 2010-03-10 | Josef Kihlberg AB | Outil de scellement pneumatique |

| TWI404603B (zh) * | 2009-04-03 | 2013-08-11 | Basso Ind Corp | 具擊發保險裝置之打釘槍 |

| US20100301091A1 (en) * | 2009-06-01 | 2010-12-02 | Chia-Sheng Liang | Linkage Mechanism between Trigger Valve and Control Valve in Pneumatic Nail Guns |

| DE102010022179A1 (de) * | 2010-05-21 | 2011-11-24 | Prebena Wilfried Bornemann Gmbh & Co. Kg | Druckmindervorrichtung sowie Druckluftverteiler mit einer Druckmindervorrichtung |

| PL2767365T3 (pl) | 2013-02-19 | 2017-07-31 | Joh. Friedrich Behrens Ag | Gwoździarka pneumatyczna z ręcznie uruchamianym spustem i czujnikiem przyłożenia |

| DE102013106657A1 (de) * | 2013-06-25 | 2015-01-08 | Illinois Tool Works Inc. | Eintreibwerkzeug zum Eintreiben von Befestigungsmitteln in ein Werkstück |

| TWM473908U (zh) * | 2013-10-04 | 2014-03-11 | Basso Ind Corp | 氣動釘槍之壓源控制裝置 |

-

2016

- 2016-06-15 EP EP16174533.6A patent/EP3257633B1/fr active Active

- 2016-06-15 ES ES16174533T patent/ES2704139T3/es active Active

-

2017

- 2017-05-15 JP JP2018564360A patent/JP6806802B2/ja active Active

- 2017-05-15 CN CN201780047677.2A patent/CN109843512B/zh active Active

- 2017-05-15 RU RU2018145827A patent/RU2706905C1/ru active

- 2017-05-15 WO PCT/EP2017/061603 patent/WO2017215860A1/fr active Application Filing

- 2017-05-15 US US16/310,006 patent/US11103986B2/en active Active

- 2017-05-15 BR BR112018075768-3A patent/BR112018075768A2/pt not_active Application Discontinuation

- 2017-05-15 AU AU2017284889A patent/AU2017284889B2/en active Active

- 2017-05-23 TW TW106117028A patent/TWI686274B/zh active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3666469A1 (fr) | 2018-12-12 | 2020-06-17 | Joh. Friedrich Behrens AG | Cloueur pneumatique doté d'un dispositif de sécurité |

Also Published As

| Publication number | Publication date |

|---|---|

| US20190134795A1 (en) | 2019-05-09 |

| CN109843512A (zh) | 2019-06-04 |

| AU2017284889A1 (en) | 2019-01-17 |

| EP3257633A1 (fr) | 2017-12-20 |

| BR112018075768A2 (pt) | 2019-03-26 |

| RU2706905C1 (ru) | 2019-11-21 |

| US11103986B2 (en) | 2021-08-31 |

| JP2019522571A (ja) | 2019-08-15 |

| JP6806802B2 (ja) | 2021-01-06 |

| ES2704139T3 (es) | 2019-03-14 |

| WO2017215860A1 (fr) | 2017-12-21 |

| AU2017284889B2 (en) | 2022-04-14 |

| CN109843512B (zh) | 2022-09-06 |

| TWI686274B (zh) | 2020-03-01 |

| TW201800191A (zh) | 2018-01-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3257633B1 (fr) | Cloueur a air comprime comprenant une chambre de commande de securite | |

| EP2767365B1 (fr) | Cloueur à air comprimé avec déclencheur manuel et capteur de contact | |

| EP3446833B1 (fr) | Cloueur à air comprimé pourvu de dispositif de soupape de sécurité | |

| DE1703110C3 (de) | Druckluftwerkzeug, insbesondere Druckluftnagler | |

| DE2400672C3 (de) | Aufsetzsicherung für Druckluftnagler | |

| DE3014803C2 (de) | Druckluftnagler | |

| DE2131752C3 (de) | Aufsetzsicherung an einem Druckluftnagler | |

| DE60214540T2 (de) | Nietsetzwerkzeug mit schnellverbindungs-nasengehäuse | |

| EP3703911B1 (fr) | Cloueur à air comprimé pourvu d'un système de soupape de sécurité | |

| EP3666469B1 (fr) | Cloueur pneumatique doté d'un dispositif de sécurité | |

| EP3471921B1 (fr) | Cloueur a air comprime comprenant un declenchement sequentiel et par contact | |

| DE2604287A1 (de) | Vorrichtung zum eintreiben von befestigungsmitteln | |

| EP3697573B1 (fr) | Clouseuse à air comprimé pourvue d'un actionneur de sécurité | |

| DE202013001537U1 (de) | Druckluftnagler mit einem handbetätigbaren Auslöser und einem Aufsetzfühler | |

| DE3100703C2 (de) | Sicherheitsvorrichtung für einen pneumatisch oder elektrisch betriebenen Nagler | |

| CH632940A5 (en) | Compressed air blower gun | |

| DE1298057B (de) | Ventilanordnung fuer die Druckluftzufuhr zu einem Druckluftnagler | |

| DE1902196C3 (de) | Aufsetzsicherung an einem Druckluftnagler | |

| DE19804456C1 (de) | Auslösegesichertes Eintreibgerät für Befestigungsmittel | |

| EP3760379B1 (fr) | Cloueur pneumatique doté d'un dispositif de sécurité | |

| DE102011123106B3 (de) | Blindnietgerät | |

| DE202018105352U1 (de) | Sicherheitsvorschaltgerät für ein druckluftbetriebenes Gerät | |

| DE202012101490U1 (de) | Nietsetzgerät mit Ventilmodul | |

| DE2166127C3 (de) | Druckluftbetriebenes Eintreibwerkzeug | |

| DE202013002056U1 (de) | Druckluftnagler und Umrüstsatz zur Umrüstung eines Druckluftnaglers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20171215 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20180405 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502016002217 Country of ref document: DE Ref country code: AT Ref legal event code: REF Ref document number: 1053433 Country of ref document: AT Kind code of ref document: T Effective date: 20181115 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20181017 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2704139 Country of ref document: ES Kind code of ref document: T3 Effective date: 20190314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190117 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190217 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190118 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190217 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502016002217 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 |

|

| 26N | No opposition filed |

Effective date: 20190718 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190630 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190615 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190630 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20160615 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502016002217 Country of ref document: DE Owner name: BEA GMBH, DE Free format text: FORMER OWNER: JOH. FRIEDRICH BEHRENS AG, 22926 AHRENSBURG, DE Ref country code: DE Ref legal event code: R082 Ref document number: 502016002217 Country of ref document: DE Representative=s name: COHAUSZ & FLORACK PATENT- UND RECHTSANWAELTE P, DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181017 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1053433 Country of ref document: AT Kind code of ref document: T Effective date: 20210615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210615 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230515 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20230608 AND 20230614 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20230622 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20230726 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A Owner name: BEA GMBH Effective date: 20240510 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240620 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240619 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20240619 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20240620 Year of fee payment: 9 |