EP1993786B1 - Meule d'ebarbage fine, utilisation de cette meule et procede pour la fabriquer. - Google Patents

Meule d'ebarbage fine, utilisation de cette meule et procede pour la fabriquer. Download PDFInfo

- Publication number

- EP1993786B1 EP1993786B1 EP07731681A EP07731681A EP1993786B1 EP 1993786 B1 EP1993786 B1 EP 1993786B1 EP 07731681 A EP07731681 A EP 07731681A EP 07731681 A EP07731681 A EP 07731681A EP 1993786 B1 EP1993786 B1 EP 1993786B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- wheel

- layers

- abrasive grains

- layer

- grinding wheel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Revoked

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D5/00—Bonded abrasive wheels, or wheels with inserted abrasive blocks, designed for acting only by their periphery; Bushings or mountings therefor

- B24D5/12—Cut-off wheels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D13/00—Wheels having flexibly-acting working parts, e.g. buffing wheels; Mountings therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D13/00—Wheels having flexibly-acting working parts, e.g. buffing wheels; Mountings therefor

- B24D13/02—Wheels having flexibly-acting working parts, e.g. buffing wheels; Mountings therefor acting by their periphery

- B24D13/08—Wheels having flexibly-acting working parts, e.g. buffing wheels; Mountings therefor acting by their periphery comprising annular or circular sheets packed side by side

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D18/00—Manufacture of grinding tools or other grinding devices, e.g. wheels, not otherwise provided for

- B24D18/0009—Manufacture of grinding tools or other grinding devices, e.g. wheels, not otherwise provided for using moulds or presses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D18/00—Manufacture of grinding tools or other grinding devices, e.g. wheels, not otherwise provided for

- B24D18/0045—Manufacture of grinding tools or other grinding devices, e.g. wheels, not otherwise provided for by stacking sheets of abrasive material

Definitions

- the present invention relates to a grinding wheel, and possibly cutting, in disk form, according to the preamble of claim 1.

- This standard defines in particular essential criteria for the production of deburring wheels, corresponding to the types referenced 27, 28 and 29 in this standard.

- a grinding wheel must imperatively have a thickness of between 4 and 10 mm, as illustrated in the document EP 1543923 on which the preamble of claim 1 is based.

- the present invention thus relates in its broadest sense to a grinding wheel, according to claim 1 characterized in that the working area has a total thickness of less than 4 mm and preferably less than or equal to 3.2 mm.

- This thickness is measurable over the entire width and the entire length of the work area.

- the wheel according to the invention has at least two adjacent working areas and preferably three working areas adjacent two by two.

- These working areas are preferably substantially perpendicular two by two.

- the grinding wheel according to the invention may in particular have a thickness greater than 2.5 mm or 3.2 mm.

- At least one outer layer containing no abrasive grains, or even the two outer layers containing no abrasive grains has (a) diameter smaller than the total diameter of the grinding wheel.

- the term "slab” designates a constituent layer formed from abrasive grains which has a consistency such that the slab can be handled, and in particular seized and moved by hand or by using a machine.

- This slab may therefore consist of a single layer formed from abrasive grains or may comprise on one side a layer containing no grains, abrasives.

- working sector designates a surface of the grinding wheel in contact with which it is possible to deburr.

- the passage time at each subsequent station can be significantly reduced since it no longer depends on the duration of operations. discharge of the powdered product or pressing under high pressure. In addition, the pressure used can be reduced.

- the present invention also relates to the use of a grinding wheel according to the invention, to perform a deburring operation.

- the grinding wheel according to the invention can be used for deburring, as well as possibly for cutting.

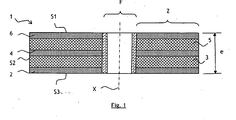

- the figure 1 illustrates a grinding wheel (1) according to the invention.

- This grinding wheel (1) has a general disk shape and thus has a central axis X, a central fixing zone F and at least one peripheral working zone Z extending externally to the central fixing zone with respect to the axis central.

- the attachment zone consists of a metal washer and allows the fixing of the wheel on a hub of a grinding machine.

- This washer may not be flat to allow to achieve a wheel with a offset.

- the grinding wheel has two layers (3, 5) formed from abrasive grains.

- the layers not containing abrasive grains (2, 4, 6) are, for example, glass fiber grids coated with phenolic resin.

- Different grammages may be used for the fiberglass grid, for example from 75 to 420 grams per square meter.

- a sheet of paper can also be glued to one or both of the outer surfaces of the grinding wheel.

- an outer layer or even the two outer layers not containing abrasive grains (2, 6) to have a diameter smaller than the total diameter of the grinding wheel, and to have a diameter reduced from about 2 to 50 mm.

- the layers (3, 5) are formed from abrasive grains which consist, for example, mainly of Alumina (Al 2 O 3 ), or for example a Zirconia-Alumina (ZrO 2 -Al 2 O 3 ) mixture, or even grains mainly consisting of silicon carbide (SiC).

- abrasive grains used may also be subjected to different thermal, mechanical, physical or chemical treatments to improve the abrasive performance (hardness, friability, roughness, etc ).

- the layers (3, 5) formed from these abrasive grains may consist of abrasive grains of different sizes, the average size of which is generally defined by those skilled in the art by the term "grit", or a mixture of grains of different sizes.

- the average size of the abrasive grains is, according to a possible embodiment of the invention, between 1035 microns (grit 24) and 122 microns (grit 150).

- the layers (3, 5) may be formed from the abrasive grains bonded together by a binder composed of various phenolic powder resins (eg Novolak) and / or in liquid (eg Resole) as well as possibly with additives or fillers.

- a binder composed of various phenolic powder resins (eg Novolak) and / or in liquid (eg Resole) as well as possibly with additives or fillers.

- the fillers or additives used may be mainly composed of iron sulphides, aluminum and potassium double fluoride, potassium sulphate or calcium carbonate (lime).

- the working zone Z has a total thickness e of less than 4 mm, and preferably less than or equal to 3.2 mm and greater than 2 mm.

- the grinding wheel (1) has three working areas (S1, S2, S3) adjacent in pairs: the sectors S1 and S3 correspond to the main working surfaces and the sector S2 corresponds to the outer edge of the grinding wheel.

- a grinding wheel was made presenting the structure illustrated on the figure 1 .

- the mixture of grains used in each layer (3,5) consists of two types of grains, one having an average size of 508 ⁇ m (grit 46) representing 85% by volume of the total volume of the mixture of abrasive grains and 1 another having an average size of 406 ⁇ m (grit 60) representing 15% by volume of the total volume of the mixture of abrasive grains.

- the binder used in each layer (3.5) consists of 65% by volume of phenolic resin (liquid + 15% by weight hexamethylenetetramine powder) and fillers: 15% by volume of iron sulphide, 18% by volume of sulphates of potassium and 2% by volume of lime.

- Each layer (3.5) thus consists of approximately 44% by volume of abrasive grains, 46% by volume of binder, the rest being porosity.

- the fabric used for the layers (2, 4, 6) has a basis weight of 195, 170 and 195 grams per square meter, respectively.

- This grinding wheel has after manufacture a thickness e of about 2.5 mm and an overall diameter of 125 mm.

- This grinding wheel although not having the thickness required by ISO 525 for a grinding wheel, has satisfied all the safety tests of the EN 12413 standard for grinding wheels type 27, 28 and 29.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Polishing Bodies And Polishing Tools (AREA)

- Electrical Discharge Machining, Electrochemical Machining, And Combined Machining (AREA)

- Pens And Brushes (AREA)

- Sliding-Contact Bearings (AREA)

- Food-Manufacturing Devices (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SI200730880T SI1993786T1 (sl) | 2006-03-06 | 2007-03-01 | Brus za fino obrezovanje, uporaba brusa in postopek za njegovo izdelavo |

| PL07731681T PL1993786T3 (pl) | 2006-03-06 | 2007-03-01 | Cienka ściernica do zdzierania, zastosowanie tej ściernicy i sposób jej wytwarzania |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0650776A FR2898070B1 (fr) | 2006-03-06 | 2006-03-06 | Meule d'ebarbage fine, utilisation de cette meule, procede et dispositif pour la fabriquer |

| PCT/FR2007/050864 WO2007101957A2 (fr) | 2006-03-06 | 2007-03-01 | Meule d'ebarbage fine, utilisation de cette meule, procede et dispositif pour la fabriquer. |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1993786A2 EP1993786A2 (fr) | 2008-11-26 |

| EP1993786B1 true EP1993786B1 (fr) | 2011-12-14 |

Family

ID=36579694

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07731681A Revoked EP1993786B1 (fr) | 2006-03-06 | 2007-03-01 | Meule d'ebarbage fine, utilisation de cette meule et procede pour la fabriquer. |

Country Status (21)

| Country | Link |

|---|---|

| EP (1) | EP1993786B1 (xx) |

| JP (2) | JP5503150B2 (xx) |

| KR (1) | KR101333329B1 (xx) |

| CN (1) | CN101394972B (xx) |

| AT (1) | ATE536960T1 (xx) |

| AU (1) | AU2007222236B2 (xx) |

| BR (1) | BRPI0707966B1 (xx) |

| CA (1) | CA2644859C (xx) |

| DE (1) | DE202007019685U1 (xx) |

| DK (1) | DK1993786T3 (xx) |

| ES (1) | ES2379114T3 (xx) |

| FR (1) | FR2898070B1 (xx) |

| MX (1) | MX2008011327A (xx) |

| NO (1) | NO20084163L (xx) |

| NZ (1) | NZ569257A (xx) |

| PL (1) | PL1993786T3 (xx) |

| PT (1) | PT1993786E (xx) |

| SI (1) | SI1993786T1 (xx) |

| TW (2) | TWI494193B (xx) |

| WO (1) | WO2007101957A2 (xx) |

| ZA (1) | ZA200806437B (xx) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103878706A (zh) | 2008-12-30 | 2014-06-25 | 圣戈班磨料磨具有限公司 | 生产粘结的磨轮的方法 |

| WO2013070576A2 (en) * | 2011-11-09 | 2013-05-16 | 3M Innovative Properties Company | Composite abrasive wheel |

| AR093483A1 (es) * | 2012-11-20 | 2015-06-10 | Saint Gobain Abrasives Inc | Articulo abrasivo que comprende particulas abrasivas de una composicion compuesta |

| CN103100985A (zh) * | 2013-03-01 | 2013-05-15 | 福建一胜多砂轮有限公司 | 超高速纤维增强树脂切割砂轮 |

| JP6412304B2 (ja) * | 2013-06-18 | 2018-10-24 | 株式会社三共 | 遊技機 |

| CN107530866B (zh) * | 2015-04-01 | 2021-04-30 | 3M创新有限公司 | 具有侧盖层的磨料盘 |

| CA3033406A1 (en) * | 2016-08-10 | 2018-02-15 | Klingspor Ag | Roughing disc having a backing layer |

| MX2019002076A (es) * | 2016-08-23 | 2019-05-15 | Rueggeberg August Gmbh & Co Kg | Herramienta para desbastar-rectificar. |

| EP3421178A1 (en) * | 2017-06-26 | 2019-01-02 | Dronco GmbH | Method of manufacturing an abrasive member, in particular rotary abrasive disc and abrasive member, in particular rotary abrasive disc |

| CN107225515B (zh) * | 2017-07-11 | 2023-06-30 | 苏州精协机械制造有限公司 | 挤压丝锥螺纹磨床的组合式多线磨轮 |

| CN107378806A (zh) * | 2017-07-20 | 2017-11-24 | 江苏苏北砂轮厂有限公司 | 高厚度砂轮 |

| CH715030B1 (de) * | 2018-05-29 | 2020-09-30 | Reishauer Ag | Verfahren zur Herstellung dünner Schleifkörper. |

| CN109202751A (zh) * | 2018-08-07 | 2019-01-15 | 安徽砥钻砂轮有限公司 | 一种切磨两用的树脂砂轮 |

| CN108972375B (zh) * | 2018-08-27 | 2024-03-26 | 洛阳希微磨料磨具有限公司 | 一种多层陶瓷结合剂砂轮及其制备方法 |

| CN114029873A (zh) * | 2021-10-27 | 2022-02-11 | 宁波大华砂轮有限公司 | 一种角磨片及其制备方法 |

| CN114473894A (zh) * | 2022-03-03 | 2022-05-13 | 江苏铁锚玻璃股份有限公司 | 玻璃数控磨边磨轮 |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5231596B1 (xx) * | 1970-05-29 | 1977-08-16 | ||

| JPS4849689U (xx) * | 1971-10-09 | 1973-06-29 | ||

| JPS5632293Y2 (xx) * | 1976-09-13 | 1981-07-31 | ||

| JPS60190565U (ja) * | 1984-05-23 | 1985-12-17 | シルバ−樹脂工業株式会社 | 成形品のバリ取り用砥石車 |

| JPS63161662U (xx) * | 1987-04-09 | 1988-10-21 | ||

| JP2543404B2 (ja) * | 1989-03-01 | 1996-10-16 | 住友化学工業株式会社 | 研磨研削材料 |

| DE4243017A1 (de) * | 1992-12-18 | 1994-06-23 | Hilti Ag | Scheibenförmiges Schleifwerkzeug |

| CN2314892Y (zh) * | 1997-11-03 | 1999-04-21 | 李广棋 | 超薄切割砂轮片 |

| KR100542088B1 (ko) * | 1998-03-04 | 2006-12-07 | 신에쓰 가가꾸 고교 가부시끼가이샤 | 연마재-블레이드다중절삭휠조립품 |

| FR2794676B1 (fr) * | 1999-06-09 | 2001-08-10 | Seva | Procede et installation de fabrication de meules abrasives, et meule fabriquee par ce procede |

| JP2001315063A (ja) * | 2000-05-10 | 2001-11-13 | Nitto Boseki Co Ltd | 回転砥石 |

| DE20017092U1 (de) * | 2000-10-05 | 2001-01-18 | Dronco Ag | Trennscheibe zum Trockenschneiden von Hartstoffen |

| JP2002178268A (ja) * | 2000-12-14 | 2002-06-25 | Nippon Plastic Seito Kk | 皮膜固定抵抗器のトリミング用研削砥石とその支持具 |

| JP2003191170A (ja) * | 2001-12-26 | 2003-07-08 | Fuji Grinding Wheel Co Ltd | 切断砥石とその製造方法 |

| JP2004299044A (ja) * | 2003-03-19 | 2004-10-28 | Kurenooton Kk | レジノイド結合剤を使用して構成されたオフセット型フレキシブル研削砥石及びその製造方法 |

| JP4175628B2 (ja) * | 2003-04-03 | 2008-11-05 | 山陽特殊製鋼株式会社 | 金属材切断用砥石及び金属材切断方法 |

| JP2004322230A (ja) * | 2003-04-22 | 2004-11-18 | Read Co Ltd | 研削砥石 |

| DE10359747A1 (de) * | 2003-12-19 | 2005-07-14 | August Rüggeberg Gmbh & Co. Kg | Schrupp-Schleifscheibe |

-

2006

- 2006-03-06 FR FR0650776A patent/FR2898070B1/fr not_active Expired - Fee Related

-

2007

- 2007-03-01 CN CN2007800078860A patent/CN101394972B/zh not_active Expired - Fee Related

- 2007-03-01 CA CA2644859A patent/CA2644859C/fr not_active Expired - Fee Related

- 2007-03-01 WO PCT/FR2007/050864 patent/WO2007101957A2/fr active Application Filing

- 2007-03-01 BR BRPI0707966-4A patent/BRPI0707966B1/pt not_active IP Right Cessation

- 2007-03-01 PL PL07731681T patent/PL1993786T3/pl unknown

- 2007-03-01 DK DK07731681.8T patent/DK1993786T3/da active

- 2007-03-01 ES ES07731681T patent/ES2379114T3/es active Active

- 2007-03-01 PT PT07731681T patent/PT1993786E/pt unknown

- 2007-03-01 KR KR1020087021689A patent/KR101333329B1/ko active IP Right Grant

- 2007-03-01 AT AT07731681T patent/ATE536960T1/de active

- 2007-03-01 SI SI200730880T patent/SI1993786T1/sl unknown

- 2007-03-01 AU AU2007222236A patent/AU2007222236B2/en not_active Ceased

- 2007-03-01 JP JP2008557804A patent/JP5503150B2/ja not_active Expired - Fee Related

- 2007-03-01 EP EP07731681A patent/EP1993786B1/fr not_active Revoked

- 2007-03-01 NZ NZ569257A patent/NZ569257A/en not_active IP Right Cessation

- 2007-03-01 MX MX2008011327A patent/MX2008011327A/es active IP Right Grant

- 2007-03-01 DE DE202007019685.7U patent/DE202007019685U1/de not_active Expired - Lifetime

- 2007-03-02 TW TW096107227A patent/TWI494193B/zh not_active IP Right Cessation

- 2007-03-02 TW TW103124149A patent/TWI492821B/zh not_active IP Right Cessation

-

2008

- 2008-07-24 ZA ZA200806437A patent/ZA200806437B/xx unknown

- 2008-10-03 NO NO20084163A patent/NO20084163L/no not_active Application Discontinuation

-

2012

- 2012-09-05 JP JP2012195107A patent/JP5506064B2/ja active Active

Also Published As

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1993786B1 (fr) | Meule d'ebarbage fine, utilisation de cette meule et procede pour la fabriquer. | |

| CA2549061A1 (en) | Polycrystalline diamond abrasive elements | |

| RU2562556C2 (ru) | Абразивное изделие | |

| CN100509292C (zh) | 多层刀片及其制造方法 | |

| EP2234760A1 (en) | Multifunction abrasive tool with hybrid bond | |

| CN102574276A (zh) | 具有实芯的磨料制品及其制备方法 | |

| US20040137834A1 (en) | Multi-resinous molded articles having integrally bonded graded interfaces | |

| US20150375368A1 (en) | Abrasive article having shaped segments | |

| US6187069B1 (en) | Composite bond wheel and wheel having resin bonding phase | |

| CA2843849C (fr) | Meule de faconnage pour verre plat | |

| CN107175589A (zh) | 一种长寿命磨床砂轮 | |

| JP4371689B2 (ja) | 超砥粒ブレード | |

| FR2832088A1 (fr) | Disque abrasif a lamelles | |

| BE501624A (xx) | ||

| JP2007175816A (ja) | 研削砥石およびその製造方法 | |

| BE673047A (xx) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20080804 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20090513 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RTI1 | Title (correction) |

Free format text: FINE FETTLING WHEEL, USE OF SAID WHEEL, AND METHOD FOR PRODUCING THE SAME |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602007019338 Country of ref document: DE Effective date: 20120209 |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20120301 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: KIRKER & CIE S.A. |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2379114 Country of ref document: ES Kind code of ref document: T3 Effective date: 20120420 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111214 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20111214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111214 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120315 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: T3 Ref document number: E 11328 Country of ref document: SK |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111214 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120314 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111214 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120414 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111214 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: AUGUST RUEGGEBERG GMBH & CO. KG Effective date: 20120829 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120331 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 602007019338 Country of ref document: DE Effective date: 20120829 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E015753 Country of ref document: HU |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111214 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: AUGUST RUEGGEBERG GMBH & CO. KG Effective date: 20120829 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20180219 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: RO Payment date: 20180227 Year of fee payment: 12 Ref country code: FI Payment date: 20180221 Year of fee payment: 12 Ref country code: CH Payment date: 20180226 Year of fee payment: 12 Ref country code: DK Payment date: 20180222 Year of fee payment: 12 Ref country code: GB Payment date: 20180226 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20180222 Year of fee payment: 12 Ref country code: SE Payment date: 20180226 Year of fee payment: 12 Ref country code: SK Payment date: 20180219 Year of fee payment: 12 Ref country code: PT Payment date: 20180301 Year of fee payment: 12 Ref country code: HU Payment date: 20180314 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20190225 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20190220 Year of fee payment: 13 Ref country code: CZ Payment date: 20190226 Year of fee payment: 13 Ref country code: DE Payment date: 20190219 Year of fee payment: 13 Ref country code: IT Payment date: 20190219 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20190221 Year of fee payment: 13 Ref country code: FR Payment date: 20190220 Year of fee payment: 13 Ref country code: TR Payment date: 20190225 Year of fee payment: 13 Ref country code: SI Payment date: 20190226 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20190401 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20190331 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190301 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190301 Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190902 Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190302 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190301 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: MM4A Ref document number: E 11328 Country of ref document: SK Effective date: 20190301 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190331 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R064 Ref document number: 602007019338 Country of ref document: DE Ref country code: DE Ref legal event code: R103 Ref document number: 602007019338 Country of ref document: DE |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190302 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190301 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 Ref country code: SK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190301 |

|

| RDAF | Communication despatched that patent is revoked |

Free format text: ORIGINAL CODE: EPIDOSNREV1 |

|

| RDAG | Patent revoked |

Free format text: ORIGINAL CODE: 0009271 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT REVOKED |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 |

|

| REG | Reference to a national code |

Ref country code: FI Ref legal event code: MGE |

|

| 27W | Patent revoked |

Effective date: 20191218 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: MC4A Ref document number: E 11328 Country of ref document: SK Effective date: 20191218 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MA03 Ref document number: 536960 Country of ref document: AT Kind code of ref document: T Effective date: 20191218 |