EP1983880B1 - Appareil manuel et outils qui peuvent y etre relies - Google Patents

Appareil manuel et outils qui peuvent y etre relies Download PDFInfo

- Publication number

- EP1983880B1 EP1983880B1 EP07701299A EP07701299A EP1983880B1 EP 1983880 B1 EP1983880 B1 EP 1983880B1 EP 07701299 A EP07701299 A EP 07701299A EP 07701299 A EP07701299 A EP 07701299A EP 1983880 B1 EP1983880 B1 EP 1983880B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tool

- hand

- guided device

- driving means

- component

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L23/00—Cleaning footwear

- A47L23/04—Hand implements for shoe-cleaning, with or without applicators for shoe polish

- A47L23/06—Hand implements for shoe-cleaning, with or without applicators for shoe polish with electric drive

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/02—Floor surfacing or polishing machines

- A47L11/04—Floor surfacing or polishing machines hand-driven

- A47L11/06—Floor surfacing or polishing machines hand-driven with reciprocating or oscillating tools

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4036—Parts or details of the surface treating tools

- A47L11/4038—Disk shaped surface treating tools

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4063—Driving means; Transmission means therefor

- A47L11/4069—Driving or transmission means for the cleaning tools

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L23/00—Cleaning footwear

- A47L23/04—Hand implements for shoe-cleaning, with or without applicators for shoe polish

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61H—PHYSICAL THERAPY APPARATUS, e.g. DEVICES FOR LOCATING OR STIMULATING REFLEX POINTS IN THE BODY; ARTIFICIAL RESPIRATION; MASSAGE; BATHING DEVICES FOR SPECIAL THERAPEUTIC OR HYGIENIC PURPOSES OR SPECIFIC PARTS OF THE BODY

- A61H7/00—Devices for suction-kneading massage; Devices for massaging the skin by rubbing or brushing not otherwise provided for

- A61H7/002—Devices for suction-kneading massage; Devices for massaging the skin by rubbing or brushing not otherwise provided for by rubbing or brushing

- A61H7/004—Devices for suction-kneading massage; Devices for massaging the skin by rubbing or brushing not otherwise provided for by rubbing or brushing power-driven, e.g. electrical

- A61H7/005—Devices for suction-kneading massage; Devices for massaging the skin by rubbing or brushing not otherwise provided for by rubbing or brushing power-driven, e.g. electrical hand-held

Definitions

- the invention relates to a hand-held device, comprising a housing and a drive part with a relative to the housing by means of a motor movable drive means, and with a releasably connectable to the drive means tool, wherein the drive means is eccentrically mounted eccentrically in the drive part.

- the invention relates to tools for the above-mentioned hand-held device, each having a treatment part and a guide part, wherein on the guide part, an element for releasable connection with the drive means of the hand-held device is provided.

- the hand-held device is, for example, a device for cleaning and / or processing and / or maintaining surfaces of objects, such as shoes, car parts and the like, or a massaging device for outdoor use on living beings.

- the appropriately executed treatment part of the respective tool for cleaning, processing or care of the surface of the respective object is used.

- hand-held devices are known with a particular electrically operable tool in many embodiments.

- the tools perform a rotating or rotationally oscillating movement about an axis.

- the WO 02/17767 A1 describes a portable shoe shine device with a trained as a handle housing, in which an electric motor with a transmission shaft Kir.kraftschlüssigen coupling of a brush is arranged.

- a flexible shaft is arranged as a transmission shaft.

- the brush performs a rotational movement or an eccentric oscillating movement when the central axis of the brush is arranged laterally offset from the axis of rotation of the transmission shaft.

- a rotational movement is unsuitable, since the shoe cream during the rotational movement of the brush can splash and thereby lead to contamination.

- the DE 36 15 918 A1 describes a manually operable cleaning device with which the tool, such as a brush, can be placed in a pure rotary motion or an oscillating Kurzhubwindzi.

- the tool such as a brush

- an oscillating Kurzhubwindzi is also unsuitable due to the inertia of the tool.

- the CH 401 384 A describes a hand-held shoe shine device with a movable drive means with the various tools can be used, all of which perform only one movement, namely a pure rotational movement.

- the US 3,775,800 A shows a hand-held device which can be coupled with different tools, in turn, only one movement, namely a pure rotational movement perform.

- the invention is now based on the object to overcome the disadvantages of the prior art and to provide a hand-held device of the type mentioned, which can be easily equipped with different tools and for the respective tools ensures a desired favorable movement of the same.

- Another object of the present invention is to provide corresponding tools for the hand-held device, which can be easily detachably connected to the drive part and with which a favorable for the respective processing movement is feasible.

- the first object is inventively achieved by an above-mentioned hand-held device in which the drive means for releasably connecting different tools with different types of movement is formed, and has a means for achieving a positive connection with the tool, and the housing distant from the drive means a fixed bearing for cooperation is arranged with a tool.

- the advantages that can be achieved with the device consist essentially in the fact that, without having to touch the selected tools, different types of tools can be connected to and detachable from the working part, wherein at the same time as the operative connection is established, the best type of tool movement is set up.

- the working part distanced has at least two orbitally movable drive means which are connectable with a tool in detachable operative connection.

- At least one undercut or the like For anchoring a detent or the like.

- a tool for example, faster rotating tools can be connected more securely to the hand-held device, as is the case, for example, in the case of the tool described below as a so-called dirt cutter.

- the drive part has a drive means with which the tool can be connected in detachable operative connection, which tool has a treatment part and a guide part, wherein the guide part is centrally provided a bearing for the drive means and spaces for receiving the fixed bearing, the tool is vibrating in the general sense.

- the tool performs an eccentric orbital motion during operation, the distanced immobile fixed bearing preventing a circular movement of the tool and only allowing it to move in one direction.

- the spaces on the guide part of the tool for receiving the fixed bearing are preferably arranged in a star shape. As a result, several possibilities of receiving the fixed bearing are created, thus facilitating the attachment of the tool to the hand-held device.

- the drive part has at least one drive means with which the tool is detachably operatively connected, which tool is formed axisymmetric and has a treatment part and a guide member, wherein the guide member centric storage for the drive means is provided, and with the tool an orbital circular motion is executable.

- the tool is rotatably mounted in the drive means and can perform an orbitally rotating and a rotating movement in the unloaded state. However, when the tool is applied to a workpiece, the friction provided thereby prevents rotation so that there is orbital motion in use.

- An embodiment of the invention also consists in that the drive part has at least one eccentrically movable drive means with which the tool is detachably operatively connected, which tool has a treatment part and a guide part, wherein on the guide part eccentrically a storage for the drive means is provided, and with the tool an eccentric rotating movement is executable.

- eccentric or orbital moving drive means can by an eccentricity of the connecting means on the tool a circular movement of the same about an axis can be achieved, with a releasable positive locking ensures axial rotation.

- the positive locking means can be designed in various ways. For example, a notch on the drive means or a crown ring connected to the drive means, which acts like a dog clutch, may be provided.

- the drive part a drive means with which the tool can be connected in detachable operative connection, and the tool has a treatment part with at least one rotatably mounted brush and a housing, which tool housing has a groove for receiving the fixed bearing, and is further one with the at least a brush operatively connected coupling element for connection to the drive means provided so that a rotational movement of the at least one brush of the tool results.

- a tool can be connected to the hand-held device, which has a housing from which protrudes at least one rotatably mounted brush.

- a plurality of brushes are arranged with different rotational direction, whereby, for example, a particularly high cleaning effect can be achieved with such a tool.

- At least one locking lug or the like can be provided for connection to at least one undercut on the housing of the hand-held device on the tool housing. Such a safer connection is advantageous or even necessary if higher centrifugal forces occur during use of the tool.

- the coupling element is preferably connected via a gear with the at least one brush.

- the transmission can preferably be formed by a planetary gear, wherein the sun gear of the planetary gear is operatively connected to the coupling element and one planetary gear, each with a brush.

- a tool with three brushes can be produced, which are each rotatably connected to a gear. These gears form the planet wheels, which are arranged around the sun gear.

- the three brushes run in opposite directions of rotation.

- a so-called dirt tiller can be constructed, which is particularly suitable for the removal of dirt from surfaces of objects, such as shoes.

- a fastening on and a release of the tool by the drive means is achieved in that the operative connection of the tool is created in the axial direction of the drive means by resilient parts in a detent, which operative connection by means of compressive force acting on the tool, the spring action in the detent overcoming Auswerfvones is solvable.

- the tool can be detached from the device with a simple push of a button without touching it by hand and put into a designated receptacle.

- the motor is preferably formed by an electric motor.

- the further object of the invention is achieved by a tool mentioned above, in which the connecting element is formed by a centrally arranged on the guide part bearing and further provided on the guide part spaces for receiving the fixed bearing of the hand-held device, so that a swinging motion of the tool results.

- a tool is particularly suitable for applying pasty substances on the surface, for example of shoes, as it comes to the centrifugal movement of the tool to no throwing off the pasty substance. In a rotating tool, it would come to a centrifuging and thus to an undesirable contamination of the environment or the user of the device, especially in liquid materials.

- the spaces on the guide member for receiving the fixed bearing of the hand-held device which are indeed required for the resulting oscillatory movement of the tool, arranged in a star shape around the guide member.

- the recording of the fixed bearing of the hand-held device can be done at different positions of the guide member and it must be when connecting the tool with the hand-held device not to its exact orientation, with respect to the fixed bearing, respected. This facilitates handling and thus increases the acceptability of the device.

- the treatment part of the above tool is preferably formed by a sponge body.

- a sponge body can, depending on the nature of the material used for various applications.

- a relatively hard and coarsely porous sponge material is suitable, for example, for roughening suede leather.

- a pasty substance such as a cream or the like is arranged in the sponge body.

- a tool can be created with the help of a pasty substance can be applied to the surface of an object.

- the tool may be a device for applying a leather care cream to the surface of leather shoes.

- the sponge body can be impregnated with the pasty substance or a corresponding liquid or arranged in a hollow body provided for this purpose.

- the sponge body may be formed by a sponge ring and an applicator connected thereto, wherein the pasty substance is arranged in the interior of the sponge ring and the applicator is formed from a permeable material for the pasty substance.

- the sponge ring, applicator and guide part of the tool are preferably glued together. Due to the two-part design of the sponge body in sponge ring and applicator located in the interior of the sponge ring pasty material can be specifically transported through the applicator to the outside by the sponge ring is made of a material that is not or only poorly permeable to the pasty substance. Of course it is also possible to make the sponge ring in one piece with the applicator.

- a cap is arranged above the treatment part of the tool. This prevents contamination by the pasty substance and protect the pasty material from drying out.

- the cap is preferably releasably connectable to the guide member, for example via a kind of bayonet lock.

- the object of the invention is also achieved by a tool, in which the connecting element is formed by a bearing arranged centrally on the guide part, so that an orbital circular movement of the tool results.

- a tool can be produced, which is particularly suitable for polishing surfaces, for example.

- the treatment part is preferably formed in this case by a synthetic fur or a textile fabric.

- a synthetic fur or a textile fabric Of course, other materials such as nonwovens or natural skins can be used as a treatment part.

- the object of the invention is also achieved by a tool in which the connecting element is formed by a bearing arranged eccentrically on the guide part.

- a rotating movement of the tool can be achieved if the eccentricity of the bearing substantially corresponds to the eccentricity of the drive means.

- Such a tool can be used in particular for cleaning surfaces of various objects are preferred.

- the treatment part is preferably formed by bristles.

- the invention is also achieved by a tool mentioned above, in which the treatment part has at least one rotatably mounted brush, further comprising a housing with a groove for receiving the fixation of the hand-held device, and the connecting element by an operatively connected to the at least one brush Coupling element is formed so that a rotational movement of the at least one brush of the tool results.

- a tool is preferably provided with a plurality of rotatably arranged brushes, with which a particularly high cleaning effect can be achieved.

- a locking lug or the like In order to achieve a secure connection between hand-held device and the tool housing, at least on the tool housing a locking lug or the like. Be provided for connection to at least one undercut on the housing of the hand-held device. Such a safer connection is advantageous or even necessary if higher centrifugal forces occur during use of the tool.

- the coupling element is preferably connected via a gear with the at least one bust.

- the transmission may preferably be formed by a planetary gear, wherein the sun gear of the planetary gear is operatively connected to the coupling element and a respective planetary gear with a brush.

- a tool with three brushes can be produced, which are each rotatably connected to a gear.

- the gears form the planet wheels, which are arranged around the sun gear of the planetary gear.

- the three brushes run in opposite directions of rotation.

- a so-called dirt tiller can be constructed, which is particularly suitable for the removal of dirt from surfaces of objects, such as shoes.

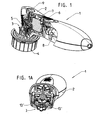

- Fig. 1 shows a perspective view of an embodiment of the hand-held device 1 according to the invention in a partially sectioned illustration.

- the hand-held device 1 comprises a housing 2 and a drive part 3 with a, relative to the housing 2 by means of a motor 7, movable drive means 5.

- a tool 4 With the drive means 5, a tool 4 can be releasably connected.

- the motor 7 is supplied in particular by batteries 8 or rechargeable batteries with electrical energy.

- the recharging of the batteries can be carried out in a suitable manner via a docking station, in which the device 1 is arranged.

- the electrical energy can be transmitted via a plug, corresponding contacts on the device 1 or inductively (not shown).

- An operating element 6 allows the commissioning of the device 1.

- the tool 4 preferably without contact and thus without risk of contamination, be solved by the drive means 5.

- the hand-guided device 1 is designed so that it with different tools 4, 4 ', 4 ", 4"' in the sequence based on the FIGS. 2 to 8 be described, can be equipped.

- the tools 4, 4 ', 4 ", 4"' are designed to that different types of movement of the same can be achieved and thus for certain activities in each case the appropriate tool 4, 4 ', 4 ", 4"' can be used.

- Figure 1A shows a further perspective view of the hand-held device 1, which is cut in the region of the drive part 3.

- the housing 2 of the device 1 there are two undercuts 13 ', which for anchoring detents 37 or the like.

- a tool 4 "' (see Figs. 8, 8A and 8B ), whereby a better hold of the tool 4 "'is achieved on the device 1.

- more undercuts 13' can also be provided in different configurations on the housing 2 of the device 1.

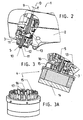

- Fig. 2 shows a section of the hand-held device 1 in the drive part 3 in a partially sectioned view.

- a projecting drive means 5 is mounted in the drive part 3 eccentrically movable with an eccentricity e and has for a locking in the direction of the axis of a tool 4, 4 ', 4'',4''' (not shown) a detent 12.

- the drive means 5 has an interlocking means, which may be formed, for example, by a recess 11 on the drive means 5 or a crown ring 11 'connected to the drive means 5.

- a stationary fixed bearing 13 is arranged distanced to the drive means 5. Due to the eccentric mounting of the drive means 5 on the one hand and this fixed bearing 13 on the other hand, different types of movement of differently shaped tools 4, 4 ', 4 ", 4' '' can be achieved. 4 '' 'described.

- a device 1 are used with a tool 4 in the form of a cream sponge.

- Fig. 3 shows a drive part 3 with a movable drive means 5, which is rotatably connected to the tool 4 in connection.

- the tool 4 has a guide part 15 and a treatment part 14, for example, a soaked with a pasty substance sponge body.

- the guide part 15 of the tool 4 has centrally a rotatable mounting 16 for the drive means 5 and star-shaped intermediate spaces 17 for receiving the fixed bearing 13 of the device 1.

- Fig. 4 shows a further embodiment of such trained as a cream sponge tool 4 in an exploded view.

- the tool 4 consists of the treatment part 14 and the guide part 15 (see Fig. 3 ).

- the treatment part 14 comprises a sponge ring 18, within which the pasty substance 19 is arranged.

- the sponge ring 18 is provided on both sides with adhesive layers 21 and bonded on the one hand with the guide member 15 and on the other hand with a disc-shaped applicator 20.

- the applicator 20 is made of a suitable material, in particular foam with pores, which are permeable to the pasty substance 19. This ensures that the pasty substance 19 can dosed out over the applicator 20 to the outside, for example, apply this to the surface of a shoe.

- 15 protrusions 22 are arranged on the circumference of the guide member, which engage in corresponding grooves 13 of a cap 24, so that the treatment part 14 of the tool 4 can be completely enclosed by the cap 24.

- the sponge ring 18 has a certain elasticity, so that the pasty substance 19 received therein can be pressed outward by means of pressure against the object to be cleaned, for example a shoe, via the applicator 20.

- the porosity of the applicator 20 must be matched to the consistency of the pasty substance 19.

- a compressible bellows made of plastic is arranged.

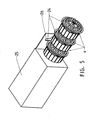

- Fig. 5 shows a packaging unit consisting of three formed as a cream sponge tools 4, each with attached cap 24. The entire unit is surrounded by a package 25, which may have a corresponding Euro hole 26.

- a package 25 which may have a corresponding Euro hole 26.

- cream sponges for creaming the surface of shoes cream sponges in the colors black, brown and colorless would be arranged in a package 25.

- these trained as a cream sponge tools 4 are formed as a disposable product, since refilling would be relatively complex and associated with the risk of contamination of the user.

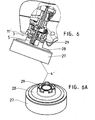

- Fig. 6 and Fig. 6A show a rotatably connected to a drive means 5 tool 4 ', which can serve as a polishing tool, for example.

- the symmetrical tool 4 'with the treatment part 27 and the guide part 28 is connected via the bearing 29 with the crown ring 11' of the drive part 3. This results in a rotating movement of the tool 4 '.

- the treatment part 27 may be formed, for example, by a faux fur or a textile fabric.

- a rotatable mounting of the tool 4 'via the eccentrically mounted drive means 5 would be possible (not shown). In this case, the tool 4 'would orbital circularly moved when the treatment part 27 of a workpiece on a workpiece while avoiding rotation, whereby, for example, polishing work on surfaces of objects are executable.

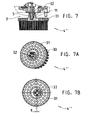

- the device 1 with a tool 4 '' operatively connected, which tool 4 ", as in Fig. 7, Fig. 7A and Fig. 7B is shown, can be moved axially rotating.

- the trained as a brush tool 4 '' is in turn formed of a guide member 31 with a bearing 32 on the drive means 5 and a treatment part 3, wherein the bearing 32 is eccentrically positioned on the guide member 31 and preferably the same degree of eccentricity e as the drive means

- a rectified eccentricity e of the drive means 5 and bearing 32 can be provided in the guide part 31 of the tool 4" interacts with the formed as a recess 11 positive locking means on the drive means 5.

- the show Figures 8, 8A and 8B a tool 4 "'designed as a so-called dirt mill, which serves mainly to remove dirt from the surface of objects, for example shoes .

- the treatment part 34 of the tool 4"' has three rotatably mounted brushes 35 in the illustrated embodiment. Also, fewer or more individual brushes 35 may be arranged.

- the latching lugs 37 can also be made in one piece with the tool housing 36, as shown in the sectional view in FIG Fig. 8 is recognizable.

- the locking lugs 37 snap into the provided on the housing 2 of the hand-held device undercuts 13 '(see Fig.

- a non-rotatable connection to the drive means 5 or associated crown ring 11' of the device 1 can be produced via a dog clutch 38.

- a groove 40 is provided on the tool housing 36 in which the fixed bearing 13 located on the housing 2 of the device 1 engages and additionally protects the tool 4 "'against rotation relative to the device 1.

- the jaw clutch 38 connected to the drive means 5 is operatively connected to the brushes 35 via a gear 39.

- the gear 39 is formed by a planetary gear, wherein the sun gear of the planetary gear is rotatably connected to the dog clutch 38.

- the brushes 35 are each rotatably connected to a gear which rotate as planet gears around the sun gear. As a result, a counter-rotating movement of the individual brushes 35 is achieved, which can be achieved with this tool 4 "'a particularly good cleaning effect.

- the hand-held device 1 and the tools 4, 4 ', 4' ', 4' '' which can be connected to it can be embodied in various ways within the scope of the invention and can be optimally adapted to the respective field of use.

Landscapes

- Health & Medical Sciences (AREA)

- Veterinary Medicine (AREA)

- Epidemiology (AREA)

- Pain & Pain Management (AREA)

- Physical Education & Sports Medicine (AREA)

- Rehabilitation Therapy (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- Public Health (AREA)

- Dermatology (AREA)

- General Health & Medical Sciences (AREA)

- Brushes (AREA)

- Manipulator (AREA)

- Automatic Tool Replacement In Machine Tools (AREA)

- Toys (AREA)

- Yarns And Mechanical Finishing Of Yarns Or Ropes (AREA)

- Forklifts And Lifting Vehicles (AREA)

- Dental Tools And Instruments Or Auxiliary Dental Instruments (AREA)

- Mechanically-Actuated Valves (AREA)

- Domestic Plumbing Installations (AREA)

- Mechanical Control Devices (AREA)

Claims (32)

- Appareil (1) manoeuvré et guidé à la main, comprenant un carter (2) et une partie d'entraînement (3) avec un moyen d'entraînement (5) mobile relativement par rapport au carter (2) au moyen d'un moteur (7), et comprenant également un outil (4) pouvant être relié de manière amovible au moyen d'entraînement (5), le moyen d'entraînement (5) étant monté de manière excentrée, avec une excentricité (e), dans la partie d'entraînement (3), caractérisé en ce que le moyen d'entraînement (5) est conçu pour la liaison amovible à différents outils (4, 4', 4", 4"') avec différents types de mouvements, et présente un moyen (11, 11') pour obtenir une liaison par complémentarité de formes avec l'outil (4, 4', 4", 4"'), et en ce que sur le carter (2) est agencé, à distance du moyen d'entraînement (5), un palier fixe (13) destiné à interagir avec un outil (4, 4''').

- Appareil (1) manoeuvré et guidé à la main, selon la revendication 1, caractérisé en ce que la partie d'entraînement (3) comprend, de manière espacée, au moins deux moyens d'entraînement (5) mobiles de façon orbitale, qui sont en liaison interactive amovible avec un outil (4, 4', 4", 4"').

- Appareil (1) manoeuvré et guidé à la main, selon la revendication 1 ou 2, caractérisé en ce que sur le carter (2) est prévue au moins une contre-dépouille (13') ou analogue pour l'ancrage d'un mentonnet d'encliquetage (37) ou analogue d'un outil (4"').

- Appareil (1) manoeuvré et guidé à la main, selon l'une des revendications 1 à 3, caractérisé en ce que la partie d'entraînement (3) comprend un moyen d'entraînement (5) avec lequel peut être lié de manière amovible l'outil (4) par une liaison active, et l'outil (4) présente une partie de traitement (14) et une partie de guidage (15), partie de guidage (15) sur laquelle sont prévus de manière centrale un système de palier de montage (16) pour le moyen d'entraînement (5), ainsi que des espaces intermédiaires (17) destinés à recevoir le palier fixe (13), et en ce qu'il est possible d'effectuer un mouvement d'oscillation avec l'outil (4).

- Appareil (1) manoeuvré et guidé à la main, selon la revendication 4, caractérisé en ce que les espaces intermédiaires (17) sont agencés en forme d'étoile sur la partie de guidage (15) de l'outil (4).

- Appareil (1) manoeuvré et guidé à la main, selon l'une des revendications 1 à 3, caractérisé en ce que la partie d'entraînement (3) comprend au moins un moyen d'entraînement (5) avec lequel peut être lié de manière amovible l'outil (4') par une liaison active, cet outil (4') étant d'une configuration symétrique par rapport à l'axe et présentant une partie de traitement (27) et une partie de guidage (28), un système de palier de montage (29) pour le moyen d'entraînement (5) étant prévu de manière centrale sur la partie de guidage (28), et en ce qu'il est possible d'effectuer un mouvement de révolution orbital avec l'outil (4').

- Appareil (1) manoeuvré et guidé à la main, selon l'une des revendications 1 à 3, caractérisé en ce que la partie d'entraînement (3) comprend au moins un moyen d'entraînement (5) mobile de façon excentrique, avec lequel ou lesquels peut être lié de manière amovible l'outil (4") par une liaison active, cet outil (4") présentant une partie de traitement (30) et une partie de guidage (31), un système de palier de montage (32) pour le moyen d'entraînement (5) étant prévu de manière excentrée sur la partie de guidage (31), et en ce qu'il est possible d'effectuer un mouvement de rotation excentrique avec l'outil (4'').

- Appareil (1) manoeuvré et guidé à la main, selon la revendication 7, caractérisé en ce que l'excentricité du système de palier de montage (32) correspond sensiblement à l'excentricité (e) du moyen d'entraînement (5), et en ce qu'il est possible d'effectuer un mouvement de rotation avec l'outil (4").

- Appareil (1) manoeuvré et guidé à la main, selon la revendication 7 ou 8, caractérisé en ce que l'outil (4") présente un dispositif de liaison par complémentarité de formes (33) interagissant avec le moyen de liaison par complémentarité de formes (11, 11') sur le moyen d'entraînement (5).

- Appareil (1) manoeuvré et guidé à la main, selon l'une des revendications 1 à 3, caractérisé en ce que la partie d'entraînement (3) comprend un moyen d'entraînement (5) avec lequel peut être lié de manière amovible l'outil (4"') par une liaison active, et l'outil (4"') présente une partie de traitement (34) avec au moins une brosse (35) montée rotative, ainsi qu'un carter (36), ce carter d'outil (36) présentant une rainure (40) destinée à recevoir le palier fixe (13), en ce que par ailleurs il est prévu un élément de couplage (38) lié de manière active à ladite au moins une brosse (35) et destiné à la liaison avec le moyen d'entraînement (5), et en ce qu'il est possible de faire effectuer un mouvement de rotation à ladite au moins une brosse (35) de l'outil (4"').

- Appareil (1) manoeuvré et guidé à la main, selon la revendication 10, caractérisé en ce que sur le carter d'outil (36) est prévu au moins un mentonnet d'encliquetage (36) ou analogue pour la liaison avec au moins une contre-dépouille (13') sur le carter (2).

- Appareil (1) manoeuvré et guidé à la main, selon la revendication 10 ou 11, caractérisé en ce que l'élément de couplage (38) est relié par l'intermédiaire d'une transmission (39) à ladite au moins une brosse (35).

- Appareil (1) manoeuvré et guidé à la main, selon la revendication 12, caractérisé en ce que la transmission (39) est formée par un train épicycloïdal, la roue centrale du train épicycloïdal étant reliée de manière active avec l'élément de couplage (38) et chaque pignon-satellite avec une brosse (35).

- Appareil (1) manoeuvré et guidé à la main, selon l'une des revendications 1 à 13, caractérisé en ce que sur le moyen d'entraînement (5) est prévu un système d'encliquetage (12) pour le blocage de retenue de l'outil (4, 4', 4", 4"').

- Appareil (1) manoeuvré et guidé à la main, selon la revendication 14, caractérisé en ce qu'il est prévu une broche d'éjection (10) pouvant coulisser, sous l'action d'une force de compression (D), du carter (2) en direction de l'outil (4, 4', 4", 4"'), pour interrompre le blocage de retenue de l'outil (4, 4', 4", 4"') par le système d'encliquetage (12).

- Appareil (1) manoeuvré et guidé à la main, selon l'une des revendications 1 à 15, caractérisé en ce que le moteur (7) est constitué par un moteur électrique.

- Outil (4) pour un appareil (1) manoeuvré et guidé à la main selon l'une des revendications 1 à 16, comprenant une partie de traitement (14) et une partie de guidage (15), un élément pour assurer la liaison amovible avec le moyen d'entraînement (5) de l'appareil (1) manoeuvré et guidé à la main étant prévu sur la partie de guidage (15), caractérisé en ce que l'élément de liaison est formé par un système de palier (16) agencé de manière centrée sur la partie de guidage (15), et en ce que par ailleurs, sur la partie de guidage (15) sont prévus des espaces intermédiaires (17) destinés à recevoir le palier fixe (13) de l'appareil (1) manoeuvré et guidé à la main, et un mouvement d'oscillation peut être effectué avec l'outil (4).

- Outil (4) selon la revendication 17, caractérisé en ce que les espaces intermédiaires (17) sont agencés en forme d'étoile sur la partie de guidage (15).

- Outil (4) selon la revendication 17 ou 18, caractérisé en ce que la partie de traitement (14) est constituée par un corps spongieux.

- Outil (4) selon la revendication 19, caractérisé en ce que dans le corps spongieux est agencée une substance pâteuse (19).

- Outil (4) selon la revendication 19, caractérisé en ce que le corps spongieux est formé par un anneau spongieux (18) et un applicateur (20) qui lui est relié, la substance pâteuse (19) étant agencée à l'intérieur de l'anneau spongieux (18), et l'applicateur (20) étant réalisé en un matériau perméable à la substance pâteuse (19).

- Outil (4) selon l'une des revendications 17 à 21, caractérisé en ce qu'un capuchon de recouvrement (24) est agencé par-dessus la partie de traitement (14).

- Outil (4) selon la revendication 22, caractérisé en ce que le capuchon de recouvrement (24) peut être relié de manière amovible à la partie de guidage (15).

- Outil (4') pour un appareil (1) manoeuvré et guidé à la main selon l'une des revendications 1 à 16, comprenant une partie de traitement (27) et une partie de guidage (28), un élément pour assurer la liaison amovible avec le moyen d'entraînement (5) de l'appareil (1) manoeuvré et guidé à la main étant prévu sur la partie de guidage (28), caractérisé en ce que l'élément de liaison est formé par un système de palier (29) agencé de manière centrée sur la partie de guidage (28), et un mouvement de révolution orbital peut être effectué avec l'outil (4').

- Outil (4') selon la revendication 24, caractérisé en ce que la partie de traitement (27) est constituée par une peau synthétique ou une étoffe textile.

- Outil (4") pour un appareil (1) manoeuvré et guidé à la main selon l'une des revendications 1 à 16, comprenant une partie de traitement (30) et une partie de guidage (31), un élément pour assurer la liaison amovible avec le moyen d'entraînement (5) de l'appareil (1) manoeuvré et guidé à la main étant prévu sur la partie de guidage (31), caractérisé en ce que l'élément de liaison est formé par un système de palier (32) agencé de manière excentrée sur la partie de guidage (31), et un mouvement de rotation excentrique peut être effectué avec l'outil (4").

- Outil (4") selon la revendication 26, caractérisé en ce que l'excentricité du système de palier (32) correspond sensiblement à l'excentricité (e) du moyen d'entraînement (5), et un mouvement rotatif peut être effectué avec l'outil (4'').

- Outil (4") selon la revendication 26 ou 27, caractérisé en ce que la partie de traitement (30) est formée par des poils de brosse.

- Outil (4"') pour un appareil (1) manoeuvré et guidé à la main selon l'une des revendications 1 à 16, comprenant une partie de traitement (34) et une partie de guidage, un élément pour assurer la liaison amovible avec le moyen d'entraînement (5) de l'appareil (1) manoeuvré et guidé à la main étant prévu sur la partie de guidage, caractérisé en ce que la partie de traitement (34) présente au moins une brosse (35) montée rotative, en ce que par ailleurs il est prévu un carter (36) avec une rainure (40) destinée à recevoir le palier fixe (13) de l'appareil (1) manoeuvré et guidé à la main, et en ce que l'élément de liaison est formé par un élément de couplage (38) relié de manière active avec ladite au moins une brosse (35), et il est possible de faire effectuer un mouvement de rotation à ladite au moins une brosse (35) de l'outil (4"').

- Outil (4"') selon la revendication 29, caractérisé en ce que sur le carter d'outil (36) est prévu au moins un mentonnet d'encliquetage (36) ou analogue pour la liaison avec au moins une contre-dépouille (13') sur le carter (2).

- Outil (4"') selon la revendication 29 ou 30, caractérisé en ce que l'élément de couplage (38) est relié par l'intermédiaire d'une transmission (39) à ladite au moins une brosse (35).

- Outil (4"') selon la revendication 31, caractérisé en ce que la transmission (39) est formée par un train épicycloïdal, la roue centrale du train épicycloïdal étant reliée de manière active avec l'élément de couplage (38) et chaque pignon-satellite avec une brosse (35).

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SI200730078T SI1983880T1 (sl) | 2006-02-03 | 2007-02-05 | Ročno upravljana naprava in z njo povezljivo orodje |

| PL07701299T PL1983880T3 (pl) | 2006-02-03 | 2007-02-05 | Urządzenie kierowane ręcznie i narzędzia nadające się do połączenia z nim |

| AT07701299T ATE435609T1 (de) | 2006-02-03 | 2007-02-05 | Handgeführtes gerät und damit verbindbare werkzeuge |

| CY20091101036T CY1109470T1 (el) | 2006-02-03 | 2009-10-08 | Χειροκινητη συσκευη και εργαλεια τα οποια μπορουν να συνδεθουν σε αυτη |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT0008106U AT8375U3 (de) | 2006-02-03 | 2006-02-03 | Handgeführtes gerät mit einem relativ zum gehäuse bewegbarem, auswechselbarem werkzeug |

| AT1712006A AT502892B1 (de) | 2006-02-03 | 2006-02-03 | Handgeführtes gerät mit einem relativ zum gehäuse bewegbarem, auswechselbarem werkzeug |

| PCT/AT2007/000054 WO2007087666A1 (fr) | 2006-02-03 | 2007-02-05 | Appareil manuel et outils qui peuvent y etre relies |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1983880A1 EP1983880A1 (fr) | 2008-10-29 |

| EP1983880B1 true EP1983880B1 (fr) | 2009-07-08 |

Family

ID=37903554

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07701299A Active EP1983880B1 (fr) | 2006-02-03 | 2007-02-05 | Appareil manuel et outils qui peuvent y etre relies |

Country Status (15)

| Country | Link |

|---|---|

| US (1) | US8185992B2 (fr) |

| EP (1) | EP1983880B1 (fr) |

| JP (1) | JP4960384B2 (fr) |

| KR (1) | KR20080094091A (fr) |

| AT (1) | ATE435609T1 (fr) |

| BR (1) | BRPI0707470A2 (fr) |

| CA (1) | CA2640951A1 (fr) |

| DE (2) | DE502007001035D1 (fr) |

| DK (1) | DK1983880T3 (fr) |

| ES (1) | ES2329950T3 (fr) |

| PL (1) | PL1983880T3 (fr) |

| PT (1) | PT1983880E (fr) |

| RU (1) | RU2415639C2 (fr) |

| SI (1) | SI1983880T1 (fr) |

| WO (1) | WO2007087666A1 (fr) |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL2001348C2 (nl) * | 2008-03-04 | 2009-09-07 | Delaval Holding Ab | Borstel voor vee, inrichting omvattende een dergelijke borstel, en werkwijze voor het borstelen van vee. |

| JP4633822B2 (ja) * | 2008-06-02 | 2011-02-16 | 正彦 日浦 | 回転掃除用具 |

| DE102008060547B4 (de) * | 2008-12-04 | 2011-03-03 | Edag Gmbh & Co. Kgaa | Verfahren und Vorrichtung zum Reinigen einer Bearbeitungsrolle eines Bearbeitungswerkzeugs |

| DE102009027223B4 (de) * | 2009-06-26 | 2022-01-13 | Robert Bosch Gmbh | Handgeführtes Elektrowerkzeug mit Rastenwerk |

| DE102009037157A1 (de) * | 2009-08-04 | 2011-02-17 | Schwab Präzision GmbH | Reinigungsvorrichtung |

| DE102009037772A1 (de) * | 2009-08-17 | 2011-02-24 | Washtec Holding Gmbh | Vorrichtung zur Reinigung von Fahrzeugrädern |

| PL2675666T3 (pl) * | 2011-02-17 | 2016-11-30 | Urządzenie do mycia kół | |

| EP2607016B1 (fr) * | 2011-12-21 | 2016-08-10 | Makita Corporation | Ponceuse |

| JP5809104B2 (ja) * | 2012-05-15 | 2015-11-10 | 有限会社アクセス | 清掃装置用連結具及び清掃装置 |

| US9555554B2 (en) | 2013-05-06 | 2017-01-31 | Milwaukee Electric Tool Corporation | Oscillating multi-tool system |

| ES2481516B1 (es) * | 2013-11-07 | 2014-12-12 | Francisca VICENT FERRER | Dispositivo y mecanismo con libertad de movimiento aplicable a la limpieza |

| US9320335B2 (en) * | 2013-12-30 | 2016-04-26 | L'oreal | Grooming devices and methods therefor |

| JP7002186B2 (ja) * | 2016-06-07 | 2022-01-20 | 株式会社 Mtg | 美容器 |

| DE102019118855B4 (de) * | 2019-07-11 | 2022-10-13 | Wolfram Seidensticker | Handgeführter, elektrischer Apparat zum Antrieb eines auswechselbaren Bearbeitungs-kopfes, zur Bearbeitung einer Oberfläche, Bearbeitungskopf und Pflegesystem |

| JP7282659B2 (ja) * | 2019-11-28 | 2023-05-29 | 株式会社マキタ | 作業工具 |

| RU2020129922A (ru) * | 2020-09-10 | 2022-03-10 | Алексей Владимирович Несмеянов | Тюбик-щетка для чистки обуви |

| FR3124368A1 (fr) * | 2021-06-24 | 2022-12-30 | Thibault LOUVARD | Système d’entretien d’objets par application d’un fluide ou d’une pâte d’entretien |

| WO2024114896A1 (fr) | 2022-11-29 | 2024-06-06 | Louvard Thibault | Système d'entretien d'objets par application d'un fluide ou d'une pâte d'entretien |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH196316A (de) * | 1937-11-11 | 1938-03-15 | August Albrecht | Elektrisches Schuhputzgerät. |

| US3239864A (en) * | 1962-06-06 | 1966-03-15 | Corata Christopher F La | Shoe brush |

| CH401384A (fr) | 1962-12-27 | 1965-10-31 | Ronson Corp | Machine à polir pourvue d'accessoires interchangeables |

| DE1503906A1 (de) * | 1965-12-18 | 1969-07-10 | Vorwerk & Co Elektrowerke Kg | Schuhputz-Handgeraet |

| US3775800A (en) | 1971-12-20 | 1973-12-04 | M Veneziani | Rotary brush |

| US4158246A (en) * | 1977-09-07 | 1979-06-19 | Disston, Inc. | Portable cordless scrubber |

| DE3615918A1 (de) | 1986-05-12 | 1987-11-19 | Eckart Mayer | Manuell handhabbare reinigungsvorrichtung |

| JPH065854B2 (ja) * | 1986-10-20 | 1994-01-19 | シャープ株式会社 | イメ−ジ入力処理装置 |

| JPH0393230U (fr) * | 1990-01-16 | 1991-09-24 | ||

| JPH0463674A (ja) * | 1990-06-29 | 1992-02-28 | Aichi Steel Works Ltd | ブラシ回転装置 |

| JP3290328B2 (ja) * | 1995-04-19 | 2002-06-10 | アマノ株式会社 | 床面処理機用ブラシ又はパッドの回転装置 |

| US5956792A (en) * | 1996-04-29 | 1999-09-28 | Black & Decker, Inc. | Hand held motorized cleaning apparatus with linear, orbital and/or dual motion |

| US5857233A (en) * | 1997-02-27 | 1999-01-12 | Wynn; Emery G. | Body lotion applicator |

| US6185781B1 (en) * | 1999-06-24 | 2001-02-13 | The Hoover Company | Hand scrub tool with interchangeable scrub drives |

| DE10042874A1 (de) | 2000-08-31 | 2002-05-16 | 2 Mad Gmbh I G | Tragbares Schuhputzgerät |

| US6984901B2 (en) * | 2000-12-01 | 2006-01-10 | International Concepts, Inc. | Battery-powered washer |

-

2007

- 2007-02-05 PL PL07701299T patent/PL1983880T3/pl unknown

- 2007-02-05 DE DE502007001035T patent/DE502007001035D1/de active Active

- 2007-02-05 WO PCT/AT2007/000054 patent/WO2007087666A1/fr active Application Filing

- 2007-02-05 CA CA002640951A patent/CA2640951A1/fr not_active Abandoned

- 2007-02-05 DE DE212007000004U patent/DE212007000004U1/de not_active Expired - Lifetime

- 2007-02-05 ES ES07701299T patent/ES2329950T3/es active Active

- 2007-02-05 US US11/794,410 patent/US8185992B2/en not_active Expired - Fee Related

- 2007-02-05 RU RU2008135705/12A patent/RU2415639C2/ru not_active IP Right Cessation

- 2007-02-05 EP EP07701299A patent/EP1983880B1/fr active Active

- 2007-02-05 AT AT07701299T patent/ATE435609T1/de active

- 2007-02-05 SI SI200730078T patent/SI1983880T1/sl unknown

- 2007-02-05 JP JP2008552639A patent/JP4960384B2/ja not_active Expired - Fee Related

- 2007-02-05 KR KR1020087021555A patent/KR20080094091A/ko not_active Application Discontinuation

- 2007-02-05 DK DK07701299T patent/DK1983880T3/da active

- 2007-02-05 PT PT07701299T patent/PT1983880E/pt unknown

- 2007-02-05 BR BRPI0707470-0A patent/BRPI0707470A2/pt not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| BRPI0707470A2 (pt) | 2011-05-03 |

| DE212007000004U1 (de) | 2007-11-15 |

| DE502007001035D1 (de) | 2009-08-20 |

| JP2009525078A (ja) | 2009-07-09 |

| EP1983880A1 (fr) | 2008-10-29 |

| ES2329950T3 (es) | 2009-12-02 |

| US20100024139A1 (en) | 2010-02-04 |

| JP4960384B2 (ja) | 2012-06-27 |

| SI1983880T1 (sl) | 2009-12-31 |

| US8185992B2 (en) | 2012-05-29 |

| PL1983880T3 (pl) | 2010-10-29 |

| RU2008135705A (ru) | 2010-03-10 |

| KR20080094091A (ko) | 2008-10-22 |

| ATE435609T1 (de) | 2009-07-15 |

| RU2415639C2 (ru) | 2011-04-10 |

| PT1983880E (pt) | 2009-10-15 |

| DK1983880T3 (da) | 2009-11-16 |

| WO2007087666A1 (fr) | 2007-08-09 |

| CA2640951A1 (fr) | 2007-08-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1983880B1 (fr) | Appareil manuel et outils qui peuvent y etre relies | |

| DE2852040C2 (de) | Vorrichtung zum wahlweisen Betätigen mindestens zweier Werkzeuge insbesondere für Zwecke der Zahnheilkunde | |

| EP2629933B1 (fr) | Outil de travail notamment outil électrique | |

| WO2016177580A1 (fr) | Appareil électrique pour les soins personnels | |

| WO2019210934A1 (fr) | Outil de déglaçage pour machine de déglaçage et machine de déglaçage portative | |

| DE2901136A1 (de) | Handgeraet fuer zahnpflege und zahnbehandlung | |

| EP1764010A1 (fr) | Dispositif de dermabrasion, procédé de fabrication d'un tel dispositif et utilisation d'un tel dispositif dans un appareil manuel électrique de soin personnel | |

| EP3471916B1 (fr) | Dispositif à outil rotatif pouvant être entraîné en rotation | |

| DE69021898T2 (de) | Rasiergerät. | |

| DE2720496B2 (de) | Tragbares Gerät zur Nagelpflege | |

| CN101212925B (zh) | 手动引导设备和可与其相连的工具 | |

| EP3262976B1 (fr) | Brosse | |

| EP2225965A1 (fr) | Applicateur destiné à appliquer un liquide | |

| AT502892B1 (de) | Handgeführtes gerät mit einem relativ zum gehäuse bewegbarem, auswechselbarem werkzeug | |

| DE4318976A1 (de) | Elektromechanische Zahnbürste | |

| DE102008017905B4 (de) | Elektrisches Behandlungsgerät | |

| EP3902655B1 (fr) | Machine-outil portative | |

| DE102021207290B4 (de) | Mehrfachbewegungsgerät | |

| DE102014102445A1 (de) | Reinigungsgerät mit einem Elektroantrieb sowie Set, bestehend aus einem zweiteiligen Reinigungsgerät | |

| DE3934373C2 (fr) | ||

| DE202015005984U1 (de) | Nagelpflegevorrichtung | |

| WO2022112334A1 (fr) | Produit de nettoyage dentaire et tête de brosse à dents | |

| DE69002329T2 (de) | Elektrisch getriebenes massagegeraet. | |

| WO1997002769A1 (fr) | Appareil de massage a commande electrique | |

| DE10003504A1 (de) | Handschleifgerät |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20080901 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 502007001035 Country of ref document: DE Date of ref document: 20090820 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20091008 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: GOOD VIBRATIONS FIT DURCH SCHWINGUNGEN E.K. INH. Free format text: QXR CLEANING PRODUCTS GMBH#KLEEBLATTGASSE 13/11A#1010 WIEN (AT) -TRANSFER TO- GOOD VIBRATIONS FIT DURCH SCHWINGUNGEN E.K. INH. VOLKER HALTER#MUENSTERPLATZ 20#89073 ULM (DE) Ref country code: CH Ref legal event code: NV Representative=s name: BOHEST AG |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: GOOD VIBRATIONS FIT DURCH SCHWINGUNG E.K. INH. VOL |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20091022 AND 20091028 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20090402499 Country of ref document: GR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090708 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2329950 Country of ref document: ES Kind code of ref document: T3 |

|

| NLS | Nl: assignments of ep-patents |

Owner name: GOOD VIBRATIONS FIT DURCH SCHWINGUNG E.K. INH. VOL Effective date: 20091020 |

|

| NLT2 | Nl: modifications (of names), taken from the european patent patent bulletin |

Owner name: GOOD VIBRATIONS FIT DURCH SCHWINGUNG E.K. Effective date: 20091111 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091108 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E006559 Country of ref document: HU |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091008 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090708 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090708 |

|

| 26N | No opposition filed |

Effective date: 20100409 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20110125 Year of fee payment: 5 Ref country code: IT Payment date: 20110218 Year of fee payment: 5 Ref country code: CZ Payment date: 20110203 Year of fee payment: 5 |

|

| PGRI | Patent reinstated in contracting state [announced from national office to epo] |

Ref country code: IT Effective date: 20110501 |

|

| PGRI | Patent reinstated in contracting state [announced from national office to epo] |

Ref country code: IT Effective date: 20110501 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20120320 Year of fee payment: 6 Ref country code: HU Payment date: 20120223 Year of fee payment: 6 Ref country code: CH Payment date: 20120312 Year of fee payment: 6 Ref country code: IE Payment date: 20120229 Year of fee payment: 6 Ref country code: MC Payment date: 20120313 Year of fee payment: 7 Ref country code: LU Payment date: 20120302 Year of fee payment: 6 Ref country code: LT Payment date: 20120203 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20120203 Year of fee payment: 6 Ref country code: DE Payment date: 20120229 Year of fee payment: 6 Ref country code: TR Payment date: 20120203 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LV Payment date: 20120214 Year of fee payment: 6 Ref country code: GB Payment date: 20120322 Year of fee payment: 6 Ref country code: FI Payment date: 20120229 Year of fee payment: 6 Ref country code: GR Payment date: 20120229 Year of fee payment: 6 Ref country code: RO Payment date: 20120130 Year of fee payment: 6 Ref country code: BE Payment date: 20120312 Year of fee payment: 6 Ref country code: SE Payment date: 20120228 Year of fee payment: 6 Ref country code: DK Payment date: 20120229 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20120301 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CY Payment date: 20120206 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120205 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20120313 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20120316 Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20130805 |

|

| BERE | Be: lapsed |

Owner name: GOOD VIBRATIONS FIT DURCH SCHWINGUNG E.K. INH. VOL Effective date: 20130228 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20130901 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MM4D Effective date: 20130205 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 435609 Country of ref document: AT Kind code of ref document: T Effective date: 20130228 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: ML Ref document number: 20090402499 Country of ref document: GR Effective date: 20130904 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20130205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130228 Ref country code: LT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130205 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130205 Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130206 Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130805 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130228 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130901 Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130904 Ref country code: HU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130206 Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130205 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130228 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20131031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130205 Ref country code: CY Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130205 |

|

| REG | Reference to a national code |

Ref country code: SI Ref legal event code: KO00 Effective date: 20131017 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502007001035 Country of ref document: DE Effective date: 20130903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130228 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130228 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130205 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130903 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130205 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130205 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: LAPE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20140610 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130205 |