EP1908863B1 - Lisse pour métier à tisser Jacquard - Google Patents

Lisse pour métier à tisser Jacquard Download PDFInfo

- Publication number

- EP1908863B1 EP1908863B1 EP06021003A EP06021003A EP1908863B1 EP 1908863 B1 EP1908863 B1 EP 1908863B1 EP 06021003 A EP06021003 A EP 06021003A EP 06021003 A EP06021003 A EP 06021003A EP 1908863 B1 EP1908863 B1 EP 1908863B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- heald

- section

- leg

- plastic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 239000004033 plastic Substances 0.000 claims description 49

- 229920003023 plastic Polymers 0.000 claims description 49

- 239000000463 material Substances 0.000 claims description 9

- 230000007704 transition Effects 0.000 claims description 6

- 239000000919 ceramic Substances 0.000 claims description 5

- 239000000853 adhesive Substances 0.000 claims description 3

- 230000001070 adhesive effect Effects 0.000 claims description 3

- 229920001169 thermoplastic Polymers 0.000 claims description 3

- 229920001187 thermosetting polymer Polymers 0.000 claims description 3

- 229920000914 Metallic fiber Polymers 0.000 claims description 2

- 239000004760 aramid Substances 0.000 claims description 2

- 229910052751 metal Inorganic materials 0.000 claims description 2

- 239000002184 metal Substances 0.000 claims description 2

- 102000004169 proteins and genes Human genes 0.000 claims description 2

- 108090000623 proteins and genes Proteins 0.000 claims description 2

- 238000007711 solidification Methods 0.000 claims description 2

- 230000008023 solidification Effects 0.000 claims description 2

- 239000004416 thermosoftening plastic Substances 0.000 claims description 2

- PNEYBMLMFCGWSK-UHFFFAOYSA-N Alumina Chemical compound [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 claims 3

- 239000011521 glass Substances 0.000 claims 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims 1

- 229910000831 Steel Inorganic materials 0.000 claims 1

- 229920003235 aromatic polyamide Polymers 0.000 claims 1

- 229910052799 carbon Inorganic materials 0.000 claims 1

- 239000010959 steel Substances 0.000 claims 1

- 210000002414 leg Anatomy 0.000 description 48

- 239000000835 fiber Substances 0.000 description 34

- 239000012783 reinforcing fiber Substances 0.000 description 8

- 238000001746 injection moulding Methods 0.000 description 4

- 238000009941 weaving Methods 0.000 description 4

- 230000001154 acute effect Effects 0.000 description 3

- 229920000049 Carbon (fiber) Polymers 0.000 description 2

- 239000004917 carbon fiber Substances 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 239000003822 epoxy resin Substances 0.000 description 2

- 239000003365 glass fiber Substances 0.000 description 2

- 229920000647 polyepoxide Polymers 0.000 description 2

- 230000002787 reinforcement Effects 0.000 description 2

- TVEXGJYMHHTVKP-UHFFFAOYSA-N 6-oxabicyclo[3.2.1]oct-3-en-7-one Chemical compound C1C2C(=O)OC1C=CC2 TVEXGJYMHHTVKP-UHFFFAOYSA-N 0.000 description 1

- 229920002430 Fibre-reinforced plastic Polymers 0.000 description 1

- 229910000760 Hardened steel Inorganic materials 0.000 description 1

- 229920001872 Spider silk Polymers 0.000 description 1

- 229920006231 aramid fiber Polymers 0.000 description 1

- 239000011195 cermet Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 239000011151 fibre-reinforced plastic Substances 0.000 description 1

- 239000004413 injection moulding compound Substances 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 239000002557 mineral fiber Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000011224 oxide ceramic Substances 0.000 description 1

- 229910052574 oxide ceramic Inorganic materials 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

- 230000008719 thickening Effects 0.000 description 1

- 210000000689 upper leg Anatomy 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03C—SHEDDING MECHANISMS; PATTERN CARDS OR CHAINS; PUNCHING OF CARDS; DESIGNING PATTERNS

- D03C9/00—Healds; Heald frames

- D03C9/02—Healds

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03C—SHEDDING MECHANISMS; PATTERN CARDS OR CHAINS; PUNCHING OF CARDS; DESIGNING PATTERNS

- D03C9/00—Healds; Heald frames

- D03C9/02—Healds

- D03C9/024—Eyelets

Definitions

- the invention relates to a heddle, which is particularly suitable for a Jacquard loom.

- Jacquard weaving machine usually use healds, which are suspended resiliently at one end. At the other end of the heald a cord, the so-called harness cord, which leads to a jacquard loom. This exerts on the cords a defined train, whereby the strands can be moved individually and independently.

- This type of Litzenbet decisivist comes at working speeds of modern looms to their limits. In order to keep the strand under control, it is necessary to keep up with growing Speed increasingly stronger springs are used. This burdens the jacquard machines unnecessarily. In addition, the possibility to use stronger springs, set limits due to the limited space.

- the heald known from the cited document has a plastic body into which a lug is inserted to form a thread eye.

- the mandrel is formed by a ring-shaped body made of a material that is harder than the plastic. At its outer periphery, this body has a circumferential, flat groove, in which engages the plastic body.

- the plastic body engages over the edges of the Maillons to secure it form-fitting.

- healds are not directly suitable for jacquard weaving in which the healds between the harness cord and the spring are constantly stretched.

- heald strand body is thickened in the region of the muzzle, which extend straight thigh away from this thickened area.

- the transition from the leg to the thickened thread eye region is formed by a short ramp-like section.

- ie material removal occur when warp threads on the strand along. If fibers of the plastic-fiber composite material are exposed as a result of the wear, then the reinforcing fibers protruding from the plastic body can damage warp threads.

- the disclosed EP 0947620 A1 a heald consisting of a flattened wire-like element.

- this element is provided with a longitudinal slot which is bounded by two legs. The legs are spread apart and hold between each other an eye.

- the strand according to the invention has a strand body consisting of a plastic body in which non-metallic fibers are embedded.

- the thread eye is formed by a Maillon, which consists of a material whose hardness is greater than the hardness of the plastic.

- the Maillon is embedded in the plastic body.

- the peculiarity lies in the strand body made of plastic, which has a ramp section in the transition between the legs and the thread eye portion whose length measured in the leg direction is at least twice as large as the height of the thread opening measured in the same direction.

- long fibers which are preferably oriented in the leg direction and do not extend transversely to the leg or thread eye.

- This type of fiber arrangement is based for example on the embedding of nonwoven fibers, for example so-called rovings in the plastic.

- the fibers then have a preferred orientation to one another, with all the fibers being oriented substantially parallel to one another. Lower deviations from the parallelism arise at most in the area of the ramp section.

- the enclosed by the fibers with each other acute angle is at most as large as the acute angle formed by the ramp section itself.

- the fibers thereof may be arranged to deviate from the circumferential direction of the mail. However, this is limited to an inner region of the plastic body, which is never exposed even with heavy wear and material removal.

- the cross section of the legs is round, with a radius of curvature R1.

- the ramp section and the thread eye section are preferably likewise rounded on their narrow sides. This preferably corresponds to a rounding radius R2 and R3, which corresponds in each case to the rounding radius R1.

- the cross section of the ramp portion and the flattened portion is preferably formed oval, wherein it is bounded by two opposite straight line pieces parallel to each other and two opposing circular arcs. This results in a uniform curvature of the lateral Edges or surfaces which face the warp threads running between the strands.

- the strands are made of a suitable plastic, for example a thermoplastic, but preferably a thermosetting plastic that can be hardened.

- a suitable plastic for example a thermoplastic, but preferably a thermosetting plastic that can be hardened.

- This can be formed, for example, by a two-component plastic, for example an epoxy resin.

- the Maillon is preferably used before the solidification of the plastic in the heald body and thereby connected to this material and form fit. An adhesive is not required to attach the mailbox.

- the strand according to the invention can be produced by injection molding or by injection molding. Preferably, continuous reinforcing fibers are provided which extend from one leg across the mandrel into the other leg.

- the fiber strand used is first soaked with a not yet cured plastic.

- the maillon is used at the desired location.

- the strand is given its final shape by insertion and possibly compression in a mold and is cured, for example by heat or ultraviolet radiation.

- the one end of the strand is preferably shaped so that it can easily be connected to a harness cord.

- the end of the heddle body is formed for example as an eyelet or as a hook. Other forms suitable for connecting a harness cord are possible.

- the second opposite End of the strand body can also be configured, if there is a cord to be connected there. If a pull-down spring is to be connected, the plastic can also be designed so that a hook or a thread is formed, onto which the end of the pull-down spring is to be screwed.

- the ramp section forms a smooth transition between the small cross section of the leg and the larger cross section of the Litzenauges. It can be designed as a straight line piece or S-shaped. Preferably, it is at least 10 mm long. In most preferred embodiments, the length of the ramp section is larger and may be up to 30 mm.

- Developments of the invention are directed to a strand with a Maillon, which forms not only the thread eye, but also, at least parts of the outer surface of the strand.

- the mail may be enlarged to an elongated part, which has the thread eye and additional attachment possibilities for the strand formed from the fibers or the plastic material.

- this enlarged Maillon receives the ramped portions of the strand and, for example, on the narrow sides or on the flat sides arranged longitudinal grooves which receive the relevant part or leg of the plastic body.

- the connection possibilities can be formed by openings through which the fibers of the plastic leg extend.

- Suitable reinforcing fibers are glass fibers, aramid fibers, protein fibers or carbon fibers.

- the fiber reinforcement gives the strands a rigidity which makes it possible to use them in jacquard machines.

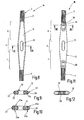

- a stranded wire 1 is illustrated for a Jacquard weaving machine.

- the strand 1 has a strand body 2 with two preferably straight and mutually aligned legs 3, 4, which include a thread eye portion 5 and ramp sections 6, 7 between each other.

- the legs 3, 4 may have the same or different diameters and cross sections. Preferably, they have a round cross-section, as it is for example in Fig. 6 is illustrated by the cross section of the leg 4.

- the leg 4 is substantially cylindrical and its circular cross-section has a radius R1.

- the ends of the legs 3, 4 are adapted for connection to other devices, such as harness cords or tension springs.

- the lower end of the leg 4 may also be formed as a hook or eye. In the preferred case, however, it carries a thread 10, such as in Fig. 7 is indicated, can be screwed to the end of a tension spring 11.

- the thread eye portion 5 includes a mandrel 12, as for example Fig. 3 can be seen.

- the mandrel is formed by an annular body of a hard, wear-resistant material, such as ceramic.

- the ceramic may be a sintered ceramic, a reaction ceramic, an oxide ceramic or the like.

- the mandrel 12 may consist of a cermet, a hard metal, a hardened steel ring or the like. It has a thread guide opening 13, which may be elliptical or oval.

- Fig. 4 illustrates is the Opening 13 of the mail 12 preferably rounded and free of sharp edges. It has, measured in the longitudinal direction of the legs 3, 4 preferably a height which is greater than its width measured transversely thereto.

- the mandrel 12 On its outer circumference, the mandrel 12 defines an all-round channel into which the heddle body 2 engages.

- the thread eye portion 5 has an oval cross-section. This is formed by two mutually parallel edges 14, 15 in the form of straight flat Abschuiften, which are connected at the ends by arcs 16, 17.

- the arcs 16, 17 have a radius of curvature R2, which preferably coincides with the rounding radius R1.

- flanks 18, 19 are there cutouts of a cylinder jacket. In the Fig. 1 visible flanks 18, 19 are oriented parallel to each other.

- the two ramp sections 6, 7 may be the same or as shown differently formed with respect to their length. It is preferably in a range between 10 and 30 mm, while the distance of the flanks 18, 19 from each other is smaller than 10 mm in most cases.

- the ramp sections 6, 7 have a length that is greater, preferably significantly greater, than the height of the thread guide opening 13 to be measured in the same direction.

- the length of the ramp sections 6, 7 is at least twice as long, optimally at least three times as large like the height of the thread opening 13.

- the ramp areas 6, 7 preferably have a constant in Fig. 1 perpendicular to the plane, ie in the direction of the thread guide opening 13, to be measured thickness.

- the ramp sections 6, 7 smoothly connect both to the legs 3, 4 and to the thread guide section 5.

- Fig. 5 illustrates a section of the ramp section 7 at the section line VV.

- the FIGS. 5 and 6 stand on the same scale. It can be seen that the ramp sections 6, 7 have on their flanks 20, 21 a curvature R3 which coincides with the curvature R1 and R2 ( Fig. 4 is drawn on a different scale as the FIGS. 5 and 6 ).

- the body 2 of the strand 1 is a plastic body which, like the Fig. 1-6 suggest reinforcing fibers 22 for reinforcement. These run substantially parallel to a longitudinal direction, which is predetermined by the legs 3, 4 and connects the eyelet 8 with the thread 10.

- the fibers 22 are preferably long fibers, which are all oriented in the longitudinal direction. An exception to the orientation in the longitudinal direction is how Fig. 3 shows, if necessary, in the area of the ramp sections 6, 7 and the thread eye portion 5.

- the reinforcing fibers 22 here circulate the Maillon 12. However, the fibers are oriented here also substantially in the longitudinal direction. In any case, no fiber is arranged transversely.

- the fibers 22 are embedded in the plastic and covered by this.

- the plastic is for example an epoxy resin or another thermosetting plastic. Alternatively, a thermoplastic Plastic used.

- the Maillon 12 is embedded in the plastic body and connected to this materially. The compound is made without additional adhesive by the Maillon is used in the initially uncured plastic, after which the plastic cure

- the fibers 22 may be glass fibers, mineral fibers, carbon fibers or proteinaceous fibers, e.g. be in the form of spider silk.

- FIGS. 8 and 9 illustrate a modified and optimized with respect to the use of aggressive warp yarns, such as Armidmaschinen, stranded la.

- This in turn has legs 3, 4, for which the above description applies accordingly.

- the ramp sections 6, 7 are significantly longer than the longitudinal extension of the thread guide opening 13 of the mail 12.

- both the ramp sections 6, 7 and the thread eye section 5 are formed, by enlarging the maillon to an oblong part.

- grooves 23, 24 may be formed through which legs 25, 26 of the plastic body 2 extend.

- the legs 25, 26 connect, as from the FIGS. 8 and 9 shows the legs 3, 4 together and hold the Maillon 12 between each other. They thus constitute a part of the heddle body 2.

- the reinforcing fibers 22 extend from one leg 3 to the other leg 4, passing either through the leg 25 or through the leg 26.

- the legs 25, 26 are substantially embedded in the grooves 23, 24 and thus protected by the hard material of the mail 12 against damage by the abrasive warp threads.

- corresponding grooves 23a, 23b, 24a, 24b according to FIG. 10 provided between which webs 27, 28 project the Maillons 12.

- the webs 27, 28 form formed on the mandrel 12 longitudinally extending ribs that form start-up or contact surfaces for the passing on the strands warp threads.

- the grooves 23a, 23b, 24a, 24b are in turn corresponding portions of the heddle body 2, which hold as Maillon 12 positive and cohesive.

- FIGS. 11 and 12 A further modified embodiment of a stranded wire 1b from the FIGS. 11 and 12 seen.

- the mandrel 12 independently forms the ramp sections 6, 7 and the thread eye section 5.

- the legs 3, 4 are on the Maillon 12 connected. For this purpose, this has recesses with fastening openings 29 at its narrow ends remote from the thread eye 13. In this extension 30 of the leg 3 or 4 may extend into, wherein the plastic including the fibers can enforce the mounting holes 29.

- This strand can be produced in particular by injection molding.

- the mounting holes 29 and recesses provided at the ends of the mailbox serve to anchor the injection molding compound.

- the strand is produced by placing the mailbox in the injection molding machine and then overmolding it.

- the plastic body 2 and the legs 3, 4 may optionally also be made of a plastic, which instead of continuously extending reinforcing fibers short fibers, so-called whiskers.

- whiskers instead of continuously extending reinforcing fibers short fibers

- An inventive strand for Jacquard machines consists essentially of fiber-reinforced plastic, wherein the thread eye is formed by a Maillon 12.

- the heddle body has two legs 3, 4. Between the relatively wide thread eye portion 5 and the legs 3, 4 ramp portions 6, 7 are provided, the length of which is greater than the length of the thread eye 13. Preferably, the length is greater than twice the longitudinal extension of the thread eye. It is in most cases between 10 and 30 mm. By this measure, the wear of the plastic in the vicinity of the thread eye 13 is kept so low that neither damage the stiffening in the plastic body Fibers 22 is still to be feared damage to the warp threads.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Looms (AREA)

- Woven Fabrics (AREA)

Claims (19)

- Lisse (1, 1a, 1b) pour métier à tisser Jacquard, comprenant un corps de lisse (2) et un maillon (12) qui présente une ouverture de fil (13) incorporée au corps de lisse (2), étant précisé que le corps de lisse (2)- possède des branches (3, 4) qui partent du maillon (12) et qui présentent une section ronde,- présente, sur une partie à oeillet de fil (5) entourant le maillon (12), une section aplatie,- présente, au passage de la partie à oeillet de fil (5) à la branche (3, 4) une partie à rampe (6, 7) dont la section s'aplatit en allant de la branche (3, 4) à la partie à oeillet de fil (5),

cette lisse étant caractérisée en ce que- la longueur, mesurée selon la direction longitudinale de la branche, de chaque partie à rampe (6, 7) est au moins deux fois plus grande que la hauteur, mesurée selon la même direction, de l'ouverture de fil (13),- le corps de lisse est fait d'une matière plastique dans laquelle sont noyées des fibres (22) non métalliques,- le maillon est fait d'une matière dont la dureté est supérieure à celle de la matière plastique. - Lisse selon la revendication 1, caractérisée en ce que la section de la branche (3, 4) présente un rayon d'arrondi (R1) et la section de la zone aplatie présente un rayon d'arrondi (R2).

- Lisse selon la revendication 2, caractérisée en ce que le rayon d'arrondi (R1) de la branche est le même que le rayon d'arrondi (R2 ou R3) de la partie à rampe (6, 7) ou de la partie à oeillet de fil (5).

- Lisse selon la revendication 1, caractérisée en ce que la section de la partie à rampe (6, 7) ou de la partie à oeillet de fil (5) a une forme ovale qui est délimitée par deux segments de droite (14, 15) se faisant face et parallèles ainsi que par deux arcs de cercle (16, 17) se faisant face.

- Lisse selon la revendication 1, caractérisée en ce que la matière plastique est un duroplaste durci.

- Lisse selon la revendication 1, caractérisée en ce que la matière plastique est un thermoplaste.

- Lisse selon la revendication 5 ou 6, caractérisée en ce que le maillon (12) est, avant durcissement de la matière plastique, inséré dans le corps de lisse (2) où il est fixé sans utilisation d'adhésif.

- Lisse selon la revendication 1, caractérisée en ce que les fibres (22) sont des fibres longues orientées exclusivement selon la direction longitudinale du corps de lisse (2).

- Lisse selon la revendication 1, caractérisée en ce que les fibres (22) sont des fibres courtes.

- Lisse selon la revendication 5, caractérisé en ce que les fibres (22) sont disposées en désordre dans le corps de lisse (2).

- Lisse selon la revendication 1, caractérisée en ce que le maillon (12) présente au moins une partie qui constitue la partie à rampe (6, 7).

- Lisse selon la revendication 1, caractérisée en ce que le corps de lisse (22) s'étend dans au moins une rainure (23) formée sur le maillon (12).

- Lisse selon la revendication 12, caractérisée en ce que la rainure (23) du maillon (12) accueille la branche (25) concernée du corps de lisse (2).

- Lisse selon la revendication 13, caractérisée en ce que la branche (25) du corps de lisse (2) est entourée par la rainure (23) du maillon (12).

- Lisse selon la revendication 1, caractérisée en ce que le maillon (12) est en verre, en aluminium, en céramique, en métal dur ou en acier fortement durcissable.

- Lisse selon la revendication 1, caractérisée en ce que les fibres sont en verre, en aramide, en carbone ou en protide.

- Lisse selon la revendication 1, caractérisée en ce que le corps de lisse (2) est interrompu sur le maillon (12) et que les branches (3, 4) sont fixées sur celui-ci.

- Lisse selon la revendication 17, caractérisée en ce que le maillon présente au moins une ouverture de fixation (29) pour le raccordement de chaque branche (3, 4).

- Harnais Jacquard comportant une lisse selon une des revendications précédentes.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP06021003A EP1908863B1 (fr) | 2006-10-06 | 2006-10-06 | Lisse pour métier à tisser Jacquard |

| BRPI0703652-3A BRPI0703652A (pt) | 2006-10-06 | 2007-10-03 | liço de tecedura para máquina de tecedura de jacquard |

| CN2007101622721A CN101158077B (zh) | 2006-10-06 | 2007-10-08 | 用于提花织机的织综 |

| US11/907,034 US7464730B2 (en) | 2006-10-06 | 2007-10-09 | Weaving heddle for jacquard weaving machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP06021003A EP1908863B1 (fr) | 2006-10-06 | 2006-10-06 | Lisse pour métier à tisser Jacquard |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1908863A1 EP1908863A1 (fr) | 2008-04-09 |

| EP1908863B1 true EP1908863B1 (fr) | 2009-04-08 |

Family

ID=37496966

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06021003A Not-in-force EP1908863B1 (fr) | 2006-10-06 | 2006-10-06 | Lisse pour métier à tisser Jacquard |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7464730B2 (fr) |

| EP (1) | EP1908863B1 (fr) |

| CN (1) | CN101158077B (fr) |

| BR (1) | BRPI0703652A (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103849973A (zh) * | 2014-03-19 | 2014-06-11 | 常州市武进牛塘如意纺织器材厂 | 碳纤维织造专用钢片综 |

| EP3839115B1 (fr) * | 2019-12-20 | 2022-09-07 | Staubli Lyon | Lisse pour métier à tisser et harnais équipé d'une telle lisse |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2347696T3 (es) * | 2007-07-26 | 2010-11-03 | Groz-Beckert Kg | Mallon acodado estrecho. |

| EP2166138A1 (fr) * | 2008-09-23 | 2010-03-24 | Groz-Beckert KG | Lisse Jacquard dotée d'une zone d'oeil gaufré |

| BE1018304A3 (nl) | 2008-10-13 | 2010-08-03 | Wiele Michel Van De Nv | Hevel. |

| DE102009010316B4 (de) * | 2009-02-24 | 2016-11-10 | Karl Mayer Textilmaschinenfabrik Gmbh | Verfahren zum Herstellen einer Wirkwerkzeugfassung |

| BE1018732A3 (nl) * | 2009-04-24 | 2011-07-05 | Wiele Michel Van De Nv | Drie-dimensionaal heveloog. |

| EP2505701B1 (fr) * | 2011-03-28 | 2014-12-31 | Groz-Beckert KG | Lisse en matière synthétique à plusieurs composants et son procédé de fabrication |

| EP2505703B1 (fr) * | 2011-03-28 | 2014-12-03 | Groz-Beckert KG | Lisse en matière synthétique et procédé de fabrication à partir d'une bande de feuilles |

| CN102776648A (zh) * | 2012-07-25 | 2012-11-14 | 浙江旷达纺织机械有限公司 | 一种用于织机的通丝线钢片棕丝杆 |

| US9328435B2 (en) * | 2013-11-08 | 2016-05-03 | Deertex, Inc. | Functional weaving vamp fabric |

| CN103668638A (zh) * | 2013-11-29 | 2014-03-26 | 湖州金能达印染有限公司 | 一种改进的多功能综丝 |

| FR3027313B1 (fr) | 2014-10-16 | 2016-11-18 | Staubli Lyon | Lisse pour metier a tisser, metier a tisser equipe d'une telle lisse et procede de fabrication d'une telle lisse |

| FR3027314B1 (fr) * | 2014-10-16 | 2019-04-26 | Staubli Lyon | Lisse pour metier a tisser et metier a tisser equipe d'une telle lisse |

| FR3027315B1 (fr) | 2014-10-16 | 2019-04-26 | Staubli Lyon | Lisse pour metier a tisser et metier equipe d'une telle lisse |

| TWM493278U (zh) * | 2014-10-21 | 2015-01-11 | Deertex Inc | 具有透氣耐磨梭織鞋面之鞋類組件 |

| JP7560407B2 (ja) | 2021-05-07 | 2024-10-02 | 津田駒工業株式会社 | ヘルド |

| FR3146149B1 (fr) | 2023-02-28 | 2025-03-07 | Staubli Lyon | Lisse pour métier à tisser et métier à tisser équipé d’une telle lisse |

| FR3155244B1 (fr) * | 2023-11-09 | 2025-11-14 | Staubli Lyon | Lisse Jacquard et métier à tisser comprenant une telle lisse Jacquard |

Family Cites Families (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE342071A (fr) * | ||||

| US887102A (en) * | 1907-09-24 | 1908-05-12 | William Shinn Lackey | Heddle. |

| US997283A (en) * | 1908-07-11 | 1911-07-11 | Steel Heddle Mfg Co | Heddle. |

| US1413949A (en) * | 1921-09-08 | 1922-04-25 | Paul A Wagner | Heddle for looms |

| US1648139A (en) * | 1925-10-28 | 1927-11-08 | Rene A Machon | Heddle for jacquard weaving |

| US1944516A (en) * | 1930-10-25 | 1934-01-23 | Atlanta Harness And Reed Mfg C | Loom harness and mail eye therefor |

| US1930151A (en) * | 1931-11-04 | 1933-10-10 | Rhode Island Warp Stop Equipme | Heddle or drop-wire |

| US2019822A (en) * | 1934-07-24 | 1935-11-05 | Steel Heddle Mfg Co | Loom heddle and method of making the same |

| US2249390A (en) * | 1939-02-26 | 1941-07-15 | Mahler Otto | Heddle |

| US3049151A (en) * | 1960-06-01 | 1962-08-14 | Greensboro Loom Reed Company I | Anti-friction instrumentalities for a loom |

| US3960182A (en) * | 1975-04-07 | 1976-06-01 | Staeubli, Ltd. | Heddles for weaving machines having heddle frame bars for several heddles, which bars are moved by a shed-forming device |

| CH631755A5 (de) | 1978-09-26 | 1982-08-31 | Braecker Ag | Webelitze. |

| US4355665A (en) * | 1980-05-26 | 1982-10-26 | Bracker Ag | Heddle |

| US4790357A (en) * | 1987-08-06 | 1988-12-13 | Steel Heddle Mfg., Inc. | Harness frame slat and heddle |

| IT1228325B (it) * | 1989-01-09 | 1991-06-11 | Vamatex Spa | Quadro di tessitura di configurazione asimmetrica. |

| US5052446A (en) * | 1989-06-12 | 1991-10-01 | Sulzer Brothers Limited | Thermoplastic heddle with braided fiber tube reinforcement |

| US5092370A (en) * | 1990-01-31 | 1992-03-03 | Asten Group, Inc. | Split heddle with superimposed blades with aligned apertures |

| DE4023498C1 (fr) * | 1990-07-24 | 1991-10-24 | Grob & Co Ag, Horgen, Zuerich, Ch | |

| US5348055A (en) * | 1993-05-06 | 1994-09-20 | Steel Heddle Mfg. Co. | Heddle eyelet structure |

| DE4336362C1 (de) * | 1993-10-25 | 1994-10-13 | Grob & Co Ag | Fadenauge für Weblitze |

| CH692587A5 (de) * | 1997-09-16 | 2002-08-15 | Braecker Ag | Stabförmiges Fadenführungselement für Textilmaschinen, insbesondere Weblitze, und Verfahren zur Herstellung desselben. |

| DE19800811B4 (de) * | 1998-01-12 | 2009-06-04 | Grob Textile Ag | Weblitze |

| FR2776676B1 (fr) * | 1998-03-31 | 2000-05-26 | Staubli Lyon | Procede de fabrication d'une lisse, lisse et dispositif de formation de la foule pour metier a tisser |

| DE19932685A1 (de) * | 1999-07-13 | 2001-01-18 | Grob Horgen Ag Horgen | Weblitzensystem |

| CH695240A5 (de) * | 2001-02-28 | 2006-02-15 | Braecker Ag | Weblitze und Verfahren zur Herstellung einer Weblitze. |

| DE10116813B4 (de) * | 2001-04-04 | 2010-04-01 | Grob Textile Ag | Webschafteckverbindung |

| DE10124022C2 (de) | 2001-05-17 | 2003-04-10 | Inst Textil & Faserforschung | Fachbildeeinrichtung mit Federdämpfung |

| FR2835538B1 (fr) * | 2002-02-07 | 2004-05-21 | Staubli Lyon | Lisse et son procede de fabrication, dispositif de formation de la foule et metier a tisser incorporant une telle lisse |

| DE10206130B4 (de) * | 2002-02-14 | 2016-09-01 | Groz-Beckert Kg | Webschaft mit mindestens einer Weblitze |

| DE10325908B4 (de) * | 2003-06-05 | 2005-07-21 | Groz-Beckert Kg | Schaftstab, Webschaft und Verfahren zur Herstellung eines Schaftstabs |

-

2006

- 2006-10-06 EP EP06021003A patent/EP1908863B1/fr not_active Not-in-force

-

2007

- 2007-10-03 BR BRPI0703652-3A patent/BRPI0703652A/pt not_active Application Discontinuation

- 2007-10-08 CN CN2007101622721A patent/CN101158077B/zh active Active

- 2007-10-09 US US11/907,034 patent/US7464730B2/en active Active

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103849973A (zh) * | 2014-03-19 | 2014-06-11 | 常州市武进牛塘如意纺织器材厂 | 碳纤维织造专用钢片综 |

| EP3839115B1 (fr) * | 2019-12-20 | 2022-09-07 | Staubli Lyon | Lisse pour métier à tisser et harnais équipé d'une telle lisse |

Also Published As

| Publication number | Publication date |

|---|---|

| US7464730B2 (en) | 2008-12-16 |

| EP1908863A1 (fr) | 2008-04-09 |

| CN101158077B (zh) | 2011-09-14 |

| CN101158077A (zh) | 2008-04-09 |

| US20080083471A1 (en) | 2008-04-10 |

| BRPI0703652A (pt) | 2008-06-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1908863B1 (fr) | Lisse pour métier à tisser Jacquard | |

| EP2162634B1 (fr) | Ensemble pour relier un element allonge a un autre composant | |

| EP2475817B1 (fr) | Corde comportant des filaments de carbone | |

| EP2166139B1 (fr) | Lisse Jacquard dotée d'une zone visuelle de fil imprégnée | |

| EP2659039A2 (fr) | Bande de ceinture de securité pour un système de ceinture de sécurité | |

| DE102010011792A1 (de) | Seilendverbindung | |

| DE102016210040A1 (de) | Verfahren zum Herstellen eines zumindest bereichsweise profilierten, faserverstärkten Kunststoffprofils, ein profiliertes, faserverstärktes Kunststoffprofil und seine Verwendung | |

| EP1739215B1 (fr) | Lisse préservant le fil | |

| EP1795636B1 (fr) | Lisse pour des fils de chaîne en forme de bande | |

| EP2198085B1 (fr) | Bande transporteuse à bord renforcé | |

| EP2505701B1 (fr) | Lisse en matière synthétique à plusieurs composants et son procédé de fabrication | |

| DE3004075A1 (de) | Elastisches gelenk, kupplung o.dgl. | |

| DE102017223577B3 (de) | Zahnstange für Greiferwebmaschinen | |

| EP1560959B1 (fr) | Peigne fixe et support de peigne fixe pour peigneuse textile | |

| EP1743966B1 (fr) | Lisse de tissage pour métier à tisser à grande vitesse | |

| EP3400131A1 (fr) | Composants renforcés par des fibres et composants structurels ainsi que procédé de fabrication | |

| DE69913301T2 (de) | Schussfadengreiferpaar für Webmaschinen | |

| EP1643157B1 (fr) | Courroie dentée | |

| DE3148086A1 (de) | Kantenschutzeinrichtung und damit versehener gliederriemen | |

| EP1586683B1 (fr) | Ruban à pinces pour métier à tisser à pinces et métier à tisser à pinces | |

| EP0564954B1 (fr) | Plaque de maillon de chaîne et son procédé de fabrication | |

| CH706587A1 (de) | Garniturträger. | |

| DE202024102779U1 (de) | Schneegleitbrett mit einer oder mehreren Funktionslagen | |

| DE202024102780U1 (de) | Schneegleitbrett mit einer oder mehreren Funktionslagen | |

| DE102011002796A1 (de) | Trägerelement für die Aufnahme in einem Zug- oder Lastträgergurt |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17P | Request for examination filed |

Effective date: 20080419 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| AKX | Designation fees paid |

Designated state(s): BE CZ FR IT |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE CZ FR IT |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20100111 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20141001 Year of fee payment: 9 Ref country code: FR Payment date: 20141022 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151006 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20160630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151102 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20200916 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20200911 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20211031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211006 |