EP1564339B1 - Enceinte résistante au feu pour des éléments d'installation ou des éléments éléctrotechniques - Google Patents

Enceinte résistante au feu pour des éléments d'installation ou des éléments éléctrotechniques Download PDFInfo

- Publication number

- EP1564339B1 EP1564339B1 EP20040009626 EP04009626A EP1564339B1 EP 1564339 B1 EP1564339 B1 EP 1564339B1 EP 20040009626 EP20040009626 EP 20040009626 EP 04009626 A EP04009626 A EP 04009626A EP 1564339 B1 EP1564339 B1 EP 1564339B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- housing

- panel element

- profiles

- metal

- metal supporting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000009434 installation Methods 0.000 title claims description 10

- 230000009970 fire resistant effect Effects 0.000 title description 2

- 239000002184 metal Substances 0.000 claims description 58

- 239000010410 layer Substances 0.000 claims description 43

- 239000000463 material Substances 0.000 claims description 33

- 239000011490 mineral wool Substances 0.000 claims description 26

- 238000010079 rubber tapping Methods 0.000 claims description 5

- 239000011324 bead Substances 0.000 claims description 4

- 230000004888 barrier function Effects 0.000 claims description 2

- 239000002356 single layer Substances 0.000 claims description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims 1

- 229910052799 carbon Inorganic materials 0.000 claims 1

- 239000011507 gypsum plaster Substances 0.000 claims 1

- 238000000465 moulding Methods 0.000 description 15

- 238000010276 construction Methods 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000003779 heat-resistant material Substances 0.000 description 2

- 238000009413 insulation Methods 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 239000004568 cement Substances 0.000 description 1

- 239000003063 flame retardant Substances 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/62—Insulation or other protection; Elements or use of specified material therefor

- E04B1/92—Protection against other undesired influences or dangers

- E04B1/94—Protection against other undesired influences or dangers against fire

- E04B1/941—Building elements specially adapted therefor

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

- E04B9/001—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation characterised by provisions for heat or sound insulation

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

- E04B9/006—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation with means for hanging lighting fixtures or other appliances to the framework of the ceiling

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

- E04B9/04—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation comprising slabs, panels, sheets or the like

- E04B9/045—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation comprising slabs, panels, sheets or the like being laminated

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V25/00—Safety devices structurally associated with lighting devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21S—NON-PORTABLE LIGHTING DEVICES; SYSTEMS THEREOF; VEHICLE LIGHTING DEVICES SPECIALLY ADAPTED FOR VEHICLE EXTERIORS

- F21S8/00—Lighting devices intended for fixed installation

- F21S8/02—Lighting devices intended for fixed installation of recess-mounted type, e.g. downlighters

Definitions

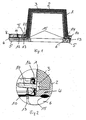

- Such a molding is from the EP-A-0908668 known.

- a layer of mineral wool, especially rock wool, is arranged between the insulating layer and the housing wall.

- the housing may be according to its purpose a large-sized sheet metal housing with one-sided open mouth, the housing is preferably formed cuboid.

- the fire protection material on the one hand a mineral wool layer or rock wool layer and on the other hand has a mineral wool or rock wool layer covering layer of material which inflates under the action of heat and / or fire, a significant advantage is achieved. Due to the combination of these two materials, optimum thermal insulation is achieved with a small wall thickness of the sandwich-type layer. In addition, the weight is kept relatively low, because a lower weight is achieved by the combination of materials; as in the case that the material layer only from the insulating layer forming, under the action of heat or fire inflatable material would consist.

- the production costs are minimized because the relatively expensive, the insulating layer forming inflatable material must be used only in relatively small wall thickness, while the cost-effective mineral wool or rock wool material can be used according to their intended use dimensioned.

- this combination is the Total wall thickness kept relatively low, so that the installation space, which is available in the housing after introducing the material layers, is kept relatively large. In a construction with mineral wool or rock wool alone, the wall layer would be considerably stronger, so that the installation space would be considerably restricted in the housing.

- the housing has a mouth edge and a mineral wool-free edge is provided in the region of the mouth edge of the housing, which is filled by the insulating layer forming material, which is directly connected to the edge of the housing, in particular glued.

- the over-molded front edge acts like a nachCumende sealing lip and ensures the space closure.

- the mineral wool plate material is fixed to the inside of the metal case by the material forming the insulating layer.

- the material forming the insulating layer is applied to the mineral wool layer and the edge of the shell during production as a castable material.

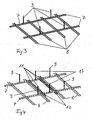

- the invention also relates to a false ceiling for fire protection purposes.

- this consists of a single-layer or preferably multi-layered plate member made of fire and heat resistant material, such as plasterboard, a support member holding the plate member with intersecting laid first and second metal support profiles to which the components of the plate member are secured in a suitable form.

- band-like or anchor-like fastening parts are provided, which are preferably fastened on the one hand to the first metal support profiles and on the other hand can be fastened to the building ceiling or similar supporting parts, so that the construction of a suspended ceiling is realized.

- the plate element has at least one opening, which is covered by a molding according to one of claims 1 to 3. The molding supports on the back of the plate element at this from.

- Rear side of the plate member are adjacent to the opening and adjacent to the edges of the molding, which covers the opening, two mutually parallel third metal support profiles, which are connected to these crossing first metal support profiles, or at least a third metal support profile is arranged with a first or second metal support profile is connected, and is aligned at a distance to a first or second metal profile parallel to this, wherein the third support profiles or laterally surrounding the opening profiles, namely a third support profile and a parallel thereto first or second metal profile in addition by means of fasteners are attached to the plate member and the mouth edge of the molding forming housing is fastened by means of fasteners to a respective adjacent leg of a first, second or third metal support profile.

- band-like or anchor-like fastening elements are arranged on the first or second metal support profiles, specifically in the area of the first metal support profiles adjacent to the wall of the housing, which are fastened to the building ceiling or similar supporting parts.

- the lower edge of the housing is aligned with the contact surface of the first, second and / or third metal support profiles on the plate member.

- screws in particular sheet-metal screws, are arranged as fastening means.

- the sub-ceiling is constructed in a conventional manner, wherein the first and second metal support profiles are attached via anchors or the like to the ceiling or the like support member and the plate elements are fixed to these profiles.

- the molding is positioned above the opening, which is provided for the installation of a lamp or the like.

- the arrangement of third metal support profiles is provided near two mutually parallel edges of the rectangular opening, which intersect the first support profiles and are secured at the intersection point to this.

- the housing with its mouth is level with the bottom edge of the mounting profiles (third metal support profiles) aligned.

- the housing is hung by means of two each attached to its sides, for example screwed or dotted angles on the additional third metal support profiles.

- tapping screws are screwed laterally from the inside or outside, so that a connection of the housing is made to the third metal support profile.

- the third metal support profile is additionally fastened by screws to the plate elements, which penetrate the plate elements, so that a firm fixation of the entire finished component is ensured on the plate member. It is thus not possible to move the molding or push up.

- the front edge of the housing is covered with the insulating layer forming material, so that in case of fire, the space closure is granted.

- the over-molded front edge acts like a nachCumende sealing lip and ensures the space closure.

- the encircling caterpillar made of fire-retardant cement supports this process and additionally causes the parts to stick to the plate material.

- first and second metal support profiles in a common plane and to connect them together or to arrange the metal support profiles on top of each other in two levels and to connect in the crossing area.

- the profiles adjacent to the parallel marginal edges of the rectangular opening can by a third metal support profile and be formed by a first or a second metal support profile.

- the housing is then hung on the profiles and secured thereto in the manner described above, the profiles also being secured in an analogous manner to the panel members.

- the layer of mineral wool 3 is formed by plate-like parts of mineral wool, which are introduced in the form of a bottom part and in the form of wall parts in the housing and which are held in a positionally secured by the insulating layer forming material 2.

- a free edge of mineral wool 3 is provided, which is filled by the material forming the insulating layer 2, which is firmly connected in this area directly to the edge of the housing 1, for example glued.

- This area is designated 4.

- Such a molded part is installed in a false ceiling for fire protection purposes.

- the lower ceiling consists of a preferably two-layered plate element 5, 6 of fire and heat resistant material, such as plasterboard. This plate element 5, 6 is held on a support structure, which in FIGS.

- first metal support profiles 7 and second metal support profiles 8 are provided, which are interconnected at the intersection points.

- the support profiles 7 are fastened by means of band-like or anchor-like fastening parts 9 to a building ceiling or the like.

- the plate element 5, 6 has an opening which is covered by the molded part (1, 2, 3). This is supported on the back of the plate element 5, 6 at this.

- the rear side of the plate element next to the opening and adjacent to the edges of the molded part, which covers the opening the arrangement of two parallel third metal support profiles 10 are provided, which are firmly connected to the crossing these extending first metal support profiles 7 in the crossing region at 11.

- the third support profiles 10 are fastened to the plate element 5, 6 by means of fastening means.

- fastening means 12 serve as fastening means 12, 13 tapping screws.

- the mouth edge of the housing forming the molding 1 is also fastened by means of fastening means 14 to a respective adjacent leg of a third metal support profile 10.

- the fastening means 14 tapping screws. These tapping screws can be inserted from the outside, as in FIG. 1 right, or from the inside, as in FIG. 1 left, where appropriate, a placeholder in the region of the layers 2, 3 is provided in order to position the fastener there after removal of the placeholder can.

- a circumferential bead 15 is applied from fire protection putty.

- additional bracket 16 are attached to the side walls of the housing 1, for example dotted or screwed, which grab in the desired mounting position on legs or webs of the third metal support profiles 10, as in particular FIG. 2 and FIG. 5 is apparent.

- 7 band-like or anchor-like fasteners 17 are arranged on the first metal support profiles, in the next to the wall of the housing 1 located portion of the first metal support profiles 7, wherein these fasteners 17 are attached to the building ceiling or the like.

- the first supports 7 are fastened by means of fastening elements 9 to the ceiling and subsequently the metal support profiles 8 are connected to the metal support profiles 7 at the crossing points.

- the third metal support profiles 10 can be arranged between two metal support profiles 8 and connected at the intersection points with the metal support profiles 7, wherein additional Ceiling fasteners 17 are secured in the region of the metal support profiles 7, which are adjacent to the molded part to be fastened.

- the workflow is in FIGS. 3 and 4 illustrated.

- the molded part in the form of the housing 1 with the brackets 16 are suspended on the third metal support profiles 10, as in FIG. 5 is illustrated.

- connection lines can be guided by perforations of the molding, which are not particularly shown in the drawing.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Building Environments (AREA)

- Casings For Electric Apparatus (AREA)

Claims (9)

- Pièce usinée, en particulier pièce usinée en forme de caisse ou en forme de pot, pour protection coupe-feu comprenant une ouverture avant pour disposer des éléments d'installation ou des éléments électrotechniques, notamment une lampe, la pièce usinée consistant en un boîtier (1) en forme stable en matériau ininflammable, en particulier tôle métallique comprenant du côté intérieur un matériau (2) formant une couche isolante, qui sous l'action de la chaleur et/ou du feu se gonfle et/ou forme une couche de barrage de carbone, caractérisée en ce qu'entre la couche isolante (2) et la paroi du boîtier, une couche (3) en laine minérale, en particulier laine de roche, est arrangée.

- Pièce usinée selon la revendication 1 comme boîtier (1) consistant en une partie de fond et une partie de paroi, caractérisée en ce que la couche (3) en laine minérale est formée par des parties en forme de panneau en laine minérale, qui sont pratiquées en forme d'une partie de fond et en forme de parties de paroi dans le boîtier (1) et sont maintenues de manière bloquée par le matériau (2) formant la couche isolante.

- Pièce usinée selon la revendication 1 ou 2, caractérisée en ce que le boîtier (1) comprend un bord d'embouchure et dans la région du bord d'embouchure du boîtier (1) un bord qui ne contient pas de laine minérale (3) est prévu, qui est rempli du matériau (2) formant la couche isolante, qui est immédiatement lié avec le bord du boîtier (1), en particulier collé.

- Faux plafond pour protection coupe-feu, consistant en un élément de panneau (5, 6) réalisé en une couche ou de préférence en plusieurs couches en un matériau résistant au feu et à la chaleur, placo-plâtre notamment, une structure porteuse maintenant l'élément de panneau (5, 6) et comprenant des premiers et deuxièmes profils porteurs métalliques (7, 8) placés en croix, auxquels les composants de l'élément de panneau (5, 6) sont fixés et qui sont fixés au moyen de pièces de fixation (9) du type bande ou du type élément d'ancrage à un plafond d'un bâtiment ou à des parties de support semblables, dans lequel l'élément de panneau (5, 6) comprend au moins une ouverture, qui est recouverte par une pièce usinée selon une des revendications 1 à 3, qui sur le côté arrière de l'élément de panneau (5, 6) s'appuie sur celui-ci, dans lequel sur le côté arrière de l'élément de panneau (5, 6) à côté de l'ouverture et à côté des bords de la pièce usinée recouvrant l'ouverture, deux troisièmes profils porteurs métalliques (10) en parallèle sont arrangés, qui sont liés à des premiers profils porteurs métalliques (7) ou (8) s'étendant en croix par rapport à ceux-ci, ou au moins un troisième profil porteur métallique (10) est arrangé, qui est lié à un premier ou deuxième profil porteur métallique (7, 8), et est orienté à distance d'un premier ou deuxième profil métallique (7, 8) en parallèle à celui-ci, les troisièmes profils porteurs (10) ou les profils qui latéralement enrobent l'ouverture, c'est-à-dire un troisième profil porteur (10) et un premier ou deuxième profil métallique (7, 8) s'étendant en parallèle à celui-ci sont en addition fixés par des moyens de fixation (12, 13) à l'élément de panneau (5, 6), et le bord d'embouchure du boîtier (1) formant la pièce usinée est fixé par des moyens de fixation (14) à une branche respectivement voisine d'un premier, deuxième ou troisième profil porteur métallique (7, 8, 10).

- Faux plafond selon la revendication 4, caractérisé en ce qu'entre le matériau (2) prévu dans la région (4) du bord d'embouchure du boîtier (1) et formant la couche isolante et la région se trouvant sous ceux-ci de l'élément de panneau (5, 6), un boudin (15) de mastic coupe-feu périphérique est appliqué.

- Faux plafond selon la revendication 4 ou 5, caractérisé en ce qu'aux parois latérales du boîtier (1), des cornières de maintien (16) sont fixées, qui engagent en recouvrement des branches ou entretoises des troisièmes profils porteurs métalliques (10).

- Faux plafond selon une des revendications 4 à 6, caractérisé en ce qu'aux premiers ou deuxièmes profils porteurs métalliques (7, 8), des pièces de fixation (17) du type bande ou du type élément d'ancrage sont arrangées, à savoir dans la région à côté de la paroi du boîtier (1) des premiers profils porteurs métalliques (7), qui sont fixés au plafond d'un bâtiment ou à des parties de support semblables.

- Faux plafond selon une des revendications 4 à 7, caractérisé en ce que l'arête inférieure du boîtier (1) est en affleurement avec la surface de contact des premiers, deuxièmes et/ou troisièmes profils porteurs métalliques (7, 8, 10) à l'élément de panneau (5, 6).

- Faux plafond selon une des revendications 4 à 8, caractérisé en ce que comme moyens de fixation (14, 12, 13), des vis, en particulier des vis à tôle, sont arrangées.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102004007453.4A DE102004007453B4 (de) | 2004-02-13 | 2004-02-13 | Formteil |

| DE102004007453 | 2004-02-13 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1564339A2 EP1564339A2 (fr) | 2005-08-17 |

| EP1564339A3 EP1564339A3 (fr) | 2009-04-15 |

| EP1564339B1 true EP1564339B1 (fr) | 2012-09-12 |

Family

ID=34684069

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20040009626 Expired - Lifetime EP1564339B1 (fr) | 2004-02-13 | 2004-04-23 | Enceinte résistante au feu pour des éléments d'installation ou des éléments éléctrotechniques |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1564339B1 (fr) |

| DE (1) | DE102004007453B4 (fr) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202006015399U1 (de) * | 2006-10-06 | 2008-02-14 | Viessmann Kältetechnik AG | Vorgefertigtes Wandpaneel |

| EP2527555B1 (fr) | 2011-05-24 | 2016-03-30 | Metalicht B.V. | Dalle pour système de plafond suspendu |

| CN103374991A (zh) * | 2013-07-25 | 2013-10-30 | 苏州金螳螂建筑装饰股份有限公司 | 造型石膏板吊顶 |

| DE202014105845U1 (de) * | 2014-12-04 | 2016-03-07 | Kaiser Gmbh & Co Kg | Hohldecke mit Brandschutzgehäuse sowie Brandschutzgehäuse |

| DE102018101461A1 (de) * | 2018-01-23 | 2019-07-25 | Matthias Trunk | Brandschutzkoffer |

| CN115042912B (zh) * | 2022-07-15 | 2023-09-26 | 靖江亚泰船用物资有限公司 | 一种船舶上建b15级复合岩棉板的耐火安装结构 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4210070A (en) * | 1978-03-06 | 1980-07-01 | Dayus Barry R | Ceiling fixture with thermal protection |

| DE3622109A1 (de) * | 1986-07-02 | 1988-01-07 | Promat Gmbh | Leuchte fuer brandgefaehrdete raeume |

| DE9318416U1 (de) | 1993-12-02 | 1994-03-17 | Adelmann-Lichtsysteme Gesellschaft für Licht mbH, 80799 München | Unterdecke für Brandschutzzwecke |

| US6105334A (en) * | 1997-09-16 | 2000-08-22 | Logic Construction Systems, L.L.C. | Fire resistant lighting enclosure |

| GB2345125B (en) * | 1998-12-23 | 2002-05-01 | Tenmat Ltd | Intumescent downlighter cover and method of manufacturing same |

| DE10223904A1 (de) * | 2002-05-29 | 2003-12-11 | Kaiser Gmbh & Co Kg | Unterdecke für Brandschutzzwecke |

-

2004

- 2004-02-13 DE DE102004007453.4A patent/DE102004007453B4/de not_active Expired - Lifetime

- 2004-04-23 EP EP20040009626 patent/EP1564339B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP1564339A3 (fr) | 2009-04-15 |

| EP1564339A2 (fr) | 2005-08-17 |

| DE102004007453A1 (de) | 2005-09-15 |

| DE102004007453B4 (de) | 2015-12-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69428366T2 (de) | Gleitschienenvorrichtung | |

| EP2314782A2 (fr) | Absorbeur de son et élément de cadre supplémentaire pour un absorbeur de son | |

| DE3631993C2 (de) | Feuerabweisende Abdeckung | |

| EP1564339B1 (fr) | Enceinte résistante au feu pour des éléments d'installation ou des éléments éléctrotechniques | |

| DE9316000U1 (de) | Brandwand mit Gipsbauplatten | |

| DE2611033C2 (de) | Feuerbeständige leichte Trennwand für Räume von Gebäuden | |

| EP1367191B1 (fr) | Panneau coupe-feu pour plafonds, cloisons ou planchers | |

| DE19714625C2 (de) | Holztafelbaustruktur | |

| DE2352444C3 (de) | Zweischalige feuerhemmende Trennwand, insbesondere für den Innenausbau von Schiffen | |

| DE2315213C3 (de) | Vorhangwand und Verfahren zum Anbringen derselben | |

| DE202004002362U1 (de) | Formteil | |

| EP1491702B1 (fr) | Trappe de visite | |

| DE102007027807A1 (de) | Brandschutztrennwandsystem | |

| DE10125349B4 (de) | Holzwandtafel | |

| EP1319790B1 (fr) | Ancrage pour une fenêtre ou une porte | |

| AT500659B1 (de) | Brandausbreitungshemmende(r) wand bzw. wandabschnitt auf basis von gipskarton-wandplatten | |

| DE29908680U1 (de) | Deckenaufbau aus Deckenelementen | |

| DE19754179C1 (de) | Schiene zum Anschließen einer Platte an eine mit einem Putz zu versehende und zur Platte senkrecht stehende Wand sowie Wandverkleidung für einen Raum mit derartiger Schiene | |

| DE102004050442B4 (de) | Gehäuse, insbesondere Instrumentenschutzhaus für elektrische Instrumente und Analysegeräte | |

| EP1643050A2 (fr) | Faux-plafond résistant au feu pour des passages de secours dans des bâtiments | |

| AT413721B (de) | Formkörper zur vorbereitung von installationen | |

| DE102014208933A1 (de) | Beschlag zur Verbindung eines Kehlbalkens mit einem Dach-Sparren | |

| DE2741946A1 (de) | Feuerwiderstandsfaehige unterdecke | |

| DE4420872C2 (de) | Feuerschutz-Deckenplattenelement für Bandraster-Unterdecken | |

| DE102019116533A1 (de) | Deckenanordnung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E04B 9/00 20060101ALI20090310BHEP Ipc: F21V 25/12 20060101ALI20090310BHEP Ipc: E04B 1/94 20060101AFI20050610BHEP Ipc: F21V 15/01 20060101ALI20090310BHEP |

|

| 17P | Request for examination filed |

Effective date: 20090430 |

|

| 17Q | First examination report despatched |

Effective date: 20090706 |

|

| AKX | Designation fees paid |

Designated state(s): DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 502004013739 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: E04B0001940000 Ipc: F21V0025000000 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E04B 9/00 20060101ALI20120511BHEP Ipc: F21V 25/12 20060101ALI20120511BHEP Ipc: E04B 1/94 20060101ALI20120511BHEP Ipc: F21V 25/00 20060101AFI20120511BHEP Ipc: F21V 15/01 20060101ALI20120511BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502004013739 Country of ref document: DE Effective date: 20121108 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20130613 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502004013739 Country of ref document: DE Effective date: 20130613 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20230630 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 502004013739 Country of ref document: DE |