EP1539403B1 - Dispositif pour la coulee continue de metaux, notamment de materiaux a base d'acier, en produits longs dans une installation de coulee continue a plusieurs lignes - Google Patents

Dispositif pour la coulee continue de metaux, notamment de materiaux a base d'acier, en produits longs dans une installation de coulee continue a plusieurs lignes Download PDFInfo

- Publication number

- EP1539403B1 EP1539403B1 EP03798146.1A EP03798146A EP1539403B1 EP 1539403 B1 EP1539403 B1 EP 1539403B1 EP 03798146 A EP03798146 A EP 03798146A EP 1539403 B1 EP1539403 B1 EP 1539403B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- continuous casting

- casting

- oscillatory

- frame

- leaf spring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Revoked

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/04—Continuous casting of metals, i.e. casting in indefinite lengths into open-ended moulds

- B22D11/053—Means for oscillating the moulds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/04—Continuous casting of metals, i.e. casting in indefinite lengths into open-ended moulds

- B22D11/0403—Multiple moulds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/04—Continuous casting of metals, i.e. casting in indefinite lengths into open-ended moulds

- B22D11/055—Cooling the moulds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/12—Accessories for subsequent treating or working cast stock in situ

Definitions

- the invention relates to a device for continuous casting of metals, in particular of steel materials, to long products in a multi-strand casting, with several continuous casting molds, which are each stored separately in an oscillating drivable oscillating frame in the casting, arranged by means of both sides of the cast strand leaf spring pairs, the extending transversely to the casting direction, is mounted for guidance and weight compensation on a foundation frame.

- a device for continuous casting of steel which consists of a casting mold oscillating in the casting direction, which is mounted transversely to the casting direction extending, clamped at both ends clamped and connected to a fixed to a support frame, designed as a servo hydraulic cylinder Oszillatlonsantrieb.

- the servo-hydraulic cylinders are arranged in a laid-by the continuous casting mold longitudinal side plane laterally adjacent to the continuous casting mold with the support frame firmly connected, the continuous casting mold is attached to the springs in one point and the free ends of the springs are in firm connection with the support frame.

- it is a so-called resonant mold, in which the spring force is adjusted to the mass of the mold such that the device oscillates in the resonance range.

- the present invention relates to so-called multi-strand casters, in which several casting strands are produced side by side at the same time.

- multi-strand casters efforts are made to minimize the strand spacing from cast strand to cast strand, i. from mold center to mold center.

- the costs are thereby reduced and, in the case of conversions of existing plants, changes can still be made subsequently.

- a stirring coil which influences the liquid core of the cast strand, can subsequently also be installed.

- the invention is based on the object, even in so-called.

- Resonant molds which are referred to at the beginning and whose essential feature is leaf spring packages to achieve structurally least possible strand spacing between the casting strands.

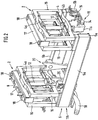

- the stated object is achieved in that in the initially described device on an elongated foundation frame In Strand running direction two successively arranged, formed in the form of compact flat boxes housing are fixed, in which run upper and lower leaf spring pairs transverse to the strand direction and that attack on the leaf spring pairs Oszillationsantriebe, wherein a front oscillating drive to the rear oscillating drive operates synchronized.

- the advantage is in such a transverse arrangement by crossing the cast strand or the strand running direction relative to the previous longitudinal arrangement a significant space and space savings, so that the distance from cast strand to cast strand, can be kept as small as possible.

- the sequential arrangement of the flat boxes with the oscillating drives in the casting direction in a crossing transverse course of the leaf springs, transverse to the strand running or strand, allows to create a sufficiently large space for the continuous casting mold to be installed between the two flat boxes. At the same time sufficient space for the installation of the so-called. Zero support roller segment is obtained. Almost the entire strand spacing "A" can be exploited.

- the front oscillation drive is set to the rear oscillation drive for a curved course of the casting strand with different strokes.

- the rear oscillating drive is to be set to a higher stroke compared to the front oscillating drive.

- oscillating drives consist of hydraulic drive units.

- the oscillation drives can be arranged in protected areas below the foundation frame.

- the flat boxes consists of two in line running direction behind one another rectangular frame for each two leaf spring pairs with the height spaced leaf springs and that between the rectangular frame Kokillenauflage a frame is arranged swinging.

- the two rectangular frames for the mold support frame simultaneously form a guide.

- the special protection for the drives is achieved in that the oscillation drive units are each arranged in the center plane of the casting strand below the two rectangular frame and between longitudinal beams of the foundation frame. In addition to the protected position, the fastening points are thereby advantageous,

- the suspension elements consist of a rotatably mounted on the longitudinal beams, two-armed levers with formed at one end of the lever attachment trough and connected to the other end of the lever Justiermittein.

- the design of the device is further developed in that a water chuck plate for supplying the continuous casting mold with cooling medium is arranged on the rear flat box and that the cooling medium supply and the cooling medium discharge run backwards away from the cast strand.

- a multi-strand caster ( Fig. 1 ) with a plurality of casting strands 3 running parallel in the casting direction 1 for the casting strands by a continuous casting mold (not shown) and support roll scaffolds in segmental shape (not shown) are for long products such as billets, bloom (pre-block), round or profile cross sections, the continuous casting molds einzein arranged side by side.

- Each of the continuous casting molds is stored separately in an oscillatingly drivable oscillating frame 2 in the casting direction 1.

- a swing frame 2 is by means of leaf springs 4 ( Fig. 2 ) is connected to the continuous casting mold or the mold table. The oscillatory movements take place in the casting direction 1 as a sinusoidal movement.

- the oscillation frequency and the oscillation height are coordinated.

- the leaf spring pairs 4a and 4b extend transversely to the casting direction 1, crossing the cast strand 3, and serve for guidance and for Gewiohtskompensation on a foundation frame fifth

- each foundation frame 5 is executed in strand direction 1 as an elongated rectangle.

- the foundation frame 5 is formed in each case from longitudinal bars 5a and 5b.

- each flat box 6 which extends transversely to the cast strand 3 in its longitudinal extent and bridges the gap between the two longitudinal bars 5a and 5b.

- Each flat box 6 consists of a closed housing 6a, wherein a rear flat boxes 6b and a front flat box 6c is formed with the required distance for installation of a continuous casting mold.

- the leaf springs to be described in more detail 4 are on the base frame 8, of which two are in each case parallel and spaced, the leaf springs to be described in more detail 4 as upper and lower leaf spring pairs 4a and 4b transverse to the strand direction 1, joints forming attached.

- a water tensioning plate 9 is provided for cooling the continuous casting mold with a cooling medium feed 10 formed from below.

- each Flachkestens 6 Is with open housings 6a, ie with removed protective cover 7 in Fig. 2 represents.

- Each flat box 6, ie always two pairs of upper leaf spring pairs 4a and lower leaf spring pairs 4b is associated with an oscillating drive 11 which is fastened via a connection bridge 12.

- the resulting front oscillating drive 11 a and the rear oscillating drive 11 b are synchronized and thereby cause unequal strokes but the same frequency a curve course.

- the oscillation drives 11 a and 11 b are designed for example as hydraulic oscillation drive units 14 and therefore via hydraulic lines 15 fed.

- a flat box 6 of two in strand direction 1 ( Fig. 1 ) arranged one behind the other, parallel rectangular frame 16 for each leaf spring pair 4a, 4b formed with height-spaced leaf springs 4 and between the rectangular frame 16 each a mold support frame 17 is arranged swingably.

- Each of the mold support frames 17 carries two mold support surfaces 18 disposed in the ends.

- the oscillation drive units 14 are located in the middle plane 19 (FIG. Fig. 1 ) of the casting strands 3 below the two rectangular frame 16 and between the longitudinal beams 5a, 5b of the foundation frame fifth

- Fig. 1 and 2 are in the foundation frame 5 between the longitudinal beams 5a, 5b suspension elements 20 for the suspension of a (not shown) Support roller segment stored, which encloses the casting strands 3 in the course behind the continuous casting mold.

- the suspension elements 20 consist of a rotatably mounted on the longitudinal beams 5a, 5b, two-armed levers 21 with a lever at a end 21a ( Fig. 3 ) formed hook-on depression 22 and connected to the other end of the lever 21b adjusting means 23 to determine the exact position of the suspended support roller segment.

- each of the compact flat boxes 6 contains two base frames 8 between each of which is the swing frame 2.

- the four mold support surfaces 18 visible.

- the adjusting means 23 for the two-armed lever 21 with the hulls 22 can be seen.

- remote protection covers 7 the view of a base frame 8, which receives an upper leaf spring pair 4a and a lower leaf spring pair 4b, and released on the connecting bridge 12.

- the view is directed perpendicular to the oscillation drive 11, the hydraulic lines 15 can be seen.

- the rectangular frame 16 is surmounted by a certain amount of the mold support frame 17 with the mold support surfaces 18.

- the cooling medium supply 10 and the cooling medium discharge 24 are arranged on the rear side of the device.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Continuous Casting (AREA)

Claims (8)

- Dispositif pour la coulée continue de métaux, en particulier de matériaux à base d'acier, pour obtenir des produits longs dans une installation de coulée à plusieurs lignes, comprenant plusieurs lingotières de coulée continue qui sont montées à l'état respectivement séparé dans un cadre oscillant (2) qui peut être entraîné en oscillation dans la direction de coulée (1), le cadre en question étant monté sur un bâti au moyen de paires de ressorts à lames (4) supérieure et inférieure approximativement horizontales disposées des deux côtés de la barre de coulée (3) à des fins de guidage et de compensation du poids, caractérisé en ce que, sur un bâti longitudinal (5), sont fixés deux logements (6a) en forme de boîtes compactes de forme plate (6) disposés l'un derrière l'autre dans la direction d'avance de la barre (1), dans lesquels s'étendent les paires de ressorts à lames (4a ; 4b) supérieure et inférieure en direction transversale par rapport à la direction d'avance de la barre (1) et en ce que des entraînements en oscillation (11) viennent s'appliquer contre les paires de ressorts à lames (4a ; 4b), un entraînement en oscillation avant (11a) travaillant de manière synchronisée par rapport à l'entraînement en oscillation arrière (11 b).

- Dispositif selon la revendication 1, caractérisé en ce que l'entraînement en oscillation avant (11a) est réglé avec des courses différentes par rapport à l'entraînement en oscillation arrière (11b) pour une allure courbe (13) de la barre de coulée (3).

- Dispositif selon la revendication 1 ou 2, caractérisé en ce que les entraînements en oscillation (11a ; 11 b) sont constitués par des unités d'entraînement de type hydraulique (14).

- Dispositif selon l'une quelconque des revendications 1 à 3, caractérisé en ce que la boîte plate (6) est constituée par deux cadres rectangulaires (16) disposés l'un derrière l'autre dans la direction d'avance de la barre pour respectivement deux paires de ressorts à lames (4a ; 4b) comprenant des ressorts à lames (4) espacés en hauteur, et en ce qu'un cadre d'appui de lingotière (17) est monté en oscillation entre les cadres rectangulaires (16).

- Dispositif selon l'une quelconque des revendications 1 à 4, caractérisé en ce que les unités d'entraînement en oscillation (14) sont disposées respectivement dans le plan médian (19) de la barre de coulée continue (3) en dessous des deux cadres rectangulaires (16) et entre des longerons longitudinaux (5a ; 5b) du bâti (5).

- Dispositif selon l'une quelconque des revendications 1 à 5, caractérisé en ce que des éléments de suspension (20) pour la suspension d'un segment de rouleau de support sont montés dans le bâti (5) entre les longerons longitudinaux (5a ; 5b).

- Dispositif selon la revendication 6, caractérisé en ce que les éléments de suspension (20) sont constitués par un levier à deux bras (21) monté en rotation sur les longerons longitudinaux (5a ; 5b) comprenant une cavité de suspension (22) réalisée à une extrémité de levier (21 a) et des moyens d'ajustement (23) raccordés à l'autre extrémité de levier (21 b).

- Dispositif selon l'une quelconque des revendications 1 à 7, caractérisé en ce qu'une plaque de raccordement rapide à l'eau (9) pour l'alimentation de la lingotière de coulée continue avec un milieu de refroidissement est disposée sur la boîte plate arrière (6b) et en ce que l'alimentation du milieu de refroidissement (10) et l'évacuation du milieu de refroidissement (24) s'étendent vers l'arrière à l'écart de la barre de coulée (3).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10244596 | 2002-09-21 | ||

| DE10244596A DE10244596B4 (de) | 2002-09-21 | 2002-09-21 | Vorrichtung zum Stranggießen von Metallen, insbesondere von Stahlwerkstoffen, zu Langprodukten in einer Mehrstrang-Gießanlage |

| PCT/EP2003/009710 WO2004028723A1 (fr) | 2002-09-21 | 2003-09-02 | Dispositif pour la coulee continue de metaux, notamment de materiaux a base d'acier, en produits longs dans une installation de coulee continue a plusieurs lignes |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1539403A1 EP1539403A1 (fr) | 2005-06-15 |

| EP1539403B1 true EP1539403B1 (fr) | 2017-01-04 |

Family

ID=31969553

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03798146.1A Revoked EP1539403B1 (fr) | 2002-09-21 | 2003-09-02 | Dispositif pour la coulee continue de metaux, notamment de materiaux a base d'acier, en produits longs dans une installation de coulee continue a plusieurs lignes |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US7036557B2 (fr) |

| EP (1) | EP1539403B1 (fr) |

| JP (1) | JP4272158B2 (fr) |

| KR (1) | KR101031610B1 (fr) |

| CN (1) | CN100584486C (fr) |

| AU (1) | AU2003266344A1 (fr) |

| CA (1) | CA2499270C (fr) |

| DE (1) | DE10244596B4 (fr) |

| TW (1) | TWI279267B (fr) |

| WO (1) | WO2004028723A1 (fr) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102004018602A1 (de) * | 2004-04-16 | 2005-11-03 | Sms Demag Ag | Oszillationsvorrichtung für Stranggießkokillen zum Gießen von flüssigem Metall, insbesondere von flüssigem Stahlwerkstoff |

| DE102005019295A1 (de) * | 2004-07-06 | 2006-02-02 | Sms Demag Ag | Vorrichtung für die Stützung und Oszillation einer Stranggiesskokille von flüssigen Metallen, insbesondere von flüssigen Stahlwerkstoffen und Verfahren zum Montieren und Demontieren sowie Instandhalten |

| DE102005017226A1 (de) * | 2004-07-06 | 2006-02-02 | Sms Demag Ag | Vorrichtung für die Stützung und Oszillation einer Stranggießkokille zum Gießen von flüssigem Metall, insbesondere von flüssigem Stahlwerkstoff |

| DE102008015827A1 (de) * | 2008-03-27 | 2009-10-01 | Sms Siemag Aktiengesellschaft | Vorrichtung für die Stützung und Oszillation einer Stranggießkokille |

| AT508395B1 (de) * | 2009-06-16 | 2014-08-15 | Tbr Casting Technologies Gmbh | Mittel zum oszillieren einer stranggiesskokille |

| EP2905093B1 (fr) * | 2014-02-07 | 2018-08-29 | SMS Concast AG | Système de lingotière pour la coulée en continu de produits métalliques |

| CN114309502A (zh) * | 2021-12-24 | 2022-04-12 | 衡阳镭目科技有限责任公司 | 一种单元式单驱动结晶器振动装置 |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4195684A (en) | 1975-12-18 | 1980-04-01 | Ishikawajima-Harima Jukogyo Kabushiki Kaisha | Apparatus for multi-strand continuous casting |

| DE3706720A1 (de) | 1987-03-02 | 1988-09-15 | Voest Alpine Ag | Stranggiessanlage mit zwei nebeneinander angeordneten druchlaufkokillen |

| EP0468607B1 (fr) | 1990-07-23 | 1995-04-19 | MANNESMANN Aktiengesellschaft | Moule refroidi par liquide pour la coulée continue de métaux |

| WO1995015232A1 (fr) | 1993-12-03 | 1995-06-08 | Mannesmann Ag | Installation pour la coulee continue d'acier |

| DE4444941A1 (de) | 1993-12-20 | 1995-06-22 | Voest Alpine Ind Anlagen | Stranggießkokille |

| US5623983A (en) | 1994-12-21 | 1997-04-29 | Voest-Alpine Industrieanlagenbau Gmbh | Continuous casting mold |

| US5642769A (en) | 1994-12-21 | 1997-07-01 | Voest-Alpine Industrieanlagenbau Gmbh | Continuous casting mold |

| WO1999012676A1 (fr) | 1997-09-08 | 1999-03-18 | Voest-Alpine Industrieanlagenbau Gmbh | Dispositif de coulee continue |

| EP0953391A1 (fr) | 1998-04-21 | 1999-11-03 | Sms Schloemann-Siemag Aktiengesellschaft | Table élévatrice entrainé à osciller pour une installation de coulée continue |

| US6167941B1 (en) | 1997-12-06 | 2001-01-02 | Sms Schloemann-Siemag Ag | Support structure for oscillating continuous casting mold |

| DE10024514A1 (de) | 1999-06-08 | 2001-01-04 | Voest Alpine Ind Anlagen | Stranggießanlage |

| WO2001085370A1 (fr) | 2000-05-10 | 2001-11-15 | Sms Demag Aktiengesellschaft | Dispositif de coulee continue de metaux, en particulier d"acier |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0305930B1 (fr) * | 1987-08-29 | 1992-08-05 | Nippon Steel Corporation | Lingotière de coulée continue et procédé pour son oscillation aux hautes fréquences |

-

2002

- 2002-09-21 DE DE10244596A patent/DE10244596B4/de not_active Expired - Fee Related

-

2003

- 2003-09-01 TW TW092124064A patent/TWI279267B/zh not_active IP Right Cessation

- 2003-09-02 JP JP2004538859A patent/JP4272158B2/ja not_active Expired - Fee Related

- 2003-09-02 KR KR1020057004823A patent/KR101031610B1/ko active IP Right Grant

- 2003-09-02 CN CN03822459A patent/CN100584486C/zh not_active Expired - Fee Related

- 2003-09-02 AU AU2003266344A patent/AU2003266344A1/en not_active Abandoned

- 2003-09-02 US US10/528,380 patent/US7036557B2/en not_active Expired - Lifetime

- 2003-09-02 WO PCT/EP2003/009710 patent/WO2004028723A1/fr active Application Filing

- 2003-09-02 EP EP03798146.1A patent/EP1539403B1/fr not_active Revoked

- 2003-09-02 CA CA2499270A patent/CA2499270C/fr not_active Expired - Fee Related

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4195684A (en) | 1975-12-18 | 1980-04-01 | Ishikawajima-Harima Jukogyo Kabushiki Kaisha | Apparatus for multi-strand continuous casting |

| DE3706720A1 (de) | 1987-03-02 | 1988-09-15 | Voest Alpine Ag | Stranggiessanlage mit zwei nebeneinander angeordneten druchlaufkokillen |

| EP0468607B1 (fr) | 1990-07-23 | 1995-04-19 | MANNESMANN Aktiengesellschaft | Moule refroidi par liquide pour la coulée continue de métaux |

| WO1995015232A1 (fr) | 1993-12-03 | 1995-06-08 | Mannesmann Ag | Installation pour la coulee continue d'acier |

| US5771957A (en) | 1993-12-03 | 1998-06-30 | Mannesmann Aktiengesellschaft | Device for the continuous casting of steel |

| DE4444941A1 (de) | 1993-12-20 | 1995-06-22 | Voest Alpine Ind Anlagen | Stranggießkokille |

| US5642769A (en) | 1994-12-21 | 1997-07-01 | Voest-Alpine Industrieanlagenbau Gmbh | Continuous casting mold |

| US5623983A (en) | 1994-12-21 | 1997-04-29 | Voest-Alpine Industrieanlagenbau Gmbh | Continuous casting mold |

| WO1999012676A1 (fr) | 1997-09-08 | 1999-03-18 | Voest-Alpine Industrieanlagenbau Gmbh | Dispositif de coulee continue |

| US6167941B1 (en) | 1997-12-06 | 2001-01-02 | Sms Schloemann-Siemag Ag | Support structure for oscillating continuous casting mold |

| EP0953391A1 (fr) | 1998-04-21 | 1999-11-03 | Sms Schloemann-Siemag Aktiengesellschaft | Table élévatrice entrainé à osciller pour une installation de coulée continue |

| DE10024514A1 (de) | 1999-06-08 | 2001-01-04 | Voest Alpine Ind Anlagen | Stranggießanlage |

| AT408625B (de) | 1999-06-08 | 2002-01-25 | Voest Alpine Ind Anlagen | Stranggiessanlage |

| WO2001085370A1 (fr) | 2000-05-10 | 2001-11-15 | Sms Demag Aktiengesellschaft | Dispositif de coulee continue de metaux, en particulier d"acier |

Non-Patent Citations (7)

| Title |

|---|

| "VOEST-ALPINE Industrieanlagenbau GmbH, Continuous Casting Division", May 1999, article "Product Info Billet/Bloom Caster, DYNAFLEX-Oscillator for Billet & Bloom Casters", XP055424638 |

| F. LEINGRUBER ET AL.: "High-Performance Machine Head - A Success Story", BILLET/BLOOM CASTING SESSION, no. 34, June 2000 (2000-06-01), pages 1 - 4, XP055424558 |

| H. HÖDL ET AL.: "VAINOX - Latest Developments in Stainless Steel Casting Technologies", SLAB CASTING SESSION - PAPER NO. 15, CONTINUOUS CASTING CONFERENCE (CCC) 2000, no. 15, June 2000 (2000-06-01), Linz/ Austria (E2e), pages 1 - 17, XP55424668 |

| O. L. MANHÄES WAGNER ET AL.: "Casting Solutions for High Productivity and High Quality at CSN", SLAB CASTING SESSION - PAPER NO. 19, CONTINUOUS CASTING CONFERENCE (CCC) 2000, no. 19, June 2000 (2000-06-01), Linz/ Austria (E2c), pages 1 - 6, XP055424627 |

| T. HARALDSON ET AL.: "Modernisation of Slab Casters at SSAB Tunnplät", ASSOCIATION OF IRON AND STEEL ENGINEERS, 1998, Sweden (E2b3), XP055424623 |

| T. HARALDSON ET AL.: "Modernisation of the slab casters at SSAB Tunnplät", STEEL TIMES, January 2001 (2001-01-01), pages 26 - 27, XP055424572 |

| T. HARALDSON ET AL.: "SSAB Tunnplät - Luleä - DYNAFLEX Oscillator and Hydraulic Width-Adjustable Mold", SLAB CASTING SESSION - PAPER NO. 18, CONTINUOUS CASTING CONFERENCE (CCC) 2000, no. 18, June 2000 (2000-06-01), Linz/ Austria (E2b1), pages 1 - 6, XP055424564 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20060048915A1 (en) | 2006-03-09 |

| US7036557B2 (en) | 2006-05-02 |

| TWI279267B (en) | 2007-04-21 |

| DE10244596B4 (de) | 2011-12-29 |

| CA2499270C (fr) | 2010-11-16 |

| CA2499270A1 (fr) | 2004-04-08 |

| WO2004028723A1 (fr) | 2004-04-08 |

| AU2003266344A1 (en) | 2004-04-19 |

| KR20050057510A (ko) | 2005-06-16 |

| CN100584486C (zh) | 2010-01-27 |

| TW200404627A (en) | 2004-04-01 |

| KR101031610B1 (ko) | 2011-04-28 |

| DE10244596A1 (de) | 2004-04-01 |

| CN1681612A (zh) | 2005-10-12 |

| JP2005538852A (ja) | 2005-12-22 |

| JP4272158B2 (ja) | 2009-06-03 |

| EP1539403A1 (fr) | 2005-06-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE4341719C1 (de) | Einrichtung zum Stranggießen von Stahl | |

| EP1763414B1 (fr) | Dispositif de support et de mise en oscillation d'une coquille pour la coulee continue de metaux liquides, en particulier d'aciers liquides, et son procede de montage | |

| EP0468607A1 (fr) | Moule refroidi par liquide pour la coulée continue de métaux | |

| EP1539403B1 (fr) | Dispositif pour la coulee continue de metaux, notamment de materiaux a base d'acier, en produits longs dans une installation de coulee continue a plusieurs lignes | |

| WO2005105342A1 (fr) | Dispositif concu pour recevoir une coquille pour la coulee continue sur une table elevatrice permettant de couler des metaux liquides, notamment des materiaux a base d'acier | |

| EP1370379B1 (fr) | Procede pour la coulee et le laminage immediat et dispositif pour le soutien, le guidage et la deformation d'une barre de metal, notamment d'une barre d'acier | |

| DE4444941C3 (de) | Stranggießkokille | |

| AT404808B (de) | Stranggiessanlage | |

| DE2021780C3 (de) | Verfahren zur Anpassung der Bogenfühning eines aus einer Stranggießkokille austretenden Stranges und Vorrichtung dazu | |

| DE1558220B2 (de) | Lagerung von Walzen fur die Form änderung eines aus einer Stranggießkokille kommenden metallischen Stranges | |

| DE19547779A1 (de) | Stranggießkokille | |

| DE10024514C5 (de) | Stranggießanlage | |

| EP1029616B1 (fr) | Dispositif d'oscillation d'un moule de coulée continue | |

| DE1758982A1 (de) | Laengsgeteilte Durchlaufgiessform fuer Metall,insbesondere Strahlstranggiessanlagen | |

| EP1991379B1 (fr) | Dispositif de coulee continue et procede pour faire fonctionner un dispositif de coulee continue | |

| DE2146963A1 (de) | Fuhrungsrollenanordnung fur Strang gußmaschine | |

| EP0041196A2 (fr) | Procédé et installation pour l'oscillation d'une lingotière de coulée continue | |

| EP0018350B1 (fr) | Dispositif de coulée continue, notamment pour la fabrication de brames | |

| EP1057556B1 (fr) | Lingotière de coulée continue pour la coulée en continue en particulier de brames d'acier minces | |

| EP3354370B1 (fr) | Dispositif pour osciller une lingotiere et procede pour generer un mouvement oscillant d'une lingotiere | |

| EP0946318A1 (fr) | Procede et installation de coulee continue de brames fines | |

| CH679650A5 (fr) | ||

| DE2947869A1 (de) | Einrichtung und verfahren zum elektromagnetischen ruehren des sumpfes in einer stahlstranggiessanlage | |

| DE4447941B4 (de) | Stranggießkokille | |

| EP0068208B1 (fr) | Installation de coulée continue d'acier |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050205 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SMS SIEMAG AG |

|

| 17Q | First examination report despatched |

Effective date: 20120625 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SMS GROUP GMBH |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160729 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 858737 Country of ref document: AT Kind code of ref document: T Effective date: 20170115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 50315607 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170405 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170404 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170504 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 50315607 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| 26 | Opposition filed |

Opponent name: PRIMETALS TECHNOLOGIES AUSTRIA GMBH Effective date: 20171003 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20170902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170902 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20180531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170902 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171002 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180920 Year of fee payment: 16 Ref country code: IT Payment date: 20180925 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20180920 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R064 Ref document number: 50315607 Country of ref document: DE Ref country code: DE Ref legal event code: R103 Ref document number: 50315607 Country of ref document: DE |

|

| RDAF | Communication despatched that patent is revoked |

Free format text: ORIGINAL CODE: EPIDOSNREV1 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20030902 |

|

| RDAG | Patent revoked |

Free format text: ORIGINAL CODE: 0009271 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT REVOKED |

|

| 27W | Patent revoked |

Effective date: 20190320 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MA03 Ref document number: 858737 Country of ref document: AT Kind code of ref document: T Effective date: 20190320 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |