EP1539403B1 - Device for the continuous casting of metals, in particular steel material, to form elongated products in a multiple casting line - Google Patents

Device for the continuous casting of metals, in particular steel material, to form elongated products in a multiple casting line Download PDFInfo

- Publication number

- EP1539403B1 EP1539403B1 EP03798146.1A EP03798146A EP1539403B1 EP 1539403 B1 EP1539403 B1 EP 1539403B1 EP 03798146 A EP03798146 A EP 03798146A EP 1539403 B1 EP1539403 B1 EP 1539403B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- continuous casting

- casting

- oscillatory

- frame

- leaf spring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Revoked

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/04—Continuous casting of metals, i.e. casting in indefinite lengths into open-ended moulds

- B22D11/053—Means for oscillating the moulds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/04—Continuous casting of metals, i.e. casting in indefinite lengths into open-ended moulds

- B22D11/0403—Multiple moulds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/04—Continuous casting of metals, i.e. casting in indefinite lengths into open-ended moulds

- B22D11/055—Cooling the moulds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/12—Accessories for subsequent treating or working cast stock in situ

Definitions

- the invention relates to a device for continuous casting of metals, in particular of steel materials, to long products in a multi-strand casting, with several continuous casting molds, which are each stored separately in an oscillating drivable oscillating frame in the casting, arranged by means of both sides of the cast strand leaf spring pairs, the extending transversely to the casting direction, is mounted for guidance and weight compensation on a foundation frame.

- a device for continuous casting of steel which consists of a casting mold oscillating in the casting direction, which is mounted transversely to the casting direction extending, clamped at both ends clamped and connected to a fixed to a support frame, designed as a servo hydraulic cylinder Oszillatlonsantrieb.

- the servo-hydraulic cylinders are arranged in a laid-by the continuous casting mold longitudinal side plane laterally adjacent to the continuous casting mold with the support frame firmly connected, the continuous casting mold is attached to the springs in one point and the free ends of the springs are in firm connection with the support frame.

- it is a so-called resonant mold, in which the spring force is adjusted to the mass of the mold such that the device oscillates in the resonance range.

- the present invention relates to so-called multi-strand casters, in which several casting strands are produced side by side at the same time.

- multi-strand casters efforts are made to minimize the strand spacing from cast strand to cast strand, i. from mold center to mold center.

- the costs are thereby reduced and, in the case of conversions of existing plants, changes can still be made subsequently.

- a stirring coil which influences the liquid core of the cast strand, can subsequently also be installed.

- the invention is based on the object, even in so-called.

- Resonant molds which are referred to at the beginning and whose essential feature is leaf spring packages to achieve structurally least possible strand spacing between the casting strands.

- the stated object is achieved in that in the initially described device on an elongated foundation frame In Strand running direction two successively arranged, formed in the form of compact flat boxes housing are fixed, in which run upper and lower leaf spring pairs transverse to the strand direction and that attack on the leaf spring pairs Oszillationsantriebe, wherein a front oscillating drive to the rear oscillating drive operates synchronized.

- the advantage is in such a transverse arrangement by crossing the cast strand or the strand running direction relative to the previous longitudinal arrangement a significant space and space savings, so that the distance from cast strand to cast strand, can be kept as small as possible.

- the sequential arrangement of the flat boxes with the oscillating drives in the casting direction in a crossing transverse course of the leaf springs, transverse to the strand running or strand, allows to create a sufficiently large space for the continuous casting mold to be installed between the two flat boxes. At the same time sufficient space for the installation of the so-called. Zero support roller segment is obtained. Almost the entire strand spacing "A" can be exploited.

- the front oscillation drive is set to the rear oscillation drive for a curved course of the casting strand with different strokes.

- the rear oscillating drive is to be set to a higher stroke compared to the front oscillating drive.

- oscillating drives consist of hydraulic drive units.

- the oscillation drives can be arranged in protected areas below the foundation frame.

- the flat boxes consists of two in line running direction behind one another rectangular frame for each two leaf spring pairs with the height spaced leaf springs and that between the rectangular frame Kokillenauflage a frame is arranged swinging.

- the two rectangular frames for the mold support frame simultaneously form a guide.

- the special protection for the drives is achieved in that the oscillation drive units are each arranged in the center plane of the casting strand below the two rectangular frame and between longitudinal beams of the foundation frame. In addition to the protected position, the fastening points are thereby advantageous,

- the suspension elements consist of a rotatably mounted on the longitudinal beams, two-armed levers with formed at one end of the lever attachment trough and connected to the other end of the lever Justiermittein.

- the design of the device is further developed in that a water chuck plate for supplying the continuous casting mold with cooling medium is arranged on the rear flat box and that the cooling medium supply and the cooling medium discharge run backwards away from the cast strand.

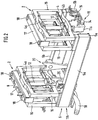

- a multi-strand caster ( Fig. 1 ) with a plurality of casting strands 3 running parallel in the casting direction 1 for the casting strands by a continuous casting mold (not shown) and support roll scaffolds in segmental shape (not shown) are for long products such as billets, bloom (pre-block), round or profile cross sections, the continuous casting molds einzein arranged side by side.

- Each of the continuous casting molds is stored separately in an oscillatingly drivable oscillating frame 2 in the casting direction 1.

- a swing frame 2 is by means of leaf springs 4 ( Fig. 2 ) is connected to the continuous casting mold or the mold table. The oscillatory movements take place in the casting direction 1 as a sinusoidal movement.

- the oscillation frequency and the oscillation height are coordinated.

- the leaf spring pairs 4a and 4b extend transversely to the casting direction 1, crossing the cast strand 3, and serve for guidance and for Gewiohtskompensation on a foundation frame fifth

- each foundation frame 5 is executed in strand direction 1 as an elongated rectangle.

- the foundation frame 5 is formed in each case from longitudinal bars 5a and 5b.

- each flat box 6 which extends transversely to the cast strand 3 in its longitudinal extent and bridges the gap between the two longitudinal bars 5a and 5b.

- Each flat box 6 consists of a closed housing 6a, wherein a rear flat boxes 6b and a front flat box 6c is formed with the required distance for installation of a continuous casting mold.

- the leaf springs to be described in more detail 4 are on the base frame 8, of which two are in each case parallel and spaced, the leaf springs to be described in more detail 4 as upper and lower leaf spring pairs 4a and 4b transverse to the strand direction 1, joints forming attached.

- a water tensioning plate 9 is provided for cooling the continuous casting mold with a cooling medium feed 10 formed from below.

- each Flachkestens 6 Is with open housings 6a, ie with removed protective cover 7 in Fig. 2 represents.

- Each flat box 6, ie always two pairs of upper leaf spring pairs 4a and lower leaf spring pairs 4b is associated with an oscillating drive 11 which is fastened via a connection bridge 12.

- the resulting front oscillating drive 11 a and the rear oscillating drive 11 b are synchronized and thereby cause unequal strokes but the same frequency a curve course.

- the oscillation drives 11 a and 11 b are designed for example as hydraulic oscillation drive units 14 and therefore via hydraulic lines 15 fed.

- a flat box 6 of two in strand direction 1 ( Fig. 1 ) arranged one behind the other, parallel rectangular frame 16 for each leaf spring pair 4a, 4b formed with height-spaced leaf springs 4 and between the rectangular frame 16 each a mold support frame 17 is arranged swingably.

- Each of the mold support frames 17 carries two mold support surfaces 18 disposed in the ends.

- the oscillation drive units 14 are located in the middle plane 19 (FIG. Fig. 1 ) of the casting strands 3 below the two rectangular frame 16 and between the longitudinal beams 5a, 5b of the foundation frame fifth

- Fig. 1 and 2 are in the foundation frame 5 between the longitudinal beams 5a, 5b suspension elements 20 for the suspension of a (not shown) Support roller segment stored, which encloses the casting strands 3 in the course behind the continuous casting mold.

- the suspension elements 20 consist of a rotatably mounted on the longitudinal beams 5a, 5b, two-armed levers 21 with a lever at a end 21a ( Fig. 3 ) formed hook-on depression 22 and connected to the other end of the lever 21b adjusting means 23 to determine the exact position of the suspended support roller segment.

- each of the compact flat boxes 6 contains two base frames 8 between each of which is the swing frame 2.

- the four mold support surfaces 18 visible.

- the adjusting means 23 for the two-armed lever 21 with the hulls 22 can be seen.

- remote protection covers 7 the view of a base frame 8, which receives an upper leaf spring pair 4a and a lower leaf spring pair 4b, and released on the connecting bridge 12.

- the view is directed perpendicular to the oscillation drive 11, the hydraulic lines 15 can be seen.

- the rectangular frame 16 is surmounted by a certain amount of the mold support frame 17 with the mold support surfaces 18.

- the cooling medium supply 10 and the cooling medium discharge 24 are arranged on the rear side of the device.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Continuous Casting (AREA)

Description

Die Erfindung betrifft eine Vorrichtung zum Stranggießen von Metallen, insbesondere von Stahlwerkstoffen, zu Langprodukten in einer Mehrstrang-Gießanlage, mit mehreren Stranggießkokillen, die jeweils getrennt in einem in Gießrichtung oszillierend antreibbaren Schwingrahmen gelagert sind, der mittels beidseitig zum Gießstrang angeordneten Blattfeder-Paaren, die sich quer zur Gießrichtung erstrecken, zur Führung und Gewichtskompensation auf einem Fundamentrahmen gelagert ist.The invention relates to a device for continuous casting of metals, in particular of steel materials, to long products in a multi-strand casting, with several continuous casting molds, which are each stored separately in an oscillating drivable oscillating frame in the casting, arranged by means of both sides of the cast strand leaf spring pairs, the extending transversely to the casting direction, is mounted for guidance and weight compensation on a foundation frame.

Aus der

Aus der

Aus der

Demgegenüber bezieht sich die vorliegende Erfindung auf sog, Mehrstrang-Gießanlagen, bei der mehrere Gießstränge nebeneinander gleichzeitig erzeugt werden. Bei solchen Mehrstrang-Gießanlagen ist man bestrebt, einen möglichst kleinen Strangabstand von Gießstrang, zu Gießstrang, d.h. von Kokillenmitte zu Kokillenmitte zu erzielen. Bei neu zu bauenden Stranggießanlagen werden dadurch die Kosten reduziert und bei Umbauten bestehender Anlagen können nachträglich noch Änderungen durchgeführt werden. So kann bspw. nachträglich noch eine Rührspule, die den flüssigen Kern des Gießstranges beeinflusst, eingebaut werden.In contrast, the present invention relates to so-called multi-strand casters, in which several casting strands are produced side by side at the same time. In such multi-strand casters, efforts are made to minimize the strand spacing from cast strand to cast strand, i. from mold center to mold center. In the case of new continuous casting plants to be constructed, the costs are thereby reduced and, in the case of conversions of existing plants, changes can still be made subsequently. For example, a stirring coil, which influences the liquid core of the cast strand, can subsequently also be installed.

Der Erfindung liegt die Aufgabe zugrunde, auch bei sog. Resonanzkokillen, die eingangs bezeichnet sind und deren wesentliches Merkmal Blattfeder-Pakete sind, konstruktiv geringstmögliche Strangabstände zwischen den Gießsträngen zu erzielen. Die gestellte Aufgabe wird erfindungsgemäß dadurch gelöst, dass bei der eingangs bezeichneten Vorrichtung auf einem länglichen Fundamentrahmen In Stranglaufrichtung zwei hintereinander angeordnete, in Form von kompakten Flachkästen ausgebildete Gehäuse befestigt sind, in denen obere und untere Blattfeder-Paare quer zur Stranglaufrichtung verlaufen und dass an den Blattfeder-Paaren Oszillationsantriebe angreifen, wobei ein vorderer Oszillationsantrieb zum hinteren Oszillationsantrieb synchronisiert arbeitet. Der Vorteil ist bei einer solchen Quer-Anordnung durch Kreuzen des Gießstrangs bzw. der Stranglaufrichtung gegenüber der bisherigen Längs-Anordnung eine erhebliche Platz- und Raumersparnis, so dass der Abstand von Gießstrang zu Gießstrang, so klein wie möglich gehalten werden kann. Die Hintereinander-Anordnung der Flachkästen mit den Oszillationsantrieben in Gießrichtung bei einem kreuzenden Querverlauf der Blattfedern, quer zur Stranglaufrichtung bzw. Strangader, ermöglicht dabei, einen ausreichend großen Raum für die einzubauende Stranggießkokille zwischen den beiden Flachkästen zu schaffen. Gleichzeitig wird auch genügend Freiraum für den Einbau des sog. Null-Stützrollen-Segmentes gewonnen. Nahezu der gesamte Strangabstand "A" kann ausgenutzt werden.The invention is based on the object, even in so-called. Resonant molds, which are referred to at the beginning and whose essential feature is leaf spring packages to achieve structurally least possible strand spacing between the casting strands. The stated object is achieved in that in the initially described device on an elongated foundation frame In Strand running direction two successively arranged, formed in the form of compact flat boxes housing are fixed, in which run upper and lower leaf spring pairs transverse to the strand direction and that attack on the leaf spring pairs Oszillationsantriebe, wherein a front oscillating drive to the rear oscillating drive operates synchronized. The advantage is in such a transverse arrangement by crossing the cast strand or the strand running direction relative to the previous longitudinal arrangement a significant space and space savings, so that the distance from cast strand to cast strand, can be kept as small as possible. The sequential arrangement of the flat boxes with the oscillating drives in the casting direction in a crossing transverse course of the leaf springs, transverse to the strand running or strand, allows to create a sufficiently large space for the continuous casting mold to be installed between the two flat boxes. At the same time sufficient space for the installation of the so-called. Zero support roller segment is obtained. Almost the entire strand spacing "A" can be exploited.

Nach weiteren Merkmalen wird vorgeschlagen, dass der vordere Oszillationsantrieb zu dem hinteren Oszillationsantrieb für einen Bogenverlauf des Gießstrangs mit unterschiedlichen Hüben eingestellt ist. Der hintere Oszilletionsantrieb ist dabei auf einen höheren Hub gegenüber dem vorderen Oszillationsantrieb einzustellen.According to further features, it is proposed that the front oscillation drive is set to the rear oscillation drive for a curved course of the casting strand with different strokes. The rear oscillating drive is to be set to a higher stroke compared to the front oscillating drive.

Ein anderer Vorteil besteht darin, dass die Oszillationsantriebe aus hydraulischen Antriebseinheiten bestehen. Die Oszillationsantriebe können In geschützten Räumen unterhalb des Fundamentrahmens angeordnet werden.Another advantage is that the oscillating drives consist of hydraulic drive units. The oscillation drives can be arranged in protected areas below the foundation frame.

Weitere Merkmale sind, dass der Flachkästen aus zwei in Stranglaufrichtung hintereinanderliegenden Rechteckrahmen für jeweils zwei Blattfeder-Paare mit der Höhe beabstandeten Blattfedern besteht und dass zwischen den Rechteckrahmen ein Kokillenauflage-Rahmen schwingbar angeordnet ist. Dadurch bilden die beiden Rechteckrahmen für den Kokillenauflage-Rahmen gleichzeitig eine Führung.Further features are that the flat boxes consists of two in line running direction behind one another rectangular frame for each two leaf spring pairs with the height spaced leaf springs and that between the rectangular frame Kokillenauflage a frame is arranged swinging. As a result, the two rectangular frames for the mold support frame simultaneously form a guide.

Der besondere Schutz für die Antriebe wird dadurch erzielt, dass die Oszillations-Antriebseinheiten jeweils in der Mitten-Ebene des Gießstrangs unterhalb den beiden Rechteckrahmen und zwischen Längsholmen des Fundamentrahmens angeordnet sind. Neben der geschützten Lage sind dadurch die Befestigungsstellen vorteilhaft,The special protection for the drives is achieved in that the oscillation drive units are each arranged in the center plane of the casting strand below the two rectangular frame and between longitudinal beams of the foundation frame. In addition to the protected position, the fastening points are thereby advantageous,

Andere Merkmale ergeben sich dadurch, dass im Fundamentrahmen zwischen den Längsholmen Einhänge-Elemente für die Aufhängung eines Stützrollen-Segmentes gelagert sind. Dadurch wird der Einbau vor der Montage der Stranggießkokille begünstigt.Other features result from the fact that in the foundation frame between the longitudinal beams suspension elements are mounted for the suspension of a support roller segment. This favors the installation prior to the installation of the continuous casting mold.

In einer Weiterbildung ist vorgesehen, dass die Einhänge-Elemente aus an einem auf den Längsholmen drehgelagerten, zweiarmigen Hebeln mit an einem Hebelende ausgebildeter Einhänge-Mulde und am anderen Hebelende angeschlossenen Justiermittein bestehen.In a further development, it is provided that the suspension elements consist of a rotatably mounted on the longitudinal beams, two-armed levers with formed at one end of the lever attachment trough and connected to the other end of the lever Justiermittein.

Die Gestaltung der Vorrichtung ist ferner dadurch weiterentwickelt, dass eine Wasserspannplatte zur Versorgung der Stranggießkokille mit Kühlmedium auf dem hinteren Flachkasten angeordnet ist und dass die Kühlmedium-Zuführung und die Kühlmedium-Abführung nach hinten vom Gießstrang weg verlaufen.The design of the device is further developed in that a water chuck plate for supplying the continuous casting mold with cooling medium is arranged on the rear flat box and that the cooling medium supply and the cooling medium discharge run backwards away from the cast strand.

In der Zeichnung sind Ausführungsbeispiele der Erfindung dargestellt, die nachfolgend näher erläutert werden.In the drawings, embodiments of the invention are shown, which are explained in more detail below.

Es zelgen:

- Fig. 1

- eine perspektivische Darstellung der Vorrichtung in Gesamtansicht,

- Fig. 2

- die perspektivische Darstellung gemäß

Fig. 1 ohne Schutzabdeckungen, - Fig. 3

- eine Seitenansicht in der Ebene, ohne den ersten Gießstrang,

- Fig. 4

- eine Draufsicht auf die Vorrichtung,

- Fig. 5

- eine Vorderansicht gegen die Vorrichtung bei abgenommener Schutzabdeckung, und

- Fig. 6

- eine Ansicht von unten gegen die Vorrichtung.

- Fig. 1

- a perspective view of the device in an overall view,

- Fig. 2

- the perspective view according to

Fig. 1 without protective covers, - Fig. 3

- a side view in the plane, without the first cast strand,

- Fig. 4

- a top view of the device,

- Fig. 5

- a front view against the device with the protective cover removed, and

- Fig. 6

- a view from below against the device.

In einer Mehrstrang-Gießanlage (

Um mehrere der Gießstränge 3 nebeneinander so eng wie möglich unterbringen zu können, d.h. um klein zu haltende Abstände "A" zu erreichen (

Am hinteren Ende und am vorderen Ende des Fundamentrahmens 5 befindet sich jeweils ein kompakter Flachkasten 6, der in seiner Längserstreckung quer zum Gießstrang 3 verläuft und den Zwischenraum der beiden Längsholme 5a und 5b überbrückt. Jeder Flachkasten 6 besteht aus einem geschlossenen Gehäuse 6a, wobei ein hinterer Flachkästen 6b und ein vorderer Flachkasten 6c mit dem erforderlichen Abstand zum Einbau einer Stranggießkokille gebildet ist.At the rear end and at the front end of the

Jeder Flachkasten 6 bildet das Gehäuse 6a zusammen mit beidseitigen Schutzabdeckungen 7. Im Innern des Gehäuses 6a sind am Grundrahmen 8, von denen jeweils zwei parallel und beabstandet sind, die noch näher zu beschreibenden Blattfedern 4. als obere und untere Blattfeder-Paare 4a und 4b quer zur Stranglaufrichtung 1, Gelenke bildend, befestigt. Zwischen den Grundrahmen 8 ist eine Wasserspannplatte 9 zur Kühlung der Stranggießkokille mit von unten gestalteter Kühlmedium-Zuführung 10 vorgesehen.In the interior of the housing 6a are on the

Die Ausbildung jedes Flachkestens 6 Ist bei geöffneten Gehäusen 6a, d.h. bei entfernter Schutzabdeckung 7 in

Wie weiterhin aus

Die Oszillations-Antriebseinheiten 14 befinden sich in der Mitten-Ebene 19 (

Gemäß den

Gemäß

In der Draufsicht der

In der Vorderansicht der

In der Ansicht von unten,

- 1 Gießrichtung , Stranglaufrichtung1 casting direction, strand direction

- 2 Schwingrahmen2 swing frame

- 3 Gießstrang3 cast strand

- 4 Blattfedern4 leaf springs

- 4a oberes Blattfeder-Paar4a upper leaf spring pair

- 4b unteres Blattfeder-Paar4b lower leaf spring pair

- 5 Fundamentrahmen5 foundation frame

- 5a Längsholm5a longitudinal spar

- 5b Längsholm5b longitudinal spar

- 6 kompakter Flachkasten6 compact flat box

- 6a Gehäuse6a housing

- 6b hinterer Flachkasten6b rear flat box

- 6c vorderer Flachkasten6c front flat box

- 7 Schutzabdeckung7 protective cover

- 8 Grundrahmen8 basic frames

- 9 Wasserspannplatte9 water tension plate

- 10 Kühlmedium-Zuführung10 cooling medium supply

- 11 Oszillationsantrieb11 oscillation drive

- 11 a vorderer Oszillatlonsantrieb11 a front oscillator drive

- 11b hinterer Oszillationsantrieb11b rear oscillation drive

- 12 Verbindungsbrücke12 connecting bridge

- 13 Bogenverlauf des Gießstrangs13 Bow path of the cast strand

- 14 hydraulische Oszillations-Antriebseinheit14 hydraulic oscillation drive unit

- 15 Hydraulikleitungen15 hydraulic lines

- 16 Rechteckrahmen16 rectangular frames

- 17 Kokillen-Auflagerahmen17 mold support frame

- 18 Kokillen-Stützfläche18 mold support surface

- 19 Mitten-Ebene des Gießstrangs19 middle level of the cast strand

- 20 Einhänge-Element20 suspension element

- 21 zweiarmiger Hebel21 two-armed lever

- 21 a Hebelende21 a lever end

- 21b Hebelende21b end of lever

- 22 Einhänge-Mulde22 suspension trough

- 23 Justiermittel23 adjustment means

- 24 Kühlmedium-Abführung24 Cooling medium discharge

Claims (8)

- Device for continuous casting of metals, particularly of steel materials, to form elongate products in a multi-strand casting plant, with a plurality of continuous casting moulds each separately mounted in an oscillatory frame (2) which is drivable to oscillate in casting direction (1) and which is mounted on a foundation frame by means of upper and lower, approximately horizontal leaf spring pairs (4), which are arranged on either side of the cast strip (3), for guidance and weight compensation, characterised in that two housings (6a), which are arranged one behind the other and constructed in the form of compact flat boxes (6) and in which the upper and lower leaf spring pairs (4a; 4b) extend transversely to the strip running direction (1), are fastened on an elongate foundation frame (5) in strip running direction (1), and that oscillatory drives (11) engage the leaf spring pairs (4a; 4b), wherein a front oscillatory drive (11 a) operates in synchronism with the rear oscillatory drive (11b).

- Device according to claim 1, characterised in that the front oscillatory drive (11a) is set relative to the rear oscillatory drive (11 b) for a curved path (13) of the cast strip (3) with different strokes.

- Device according to one of claims 1 and 2, characterised in that the oscillatory drives (11a; 11b) consist of hydraulic drive units (14).

- Device according to any one of claims 1 to 3, characterised in that the flat boxes (6) consist of two rectangular frames (16), which lie one behind the other in strip running direction (1), in each instance for a respective two leaf spring pairs (4a; 4b) with leaf springs (4) spaced apart in height and that a mould support frame (17) is pivotably arranged between the rectangular frames (16).

- Device according to any one of claims 1 to 4, characterised in that the oscillatory drive units (14) are respectively arranged in the centre plane (19) of the cast strip (3) below the two rectangular frames (16) and between longitudinal beams (5a; 5b) of the foundation frame (5).

- Device according to any one of claims 1 to 5, characterised in that suspension elements (20) for suspension of a support roller segment are mounted in the foundation frame (5) between the longitudinal beams (5a; 5b).

- Device according to claim 6, characterised in that the suspension elements (20) consist of double-arm levers (21), which are rotatably mounted on the longitudinal beams (5a; 5b), with a suspension trough (22) formed at one lever end (21 a) and adjusting means (23) connected with the other lever end (21 b).

- Device according to any one of claims 1 to 7, characterised in that a water clamping plate (9) for supply of the continuous casting mould with cooling medium is arranged on the rear flat box (6b) and that the cooling medium feed (10) and cooling medium discharge (24) extend rearwardly away from the cast strip (3).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10244596 | 2002-09-21 | ||

| DE10244596A DE10244596B4 (en) | 2002-09-21 | 2002-09-21 | Apparatus for continuous casting of metals, in particular of steel materials, to long products in a multi-strand casting plant |

| PCT/EP2003/009710 WO2004028723A1 (en) | 2002-09-21 | 2003-09-02 | Device for the continuous casting of metals, in particular steel material, to form elongated products in a multiple casting line |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1539403A1 EP1539403A1 (en) | 2005-06-15 |

| EP1539403B1 true EP1539403B1 (en) | 2017-01-04 |

Family

ID=31969553

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03798146.1A Revoked EP1539403B1 (en) | 2002-09-21 | 2003-09-02 | Device for the continuous casting of metals, in particular steel material, to form elongated products in a multiple casting line |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US7036557B2 (en) |

| EP (1) | EP1539403B1 (en) |

| JP (1) | JP4272158B2 (en) |

| KR (1) | KR101031610B1 (en) |

| CN (1) | CN100584486C (en) |

| AU (1) | AU2003266344A1 (en) |

| CA (1) | CA2499270C (en) |

| DE (1) | DE10244596B4 (en) |

| TW (1) | TWI279267B (en) |

| WO (1) | WO2004028723A1 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102004018602A1 (en) * | 2004-04-16 | 2005-11-03 | Sms Demag Ag | Oscillating device for continuous casting molds for casting of liquid metal, in particular of liquid steel material |

| DE102005019295A1 (en) * | 2004-07-06 | 2006-02-02 | Sms Demag Ag | Device for the support and oscillation of a continuous casting mold of liquid metals, in particular of liquid steel materials, and methods of assembly and disassembly and maintenance |

| DE102005017226A1 (en) * | 2004-07-06 | 2006-02-02 | Sms Demag Ag | Device for the support and oscillation of a continuous casting mold for the casting of liquid metal, in particular of liquid steel material |

| DE102008015827A1 (en) * | 2008-03-27 | 2009-10-01 | Sms Siemag Aktiengesellschaft | Device for the support and oscillation of a continuous casting mold |

| AT508395B1 (en) * | 2009-06-16 | 2014-08-15 | Tbr Casting Technologies Gmbh | MEDIUM FOR OSCILLATING A CONTINUOUS GASKILKILLE |

| EP2905093B1 (en) * | 2014-02-07 | 2018-08-29 | SMS Concast AG | Mould assembly for continuous casting of metallic products |

| CN114309502A (en) * | 2021-12-24 | 2022-04-12 | 衡阳镭目科技有限责任公司 | Unit type single-drive crystallizer vibration device |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4195684A (en) | 1975-12-18 | 1980-04-01 | Ishikawajima-Harima Jukogyo Kabushiki Kaisha | Apparatus for multi-strand continuous casting |

| DE3706720A1 (en) | 1987-03-02 | 1988-09-15 | Voest Alpine Ag | Continuous casting installation with two continuous casting moulds arranged next to one another |

| EP0468607B1 (en) | 1990-07-23 | 1995-04-19 | MANNESMANN Aktiengesellschaft | Fluid cooled mould for continuous casting of metals |

| WO1995015232A1 (en) | 1993-12-03 | 1995-06-08 | Mannesmann Ag | Device for the continuous casting of steel |

| DE4444941A1 (en) | 1993-12-20 | 1995-06-22 | Voest Alpine Ind Anlagen | A continuously casting chill mould for rectangular slabs |

| US5623983A (en) | 1994-12-21 | 1997-04-29 | Voest-Alpine Industrieanlagenbau Gmbh | Continuous casting mold |

| US5642769A (en) | 1994-12-21 | 1997-07-01 | Voest-Alpine Industrieanlagenbau Gmbh | Continuous casting mold |

| WO1999012676A1 (en) | 1997-09-08 | 1999-03-18 | Voest-Alpine Industrieanlagenbau Gmbh | Device for continuous casting |

| EP0953391A1 (en) | 1998-04-21 | 1999-11-03 | Sms Schloemann-Siemag Aktiengesellschaft | Elevator table with oscillating drive for a continuous casting installation |

| US6167941B1 (en) | 1997-12-06 | 2001-01-02 | Sms Schloemann-Siemag Ag | Support structure for oscillating continuous casting mold |

| DE10024514A1 (en) | 1999-06-08 | 2001-01-04 | Voest Alpine Ind Anlagen | Continuous casting apparatus has springs directed in the longitudinal extension normally onto the longitudinal plane of the apparatus receiving the mold longitudinal axis and the casting axis |

| WO2001085370A1 (en) | 2000-05-10 | 2001-11-15 | Sms Demag Aktiengesellschaft | Device for the continuous casting of metals, especially steel |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA1316325C (en) * | 1987-08-29 | 1993-04-20 | Masatsugu Uehara | Method of oscillating continuous casting mold at high frequencies and mold oscillated by such method |

-

2002

- 2002-09-21 DE DE10244596A patent/DE10244596B4/en not_active Expired - Fee Related

-

2003

- 2003-09-01 TW TW092124064A patent/TWI279267B/en not_active IP Right Cessation

- 2003-09-02 CN CN03822459A patent/CN100584486C/en not_active Expired - Fee Related

- 2003-09-02 CA CA2499270A patent/CA2499270C/en not_active Expired - Fee Related

- 2003-09-02 US US10/528,380 patent/US7036557B2/en not_active Expired - Lifetime

- 2003-09-02 WO PCT/EP2003/009710 patent/WO2004028723A1/en active Application Filing

- 2003-09-02 AU AU2003266344A patent/AU2003266344A1/en not_active Abandoned

- 2003-09-02 EP EP03798146.1A patent/EP1539403B1/en not_active Revoked

- 2003-09-02 JP JP2004538859A patent/JP4272158B2/en not_active Expired - Fee Related

- 2003-09-02 KR KR1020057004823A patent/KR101031610B1/en active IP Right Grant

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4195684A (en) | 1975-12-18 | 1980-04-01 | Ishikawajima-Harima Jukogyo Kabushiki Kaisha | Apparatus for multi-strand continuous casting |

| DE3706720A1 (en) | 1987-03-02 | 1988-09-15 | Voest Alpine Ag | Continuous casting installation with two continuous casting moulds arranged next to one another |

| EP0468607B1 (en) | 1990-07-23 | 1995-04-19 | MANNESMANN Aktiengesellschaft | Fluid cooled mould for continuous casting of metals |

| WO1995015232A1 (en) | 1993-12-03 | 1995-06-08 | Mannesmann Ag | Device for the continuous casting of steel |

| US5771957A (en) | 1993-12-03 | 1998-06-30 | Mannesmann Aktiengesellschaft | Device for the continuous casting of steel |

| DE4444941A1 (en) | 1993-12-20 | 1995-06-22 | Voest Alpine Ind Anlagen | A continuously casting chill mould for rectangular slabs |

| US5642769A (en) | 1994-12-21 | 1997-07-01 | Voest-Alpine Industrieanlagenbau Gmbh | Continuous casting mold |

| US5623983A (en) | 1994-12-21 | 1997-04-29 | Voest-Alpine Industrieanlagenbau Gmbh | Continuous casting mold |

| WO1999012676A1 (en) | 1997-09-08 | 1999-03-18 | Voest-Alpine Industrieanlagenbau Gmbh | Device for continuous casting |

| US6167941B1 (en) | 1997-12-06 | 2001-01-02 | Sms Schloemann-Siemag Ag | Support structure for oscillating continuous casting mold |

| EP0953391A1 (en) | 1998-04-21 | 1999-11-03 | Sms Schloemann-Siemag Aktiengesellschaft | Elevator table with oscillating drive for a continuous casting installation |

| DE10024514A1 (en) | 1999-06-08 | 2001-01-04 | Voest Alpine Ind Anlagen | Continuous casting apparatus has springs directed in the longitudinal extension normally onto the longitudinal plane of the apparatus receiving the mold longitudinal axis and the casting axis |

| AT408625B (en) | 1999-06-08 | 2002-01-25 | Voest Alpine Ind Anlagen | CASTING |

| WO2001085370A1 (en) | 2000-05-10 | 2001-11-15 | Sms Demag Aktiengesellschaft | Device for the continuous casting of metals, especially steel |

Non-Patent Citations (7)

| Title |

|---|

| "VOEST-ALPINE Industrieanlagenbau GmbH, Continuous Casting Division", May 1999, article "Product Info Billet/Bloom Caster, DYNAFLEX-Oscillator for Billet & Bloom Casters", XP055424638 |

| F. LEINGRUBER ET AL.: "High-Performance Machine Head - A Success Story", BILLET/BLOOM CASTING SESSION, no. 34, June 2000 (2000-06-01), pages 1 - 4, XP055424558 |

| H. HÖDL ET AL.: "VAINOX - Latest Developments in Stainless Steel Casting Technologies", SLAB CASTING SESSION - PAPER NO. 15, CONTINUOUS CASTING CONFERENCE (CCC) 2000, no. 15, June 2000 (2000-06-01), Linz/ Austria (E2e), pages 1 - 17, XP55424668 |

| O. L. MANHÄES WAGNER ET AL.: "Casting Solutions for High Productivity and High Quality at CSN", SLAB CASTING SESSION - PAPER NO. 19, CONTINUOUS CASTING CONFERENCE (CCC) 2000, no. 19, June 2000 (2000-06-01), Linz/ Austria (E2c), pages 1 - 6, XP055424627 |

| T. HARALDSON ET AL.: "Modernisation of Slab Casters at SSAB Tunnplät", ASSOCIATION OF IRON AND STEEL ENGINEERS, 1998, Sweden (E2b3), XP055424623 |

| T. HARALDSON ET AL.: "Modernisation of the slab casters at SSAB Tunnplät", STEEL TIMES, January 2001 (2001-01-01), pages 26 - 27, XP055424572 |

| T. HARALDSON ET AL.: "SSAB Tunnplät - Luleä - DYNAFLEX Oscillator and Hydraulic Width-Adjustable Mold", SLAB CASTING SESSION - PAPER NO. 18, CONTINUOUS CASTING CONFERENCE (CCC) 2000, no. 18, June 2000 (2000-06-01), Linz/ Austria (E2b1), pages 1 - 6, XP055424564 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN100584486C (en) | 2010-01-27 |

| US20060048915A1 (en) | 2006-03-09 |

| CA2499270C (en) | 2010-11-16 |

| CN1681612A (en) | 2005-10-12 |

| WO2004028723A1 (en) | 2004-04-08 |

| KR20050057510A (en) | 2005-06-16 |

| US7036557B2 (en) | 2006-05-02 |

| JP2005538852A (en) | 2005-12-22 |

| DE10244596B4 (en) | 2011-12-29 |

| EP1539403A1 (en) | 2005-06-15 |

| DE10244596A1 (en) | 2004-04-01 |

| JP4272158B2 (en) | 2009-06-03 |

| CA2499270A1 (en) | 2004-04-08 |

| AU2003266344A1 (en) | 2004-04-19 |

| TWI279267B (en) | 2007-04-21 |

| TW200404627A (en) | 2004-04-01 |

| KR101031610B1 (en) | 2011-04-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE4341719C1 (en) | Device for the continuous casting of steel | |

| EP1763414B1 (en) | Device for supporting an oscillating a continuous casting mold for continuously casting molten metals, particularly molten metal materials, and method for assembling, disassembling and maintaining the device | |

| EP0468607A1 (en) | Fluid cooled mould for continuous casting of metals | |

| EP1539403B1 (en) | Device for the continuous casting of metals, in particular steel material, to form elongated products in a multiple casting line | |

| WO2005105342A1 (en) | Device for accommodating a continuous casting mold on an elevating table for casting molten metals, particularly molten steel materials | |

| EP1370379B1 (en) | Method for casting and immediate rolling, and device for the support, guidance and deformation of a metal strand, especially a steel strand | |

| DE4444941C3 (en) | continuous casting | |

| DE2021780C3 (en) | Method for adapting the arch guide of a strand emerging from a continuous casting mold and device for this | |

| DE1558220B2 (en) | Storage of rollers for changing the shape of a metallic strand coming from a continuous casting mold | |

| DE19547779A1 (en) | Continuous casting mould | |

| DE10024514C5 (en) | continuous casting plant | |

| EP2275216B1 (en) | Device for oscillating a continuous casting mold | |

| EP1029616B1 (en) | Device for oscillating a continuous-casting mould | |

| DE1758982A1 (en) | Longitudinally split continuous casting mold for metal, in particular continuous jet casting systems | |

| EP1991379B1 (en) | Continuous casting plant and method of operating a continuous casting plant | |

| DE2146963A1 (en) | Guide roller arrangement for continuous casting machine | |

| EP0018350B1 (en) | Continuous-casting plant, especially for producing slabs | |

| EP1057556B1 (en) | Continuous casting mould for continuous casting, preferably of thin steel slabs | |

| EP3354370B1 (en) | Oscillation system for a contiunous casting mould and method for generating an oscillating movement of a continuous casting mould | |

| EP0946318A1 (en) | Method and device for continuous thin slab steel casting | |

| CH679650A5 (en) | ||

| DE2947869A1 (en) | DEVICE AND METHOD FOR ELECTROMAGNETICALLY STIRING THE SWAMP IN A STEEL CONTINUOUS CASTING SYSTEM | |

| DE4447941B4 (en) | A continuously casting chill mould for rectangular slabs - which reduces construction costs, maintenance and mould change times, without sacrificing rigidity | |

| EP0068208B1 (en) | Plant for the continuous casting of steel | |

| DE3407139A1 (en) | Guiding device for casting strands of a double-strip continuous casting mould |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050205 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SMS SIEMAG AG |

|

| 17Q | First examination report despatched |

Effective date: 20120625 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SMS GROUP GMBH |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160729 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 858737 Country of ref document: AT Kind code of ref document: T Effective date: 20170115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 50315607 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170405 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170404 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170504 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 50315607 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| 26 | Opposition filed |

Opponent name: PRIMETALS TECHNOLOGIES AUSTRIA GMBH Effective date: 20171003 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20170902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170902 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20180531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170902 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171002 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180920 Year of fee payment: 16 Ref country code: IT Payment date: 20180925 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20180920 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R064 Ref document number: 50315607 Country of ref document: DE Ref country code: DE Ref legal event code: R103 Ref document number: 50315607 Country of ref document: DE |

|

| RDAF | Communication despatched that patent is revoked |

Free format text: ORIGINAL CODE: EPIDOSNREV1 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20030902 |

|

| RDAG | Patent revoked |

Free format text: ORIGINAL CODE: 0009271 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT REVOKED |

|

| 27W | Patent revoked |

Effective date: 20190320 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MA03 Ref document number: 858737 Country of ref document: AT Kind code of ref document: T Effective date: 20190320 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170104 |