EP1536066B1 - Elément d'isolation acoustique - Google Patents

Elément d'isolation acoustique Download PDFInfo

- Publication number

- EP1536066B1 EP1536066B1 EP04014299A EP04014299A EP1536066B1 EP 1536066 B1 EP1536066 B1 EP 1536066B1 EP 04014299 A EP04014299 A EP 04014299A EP 04014299 A EP04014299 A EP 04014299A EP 1536066 B1 EP1536066 B1 EP 1536066B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- sound

- soundproofing element

- element according

- absorption structure

- soundproofing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000004888 barrier function Effects 0.000 claims abstract description 21

- 239000002250 absorbent Substances 0.000 claims abstract description 15

- 238000010521 absorption reaction Methods 0.000 claims description 25

- 239000000463 material Substances 0.000 claims description 23

- 239000006096 absorbing agent Substances 0.000 claims description 18

- 229910052782 aluminium Inorganic materials 0.000 claims description 6

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 6

- 229910052751 metal Inorganic materials 0.000 claims description 6

- 239000002184 metal Substances 0.000 claims description 6

- 239000004033 plastic Substances 0.000 claims description 4

- 229920003023 plastic Polymers 0.000 claims description 4

- 239000012780 transparent material Substances 0.000 claims description 4

- 239000011521 glass Substances 0.000 claims description 3

- 238000010276 construction Methods 0.000 claims description 2

- 229920003229 poly(methyl methacrylate) Polymers 0.000 claims description 2

- 239000004926 polymethyl methacrylate Substances 0.000 claims description 2

- 239000013535 sea water Substances 0.000 claims description 2

- 239000004411 aluminium Substances 0.000 claims 2

- 239000000835 fiber Substances 0.000 claims 1

- 229910052500 inorganic mineral Inorganic materials 0.000 claims 1

- 239000011707 mineral Substances 0.000 claims 1

- 230000000007 visual effect Effects 0.000 description 5

- 238000009413 insulation Methods 0.000 description 4

- 239000011435 rock Substances 0.000 description 3

- 230000002745 absorbent Effects 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 230000006355 external stress Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002557 mineral fiber Substances 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01F—ADDITIONAL WORK, SUCH AS EQUIPPING ROADS OR THE CONSTRUCTION OF PLATFORMS, HELICOPTER LANDING STAGES, SIGNS, SNOW FENCES, OR THE LIKE

- E01F8/00—Arrangements for absorbing or reflecting air-transmitted noise from road or railway traffic

- E01F8/0005—Arrangements for absorbing or reflecting air-transmitted noise from road or railway traffic used in a wall type arrangement

- E01F8/0017—Plate-like elements

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01F—ADDITIONAL WORK, SUCH AS EQUIPPING ROADS OR THE CONSTRUCTION OF PLATFORMS, HELICOPTER LANDING STAGES, SIGNS, SNOW FENCES, OR THE LIKE

- E01F8/00—Arrangements for absorbing or reflecting air-transmitted noise from road or railway traffic

- E01F8/0005—Arrangements for absorbing or reflecting air-transmitted noise from road or railway traffic used in a wall type arrangement

- E01F8/0023—Details, e.g. foundations

Definitions

- the invention relates to a soundproofing element and a noise barrier, in particular for roads, highways, railways u. like.

- Noise barriers, noise barriers or noise barriers are used everywhere where citizens are to be protected from noise, especially traffic noise. Noise barriers, however, can not be poured everywhere due to the large space requirement. Especially at the edge of roads, highways and railways is the space available for noise protection often low. Only narrow noise barriers or noise barriers can be used in these areas. At noise barriers high demands are made. They must absorb the sound in the best possible way, be weather-resistant, robust against falling rocks or vandalism and be cost-effective. At the same time, the visual impression is important. Inner city areas should not be spoiled by concrete walls, and motorists and train passengers should not be completely excluded from the environment. Noise barriers are therefore at least partially transparent.

- the soundproofing element described therein has two posts that hold a sound-absorbing insert of transparent material. In addition to the posts are still a cross member on the ground and a cross member to about two-thirds of the height of the sound-absorbing insert for holding just this provided.

- the aforementioned soundproofing element Due to its structure, the aforementioned soundproofing element is largely transparent. However, the visual impression and the transparency are disturbed by the massive cross members. In addition, the sound absorption of the soundproofing element is not optimal.

- a soundproofing element is known, is dispensed with the cross member.

- the sound insulation element itself consists only of a self-supporting, transparent, sound-absorbing insert.

- To build a noise barrier several of these sound insulation elements are lined up and connected. At the ends of the noise barrier posts are provided, which serve to hold the respective edge sound insulation elements.

- the soundproofing element described above Even with the soundproofing element described above, the soundproofing is not optimal. Likewise, it is not necessarily desirable to have a completely free view of a busy traffic route, especially in the inner-city area.

- FR 2 551 784 A3 a soundproofing element is known in which a sound-absorbing insert is held in a profile frame.

- a sound absorbing structure disposed between the sound absorbing liner and the profile frame. The sound absorption structure surrounds the sound-absorbing insert in its edge region, but leaves the middle area free. The problem with this arrangement is that the additional sound absorption structure is at least partially exposed to the weather conditions unprotected.

- the present invention is based on the problem of performing a soundproofing element of the type in question as weather resistant and robust as possible, at the same time to ensure optimum sound insulation and to achieve a pleasant visual impression. Along with this, noise barriers should also be optimized.

- the sound absorption structure comprises a core of absorber material surrounded by a moisture protection cover at least on the sides which are exposed to the weather, and an outer support element is provided which simultaneously serves as a support for the absorber material and as protection against falling rocks or vandalism serves.

- the additional sound absorption structure covers the sound-absorbing liner peripherally circumferential.

- the central region of the soundproofing element remains transparent.

- sound passage openings should be provided in the sides of the support element which are primarily acted upon by sound waves.

- the free area thus formed should be about 60% to about 90% of the total area, preferably about 70% to about 80%, so that the sound waves can penetrate into the absorber material.

- the sound-absorbing, transparent insert consists of acrylic glass. This is unbreakable, weatherproof and easy to handle.

- Fig. 1 shows a soundproofing element 1 for a noise barrier.

- the soundproofing element 1 has a dimensionally stable profile frame 2 and a sound-absorbing insert 3 held by the profile frame 2.

- the sound-absorbing insert 3 is made of transparent material.

- a sound absorption structure 4 is provided.

- the sound absorption structure 4 is here and preferably arranged so that it covers the sound-absorbing insert 3 peripherally circumferentially. critical for all embodiments, the sound absorption structure 4 covers at most a part of the sound-absorbing insert 3. In the case of the edge-side arrangement of the sound absorption structure 4, it can also project beyond the insert 3 at the edge, that is, at least in part next to the insert 3. However, the sound absorption structure 4 can also be arranged completely next to the sound-absorbing insert 3. In this arrangement, the sound-absorbing insert 3 is also not partially covered by the sound absorption structure 4.

- the sound absorption structure 4 here and preferably has a core of absorber material 5, a moisture protection sleeve 6 and an outer support element 7.

- the absorber material 5 is designed here as a mineral fiber material, which is particularly well suited to absorb sound.

- the absorber material 5 has a density of about 80 kg / m 3 to about 120 kg / m 3 .

- the density is preferably about 90 kg / m 3 to about 110 kg / m 3 .

- the moisture protection cover 6 is arranged so that here the absorber material 5 is covered from all sides, which are exposed to the weather. In the present case, these are two sides 8, 9.

- the moisture protection cover 6 is designed as Glasvlieskaschtechnik.

- the outer support member 7 comprises the absorber material from other sides.

- the outer support member 7 thus serves simultaneously to protect the absorber material 5 from falling rocks, vandalism o. ⁇ ..

- sound passage openings 7 ' are provided, so that the sound waves can penetrate into the absorber material 5 and are not only reflected back.

- the free surface formed by the sound passage openings 7 ' is about 60% to about 90%, preferably about 70% to about 80%.

- the outer support member 7 may be designed as an expanded metal grid, perforated plate or plastic grid element.

- the outer support member 7 is designed as a perforated plate consisting of aluminum. The free surface in the outer support element also loosens the visual impression of the soundproofing element 1. It does not seem so massive.

- the sound absorption structure 4 usually has a thickness of about 50 mm to about 250 mm, preferably from about 70 mm to about 150 mm.

- the sound-absorbing insert 3 has a thickness of about 5 mm to about 30 mm, preferably from about 15 mm to about 25 mm. The parameters are chosen so that the sound absorption is sufficient, while the soundproofing element is not too massive and still manageable.

- an amorphous material is preferably used, in particular a glass or a plastic.

- a glass or a plastic for further information on which material is suitable, reference is hereby made to DE 199 06 989 A1.

- the profile frame 2 made of aluminum and is designed in particular seawater resistant. This is of particular advantage since the soundproofing element 1 is exposed to high loads in the winter when using salt as a scattering agent.

- the sound-absorbing insert 3 and the sound absorption structure 4 are held on the edge side by the profile frame 2.

- the attachment to the profile frame 2 is effected by a clamping pressure, screwing o. ⁇ .

- the sound-absorbing insert 3 is surrounded by a separate frame 10 which is then attached to / in the profile frame.

- the soundproofing element 1 is designed to be absorbent in a preferred embodiment in accordance with the requirements of ZTV-Lsw 88 (Additional Technical Regulations and Guidelines for the Construction of Noise Protection Roads, Edition 1988). It also complies in particular with the requirements of Group A2 of Annex A of the standard DIN EN 1793-1 (German Industrial Standard - European Standard). Compliance with certain standards and regulations are prescribed in Germany for the use of a soundproofing element 1 on certain roads.

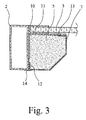

- Fig. 3 shows a further embodiment of a soundproofing element 1 according to the invention.

- the sound-absorbing insert 3 has its own frame 10.

- the frame 10 of the sound-absorbing insert 3 comprises these at two opposite edges.

- the sound-absorbing insert 3 is covered only at these edges.

- the sound-absorbing insert 3 is fastened by means of its frame 10 to the profile frame 2.

- the profile frame 2 of the soundproofing element 1 is here and preferably designed as a rectangular tube.

- the profile frame 2 is significantly wider than the sound-absorbing insert 3 together with its frame 10, so that a substantially right-angled corner is formed by the profile frame 2 and the sound-absorbing insert 3.

- an angle section 11 made of metal, preferably made of aluminum, arranged so that one side of the angle section 11 can be fastened to the profile frame 2 and the other side of the angle section 11 on the frame 10 of the sound-absorbing insert 3 can be fastened.

- a Z-profile 12, 13 made of metal, preferably made of aluminum.

- the Z-profile 12 is arranged so that at the sound-absorbing insert 3 opposite side between the profile frame 2 and Z-profile 12 is a gap.

- the Z-profile 13 is arranged so that at the profile frame 2 opposite side between the angle section 11 and the Z-profile 13 is a gap.

- the outer support member 7 is shaped so that it projects into both columns.

- the cavity formed between the angle section 11 and the outer support member 7 is filled by the absorber material 5 with the moisture protection sleeve 6.

- the outer support member 7 is fixed by an adhesive joint, a welded joint, a screw o. ⁇ .

- the outer support element 7 can also be fastened by a striking plate 14, which is arranged on the profile frame 2 and the outer support element 7.

- the soundproofing element 1 usually has a length of about 1.5 m to about 6.0 m, preferably, from about 2.0 m to about 2.5 m or about 4.0 m to about 5.0 m.

- the soundproofing element 1 usually has a height of from about 0.3 m to about 4.0 m, preferably from about 0.5 m to about 1.0 m or from about 1.0 m to about 3.0 m.

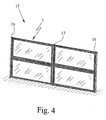

- Fig. 4 shows a noise barrier 15 which consists of at least one soundproofing element 1 and two edge-side posts 16, 17.

- the posts 16, 17 are used to hold the soundproofing element 1.

- an arbitrarily long noise protection wall 15 can be formed.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Devices Affording Protection Of Roads Or Walls For Sound Insulation (AREA)

- Soundproofing, Sound Blocking, And Sound Damping (AREA)

- Surgical Instruments (AREA)

- Glass Compositions (AREA)

- Materials For Medical Uses (AREA)

Claims (14)

- Élément d'isolation acoustique pour un mur antibruit comprenant un cadre profilé (2) indéformable et au moins une garniture d'absorption acoustique (3) maintenue par le cadre profilé (2), une structure d'absorption acoustique (4) étant prévue en plus de la garniture d'absorption acoustique (3), la structure d'absorption acoustique (4) étant disposée dans le cadre profilé (2) de telle sorte qu'elle recouvre au maximum une partie de la garniture d'absorption acoustique (3), caractérisé en ce que la garniture d'absorption acoustique se compose de matériau transparent et que la structure d'absorption acoustique (4) présente un noyau en matériau absorbant (5), une gaine de protection contre l'humidité (6) et un élément support extérieur (7).

- Élément d'isolation acoustique selon la revendication 1, caractérisé en ce que la structure d'absorption acoustique (4) est disposée de telle sorte qu'une partie de la garniture d'absorption acoustique (3) est recouverte par la surface totale de la structure d'absorption acoustique (4).

- Élément d'isolation acoustique selon la revendication 1 ou 2, caractérisé en ce que la structure d'absorption acoustique (4) recouvre la garniture d'absorption acoustique (3) au niveau du bord et de préférence de sorte que la structure d'absorption acoustique (4) recouvre la garniture d'absorption acoustique (3) au niveau du bord sur tout le pourtour.

- Élément d'isolation acoustique selon la revendication 1, caractérisé en ce que la structure d'absorption acoustique (4) est disposée à côté de la garniture d'absorption acoustique (3) de sorte qu'aucune partie de la garniture d'absorption acoustique (3) ne soit recouverte.

- Élément d'isolation acoustique selon l'une des revendications précédentes, caractérisé en ce que le matériau absorbant (5) est réalisé sous la forme de matériau à fibres minérales et/ou que le matériau absorbant (5) présente une densité d'environ 80 kg/m3 à environ 120 kg/m3, de préférence d'environ 90 kg/m3 à environ 110 kg/m3.

- Élément d'isolation acoustique selon l'une des revendications 1 à 5, caractérisé en ce que la gaine de protection contre l'humidité (6) est réalisée sous la forme d'une doublure en toison de fibres de verre.

- Élément d'isolation acoustique selon l'une des revendications 1 à 6, caractérisé en ce que la gaine de protection contre l'humidité (6) recouvre le matériau absorbant (5) d'au moins un côté, de préférence des deux côtés.

- Élément d'isolation acoustique selon l'une des revendications 1 à 7, caractérisé en ce que l'élément support extérieur (7) comprend au moins deux côtés de matériau absorbant (5).

- Élément d'isolation acoustique selon l'une des revendications 1 à 8, caractérisé en ce que des ouvertures de passage du bruit (7') sont prévues dans au moins un côté, de préférence dans deux côtés de l'élément support extérieur (7) et de préférence que la surface libre formée par les ouvertures de passage du bruit (7') est égale à environ 60 % à environ 90 % de la surface totale, de préférence à environ 70 % à environ 80 % et/ou que l'élément support extérieur (7) est réalisé sous la forme d'une grille en métal étiré, d'une tôle perforée ou d'un élément de grille en matière plastique, de préférence que l'élément support extérieur (7) est réalisé sous la forme d'une grille en métal étiré ou d'une tôle perforée en aluminium.

- Élément d'isolation acoustique selon l'une des revendications précédentes, caractérisé en ce que la structure d'absorption acoustique (4) présente une épaisseur d'environ 50 mm à environ 250 mm, de préférence d'environ 70 mm à environ 150 mm et/ou que la garniture d'absorption acoustique (3) présente une épaisseur d'environ 5 mm à environ 30 mm, de préférence d'environ 15 mm à environ 25 mm.

- Élément d'isolation acoustique selon l'une des revendications précédentes, caractérisé en ce que l'élément d'isolation acoustique (1) présente une longueur d'environ 1,5 m à environ 6,0 m, de préférence d'environ 2,0 m à environ 2,5 m ou d'environ 4,0 m à environ 5,0 m et/ou que l'élément d'isolation acoustique (1) présente une hauteur d'environ 0,3 m à environ 4,0 m, de préférence d'environ 0,5 m à environ 1,0 m ou d'environ 1,0 m à environ 3,0 m.

- Élément d'isolation acoustique selon l'une des revendications précédentes, caractérisé en ce que le matériau transparent de la garniture d'absorption acoustique (3) est un matériau amorphe et/ou, de préférence, que la garniture d'absorption acoustique (3) est réalisée dans un verre ou une matière plastique, notamment du plexiglas.

- Élément d'isolation acoustique selon l'une des revendications précédentes, caractérisé en ce que le cadre profilé (2) est réalisé sous la forme d'un tube rectangulaire et/ou, de préférence, que le cadre profilé (2) se compose de métal, de préférence d'aluminium, et/ou, encore de préférence, que le cadre profilé (2) est réalisé résistant à l'eau de mer.

- Mur antibruit composé d'au moins un élément d'isolation acoustique (1) selon l'une des revendications 1 à 13 et d'au moins deux poteaux (16, 17).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10356291A DE10356291B4 (de) | 2003-11-28 | 2003-11-28 | Schallschutzelment |

| DE10356291 | 2003-11-28 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1536066A1 EP1536066A1 (fr) | 2005-06-01 |

| EP1536066B1 true EP1536066B1 (fr) | 2006-05-17 |

Family

ID=34442399

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04014299A Expired - Lifetime EP1536066B1 (fr) | 2003-11-28 | 2004-06-18 | Elément d'isolation acoustique |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1536066B1 (fr) |

| CN (1) | CN100419167C (fr) |

| AT (1) | ATE326583T1 (fr) |

| DE (2) | DE10356291B4 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202014008764U1 (de) | 2014-11-06 | 2015-01-09 | Eurovia Beton Gmbh Nl Teco Schallschutz | Schallschutzelement |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101899817B (zh) * | 2010-06-28 | 2012-11-07 | 四川正升声学科技有限公司 | 一种高速铁路通风泄压式吸隔声屏障 |

| CN101858061B (zh) * | 2010-06-28 | 2012-10-24 | 四川正升声学科技有限公司 | 通风泄压式声屏障模块 |

| CN107165069A (zh) * | 2017-06-13 | 2017-09-15 | 合肥钢骨玻璃制品有限公司 | 一种钢骨玻璃隔音屏障 |

| CN111503807A (zh) * | 2020-05-26 | 2020-08-07 | 重庆恒鼎泰环境科技有限公司 | 一种自然隔音通风器 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL8002686A (nl) * | 1980-05-09 | 1981-12-01 | Vapotherm Bv | Geluidwerend schot. |

| NL8303128A (nl) * | 1983-09-09 | 1985-04-01 | Alcoa Nederland Bv | Geluidsisolerende wand. |

| DD219529A1 (de) * | 1983-11-11 | 1985-03-06 | Berlin Baumechanisierung | Leichtes aufsatzfenster fuer fensterfluegel |

| DE8524319U1 (de) * | 1985-08-24 | 1985-10-10 | Röhm GmbH, 6100 Darmstadt | Verglasungssprosse |

| US5015119A (en) * | 1989-09-11 | 1991-05-14 | Schmanski Donald W | Vision blocking barrier |

| DE9200477U1 (de) * | 1992-01-17 | 1992-04-16 | Colberg Metall-, Stahl- und Kunststofftechnik GmbH, 3150 Peine | Lärmschutzwandelement |

| DE4230786A1 (de) * | 1992-09-15 | 1994-05-19 | Simon Ernst Otto Karl | Lärmschutzwandsegment |

| DE29510861U1 (de) * | 1995-07-05 | 1995-09-28 | Koch GmbH & Co. KG, 56412 Nentershausen | Lärmschutzwand |

| DE29608228U1 (de) * | 1996-05-07 | 1996-08-01 | Koch GmbH & Co. KG, 56412 Nentershausen | Lärmschutzwand |

| DE19906989A1 (de) * | 1999-02-19 | 2000-09-14 | Roehm Gmbh | Lärmschutzwandsegment |

| DE29911461U1 (de) * | 1999-07-02 | 2000-04-06 | Jung, Thomas, Dipl.-Designer, 45529 Hattingen | Großflächig transparente Schallschutzwände |

| DE20021724U1 (de) * | 2000-12-21 | 2001-03-01 | R. Kohlhauer GmbH, 76571 Gaggenau | Lärmschutzwand |

-

2003

- 2003-11-28 DE DE10356291A patent/DE10356291B4/de not_active Expired - Fee Related

-

2004

- 2004-06-18 DE DE502004000579T patent/DE502004000579D1/de not_active Expired - Fee Related

- 2004-06-18 AT AT04014299T patent/ATE326583T1/de not_active IP Right Cessation

- 2004-06-18 EP EP04014299A patent/EP1536066B1/fr not_active Expired - Lifetime

- 2004-07-30 CN CNB2004100552906A patent/CN100419167C/zh not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202014008764U1 (de) | 2014-11-06 | 2015-01-09 | Eurovia Beton Gmbh Nl Teco Schallschutz | Schallschutzelement |

| EP3018256A1 (fr) | 2014-11-06 | 2016-05-11 | EUROVIA Beton GmbH | Élement d'insonorisation |

Also Published As

| Publication number | Publication date |

|---|---|

| DE10356291B4 (de) | 2006-01-05 |

| ATE326583T1 (de) | 2006-06-15 |

| DE502004000579D1 (de) | 2006-06-22 |

| CN100419167C (zh) | 2008-09-17 |

| DE10356291A1 (de) | 2005-07-07 |

| CN1621621A (zh) | 2005-06-01 |

| EP1536066A1 (fr) | 2005-06-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1536066B1 (fr) | Elément d'isolation acoustique | |

| EP2163705A2 (fr) | Habillage mural doté d'un matériau de remplissage et d'une couche fonctionnelle | |

| EP2126218B1 (fr) | Absorbeur de bruit avec profilés de support | |

| EP1911901B1 (fr) | Paroi de séparation | |

| EP0278326B1 (fr) | Dispositif de fixation pour panneaux de revêtement | |

| DE7711360U1 (de) | Wandelement gegen laermimmission | |

| DE3631257C2 (de) | Bauelement für Schallschutzwände | |

| DE3426639C2 (fr) | ||

| DE3937756A1 (de) | Schallabsorbierende wand | |

| DE3009082A1 (de) | Wandelement zum errichten von laermschutzwaenden | |

| EP1992740B1 (fr) | Elément d'insonorisation et son procédé de fabrication | |

| DE2544469A1 (de) | Laermschutzwand | |

| CH688097A5 (de) | Bausatz zur Erstellung einer Schallschutzwand. | |

| DE102004056332B4 (de) | Verwendung eines Verbundwerkstoffs zur Dämmung von Schall und Erschütterungen | |

| DE19938676A1 (de) | Schallschutzwand für Verkehrswege | |

| DE102010005484B4 (de) | Lärmschutz-Vorrichtung | |

| EP2276891B1 (fr) | Partie superieure pour murs, notamment pour murs antibruit | |

| DE102009041730A1 (de) | Bügel zur Festlegung zumindest einer Tafel an einem Befestigungsgrund | |

| DE3919280A1 (de) | Schallschutzwand | |

| DE102009041731A1 (de) | Pfosten einer Wand aus einen Füllraum begrenzenden Tafeln und Pfosten | |

| EP2521815B1 (fr) | Élément antibruit végétal et paroi antibruit | |

| EP3018256B1 (fr) | Élement d'insonorisation | |

| DE2354047B2 (de) | Lärmschutzwand | |

| DE102007015861A1 (de) | Trennwand | |

| DE202012006256U1 (de) | Schallschutzelement |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20050527 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060517 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060517 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060517 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060517 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060517 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060517 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060517 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060517 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060517 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: RIEMANN, REINHARD Inventor name: METHNER, BERND Inventor name: MACKO, TORSTEN |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: KELLER & PARTNER PATENTANWAELTE AG |

|

| REF | Corresponds to: |

Ref document number: 502004000579 Country of ref document: DE Date of ref document: 20060622 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060630 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060817 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060817 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060828 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061017 |

|

| ET | Fr: translation filed | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20060517 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070220 |

|

| BERE | Be: lapsed |

Owner name: EUROVIA BETON G.M.B.H. NL TECO SCHALLSCHUTZ Effective date: 20060630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060818 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060817 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060618 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061118 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060517 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20080618 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060517 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080613 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20090615 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20090617 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20090821 Year of fee payment: 6 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20100101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100226 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100101 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110101 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100630 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100618 |