EP1462601B1 - Sektionaltor - Google Patents

Sektionaltor Download PDFInfo

- Publication number

- EP1462601B1 EP1462601B1 EP03026688.6A EP03026688A EP1462601B1 EP 1462601 B1 EP1462601 B1 EP 1462601B1 EP 03026688 A EP03026688 A EP 03026688A EP 1462601 B1 EP1462601 B1 EP 1462601B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- door

- door leaf

- section

- driven impeller

- power transmission

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000005540 biological transmission Effects 0.000 claims description 21

- 239000011324 bead Substances 0.000 claims 2

- 208000027418 Wounds and injury Diseases 0.000 description 5

- 230000006378 damage Effects 0.000 description 5

- 208000014674 injury Diseases 0.000 description 5

- 230000008878 coupling Effects 0.000 description 4

- 238000010168 coupling process Methods 0.000 description 4

- 238000005859 coupling reaction Methods 0.000 description 4

- 230000003068 static effect Effects 0.000 description 3

- 230000002349 favourable effect Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05D—HINGES OR SUSPENSION DEVICES FOR DOORS, WINDOWS OR WINGS

- E05D15/00—Suspension arrangements for wings

- E05D15/16—Suspension arrangements for wings for wings sliding vertically more or less in their own plane

- E05D15/24—Suspension arrangements for wings for wings sliding vertically more or less in their own plane consisting of parts connected at their edges

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05F—DEVICES FOR MOVING WINGS INTO OPEN OR CLOSED POSITION; CHECKS FOR WINGS; WING FITTINGS NOT OTHERWISE PROVIDED FOR, CONCERNED WITH THE FUNCTIONING OF THE WING

- E05F15/00—Power-operated mechanisms for wings

- E05F15/60—Power-operated mechanisms for wings using electrical actuators

- E05F15/603—Power-operated mechanisms for wings using electrical actuators using rotary electromotors

- E05F15/665—Power-operated mechanisms for wings using electrical actuators using rotary electromotors for vertically-sliding wings

- E05F15/668—Power-operated mechanisms for wings using electrical actuators using rotary electromotors for vertically-sliding wings for overhead wings

- E05F15/67—Power-operated mechanisms for wings using electrical actuators using rotary electromotors for vertically-sliding wings for overhead wings operated by flexible or rigid rack-and-pinion arrangements

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05F—DEVICES FOR MOVING WINGS INTO OPEN OR CLOSED POSITION; CHECKS FOR WINGS; WING FITTINGS NOT OTHERWISE PROVIDED FOR, CONCERNED WITH THE FUNCTIONING OF THE WING

- E05F15/00—Power-operated mechanisms for wings

- E05F15/60—Power-operated mechanisms for wings using electrical actuators

- E05F15/603—Power-operated mechanisms for wings using electrical actuators using rotary electromotors

- E05F15/665—Power-operated mechanisms for wings using electrical actuators using rotary electromotors for vertically-sliding wings

- E05F15/668—Power-operated mechanisms for wings using electrical actuators using rotary electromotors for vertically-sliding wings for overhead wings

- E05F15/676—Power-operated mechanisms for wings using electrical actuators using rotary electromotors for vertically-sliding wings for overhead wings operated by friction wheels

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/40—Motors; Magnets; Springs; Weights; Accessories therefor

- E05Y2201/43—Motors

- E05Y2201/434—Electromotors; Details thereof

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/60—Suspension or transmission members; Accessories therefor

- E05Y2201/622—Suspension or transmission members elements

- E05Y2201/644—Flexible elongated pulling elements

- E05Y2201/656—Chains

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2600/00—Mounting or coupling arrangements for elements provided for in this subclass

- E05Y2600/40—Mounting location; Visibility of the elements

- E05Y2600/46—Mounting location; Visibility of the elements in or on the wing

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2900/00—Application of doors, windows, wings or fittings thereof

- E05Y2900/10—Application of doors, windows, wings or fittings thereof for buildings or parts thereof

- E05Y2900/106—Application of doors, windows, wings or fittings thereof for buildings or parts thereof for garages

Definitions

- Sectional doors of the type described above must meet the safety requirements described in the European standard EN 12453: 2000. It stipulates that during an opening or closing operation of the door leaf a dynamic force between closing edges and Gegenschschreibkanten of a maximum of 400 N may occur. However, such high forces are only permitted for a maximum period of 0.75 seconds. To During this period, no static force exceeding 150 N is allowed. In the known in practice sectional doors with the features described above, during a regular opening or closing movement of the door leaf, a tolerated static force of 150 N within the allowable frame often exceeded for a short time, so that powerful door drives must be used. If the force required to move the door leaf exceeds 150 N over a period of more than 0.75 s, the door drive must be switched off by emergency shutdown.

- the comparatively high power requirement during the opening and closing movements in known sectional doors is based inter alia on the following facts.

- the head section of the door leaf has on both sides in each case a roller, which is guided in an associated horizontal track rail.

- the horizontal rails are provided on the frame side with a vertical end portion, in which the rollers of the top section are pulled in at a closing movement of the door leaf.

- the rollers inserted in the vertical end pieces secure the head section in the door leaf closing position against unauthorized pressing from the outside.

- the wheels of the head section must first overcome a vertical distance before they then enter the horizontal region of the running rail. This lifting movement at the beginning of Opening movement of the door leaf forms a technical problem for the electric door drive.

- a sectional door with the features described above is made EP-A 1 176 280 known.

- the electric door drive is moved along a horizontal track and connected by a coupling rod to the head section.

- the coupling rod is aligned obliquely to the door leaf level.

- the transmitted during an opening movement of the door leaf with the coupling rod tensile force has a horizontal and a vertical component. Due to the vertical component, the roller of the head section can be pulled out with a driving movement of the door drive from the vertical end portion of the vertical track rail.

- powerful door drives are required, which have the risk described above.

- the head section of the door leaf is guided on rails, which extend substantially horizontally to the door frame. On the horizontal rails no vertical end sections are provided.

- a door drive is provided, which is connected to either the head section or a section below the head section and has a trained as a pinion driven impeller.

- the driven impeller meshes with a profiled surface, which is arranged along a running rail or guide rail.

- the invention has for its object to provide a sectional door with the features described above, from which a reduced risk of injury emanates. It should be guaranteed in each position of the door leaf during an opening and closing movement a favorable force from the door drive on the door leaf.

- the door drive is attached to one of the sections connected below the head section and has at least one output shaft mounted on the output shaft with an end-side impeller, which engages in the guide rail of the section and moves the door leaf.

- the door drive is fixedly mounted on the door leaf inner surface of a section and drives an impeller which engages in a guide rail of the sections serving guide rail.

- the guide rail has a vertical portion along the door frame, a horizontal portion parallel to the leading edge of the head rail and an arc connecting the two sections.

- the driven impeller enters the vertical section of the guide rail.

- the rollers of the head section are lifted out of the cranked end portions of the horizontal track by the initially vertical movement of the driven wheels.

- the door drive is attached to the bottom in TorblattschOUGllOUGll section.

- the force required to lift the door leaf out of the cranked end regions of the horizontal running rail after the rollers have been lifted out of the head section is also significantly reduced in comparison with the prior art.

- Due to the arrangement of the door drive at the lowest in Torblattscheuerbachbericht ein section is also a short power flow between the door drive and the potential danger spot on the bottom-side closing edge of the door leaf, so that a shutdown of the door drive leads to a very rapid relief at the danger point.

- the door drive is dimensioned such that the maximum driving force for moving the door leaf is not more than 150 N.

- the dimensioning is done so that the total maximum driving force is below the specified limit.

- the Torblattantriebes said critical force values of more than 150 N during the regular opening and closing operation of a door leaf the standard dimensions for a garage with one or two car parking spaces not reached, so that the function of the door leaf is ensured even with the reduced drive power of the door drive.

- the above-explained dynamic range between 150 N and 400 N within which there is an increased risk of injury, can thus never be achieved.

- An emergency shutdown when the critical value of 150 N is exceeded over a period of more than 0.75 s is therefore superfluous.

- the emergency shutdown can be set to a lower force limit value.

- the door drive may have a branching gear for two output shafts, which extend to the two sides of the sections and have end, engaging in the guide rails wheels. It is also possible that on one or both sides of the door leaf, a door drive is provided with only one output shaft.

- the guide rails expediently have a C-shaped cross-sectional profile, one leg of the profile being designed as a trough-shaped running surface and the other leg forming a support surface arranged at a distance from the running surface.

- the driven impeller cooperates with a tensioned in the guide rail flexible power transmission line.

- guide rollers are provided which press the driven impeller to the power transmission train, so that the power transmission line partially wraps around the driven impeller.

- the driven impeller may be provided in front of or behind the driven impeller, a guide roller, so that the power transmission line wraps around the driven impeller Z-shaped.

- tensioning stations for maintaining the tension during an opening and closing operation of the door leaf are expedient at both ends of the power transmission line.

- guide rollers may be provided in front of and behind the driven impeller, so that the power transmission line wraps around the driven impeller in a loop shape. In this case, only at one end of the power train a tensioning station must be provided.

- the driven impeller may be formed as a pinion, which meshes with the trained as a toothed belt or chain power transmission train.

- the driven impeller may also have a throat-shaped running surface delimited by lateral flanks, in which case the power transmission line is expediently designed as a cable.

- the power transmission line is formed as a pearl necklace, which consists of a soul and a plurality of equally spaced at the same distance to the soul bodies, and that the driven impeller has a limited lateral flanks throat-shaped tread, in the running reason contains the body of the pearl necklace adapted wells.

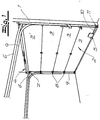

- Sectional door shown in its basic structure consists of a door frame 1, a door leaf 2 of articulated sections 3, 3 ', connected to the door leaf 2 weight compensation device 4 and an electric door drive 5 for opening and closing movements of the door leaf 2.

- the weight compensation device 4 formed in the embodiment as Torsionsfedenivelle which is connected via pull cables with the lower section of the door leaf.

- Torblattschschsted ein section is guided as a head section 3 'to rails 6, which extend substantially horizontally to the door frame 1 and the frame side have a vertical end portion 7.

- the below the head section 3 'subsequent further sections 3 are guided with rollers 8 in guide rails 9, which have a vertical portion along the door frame 1, a horizontal portion parallel to the head section 3' leading rail 6 and an arc connecting the two sections.

- the door drive 5 is preferably laterally attached to the bottom in Torblattschschbach ein section 3 and has a mounted on the section 3 output shaft 10 with an end-side impeller 11.

- the driven wheel 11 engages in the guide rail 9 and moves the door leaf 2.

- the door drive 5 has a branching gear for two output shafts 10 which extend up to the two sides of the section 3 and have end wheels 11 engaging in the lateral guide rails 9.

- the door drive is arranged on one of the section 3 below the head section 3 '.

- Fig. 2 is the force acting on the door leaf tensile force during an opening movement of the door leaf shown.

- the course shown with a dashed line shows measured values on a sectional door with a designed as a ceiling tractor gate drive according to the prior art, which is connected with a coupling rod to the uppermost in the closed position section of the door leaf.

- a thicker, solid line the measured values for a sectional door are shown, which is equipped with a door drive according to the invention at the lowest section.

- the driven impeller 11 cooperates with a tensioned in the Fckenngsschiene 9 flexible power transmission line 18.

- the driven impeller 11 is formed as a pinion, which meshes with the power transmission line 18 designed as a toothed belt.

- the toothed belt 18 wraps around the pinion 11 partially.

- the live toothed belt 18 transmits the forces required for the opening and closing movements.

- a clamping station 20 is provided at one end.

- Fig. 5 is the power transmission line 18 formed as a pearl necklace, which consists of a soul 23 and a plurality of each at the same distance to the soul 23 fixed bodies 24.

- the driven impeller 11 has a lateral flanks 25 limited throat-shaped tread 26, the bottom of the body 24 of the pearl necklace 18 adapted recesses 27 contains (see. Fig. 6 ).

- only one guide roller 19 is provided in the opening running direction in front of the driven wheel 11, so that the pearl chain 18 wraps around the driven wheel 11 in a Z-shaped manner.

- tension stations are provided at both ends of the pearl necklace.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Power-Operated Mechanisms For Wings (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10312904 | 2003-03-22 | ||

| DE10312904 | 2003-03-22 | ||

| DE10349904.0A DE10349904C5 (de) | 2003-03-22 | 2003-10-25 | Sektionaltor |

| DE10349904 | 2003-10-25 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1462601A2 EP1462601A2 (de) | 2004-09-29 |

| EP1462601A3 EP1462601A3 (de) | 2007-08-29 |

| EP1462601B1 true EP1462601B1 (de) | 2018-01-10 |

Family

ID=32826224

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03026688.6A Expired - Lifetime EP1462601B1 (de) | 2003-03-22 | 2003-11-20 | Sektionaltor |

Country Status (3)

| Country | Link |

|---|---|

| US (2) | US7048029B2 (enExample) |

| EP (1) | EP1462601B1 (enExample) |

| JP (1) | JP2004285825A (enExample) |

Families Citing this family (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1370744B1 (en) * | 2001-02-28 | 2017-05-31 | VKR Holding A/S | Screening device and drive means for the screening device and method of manual operating the screening device and a mounting for the screening device |

| US20040059474A1 (en) * | 2002-09-20 | 2004-03-25 | Boorman Daniel J. | Apparatuses and methods for displaying autoflight information |

| US7321318B2 (en) * | 2004-03-31 | 2008-01-22 | The Boeing Company | Methods and systems for controlling the display of information at an aircraft flight deck |

| FR2868460B1 (fr) * | 2004-03-31 | 2008-01-11 | Somfy Soc Par Actions Simplifi | Mecanisme de manoeuvre d'une porte, utilisation d'un frein dans un tel mecanisme et procede de regulation d'un couple moteur dans un tel mecanisme |

| US20060144529A1 (en) * | 2005-01-04 | 2006-07-06 | Emerge Technologies, Inc. | Automated door openers |

| DE102005053560B4 (de) * | 2005-01-14 | 2012-07-12 | Novoferm Tormatic Gmbh | Elektromechanischer Antrieb für ein Tor oder dergleichen |

| CA2603178A1 (en) * | 2005-12-08 | 2007-06-14 | Canimex Inc. | Chain guide and drive mechanism including the same |

| GB0606579D0 (en) * | 2006-03-31 | 2006-05-10 | Cutler Daniel | Covering system |

| US7600344B2 (en) | 2006-05-08 | 2009-10-13 | Canimex, Inc. | Brake device with integrated anti-theft mechanism for garage doors and the like, and door assembly including the same |

| DE102008004050B4 (de) * | 2008-01-11 | 2011-04-07 | Sommer Antriebs- Und Funktechnik Gmbh | Antriebssystem für ein Tor |

| BE1018497A3 (fr) * | 2008-11-12 | 2011-02-01 | Becoflex S A | Dispositif de couverture d'une surface. |

| DE202009000929U1 (de) * | 2009-01-24 | 2009-03-26 | Sommer Antriebs- Und Funktechnik Gmbh | Antriebssystem für ein Tor |

| CN103352410B (zh) * | 2013-07-12 | 2015-09-02 | 河南师范大学 | 一种覆盖式机场防雪装置 |

| US9624708B2 (en) * | 2015-03-10 | 2017-04-18 | Ciw Enterprises, Inc. | Closure with roller endlock |

| ITUB20153409A1 (it) * | 2015-09-04 | 2017-03-04 | Like Blinds Srl Socio Unico | ?sistema di movimentazione per due pannelli? |

| PL3679214T3 (pl) * | 2017-09-06 | 2024-04-08 | Assa Abloy Entrance Systems Ab | System obsługi bramy segmentowej |

| AU2019400732B2 (en) | 2018-12-19 | 2025-06-26 | Assa Abloy Entrance Systems Ab | Sectional door operator system |

| EP3980620A1 (en) * | 2019-06-10 | 2022-04-13 | ASSA ABLOY Entrance Systems AB | Door operator system |

| JP2023510103A (ja) * | 2020-01-15 | 2023-03-13 | アッサ・アブロイ・エントランス・システムズ・アーベー | ドアオペレータシステム |

| AU2021216105A1 (en) * | 2020-02-06 | 2022-09-15 | Assa Abloy Entrance Systems Ab | Door operator system |

| EP3872585A1 (en) * | 2020-02-26 | 2021-09-01 | Bulinfo Eood | Device for opening or closing of a window or door and a system and method for controlling and management of the air quality of indoor premises |

| WO2021180831A1 (en) * | 2020-03-12 | 2021-09-16 | Assa Abloy Entrance Systems Ab | A door operation system |

| CN115768962A (zh) | 2020-06-17 | 2023-03-07 | 亚萨合莱自动门系统有限公司 | 升降门操作系统 |

| EP4172442A1 (en) * | 2020-06-25 | 2023-05-03 | ASSA ABLOY Entrance Systems AB | A door operator system |

| KR102330557B1 (ko) * | 2020-11-18 | 2021-11-24 | 주식회사 이지라이더 | 물품 배송차량의 후면도어 자동 개폐장치 |

| TWI739671B (zh) * | 2020-11-20 | 2021-09-11 | 陳柏穎 | 折疊門結構 |

| FR3130698B1 (fr) * | 2021-12-16 | 2023-11-17 | Paul Esnault | Caisse de véhicule automobile pourvue d’une ouverture recevant un ouvrant articulé entre une position basse fermée et une position haute ouverte |

| WO2024057055A1 (en) * | 2022-09-18 | 2024-03-21 | Houtveen Beheer Achterveld B.V. | A device for operating a rolling door, a method for operating a rolling door, a storage room and a truck |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2064470A (en) * | 1931-01-17 | 1936-12-15 | Richards Wilcox Mfg Co | Overhead door |

| US2015402A (en) * | 1932-02-01 | 1935-09-24 | Johanson Karl Erhard | Overhead door construction for garages and other buildings |

| US3012520A (en) * | 1959-11-18 | 1961-12-12 | Guy A Curtis | Reversible driving mechanism with automatic stop |

| DE3538947A1 (de) | 1985-11-02 | 1987-05-21 | Alten K | Tor, insb. sektionaltor, fuer gebaeude od.dgl. |

| US4625456A (en) * | 1986-02-20 | 1986-12-02 | Lucien Lafontaine | Power door operating device |

| US5036899A (en) * | 1990-08-02 | 1991-08-06 | Mullet Willis J | Panel garage door opening and closing |

| US5343923A (en) * | 1991-02-11 | 1994-09-06 | Hi-Fold Door Corporation | Automatic jamb latch mechanism for overhead bifold door |

| DE4123575A1 (de) | 1991-07-16 | 1993-01-21 | Kurz Rudolf Gmbh & Co | Antrieb fuer sektionaltore |

| DE20022292U1 (de) * | 2000-02-25 | 2001-06-28 | Rademacher, Wilhelm, 46414 Rhede | Schwenktor o.dgl., insbesondere Garagenschwenktor, sowie elektrische Antriebsvorrichtung dafür |

| ES2455990T3 (es) * | 2000-07-28 | 2014-04-21 | Novoferm Gmbh | Puerta, en particular puerta de garaje |

-

2003

- 2003-11-20 EP EP03026688.6A patent/EP1462601B1/de not_active Expired - Lifetime

-

2004

- 2004-01-12 US US10/755,485 patent/US7048029B2/en not_active Expired - Fee Related

- 2004-03-16 JP JP2004074845A patent/JP2004285825A/ja not_active Withdrawn

-

2005

- 2005-11-29 US US11/288,682 patent/US8122933B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP1462601A3 (de) | 2007-08-29 |

| US20060076114A1 (en) | 2006-04-13 |

| US7048029B2 (en) | 2006-05-23 |

| US8122933B2 (en) | 2012-02-28 |

| EP1462601A2 (de) | 2004-09-29 |

| JP2004285825A (ja) | 2004-10-14 |

| US20040182528A1 (en) | 2004-09-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1462601B1 (de) | Sektionaltor | |

| EP1886853B1 (de) | Fensterrollo mit Antrieb über den Fensterheber | |

| EP1981800B1 (de) | Parkbühne für kraftfahrzeuge | |

| EP0701649B1 (de) | Seilzug-fensterheber | |

| EP1176280B1 (de) | Tor, insbesondere Garagentor | |

| DE10349904C5 (de) | Sektionaltor | |

| EP2634341A2 (de) | Falttor mit zwei oder mehreren in sich starren Faltladenelementen mit abwechselnd nicht ausknickenden und ausknickenden Elementkanten sowie Betätigungsvorrichtung hierfür | |

| DE10203904B4 (de) | Antriebsvorrichtung für Kraftfahrzeugschiebedächer | |

| DE3508175A1 (de) | Garagentor oder hallentor mit feder-hubmechanik | |

| EP1176279B1 (de) | Sektionaltor | |

| DE10354255A1 (de) | Fensterheberseilzugbaugruppen | |

| EP1366259B1 (de) | Sektionaltor | |

| WO2006136129A1 (de) | Torantrieb mit schubkette oder rückensteifer kette | |

| DE2702032A1 (de) | Kipptor | |

| DE10115096C1 (de) | Toranlage mit einem entlang mindestens eines ortsfesten Rollenbocks geführten Tragprofil | |

| DE10248608B4 (de) | Seitensektionaltor mit elektrischem Torantrieb | |

| DE102006013086A1 (de) | Beschlag für ein Fenster oder eine Tür | |

| DE10003160C1 (de) | Tor mit elektrischem Torantrieb | |

| EP1496185A1 (de) | Sektionaltor | |

| DE10261083B3 (de) | Sektionaltor | |

| EP1225292A2 (de) | Tor | |

| EP4279697B1 (de) | Tor mit antriebseinrichtung | |

| EP4065802B1 (de) | Tor für eine garage, halle und dergleichen mit einem verschlusssystem zum öffnen und schliessen der toröffnung | |

| DE9417280U1 (de) | Antriebseinrichtung für ein Industrietor | |

| EP1726560A1 (de) | Scherenhubtisch |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20071206 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20110610 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 50315730 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: E05F0015160000 Ipc: E05F0015670000 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E05F 15/676 20150101ALI20170407BHEP Ipc: E05D 15/24 20060101ALI20170407BHEP Ipc: E05F 15/67 20150101AFI20170407BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20170621 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 962608 Country of ref document: AT Kind code of ref document: T Effective date: 20180115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 50315730 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 Effective date: 20180424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180410 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 50315730 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| 26N | No opposition filed |

Effective date: 20181011 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50315730 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20181130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20181201 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20181120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181120 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20181130 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181130 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181130 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190601 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181120 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181130 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181120 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 962608 Country of ref document: AT Kind code of ref document: T Effective date: 20181120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20031120 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180110 |