EP1145862B1 - Streichfarben für Inkjet-Medien - Google Patents

Streichfarben für Inkjet-Medien Download PDFInfo

- Publication number

- EP1145862B1 EP1145862B1 EP00107733A EP00107733A EP1145862B1 EP 1145862 B1 EP1145862 B1 EP 1145862B1 EP 00107733 A EP00107733 A EP 00107733A EP 00107733 A EP00107733 A EP 00107733A EP 1145862 B1 EP1145862 B1 EP 1145862B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- media

- color

- hydrophobic

- der

- ink jet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000008199 coating composition Substances 0.000 title 1

- 230000002209 hydrophobic effect Effects 0.000 claims abstract description 15

- 238000000576 coating method Methods 0.000 claims description 19

- 239000011248 coating agent Substances 0.000 claims description 17

- 239000002245 particle Substances 0.000 claims description 3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 abstract description 19

- 239000000377 silicon dioxide Substances 0.000 abstract description 9

- 239000000976 ink Substances 0.000 description 13

- 239000003086 colorant Substances 0.000 description 12

- 238000012360 testing method Methods 0.000 description 12

- 239000000123 paper Substances 0.000 description 10

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 9

- 239000000203 mixture Substances 0.000 description 8

- 239000004372 Polyvinyl alcohol Substances 0.000 description 5

- 238000001035 drying Methods 0.000 description 5

- 239000000049 pigment Substances 0.000 description 5

- 229920002451 polyvinyl alcohol Polymers 0.000 description 5

- 239000000654 additive Substances 0.000 description 4

- 239000011230 binding agent Substances 0.000 description 4

- 238000009472 formulation Methods 0.000 description 4

- 238000007639 printing Methods 0.000 description 4

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 3

- 230000000996 additive effect Effects 0.000 description 3

- 229920000036 polyvinylpyrrolidone Polymers 0.000 description 3

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 description 3

- 208000032843 Hemorrhage Diseases 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 2

- 230000000740 bleeding effect Effects 0.000 description 2

- 238000003490 calendering Methods 0.000 description 2

- 239000000945 filler Substances 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 229910021485 fumed silica Inorganic materials 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 150000004760 silicates Chemical class 0.000 description 2

- 235000012239 silicon dioxide Nutrition 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 206010015719 Exsanguination Diseases 0.000 description 1

- BPQQTUXANYXVAA-UHFFFAOYSA-N Orthosilicate Chemical compound [O-][Si]([O-])([O-])[O-] BPQQTUXANYXVAA-UHFFFAOYSA-N 0.000 description 1

- 230000002745 absorbent Effects 0.000 description 1

- 239000002250 absorbent Substances 0.000 description 1

- 125000000129 anionic group Chemical group 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 125000002091 cationic group Chemical group 0.000 description 1

- 229920001577 copolymer Polymers 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 239000012153 distilled water Substances 0.000 description 1

- 239000000975 dye Substances 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000000499 gel Substances 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000007641 inkjet printing Methods 0.000 description 1

- 238000003475 lamination Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000010422 painting Methods 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 239000001267 polyvinylpyrrolidone Substances 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 239000011164 primary particle Substances 0.000 description 1

- 230000001698 pyrogenic effect Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- RMAQACBXLXPBSY-UHFFFAOYSA-N silicic acid Chemical compound O[Si](O)(O)O RMAQACBXLXPBSY-UHFFFAOYSA-N 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 238000009736 wetting Methods 0.000 description 1

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M5/00—Duplicating or marking methods; Sheet materials for use therein

- B41M5/50—Recording sheets characterised by the coating used to improve ink, dye or pigment receptivity, e.g. for ink-jet or thermal dye transfer recording

- B41M5/52—Macromolecular coatings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M5/00—Duplicating or marking methods; Sheet materials for use therein

- B41M5/50—Recording sheets characterised by the coating used to improve ink, dye or pigment receptivity, e.g. for ink-jet or thermal dye transfer recording

- B41M5/502—Recording sheets characterised by the coating used to improve ink, dye or pigment receptivity, e.g. for ink-jet or thermal dye transfer recording characterised by structural details, e.g. multilayer materials

- B41M5/508—Supports

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M5/00—Duplicating or marking methods; Sheet materials for use therein

- B41M5/50—Recording sheets characterised by the coating used to improve ink, dye or pigment receptivity, e.g. for ink-jet or thermal dye transfer recording

- B41M5/52—Macromolecular coatings

- B41M5/5218—Macromolecular coatings characterised by inorganic additives, e.g. pigments, clays

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M5/00—Duplicating or marking methods; Sheet materials for use therein

- B41M5/50—Recording sheets characterised by the coating used to improve ink, dye or pigment receptivity, e.g. for ink-jet or thermal dye transfer recording

- B41M5/52—Macromolecular coatings

- B41M5/5236—Macromolecular coatings characterised by the use of natural gums, of proteins, e.g. gelatins, or of macromolecular carbohydrates, e.g. cellulose

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M5/00—Duplicating or marking methods; Sheet materials for use therein

- B41M5/50—Recording sheets characterised by the coating used to improve ink, dye or pigment receptivity, e.g. for ink-jet or thermal dye transfer recording

- B41M5/52—Macromolecular coatings

- B41M5/5254—Macromolecular coatings characterised by the use of polymers obtained by reactions only involving carbon-to-carbon unsaturated bonds, e.g. vinyl polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M5/00—Duplicating or marking methods; Sheet materials for use therein

- B41M5/50—Recording sheets characterised by the coating used to improve ink, dye or pigment receptivity, e.g. for ink-jet or thermal dye transfer recording

- B41M5/52—Macromolecular coatings

- B41M5/529—Macromolecular coatings characterised by the use of fluorine- or silicon-containing organic compounds

Definitions

- the invention relates to coating colors for inkjet media, such as for example paper, foils and textiles, as well as their Use in papermaking and finishing, especially in inject media.

- Inkjet media are used for printing on Inkjet printer.

- fillers that absorb ink well, for example in inkjet media and maintain the brilliance of the colors needed.

- the inkjet media adjust hydrophobic and thus protect or through subsequent film application, lamination or Laminate a hydrophobization of the media and with it to achieve associated color fixation.

- the invention relates to coating colors for inkjet media, which are characterized in that they at least one partially hydrophobic and / or hydrophobic Contain silica of particle size from 5 to 12 microns.

- the coating colors according to the invention in particular those which Containing precipitated silicas show in comparison to Standard formulations Advantages in the printed image in particular in point sharpness. Furthermore, they have an improved Water resistance.

- the overall assessment includes the familiarization, the Wiping behavior, line adhesion, that Absorbent behavior, the printability and the hydrophobic Characteristics.

- the dissolved binder 37 parts of PVA / 3 parts PVP / VA

- the corresponding sample in one Given a glass bottle and ten with the Turbula mixer Mixed for minutes. Then the system is in a Double wall vessel transferred and using a dissolver at 3000 RPM dispersed.

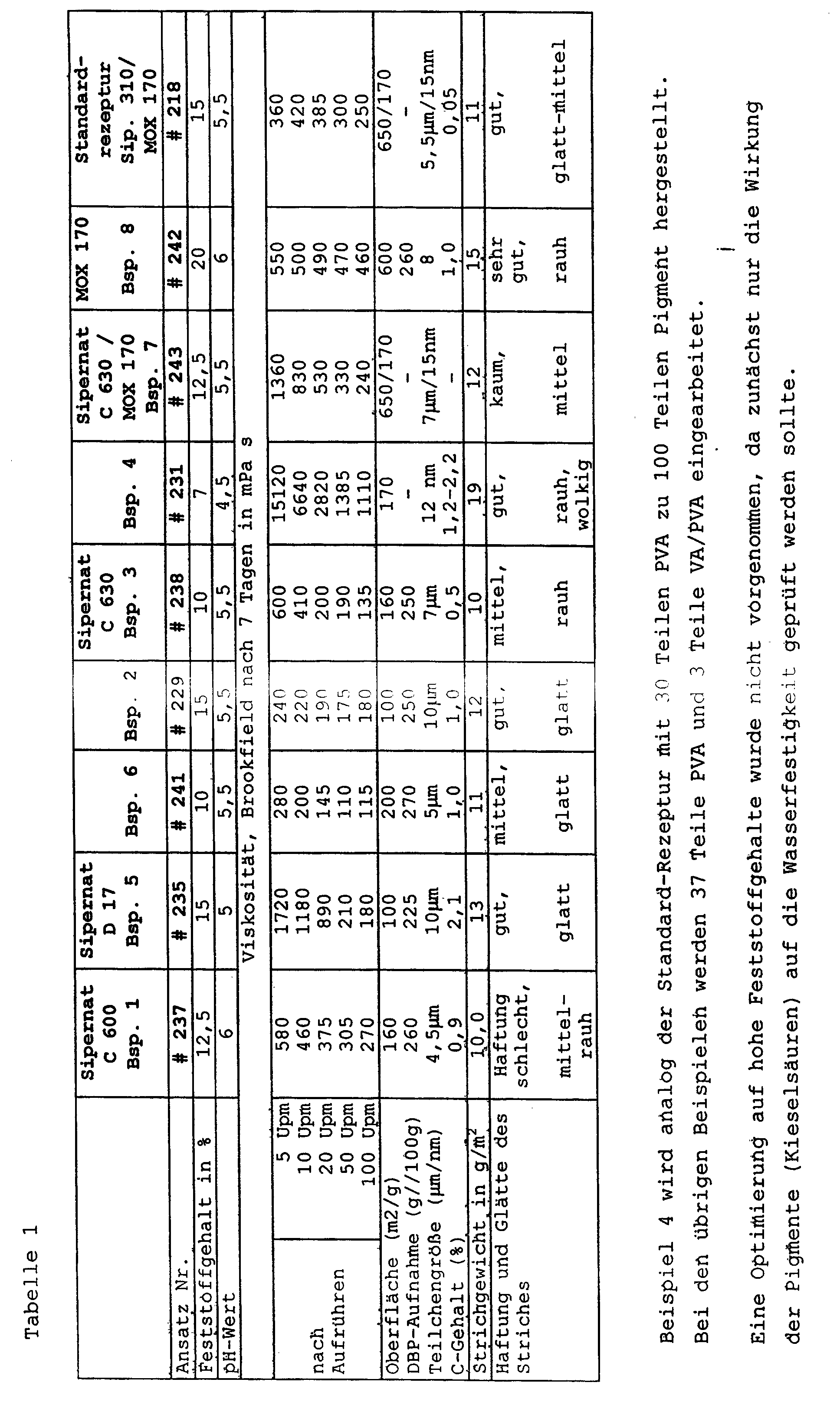

- the coating colors formulated in this way contain 100 parts of silica, respectively Silica mixture and 37 parts of polyvinyl alcohol (PVA), and 3 parts of polyvinylpyrrolidone / vinyl acetate copolymer (PVP / VA), or 100 parts of silica mixture and 30 parts of PVA for the standard recipe.

- Another way of producing the coating color consists in wetting the silica and / or hydrophobized pigment by means of a mixture Methanol and water and then stirring into the Binder solution.

- the coating colors are not as usual with additives and Co-binders added.

- the coating color formulation was not further optimized for a floodproof property. Coating color formulations for different media among others in the Technical Information No. 1212 of Degussa-Hüls, business area FP stated. The Use of the partial, or highly hydrophobic silicas can be used on other recipes be transmitted.

- 60 ⁇ l of distilled water are added to one black printed and colored printed area abandoned and leave on for 30 seconds. After careful Dab off the excess amount of water Rating. 60 ⁇ l are also placed on a blank Given area and the paper on a suitable surface rotated slowly and continuously up to 90 °. The Rolling behavior of the drop and the possible color gradient contact with printed surfaces is assessed.

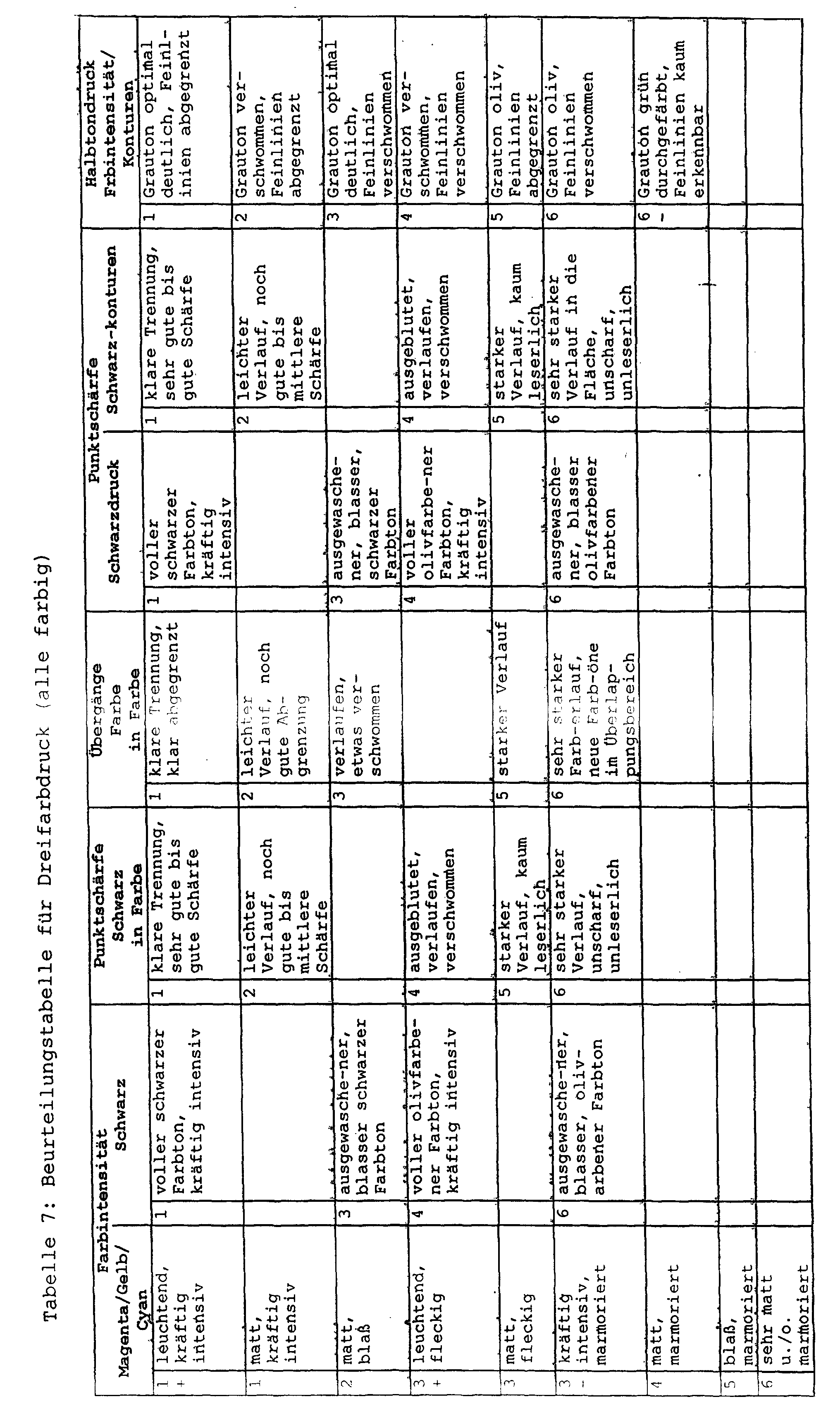

- the papers are printed using the HP 550 C in tri-color and Four-color printing mode printed.

- the partially hydrophobic silicas according to Examples 1, 2, 3, 6, 7 and 8 are known from document EP 0 798 348 B1.

- the partially hydrophobic silicas according to Examples 1, 3 and 7 and the hydrophobic silicas according to Example 5 are sales products which are described in the brochure "Precipitated Silicas and Silicates" from Degussa-Hüls AG, Business Unit Filler Systems and Pigments.

Landscapes

- Ink Jet Recording Methods And Recording Media Thereof (AREA)

- Paints Or Removers (AREA)

- Inks, Pencil-Leads, Or Crayons (AREA)

- Paper (AREA)

- Ink Jet (AREA)

- Medicinal Preparation (AREA)

Description

- Sie sind kostenintensiv.

- Es ist ein zusätzlicher Produktionsschritt notwendig.

- Es sind intensive Entwicklungsarbeiten im Vorfeld notwendig.

- Die Streichfarben müssen durch zusätzliche Komponenten, wie kationische Additive, eingestellt werden.

- Die Tinten sind nicht ausreichend fixiert.

- die Wasserfestigkeit der Medien erhöhen,

- eine bessere Fixierung der anionischen Tinten ermöglichen,

- eine Erhöhung der Druckqualität aufweisen,

- eine Fixierung der Tinten/Farbstoffe in der oberen Strichschicht bewirken,

- die Reduktion von Ausbluten aufweisen,

- die Kombination von Additiveigenschaften und Pigmenteigenschaften besitzen.

- Erhöhung der Wasserfestigkeit

- Erhöhung der Tintenfixierung

- Erhöhung der Druckqualität

- Fixierung der Tinten in den oberen Strichschichten

- Kombination von Additiv- und Pigmenteigenschaften in einem Produkt

- Erhöhung der Farbintensität

- Erhöhung der Punktschärfe

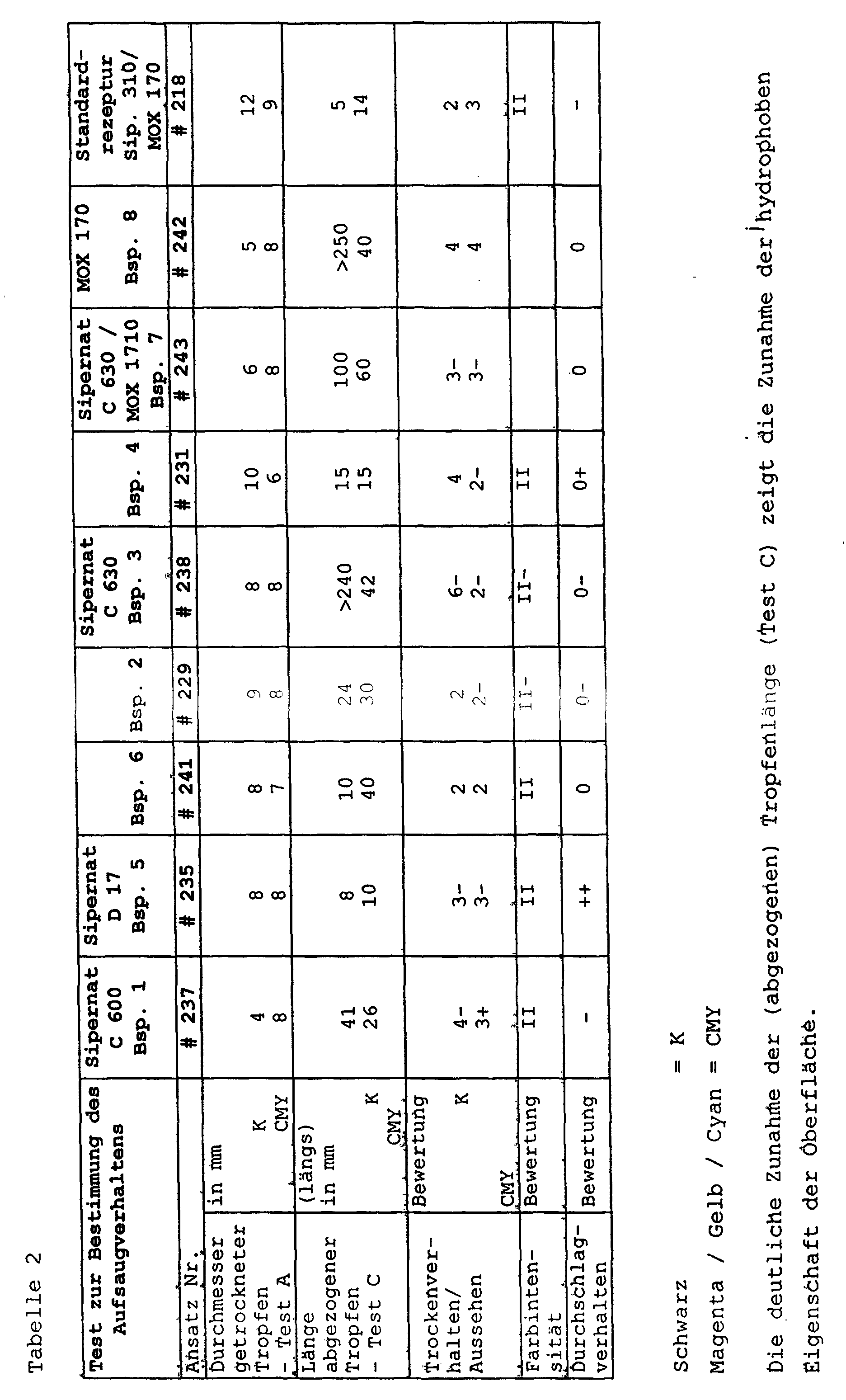

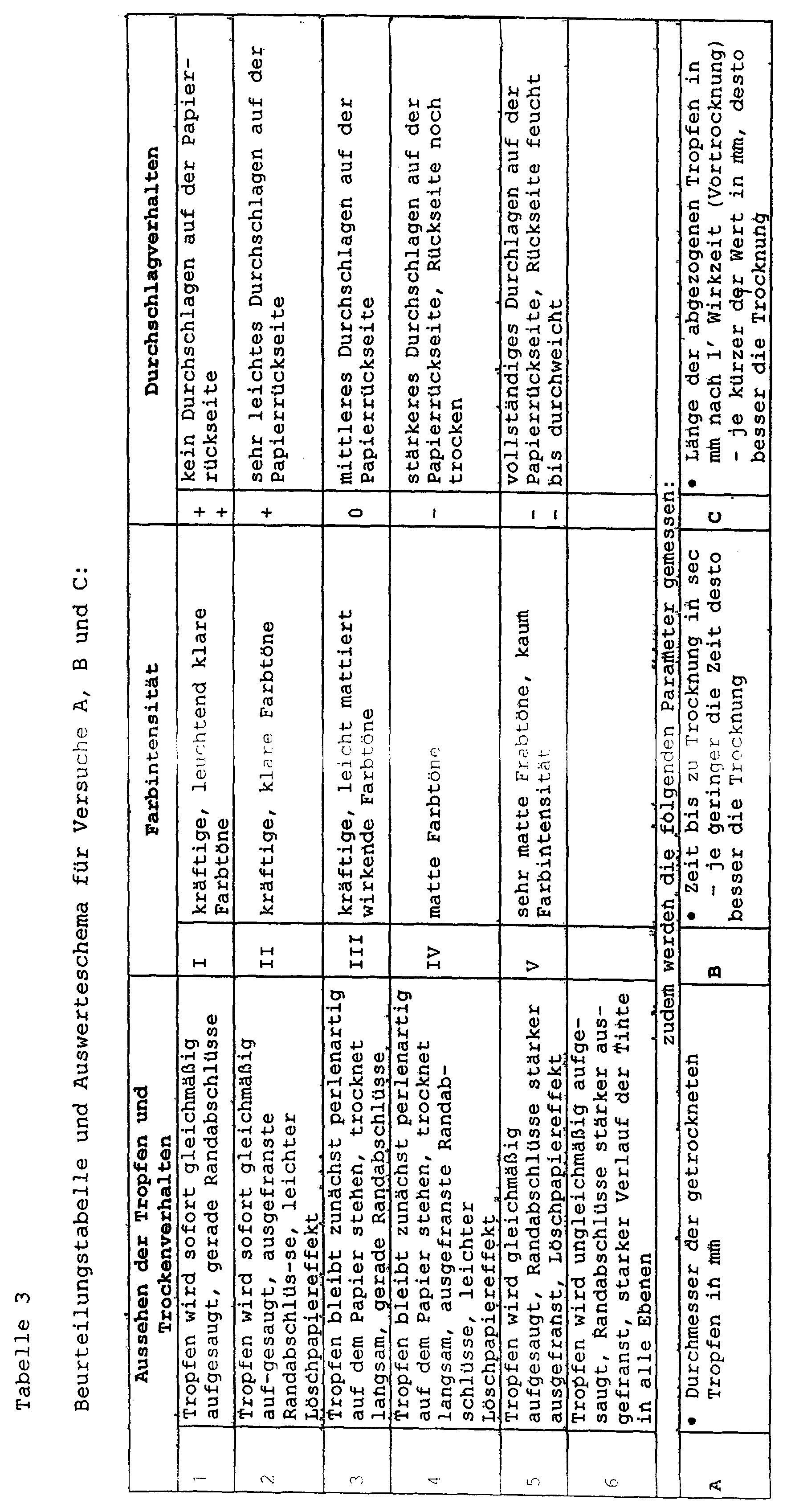

werden mittels Eppendorf Variopet von jeder Tintenfarbe je 7,5 µl auf das Substrat aufgetragen und trocknengelassen. Analog der Beurteilungstabelle wird das Trocknungsverhalten beurteilt und der Durchmesser in mm gemessen.

werden mittels Hamilton Microliterpipette von jeder Tintenfarbe je 1 µl auf das Substrat aufgetragen. Analog der Beurteilungstabelle wird das Trocknungsverhalten und das Durchschlagsverhalten beurteilt sowie die Zeit bis zur Trocknung in Sekunden gemessen.

werden mittels Hamilton Microliterpipette von jeder Tintenfarbe je 1 µl auf das Medium aufgetragen. Eine Minute danach wird mit einem ca. 45° schräg gehaltenen Löffelspatel der Tropfen verzogen und die Länge in mm gemessen.

Claims (2)

- Streichfarben für Inkjet-Medien, dadurch gekennzeichnet, daß sie mindestens eine teilhydrophobe und/oder hydrophobe Kieselsäure der Teilchengröße 5 bis 12 µm enthalten.

- Injekt-Medien, dadurch gekennzeichnet, daß sie mit Streichfarben gemäß Anspruch 1 beschichtet werden.

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT00107733T ATE261821T1 (de) | 2000-04-11 | 2000-04-11 | Streichfarben für inkjet-medien |

| DE50005683T DE50005683D1 (de) | 2000-04-11 | 2000-04-11 | Streichfarben für Inkjet-Medien |

| EP00107733A EP1145862B1 (de) | 2000-04-11 | 2000-04-11 | Streichfarben für Inkjet-Medien |

| JP2001110418A JP2002012831A (ja) | 2000-04-11 | 2001-04-09 | インキジェット−媒体用の塗料 |

| US09/829,943 US6840992B2 (en) | 2000-04-11 | 2001-04-11 | Coatings for inkjet media |

| IDP20010320D ID29907A (id) | 2000-04-11 | 2001-04-11 | Penyapuan cat-cat untuk media inkjet |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP00107733A EP1145862B1 (de) | 2000-04-11 | 2000-04-11 | Streichfarben für Inkjet-Medien |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1145862A1 EP1145862A1 (de) | 2001-10-17 |

| EP1145862B1 true EP1145862B1 (de) | 2004-03-17 |

Family

ID=8168431

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00107733A Expired - Lifetime EP1145862B1 (de) | 2000-04-11 | 2000-04-11 | Streichfarben für Inkjet-Medien |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US6840992B2 (de) |

| EP (1) | EP1145862B1 (de) |

| JP (1) | JP2002012831A (de) |

| AT (1) | ATE261821T1 (de) |

| DE (1) | DE50005683D1 (de) |

| ID (1) | ID29907A (de) |

Families Citing this family (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6861115B2 (en) * | 2001-05-18 | 2005-03-01 | Cabot Corporation | Ink jet recording medium comprising amine-treated silica |

| US20070103528A1 (en) * | 2003-06-16 | 2007-05-10 | Kornit Digital Ltd. | Ink composition |

| US20070103529A1 (en) * | 2003-06-16 | 2007-05-10 | Kornit Digital Ltd. | Process and system for printing images on absorptive surfaces |

| IL162231A (en) * | 2004-05-30 | 2007-05-15 | Kornit Digital Ltd | Direct digital printing process of jet propulsion inkjet on a wet fabric section |

| US20070104899A1 (en) * | 2003-06-16 | 2007-05-10 | Kornit Digital Ltd. | Process for printing images on dark surfaces |

| US20050003112A1 (en) * | 2003-07-02 | 2005-01-06 | Tienteh Chen | Inkjet recording materials containing siloxane copolymer surfactants |

| DE102004002499A1 (de) * | 2004-01-17 | 2005-08-11 | Degussa Ag | Verfahren zur Verhinderung von Anfeuerungseffekten bei Imprägnierungen von Substraten |

| US7607745B2 (en) * | 2004-02-12 | 2009-10-27 | Kornit Digital Ltd. | Digital printing machine |

| US11447648B2 (en) | 2004-05-30 | 2022-09-20 | Kornit Digital Ltd. | Process and system for printing images on absorptive surfaces |

| BRPI0512134A (pt) | 2004-06-15 | 2008-02-06 | Grace W R & Co | moagem quimicamente assistida em sìlicas |

| DE102004029074A1 (de) * | 2004-06-16 | 2005-12-29 | Degussa Ag | Lackformulierung zur Verbesserung der Oberflächeneigenschaften |

| DE102004029073A1 (de) * | 2004-06-16 | 2005-12-29 | Degussa Ag | Lackformulierung mit verbesserten rheologischen Eigenschaften |

| WO2007101203A2 (en) * | 2006-02-28 | 2007-09-07 | Evonik Degussa Corporation | Colored paper and substrates coated for enhanced printing performance |

| US8455165B2 (en) * | 2006-09-15 | 2013-06-04 | Cabot Corporation | Cyclic-treated metal oxide |

| US8202502B2 (en) | 2006-09-15 | 2012-06-19 | Cabot Corporation | Method of preparing hydrophobic silica |

| US20080070146A1 (en) * | 2006-09-15 | 2008-03-20 | Cabot Corporation | Hydrophobic-treated metal oxide |

| US8435474B2 (en) * | 2006-09-15 | 2013-05-07 | Cabot Corporation | Surface-treated metal oxide particles |

| CA2663120A1 (en) * | 2006-09-26 | 2008-04-03 | Evonik Degussa Corporation | Multi-functional paper for enhanced printing performance |

| WO2008094928A1 (en) | 2007-01-29 | 2008-08-07 | Evonik Degussa Gmbh | Fumed metal oxides for investment casting |

| US9550374B1 (en) | 2007-06-27 | 2017-01-24 | Cafepress Inc. | System and method for improved digital printing on textiles |

| EP2053163A1 (de) * | 2007-10-26 | 2009-04-29 | SAPPI Netherlands Services B.V. | Beschichtungsformulierung für Offsetpapier und damit beschichtetes Papier |

| WO2010123505A1 (en) * | 2009-04-23 | 2010-10-28 | Hewlett-Packard Development Company, L.P. | Coated print media and method for making the same |

| WO2011018786A1 (en) | 2009-08-10 | 2011-02-17 | Kornit Digital Ltd. | Inkjet compositions and processes for stretchable substrates |

| DE102010001135A1 (de) * | 2010-01-22 | 2011-07-28 | Evonik Degussa GmbH, 45128 | Stabile wässrige Dispersionen aus gefällter Kieselsäure |

| US8926080B2 (en) | 2010-08-10 | 2015-01-06 | Kornit Digital Ltd. | Formaldehyde-free inkjet compositions and processes |

| US8398233B2 (en) | 2011-01-31 | 2013-03-19 | Hewlett-Packard Development Company, L.P. | Inkjet recording medium |

| JP2015131413A (ja) * | 2014-01-10 | 2015-07-23 | キヤノン株式会社 | 記録媒体 |

| BR112019008862A2 (pt) | 2016-10-31 | 2019-09-17 | Kornit Digital Ltd | processo de impressão por jato de tinta direto de uma imagem em um substrato absorvente, composição de tinta de sublimação de cor, kit de impressão por jato de tinta e máquina de impressão digital |

| JP2021500437A (ja) | 2017-10-22 | 2021-01-07 | コーニット・デジタル・リミテッド | インクジェット印刷による低摩擦画像 |

| EP3954743A1 (de) | 2020-08-12 | 2022-02-16 | Evonik Operations GmbH | Verwendung von siliziumdioxid zur verbesserung der leitfähigkeit von beschichtungen |

| CN114015298B (zh) * | 2021-12-16 | 2022-11-29 | 上海绘兰材料科技有限公司 | 一种耐水吸墨涂层材料及其制备方法和应用 |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1348372A (en) | 1970-02-16 | 1974-03-13 | Ici Ltd | Foam-compatible powder compositions |

| US3830738A (en) * | 1970-02-16 | 1974-08-20 | Ici Ltd | Surface treatment of particulate solids |

| DE2628975A1 (de) * | 1976-06-28 | 1977-12-29 | Degussa | Faellungskieselsaeure |

| DE2629535C3 (de) * | 1976-07-01 | 1979-10-11 | Beiersdorf Ag, 2000 Hamburg | Verfahren zur Herstellung von blatt- oder bahnförmigen Materialien, die mindestens auf einer Seite eine beschriftbare klebstoffabweisende Beschichtung tragen |

| DE2729244A1 (de) | 1977-06-29 | 1979-01-04 | Degussa | Faellungskieselsaeure |

| US4208316A (en) * | 1978-06-29 | 1980-06-17 | Deutsche Gold- Und Silber-Scheideanstalt Vormals Roessler | Hydrophobic precipitated silicic acid and compositions containing same |

| DE2844052A1 (de) * | 1978-10-10 | 1980-04-30 | Degussa | Waessrige dispersion einer hydrophoben kieselsaeure |

| JPS60224580A (ja) * | 1984-04-23 | 1985-11-08 | Mitsubishi Paper Mills Ltd | インクジエツト用記録媒体 |

| JPS62178384A (ja) | 1986-02-03 | 1987-08-05 | Canon Inc | 被記録材 |

| JPS62224580A (ja) | 1986-03-26 | 1987-10-02 | Toray Monofilament Co Ltd | ブラシ用毛材 |

| US4824789B1 (en) * | 1986-10-10 | 1996-08-13 | Minnesota Mining & Mfg | Gas sensor |

| US5213846A (en) * | 1989-09-27 | 1993-05-25 | Dai Nippon Toryo Co., Ltd. | Corrison resistant coating composition |

| US5106675A (en) * | 1989-12-29 | 1992-04-21 | Nihon Parkerizing Co., Ltd. | Nonaqueous coating composition and coated metal |

| GB9214569D0 (en) * | 1992-07-09 | 1992-08-19 | Dow Corning Sa | Method of controlling foam |

| GB9214567D0 (en) * | 1992-07-09 | 1992-08-19 | Dow Corning Sa | Foam control agents |

| JPH07257015A (ja) * | 1994-03-18 | 1995-10-09 | Mitsubishi Paper Mills Ltd | 透明性および光沢に優れたインキジェット用被記録材 |

| DE4419234A1 (de) | 1994-06-01 | 1995-12-07 | Wacker Chemie Gmbh | Verfahren zur Silylierung von anorganischen Oxiden |

| FR2738830B1 (fr) * | 1995-09-14 | 1997-12-05 | Rhone Poulenc Chimie | Emulsion aqueuse de polyorganosiloxane pour l'enduction de matiere textile |

| US6191122B1 (en) * | 1996-03-29 | 2001-02-20 | DEGUSSA HüLS AKTIENGESELLSCHAFT | Partially hydrophobic precipitated silicas |

| IN191468B (de) * | 1996-03-29 | 2003-12-06 | Degussa | |

| US6270855B1 (en) * | 1996-05-17 | 2001-08-07 | The Valspar Corporation | Powder coating compositions and methods |

| EP0958865A1 (de) * | 1997-01-29 | 1999-11-24 | Bando Chemical Industries, Ltd. | Bildempfangsblatt zum aufzeichnen und verfahren zu dessen herstellung |

| JP3525705B2 (ja) * | 1997-10-29 | 2004-05-10 | ミノルタ株式会社 | 負荷電性トナー |

| US6228475B1 (en) * | 1998-09-01 | 2001-05-08 | Eastman Kodak Company | Ink jet recording element |

-

2000

- 2000-04-11 EP EP00107733A patent/EP1145862B1/de not_active Expired - Lifetime

- 2000-04-11 DE DE50005683T patent/DE50005683D1/de not_active Expired - Lifetime

- 2000-04-11 AT AT00107733T patent/ATE261821T1/de not_active IP Right Cessation

-

2001

- 2001-04-09 JP JP2001110418A patent/JP2002012831A/ja active Pending

- 2001-04-11 ID IDP20010320D patent/ID29907A/id unknown

- 2001-04-11 US US09/829,943 patent/US6840992B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2002012831A (ja) | 2002-01-15 |

| US6840992B2 (en) | 2005-01-11 |

| DE50005683D1 (de) | 2004-04-22 |

| EP1145862A1 (de) | 2001-10-17 |

| US20020040661A1 (en) | 2002-04-11 |

| ID29907A (id) | 2001-10-25 |

| ATE261821T1 (de) | 2004-04-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1145862B1 (de) | Streichfarben für Inkjet-Medien | |

| DE69208773T2 (de) | Durch Tintenstrahlverfahren bedrucktes Papier | |

| DE69637213T2 (de) | Papier für die Tintenstrahlaufzeichnung, gemahlenes ausgefälltes Kalziumkarbonatpigment enthaltend | |

| DE69708999T2 (de) | Aufzeichnungsmaterial für den Tintenstrahldruck | |

| DE69011991T2 (de) | Registriermittel und Verfahren zum Registrieren damit. | |

| EP0332102A2 (de) | Pigment-Mischung für die Papierindustrie | |

| EP1048480A1 (de) | Ink-Jet-Aufzeichnungspapier mit Pigmentschichten | |

| EP0633299A2 (de) | Offset-Druckfarbe | |

| EP0445327A1 (de) | Aufzeichnungsmaterial für das Tintenstrahldruck-Verfahren | |

| EP3098085A1 (de) | Transfer-material für den sublimationsdruck | |

| DE10117504A1 (de) | Injekt-Tinte | |

| DE10048616A1 (de) | Dotierte Fällungskieselsäure | |

| DE3316949C3 (de) | Calciumcarbonat | |

| DE2632105A1 (de) | Latente sensibilisierungsdruckfarbe | |

| DE60118349T2 (de) | Wasserbeständige tintenempfangsbeschichtungen für tintenstrahldruckmaterialien und beschichtungsverfahren damit | |

| EP3323624A1 (de) | Haftendes mikroporöses transfermaterial | |

| DE69632843T2 (de) | Aufzeichnungspapier | |

| DE19934281A1 (de) | Wäßrige Rußdispersionen | |

| DE69925761T2 (de) | Farbe und damit beschichtetes papier | |

| EP0539678B1 (de) | Aufzeichnungsmaterial für das ink jet-Verfahren | |

| EP0764546B1 (de) | Aufzeichnungsmaterial für das Ink Jet Druckverfahren | |

| DE112018002297T5 (de) | Beschichtetes Druckpapier | |

| DE60009240T2 (de) | Aufzeichnungsmaterial, Herstellungsverfahren davon, Aufzeichnungsverfahren und damit aufgezeichnetes Produkt | |

| EP1226959B1 (de) | Poröses Tintenstrahlaufzeichnungsmaterial | |

| EP0786552A2 (de) | Aufzeichnungsmaterial für das Tintenstrahl-Druckverfahren |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20011112 |

|

| 17Q | First examination report despatched |

Effective date: 20020313 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: MUELLER, ASTRID Inventor name: GLAUM, HOLGER, DR. |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 20040317 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040317 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040317 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040317 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: SCHMAUDER & PARTNER AG PATENTANWALTSBUERO Ref country code: CH Ref legal event code: EP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040411 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040411 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50005683 Country of ref document: DE Date of ref document: 20040422 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040430 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040430 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040414 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040617 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040617 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040617 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040628 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| BERE | Be: lapsed |

Owner name: DEGUSSA A.G. Effective date: 20040430 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20041220 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20050413 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040817 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: SCHMAUDER & PARTNER AG PATENT- UND MARKENANWAELTE VSP;ZWAENGIWEG 7;8038 ZUERICH (CH) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20090414 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: EVONIK DEGUSSA GMBH Free format text: DEGUSSA AG#BENNIGSENPLATZ 1#40474 DUESSELDORF (DE) -TRANSFER TO- EVONIK DEGUSSA GMBH#RELLINGHAUSER STRASSE 1-11#45128 ESSEN (DE) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20090421 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CA Ref country code: FR Ref legal event code: CD Ref country code: FR Ref legal event code: CJ |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20100411 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20101230 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100430 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20120420 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130430 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130430 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20160421 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50005683 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171103 |