EP0953380A2 - Verfahren und Vorrichtung zum Ausräumen des Kristallisats aus einer Zentrifugentrommel - Google Patents

Verfahren und Vorrichtung zum Ausräumen des Kristallisats aus einer Zentrifugentrommel Download PDFInfo

- Publication number

- EP0953380A2 EP0953380A2 EP99102995A EP99102995A EP0953380A2 EP 0953380 A2 EP0953380 A2 EP 0953380A2 EP 99102995 A EP99102995 A EP 99102995A EP 99102995 A EP99102995 A EP 99102995A EP 0953380 A2 EP0953380 A2 EP 0953380A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- drum

- peeling knife

- product

- peeling

- centrifuge

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B04—CENTRIFUGAL APPARATUS OR MACHINES FOR CARRYING-OUT PHYSICAL OR CHEMICAL PROCESSES

- B04B—CENTRIFUGES

- B04B11/00—Feeding, charging, or discharging bowls

- B04B11/08—Skimmers or scrapers for discharging ; Regulating thereof

Definitions

- the invention relates to a method for clearing the product from the centrifuge drum of a discontinuous centrifuge, whereby a peeling knife is pivoted into the flung off product layer and here with one against the direction of drum rotation the cutting edge peels off the product.

- the invention further relates to a device for performing of the method, with a attached to a clearing bar and through this or around this swiveling paring knife, which in its pivoted position the product layer with one of the Drum direction of rotation against the cutting edge.

- the clearing device from a pivotable about a vertical clearing bar Ploughshare on which a peeling knife is spring-mounted rotatably.

- the paring knife which extends only over a short height section the centrifuge drum extends against the direction of rotation the centrifuge drum into the product layer, e.g. B. sugar layer pressed in until it touches the working sieve.

- the peeling knife is then moved axially from its uppermost position moved towards the bottom of the drum and is then again move axially upwards before it goes into its Rest position is pivoted out.

- the invention has for its object the product discharge, the discharge time and the remaining product in the centrifuge bowl to optimize.

- this is Object achieved in that the peeling knife after its pivoting over almost the entire drum height of product contact the product over the entire drum height at the same time of the product layer rotating at the clearing speed peels off in layers and again when the drum screen is reached is swung out.

- the above object is achieved in that the cutting edge almost over when the peeling knife is swung in the entire drum height extends.

- This axial distance can be about Be 200 mm so that the peeling knife is in its idle state at a sufficient distance from the internals and the drum edge located.

- the efficiency of the product discharge is thereby according to the invention increases that the pivoting of the peeling knife in the direction of rotation the centrifuge drum and its swiveling against this direction of rotation he follows. By swiveling against the direction of rotation The remaining product on the lower edge of the peeling knife becomes the drum spent on product discharge.

- the Swinging in of the peeling knife is stopped immediately before the peeling knife touches the drum sieve.

- the peeling knife can be controlled pneumatically via electropneumatic Valves.

- Peeling knife is flatly concave on its front.

- the cutting edge of the peeling knife with the Drum screen or drum shell an angle of 80 ° to a little less than 90 °.

- the clearing bar is designed as a tube into which a nozzle assembly or individual nozzles are integrated for a deck or wash water task. Thereby can be a complete assembly from the product room Eliminate centrifuge.

- the schematic representations show a centrifuge drum 1, the drum casing with holes 2 on its inner wall by a not shown Working strainer is covered.

- the drum base 3 has a central one Product outlet opening on by a not shown Locking hood is lockable.

- the direction of rotation of the Centrifuge drum 1 is indicated by an arrow 5.

- An eccentric protrudes perpendicularly into the centrifuge drum 1 from above fixedly arranged clearing device from which only an axially parallel clearing bar 6 and a attached peeling knife 7 are shown.

- the peeling knife 7 can be in the direction swivel onto the drum jacket 2.

- Figure 3 shows the clearing device in the lowered position, in the peeling knife, which extends over the full drum height h 7 is lowered to the drum base 3. Also show Figures 3 and 4, the peeling knife 7 in its pivoted Position in which there is a Sugar layer 9 is present.

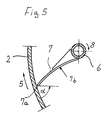

- Figure 5 shows the peeling knife 7 in its pivoted position after the peeling process, in which the Cut 7a of the peeling knife 7 immediately before that drawn working sieve of the drum shell 2 is, however without making a metallic contact with this working sieve.

- the cutting edge or cutting edge 7a closes with the Drum screen or drum shell 3 an angle ⁇ , the can be between 80 ° and a little less than 90 °.

- Figure 5 leaves also recognize that the peeling knife seen in horizontal section 7 is formed flat concave on its front side 7b.

- the magma fed into the centrifuge drum 1 is from the centrifugal drum 1 driven at high speed, the mother syrup adhering to the crystals through the Working sieve enters and out of the holes in the drum casing 3 the centrifuge housing, not shown, expires. Subsequently the crystals with a pure liquid washed. Those remaining in the drum after the separation process Crystals form a sugar layer 9 on the working sieve is peeled off from the clearing device. The peeled off Sugar crystals are subordinated after opening the cap Transport units fed.

- Figure 1 shows the clearing device in the raised state, in the lower end of the pivoted peeling knife 7 from the drum base 3 has an axial distance a, which is about 200 mm can be.

- the peeling knife 7 becomes from this idle state already during braking of the centrifuge drum 1 from it Spin speed to the clearing speed axially in the direction of Arrow 10 lowered until the lower end of the peeling knife 7 is immediately above the drum base 3 (see Figure 3). After It will reach the lower position and the clearing speed Swinging the peeling knife 7 in the direction of arrow 8 initiated.

- Figure 4 shows that the pivoting process of the peeling knife 7 in the direction of rotation 5 of the centrifuge drum 1 takes place.

- the peeling the sugar crystals then occur simultaneously over the entire Drum height h with continuous infeed of the peeling knife 7 in the radial direction to the outside.

- the one in front of the peeling knife 7 Line 11 drawn in dashed lines indicates the product flow the crystals peeled from the sugar layer 9 by the peeling knife 7 on.

- the peeling knife 7 has its shown in FIG When the end position is reached, the peeling knife remains for a few seconds in this end position before it returns to its position shown in FIGS and 2 shown starting position is pivoted out.

Landscapes

- Centrifugal Separators (AREA)

Abstract

Description

- Figur 1

- in einem lotrechten Mittelschnitt die linke Hälfte der Zentrifugentrommel einer diskontinuierlichen Zuckerzentrifuge mit einer in diese von oben lotrecht hineinragenden, sich in angehobener Stellung befindlichen Ausräumeinrichtung mit ausgeschwenktem Schälmesser;

- Figur 2

- die Darstellung gemäß Figur 1 in Draufsicht;

- Figur 3

- in einer Darstellung gemäß Figur 1 die Ausräumeinrichtung in abgesenkter Stellung mit eingeschwenktem Schälmesser;

- Figur 4

- die Darstellung gemäß Figur 3 in Draufsicht und

- Figur 5

- in gegenüber den Figuren 1 bis 4 vergrößertem Maßstab in einem Horizontalschnitt das Schälmesser in eingeschwenkter Position.

Claims (13)

- Verfahren zum Ausräumen des Produktes aus der Zentrifugentrommel (1) einer diskontinuierlichen Zentrifuge, wobei ein Schälmesser (7) in die abgeschleuderte Produktschicht (9) eingeschwenkt wird und hier mit einer gegen die Trommeldrehrichtung (5) gerichteten Schneide (7a) das Produkt abschält, dadurch gekennzeichnet, daß das Schälmesser (7) nach seinem Einschwenken über nahezu die gesamte Trommelhöhe (h) Produktkontakt hat, gleichzeitig über die gesamte Trommelhöhe (h) das Produkt von der mit Räumdrehzahl rotierenden Produktschicht schichtweise abschält und bei Erreichen des Trommelsiebes wieder ausgeschwenkt wird.

- Verfahren nach Anspruch 1, dadurch gekennzeichnet, daß das Schälmesser (7) vor seinem Einschwenken in Axialrichtung (10) geringfügig in die Zentrifugentrommel (1) auf den Trommelboden (3) abgesenkt und nach seinem Ausschwenken vom Trommelboden (3) um einen entsprechenden axialen Abstand (a) wieder abgehoben wird.

- Verfahren nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß das Absenken des Schälmessers (7) bereits während des Abbremsens der Zentrifugentrommel (1) von ihrer Schleuderdrehzahl auf die Räumdrehzahl erfolgt.

- Verfahren nach Anspruch 1, 2 oder 3, dadurch gekennzeichnet, daß nach dem Erreichen des Trommelsiebes das Ausschwenken des Schälmessers (7) erst nach einer Verharrzeit von einigen Sekunden erfolgt.

- Verfahren nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß das Einschwenken des Schälmessers (7) in Drehrichtung (5) der Zentrifugentrommel (1) und sein Ausschwenken gegen diese Drehrichtung (5) erfolgt.

- Verfahren nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß der Einschwenkvorgang des Schälmessers (7) gestoppt wird unmittelbar bevor das Schälmesser (7) das Trommelsieb metallisch berührt.

- Verfahren nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß die Steuerung des Schälmessers (7) pneumatisch erfolgt.

- Vorrichtung zur Durchführung des Verfahrens nach einem der vorhergehenden Ansprüche, mit einem an einer Räumstange (6) befestigten und durch diese oder um diese verschwenkbaren Schälmesser (7), das in seiner eingeschwenkten Stellung die Produktschicht (9) mit einer der Trommeldrehrichtung (5) entgegengerichteten Schneide (7a) beaufschlagt, dadurch gekennzeichnet, daß sich die Schneide (7a) bei eingeschwenktem Schälmesser (7) über nahezu die gesamte Trommelhöhe (h) erstreckt.

- Vorrichtung nach Anspruch 8, gekennzeichnet durch eine Hub-, Absenk- und Verschwenkeinrichtung, über die das sich in abgeschwenkter Stellung befindliche Schälmesser (7) bis auf den Trommelboden (3) absenkbar, dann gegen die Produktschicht (9) einschwenkbar, nach Beendigung des Abschälprozesses wieder abschwenkbar und dann vom Trommelboden (3) wieder abhebbar ist.

- Vorrichtung nach Anspruch 8 oder 9, dadurch gekennzeichnet, daß im Horizontalschnitt das Schälmesser (7) auf seiner Vorderseite (7b) flach konkav ausgebildet ist.

- Vorrichtung nach Anspruch 8, 9 oder 10, dadurch gekennzeichnet, daß die Schneidkante (7a) des Schälmessers (7) mit dem Trommelsieb bzw. dem Trommelmantel (3) einen Winkel (α) von 80° bis etwas kleiner 90° einschließt.

- Vorrichtung nach einem der Ansprüche 8 bis 11, dadurch gekennzeichnet, daß das Schälmesser (7) eine Antihaftbeschichtung aufweist.

- Vorrichtung nach einem der Ansprüche 8 bis 12, dadurch gekennzeichnet, daß die Räumstange (6) als Rohr ausgebildet ist, in das ein Düsenstock oder Einzeldüsen für eine Deck- bzw. Waschwasser-Aufgabe integriert sind.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19819065 | 1998-04-29 | ||

| DE19819065A DE19819065C1 (de) | 1998-04-29 | 1998-04-29 | Verfahren und Vorrichtung zum Ausräumen des Produktes aus einer Zentrifugentrommel |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0953380A2 true EP0953380A2 (de) | 1999-11-03 |

| EP0953380A3 EP0953380A3 (de) | 2000-06-07 |

| EP0953380B1 EP0953380B1 (de) | 2002-08-21 |

Family

ID=7866108

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99102995A Expired - Lifetime EP0953380B1 (de) | 1998-04-29 | 1999-02-16 | Verfahren und Vorrichtung zum Ausräumen des Kristallisats aus einer Zentrifugentrommel |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US6177021B1 (de) |

| EP (1) | EP0953380B1 (de) |

| DE (2) | DE19819065C1 (de) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR3011192A1 (fr) * | 2013-09-30 | 2015-04-03 | Fives Cail Babcock | Essoreuse discontinue |

| US9764337B2 (en) | 2011-11-24 | 2017-09-19 | Bma Braunschweigische Maschinenbauanstalt Ag | Discontinuous centrifuge with a scraper for scraping a product |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102017205551A1 (de) * | 2017-03-31 | 2018-10-04 | Krones Ag | Flaschenbehandlungsmaschine und Verfahren zum Reinigen des Pumpen-/Düsenschutzes der Flaschenbehandlungsmaschine |

| CN107094820A (zh) * | 2017-05-31 | 2017-08-29 | 平湖市凯宇鲜菜有限公司 | 一种豆皮摊制装置 |

| JP6736149B2 (ja) * | 2018-05-15 | 2020-08-05 | 株式会社荒井鉄工所 | せん断部材及び濾過装置 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE558786A (de) * | 1955-10-19 | |||

| IT1254625B (it) | 1991-11-19 | 1995-09-28 | Dispositivo e procedimento per il trattamento di acque fangose e di scarico. | |

| GB9221956D0 (en) * | 1992-10-20 | 1992-12-02 | Broadbent & Sons Ltd Thomas | Particle separation and drying apparatus |

| US5443726A (en) * | 1993-10-13 | 1995-08-22 | Tm Industrial Supply, Inc. | Self-cleaning filter assembly |

| US5733238A (en) * | 1995-10-24 | 1998-03-31 | Carr Separations, Inc. | Scraping assembly having angularly offset scraper blades for removing solids from an imperforate bowl centrifuge |

| JP3313286B2 (ja) * | 1996-01-17 | 2002-08-12 | 株式会社松本機械製作所 | 遠心ろ過方法及び装置 |

-

1998

- 1998-04-29 DE DE19819065A patent/DE19819065C1/de not_active Expired - Fee Related

-

1999

- 1999-02-16 DE DE59902395T patent/DE59902395D1/de not_active Expired - Lifetime

- 1999-02-16 EP EP99102995A patent/EP0953380B1/de not_active Expired - Lifetime

- 1999-04-29 US US09/301,624 patent/US6177021B1/en not_active Expired - Lifetime

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9764337B2 (en) | 2011-11-24 | 2017-09-19 | Bma Braunschweigische Maschinenbauanstalt Ag | Discontinuous centrifuge with a scraper for scraping a product |

| FR3011192A1 (fr) * | 2013-09-30 | 2015-04-03 | Fives Cail Babcock | Essoreuse discontinue |

Also Published As

| Publication number | Publication date |

|---|---|

| US6177021B1 (en) | 2001-01-23 |

| EP0953380B1 (de) | 2002-08-21 |

| DE59902395D1 (de) | 2002-09-26 |

| EP0953380A3 (de) | 2000-06-07 |

| DE19819065C1 (de) | 1999-10-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2741710A1 (de) | Verfahren und vorrichtung zum trennen von feststoffen und fluessigkeiten aus einer suspension | |

| DE69000506T2 (de) | Verfahren und vorrichtung zur gewinnung von fruchtfleisch durch fluessigkeitsaufprall. | |

| EP2484451A2 (de) | Vollmantelzentrifuge mit Trocknung des Feststoffkuchens | |

| DE2743556A1 (de) | Vorrichtung zur abtrennung suspendierter feststoffe aus einer fluessigkeit | |

| DE4021350C2 (de) | Papierstoff-Siebvorrichtung | |

| EP0953380A2 (de) | Verfahren und Vorrichtung zum Ausräumen des Kristallisats aus einer Zentrifugentrommel | |

| DE4303043A1 (en) | Fish grinding process - by chopping whole fish into pieces, washing clean and grinding, esp. for fish with hard meat | |

| DE1502235A1 (de) | Vorrichtung zum Extrahieren von Citrusoel aus Citrusschale | |

| DE1667880B2 (de) | Verfahren und vorrichtung zum trennen eines gemisches aus kaesebruchkoernern und molke in seine bestandteile | |

| DE2547863A1 (de) | Schaelmaschine fuer erd- oder baumfruechte | |

| DE1761900A1 (de) | Vorrichtung und Verfahren zur Behandlung von Suspensionen | |

| DE2925754A1 (de) | Verfahren und maschine zum waschen tierischer huellen oder daerme, wie z.b. von blinddaermen | |

| DE4038253A1 (de) | Fliehkraftbearbeitungsmaschine | |

| DE9204727U1 (de) | Geschirrspüler mit selbstreinigendem Rezirkulationsfilter | |

| DE202010000494U1 (de) | Vorrichtung zur Aufbereitung von Pökellake | |

| EP0443382B1 (de) | Verfahren zum Reinigen des Filtermittels einer Filterzentrifuge | |

| DE3439146A1 (de) | Verkuerzungs- und reinigungsgeraet fuer porree | |

| DE19908852A1 (de) | Verfahren und Vorrichtung zum Reinigen von Agrarprodukten | |

| EP3075242A1 (de) | Honigschleuder zur verringerung des wassersgehalts im honig | |

| DE2227693A1 (de) | Abspülvorrichtung für drehbare Blattfilteranlage | |

| DE3706132C2 (de) | ||

| EP3735322B1 (de) | Schälzentrifuge | |

| AT393097B (de) | Verfahren und vorrichtung zur benetzung und schalenlockerung von getreidekoernern | |

| DE1442316C (de) | Vorrichtung zum Trennen von Hopfenblättern und Würze | |

| DE2928168C2 (de) | Vorrichtung zum Weichen von Braumaterialien |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20000511 |

|

| AKX | Designation fees paid |

Free format text: DE FR GB SE |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 20010806 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB SE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 59902395 Country of ref document: DE Date of ref document: 20020926 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20020920 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030522 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59902395 Country of ref document: DE Representative=s name: GRAMM, LINS & PARTNER PATENT- UND RECHTSANWAEL, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180221 Year of fee payment: 20 Ref country code: GB Payment date: 20180221 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20180222 Year of fee payment: 20 Ref country code: FR Payment date: 20180226 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59902395 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20190215 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20190215 |