EP0945385B1 - Triangle plieur d'un appareil de pliage d'une machine d'impression rotative - Google Patents

Triangle plieur d'un appareil de pliage d'une machine d'impression rotative Download PDFInfo

- Publication number

- EP0945385B1 EP0945385B1 EP99101732A EP99101732A EP0945385B1 EP 0945385 B1 EP0945385 B1 EP 0945385B1 EP 99101732 A EP99101732 A EP 99101732A EP 99101732 A EP99101732 A EP 99101732A EP 0945385 B1 EP0945385 B1 EP 0945385B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- former

- air

- slot

- web

- plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H45/00—Folding thin material

- B65H45/12—Folding articles or webs with application of pressure to define or form crease lines

- B65H45/22—Longitudinal folders, i.e. for folding moving sheet material parallel to the direction of movement

- B65H45/221—Longitudinal folders, i.e. for folding moving sheet material parallel to the direction of movement incorporating folding triangles

- B65H45/223—Details of folding triangles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2406/00—Means using fluid

- B65H2406/10—Means using fluid made only for exhausting gaseous medium

- B65H2406/11—Means using fluid made only for exhausting gaseous medium producing fluidised bed

- B65H2406/113—Details of the part distributing the air cushion

- B65H2406/1132—Multiple nozzles arrangement

Definitions

- the present invention relates to a former in a folder Rotary printing machine according to the preamble of claims 1 and 2.

- the former For folding oneself continuously through a web-fed rotary press moving formers are used.

- the former usually have them The shape of an inverted triangle over which the moving path is passed.

- air is drawn into the space between the web and the former, blown through radial openings located on the Edges or in bars of the former arranged along the edges, over which the train moves.

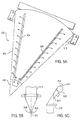

- Fig. 1 and Fig. 2 show different forms of formers according to the prior art Technology.

- a web moves from a wide section of the former to a lower section of the former, at which point the Web has a folded shape, d. H. that the train at or near it previous center line was folded.

- the conical former of Fig. 2 points along its former bars trained openings through which air is blown and an air cushion between the Side surfaces and the moving web is created.

- the low pressure areas can not only be between the air openings on the Forming formers, but also in the openings themselves when the airflow is not is properly regulated.

- the through the individual openings in the funnel rods of the 1 and 2 flowing air flow is not controlled individually.

- the flow of air through the different openings of the funnel rods is controlled collectively, for example by a measuring valve.

- the measuring valve only allows a very rough one Regulation of the air cushion installed between the web and the former. This Low pressure problems can cause the air vents to paint or Paper dust become clogged and the flow of air is blocked. This in turn leads to premature wear of the former and damage to the Train.

- DE 44 35 528 C2 describes a former which is similar to that in FIG. 2 has individual air outlet openings shown, through the air from the interior of the The former into the space between the former surface and the one above it guided paper web is blown. Trench-shaped can form between the openings Wells are located on the surface of the former, one of which is the spread of the Compressed air is supported on the surface. The exiting amount of air is however from the individual air outlet openings.

- EP 0 019 708 A1 describes a method for producing a former. in which the air outlet openings can be punched out in a slot shape. Between However, no air escapes from these slotted holes, so that the problem of Low pressure areas between the air openings results.

- the present invention relates to the introduction of air into a space between the former and the web without the use of air openings or internal Airways in the funnel rods. Achieve the embodiments of the invention an even air distribution on the surface of the former, so that the required air gap or air space between the former surface and the moving path is minimal. So it can be the former for the production of a Fold can be used in the web without any significant contact between the former and the web. Damage to the web and the Wear of the former is thus minimized and / or eliminated.

- the exemplary embodiments of the present invention show a web transporting former with a first surface over which the web moves is, and with a device that air in a space between the web and the first surface in order to let the web float freely, the Air supply device comprises at least one slot which is in the first surface is formed and extends over a substantial part of the length of the first surface extends.

- Fig. 3 shows a former 300 as part of a rotary printing machine 302.

- Die Printing machine 302 comprises at least one roller 304 which forms a web 326 over a web first surface 306 of a front plate 308, which is part of the former 300, feeds.

- the former 300 includes means that extend into the space between the web 326 and supplies air to the first surface 306.

- the air is fed into this intermediate space through at least one slot 310 (FIG. 4), along a substantial portion of the length of the first surface 306 is formed so that the web moves over the first surface on an air cushion.

- the reference to a substantial part of the length means a length sufficient to an adequate air cushion between moving web 326 and the first Generate surface 306 where the size (e.g., width), weight, and The running speed of the web must be taken into account.

- the preferred Embodiment of the invention is at least one slot 310 between one Slot surface 312 and a respective one of the two funnel rods 314 and 316 are formed, however, there is also the possibility of several slots in a row to be provided if desired.

- the front plate 308 is opposite one another the funnel rods 314, 316 in the lowered position. It was on individual air openings in the circumferential areas of the funnel rods (i.e. in Areas of the funnel rods in which these on both sides of the front plate 308th exposed) waived. Instead of these individual air openings in the extensive Areas of the exposed parts of the funnel rods are shown in the embodiment of FIG Fig. 3 is a layered construction in which at least one slot 310 air exit. An equal slot can be on the other side of the front panel 308, namely be formed between the front plate 308 and the funnel rod 316.

- the two funnel rods 314, 316 shown in Fig. 3 are as two cylindrical Poles constructed and assembled so that the center lines of the cylindrical The rods meet at one point and form a funnel nose 318.

- any of the features of the present invention may be implemented Constructions are used.

- the cylindrical rods can also be conical or the like.

- the front panel 308 is immediately below the tangent plane of the two Hopper bars are mounted on the former structure so that the slots 310 are formed between the front plate 308 and the funnel rods 314, 316.

- a Backplate 320 having a lower edge 328 and an upper edge 332 may be attached to one side of the funnel rods 314, 316 that side opposite, on which the front plate 308 is arranged. In Fig. 3 the moves Web 326 non-contact on an air cushion over the front panel 308.

- the front panel 308 and the rear panel 320 form a layered construction, in a desired amount of compressed air through one or more air inlet openings 322 can be initiated.

- the air volumes can be chosen in any way you want be measured.

- the can in the interior Airflow conducted between the front panel 308 and the rear panel 320 with a conventional air valve 324 can be regulated. This let in air fulfills the Interior that of the front panel 308, the rear panel 320 and the two Funnel rods 314, 316 is determined.

- FIG. 3 also shows a stationary Support plate 330, which holds the lower part 318 of the funnel rods 314, 316 together and a portion of the interior between the front panel 308, the rear panel 320 and the funnel rods 314, 316 forms.

- a stationary upper one Support plate 334 is provided on an upper part of the former 300, which is connected to the upper Edge 332 of the rear plate 320 is adjacent. Air from the interior can only pass through Slots such as slot 310 shown in FIG. 3 escape. So the air moves under the web 326 and over the front panel in such a way that the web 326 is free floats.

- the web running over the former into a well to set the defined floating state and the compressed air supplied by the Controlling slots 310 has the advantage of creating folds in the web takes place without increased wear of the former and no danger of Lubrication of the printed web 326 due to clogged air openings consists.

- Fig. 4 shows a partial cross section of the former of Fig. 3 can be seen that the air supply to create an air cushion between the moving web and surface 306 of front panel 308 by changing the Dimension of the slots 310 can be regulated.

- the slots 310 can for example, wider or narrower to allow the airflow to any Adjust web width.

- the air flow is controlled so that the air escapes from the interior of the former only below the web 326, as it moves over the front panel 308.

- Through slots 310 amount of air supplied is controlled by moving the effective width of the slots 310 along their length is varied.

- At least one adjusting button 402 is provided, which is rotatable about an axis 404 and how a screw can be rotated around one to laterally move the air flow control slit closure 406.

- the Slit closure 406 may be responsive to one triggered by the set knob 402 Rotary movement of an eccentric 408 can be shifted.

- a slot closure 406, the has been moved to narrow the slot 310 is in the right part of the Fig. 4 shown in broken lines.

- FIG. 4 is also the use of an air lock 410 between the Rear plate 320 and the funnel rods 314, 316 shown.

- an air seal 410 may be provided between the upper edge 332 of the rear plate 320 and the upper support plate 334.

- the shafts 412 of the adjusting buttons 402 serve to faceplate 308 spaced apart from hopper rods 314, 316 hold and form the slots 310.

- FIG lateral movement of the slot closures also by a vertical movement of the Front panel 308 done, d. H. by changing the distance between Front panel 308 and rear panel 320 to allow air to enter the space between the first surface 306 and the web 326.

- Front plate 308 to move in the tangential direction, or the slots 310, which in Fig. 3 along an essential part of the former as continuous slots are formed, in alternative embodiments also by several slots of to replace any desired length along the former. Additional slots may also be provided in the front panel 308 parallel to the slots 310.

- FIG. 5A to 5C illustrate an alternative embodiment of a former 500 according to the present invention.

- the funnel rods and a faceplate used to form the slots 310 a single hopper plate 502 with preferably conical side walls replaced.

- the funnel plate 502 represents a first surface which is used to form the Gap between the moving web 512 and the former 500 is used.

- the slots 504 and 506 extend substantially along one Part of the length of the funnel plate 502.

- the former nose 508 of the former 500 can be removed with the former plate 502 be connected (z. B. by means of screws or the like), so that this nose, which is to form a fold in the running web 512 is used in a simple manner by a other nose 508 can be replaced.

- An upper part of the former can be on a stationary support 510 can be mounted.

- airflow control may be similar Way, as described in relation to the embodiment of FIG. 3, take place. That is, it can be in the interior between the hopper plate 502 and one Airflow regulation takes place behind the backplate (not shown in FIG. 5A).

- the Airflow regulation can be done in the same manner as in the embodiment of FIG. 3 and 4 by controlling the width of the slots in the hopper plate 502 using an or several slot closures 406. Closing the interior can be done in the same way as described with reference to FIG. 3.

- FIG. 5B shows a front view of the former of FIG. 5A, with the web 512 in moving in a vertically downward direction.

- the edges of the web are pulled down over the conical sides of the funnel plate 502, so to form a fold 514 in the moving web.

- the fold as such will be there by rollers 516, 518, which with the tapering, conically shaped side walls of the funnel plate 502 cooperate.

- FIG. 5C shows a side view of the process shown in FIG. 5B. How in it as can be seen, the web 512 moves over a hopper inlet roller 520 of FIG Printing machine and further over the former 500 and is folded; then the leaves Web 512 the lower, reduced width part of the former 500.

- the embodiments shown in Figs. 3-5 are only Examples are and that there are a number of variations.

- the in slots shown in these figures can be designed in any manner a uniform air flow in the space between the web and the To achieve the surface of the former, over which the web moves.

- the air flow control slits 406 may alternatively Embodiments can be designed differently.

- the Slot fasteners extend the length of the slots.

- Number of individual airflow control closures along the length of the Slots are either adjacent or spaced apart.

Landscapes

- Folding Of Thin Sheet-Like Materials, Special Discharging Devices, And Others (AREA)

Claims (11)

- Triangle ou cône plieur destiné au pliage d'une bande de papier en circulation dans une rotative d'impression à bobines, comprenant une première surface (306 ; 502) par-dessus laquelle est transportée la bande (326 ; 512), un espace intérieur du cône plieur (3, 300, 500), qui est rempli d'air, et un dispositif pour amener de l'air de l'espace intérieur dans un espace intermédiaire formé par la première surface (306 ; 502) et la bande (326 ; 512),

caractérisé en ce que dans la première surface (306 ; 502) est formée au moins une fente (310 ; 504, 506) à travers laquelle l'air de l'espace intérieur s'échappe dans l'espace intermédiaire, la fente s'étendant sur une grande partie de la longueur de la première surface. - Cône plieur selon la revendication 1, caractérisé en ce que celui-ci comprend par ailleurs, au moins deux tiges (314, 316) pour plier la bande et une première plaque (308) ainsi qu'une seconda plaqua (320), qui sont placées sur les côtés opposés des deux tiges (314, 316), ladite au moins une fente (310) étant formée entre la première plaque (308) et au moins l'une des deux tiges (314, 316).

- Cône plieur selon la revendication 1 ou 2, caractérisé en ce que celui-ci comprend par ailleurs, au moins une fente supplémentaire (310) entre l'autre desdites au moins deux tiges (314, 316) et la première plaque (308), en vue de laisser pénétrer de l'air dans l'espace intermédiaire.

- Cône plieur selon l'une des revendications 2 ou 3, caractérisé en ce qu'entre la première plaque (308) et les deux tiges (314, 316) est défini un espace intérieur dans lequel est introduit l'air sous la forme d'un écoulement prédéterminé ou prescrit.

- Cône plieur selon l'une des revendications précédentes, caractérisé en ce que celui-ci comprend par ailleurs un dispositif de réglage de la largeur de ladite au moins une fente (310) pour commander l'écoulement d'air envoyé dans l'espace intermédiaire.

- Cône plieur selon la revendication 5, caractérisé en ce que le dispositif de réglage de la largeur comprend par ailleurs, au moins une fermeture de fente (406) mobile, pour commander l'écoulement d'air, et un dispositif (402) pour régler la position de ladite au moins une fermeture de fente (406) à l'intérieur de ladite au moins une fente (310).

- Cône plieur selon la revendication 6, caractérisé en ce que le dispositif (402) pour régler la position de ladite au moins une fermeture de fente (406) comprend par ailleurs, au moins un excentrique (408) qui est relié sur le plan opérationnel à ladite au moins une fermeture de dente (406), et un bouton de réglage rotatif (402) pour régler la position de l'excentrique (408).

- Cône plieur selon la revendication 5, caractérisé en ce que le dispositif de réglage de la largeur de fente fait varier la distance entre une plaque frontale (308) et les pièces (314, 316) définissant l'espace intérieur du cône plieur.

- Cône plieur selon la revendication 1, caractérisé en ce que la première surface (306) est réalisée en tant que plaque de cône (502) adaptée à la forme du cône plieur (500), et dans laquelle est réalisée directement ladite au moins une fente (504, 506).

- Cône plieur selon la revendication 9, caractérisé en ce qu'au total deux fentes (504, 506) sont réalisées dans la plaque de cône (502), dans la zone des bords latéraux de celle-ci.

- Cône plieur selon l'une des revendications 9 ou 10, caractérisé en ce qu'à l'extrémité en pointe de la plaque de cône (502) est prévu un nez de cône (508) qui est relié de manière amovible à la plaque de cône (502).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US09/048,011 US5947411A (en) | 1998-03-26 | 1998-03-26 | Method and apparatus for air flotation |

| US48011 | 1998-03-26 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0945385A2 EP0945385A2 (fr) | 1999-09-29 |

| EP0945385A3 EP0945385A3 (fr) | 1999-12-22 |

| EP0945385B1 true EP0945385B1 (fr) | 2002-10-02 |

Family

ID=21952278

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99101732A Expired - Lifetime EP0945385B1 (fr) | 1998-03-26 | 1999-02-10 | Triangle plieur d'un appareil de pliage d'une machine d'impression rotative |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US5947411A (fr) |

| EP (1) | EP0945385B1 (fr) |

| JP (1) | JP4195143B2 (fr) |

| DE (2) | DE19905387A1 (fr) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10031814A1 (de) | 2000-06-30 | 2002-01-10 | Heidelberger Druckmasch Ag | Einrichtung zum berührungsfreien Führen eines Bahnmaterials über eine Fläche |

| DE10057886A1 (de) * | 2000-11-22 | 2002-05-23 | Heidelberger Druckmasch Ag | Wendestangenanordnung für bahnverarbeitende Rotationsdruckmaschinen |

| WO2004037537A2 (fr) * | 2002-10-19 | 2004-05-06 | Koenig & Bauer Aktiengesellschaft | Elements de guidage pour unite d'impression |

| US20110064509A1 (en) * | 2009-09-17 | 2011-03-17 | Goss International Americas, Inc. | Air delivery apparatus for delivering air to a moving substrate in a printing press |

| DE102012201238B3 (de) * | 2012-01-30 | 2012-12-27 | Koenig & Bauer Aktiengesellschaft | Vorrichtung einer Rollenrotationsdruckmaschine zur Verarbeitung einer oder mehrerer bedruckter Bahnen sowie Verfahren zur Bildung eines längsgefalzten Stranges |

| US9336466B2 (en) | 2014-09-08 | 2016-05-10 | Fuji Xerox Co., Ltd. | Printing apparatus including a moving guiding portion |

| DE102021103766A1 (de) | 2021-02-17 | 2022-08-18 | Manroland Goss Web Systems Gmbh | Trichternase und Falztrichter |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2619057A (en) * | 1951-02-15 | 1952-11-25 | Dwight W Ellis Jr | Web folder and stitcher apparatus |

| DE1142878B (de) * | 1961-01-28 | 1963-01-31 | Maschf Augsburg Nuernberg Ag | Falztrichter zum Laengsfalzen von in Rotationsdruckmaschinen verarbeiteten Papierbahnen |

| US3191926A (en) * | 1963-02-06 | 1965-06-29 | Avisun Corp | Web folding apparatus |

| BE680532A (fr) * | 1966-05-04 | 1966-10-17 | ||

| US4043495A (en) * | 1975-03-03 | 1977-08-23 | Frank Sander | Air cushioned turn bar |

| DE2657789A1 (de) * | 1976-12-21 | 1978-06-29 | Maschf Augsburg Nuernberg Ag | Einrichtung zum einziehen einer papierbahn in den falzapparat einer rotationsdruckmaschine |

| US4308984A (en) * | 1978-05-11 | 1982-01-05 | Vits Maschinenbau Gmbh | Jet-conveyor box for floatingly guiding a conveyed strip or sheet material |

| DE2921757A1 (de) * | 1979-05-29 | 1980-12-04 | Maschf Augsburg Nuernberg Ag | Verfahren zum herstellen eines trichterbleches fuer einen falztrichter einer rotationsdruckmaschine und danach hergestelltes trichterblech |

| FI60261C (fi) * | 1980-03-28 | 1981-12-10 | Valmet Oy | Oevertrycksmunstycke foer behandling av banor |

| DE3215472C2 (de) * | 1982-04-24 | 1984-02-23 | M.A.N.- Roland Druckmaschinen AG, 6050 Offenbach | Luftumspülte Wendestange |

| US4848633A (en) * | 1986-02-28 | 1989-07-18 | Thermo Electron Web Systems, Inc. | Non-contact web turning and drying apparatus |

| US4698914A (en) * | 1986-05-29 | 1987-10-13 | E. I. Du Pont De Nemours And Company | Setting/drying process for flexible web coating |

| US4726502A (en) * | 1986-07-07 | 1988-02-23 | Cryderman Gary G | Apparatus for entraining and directing a wet paper web |

| FI77708C (fi) * | 1987-09-28 | 1989-04-10 | Valmet Paper Machinery Inc | Arrangemang av oevertrycksmunstycken avsett foer behandling av banor. |

| US5233919A (en) * | 1992-06-18 | 1993-08-10 | Heidelberg Harris Gmbh | Angle bar air regulating device for turning a web |

| DE4428593A1 (de) * | 1993-11-04 | 1995-05-11 | Heidelberger Druckmasch Ag | Vorrichtung und Verfahren zum Messen und Regulieren der Spannung einer Bahn in dem Trichterbereich eines Falzapparates für eine Druckmaschine |

| DE4435528C2 (de) * | 1994-10-05 | 1997-09-04 | Roland Man Druckmasch | Falztrichter für eine Druckmaschine |

| DE19607397A1 (de) * | 1996-02-28 | 1997-09-04 | Heidelberger Druckmasch Ag | Vorrichtung und Verfahren zur Führung von bogenförmigem Material in einer Druckmaschine, insbesondere in einer Bogenrotations-Offsetdruckmaschine |

| DE19619547A1 (de) * | 1996-05-15 | 1997-11-27 | Vits Maschinenbau Gmbh | Luftkissendüse und Vorrichtung zur Wärmebehandlung einer kontinuierlich bewegten Warenbahn mit Luftkissendüsen |

-

1998

- 1998-03-26 US US09/048,011 patent/US5947411A/en not_active Expired - Lifetime

-

1999

- 1999-02-10 DE DE19905387A patent/DE19905387A1/de not_active Withdrawn

- 1999-02-10 EP EP99101732A patent/EP0945385B1/fr not_active Expired - Lifetime

- 1999-02-10 DE DE59902899T patent/DE59902899D1/de not_active Expired - Lifetime

- 1999-03-26 JP JP08438899A patent/JP4195143B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP0945385A3 (fr) | 1999-12-22 |

| DE59902899D1 (de) | 2002-11-07 |

| JPH11314837A (ja) | 1999-11-16 |

| EP0945385A2 (fr) | 1999-09-29 |

| US5947411A (en) | 1999-09-07 |

| JP4195143B2 (ja) | 2008-12-10 |

| DE19905387A1 (de) | 1999-09-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69923544T2 (de) | Papierbahnzuführvorrichtung in einer Rollenrotationsdruckmaschine mit einer Bahnspannungsregeleinrichtung | |

| DE2857473C2 (fr) | ||

| DE2708390B2 (de) | Verfahren und Vorrichtung zur Steuerung der Dicke von Bahnen | |

| DE69308064T2 (de) | Luftführungsvorrichtung mit einer Ablaufplatte zum Wenden einer bewegten Bahn | |

| EP0945385B1 (fr) | Triangle plieur d'un appareil de pliage d'une machine d'impression rotative | |

| EP0071769B1 (fr) | Dispositif s'opposant à la courbure du bord frontal des feuilles dans un appareil de sortie d'une machine d'impression rotative de feuilles | |

| DE19651739A1 (de) | Auftragwerk zum direkten oder indirekten Auftragen eines flüssigen oder pastösen Streichmediums auf eine laufende Materialbahn, insbesondere aus Papier oder Karton | |

| DD159142A5 (de) | Vorrichtung zur gleichzeitigen erzeugung zweier kontinuierlicher zigarettenstraenge | |

| DE69004704T2 (de) | Deckel für eine Krempel. | |

| DE2549726B2 (de) | Maschine zum Herstellen von Faserbahnen | |

| EP0406529B1 (fr) | Dispositif d'enduction | |

| DE4024229C1 (fr) | ||

| DE3229402C2 (de) | Vorrichtung an einer karde oder krempel zur vlieserzeugung | |

| DE2736644B1 (de) | Stoffauflauf | |

| DE1511218B2 (de) | Papierbrei-aufgabevorrichtung fuer papiermaschinen | |

| DE4409415C5 (de) | Dosiervorrichtung für einen Stoffauflauf einer Papiermaschine | |

| DE69530679T2 (de) | Vorrichtung zur durchbiegungssteuerung der walzen in einer maschine zum krumpfen von warenbahnen | |

| DE4328997C2 (de) | Naßpartie eines Doppelsieb-GAP-Formers | |

| DE2800547B2 (de) | Stoffauflauf für Papiermaschinen | |

| DE3940357A1 (de) | Maschine zur gleichzeitigen herstellung von zwei kontinuierlichen zigarettenstraengen | |

| EP0570733A1 (fr) | Dispositif d'enduction pour déposer une couleur d'enduction sur une bande de papier | |

| DE4237310C2 (de) | Stoffauflauf mit Vorrichtung zur Einstellung der Faserorientierung | |

| EP0887462A2 (fr) | Machine pour la fabrication d'une bande de matériau | |

| DE9206750U1 (de) | Auftragswerk zum Auftragen von Streichfarbe auf eine Papierbahn | |

| DE10324711A1 (de) | Stoffauflauf |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): CH DE FR GB IT LI |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19991126 |

|

| AKX | Designation fees paid |

Free format text: CH DE FR GB IT LI |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: BURKE, DAVID CHARLES Inventor name: ALBERT, KEVIN FRANCIS |

|

| 17Q | First examination report despatched |

Effective date: 20010913 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE FR GB IT LI |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20021002 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59902899 Country of ref document: DE Date of ref document: 20021107 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20021127 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030703 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20110223 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20110223 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20120306 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20120228 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120229 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120210 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20131031 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59902899 Country of ref document: DE Effective date: 20130903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130903 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130228 |