EP0945385B1 - Folding triangle of a folding apparatus of a rotary printing press - Google Patents

Folding triangle of a folding apparatus of a rotary printing press Download PDFInfo

- Publication number

- EP0945385B1 EP0945385B1 EP99101732A EP99101732A EP0945385B1 EP 0945385 B1 EP0945385 B1 EP 0945385B1 EP 99101732 A EP99101732 A EP 99101732A EP 99101732 A EP99101732 A EP 99101732A EP 0945385 B1 EP0945385 B1 EP 0945385B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- former

- air

- slot

- web

- plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H45/00—Folding thin material

- B65H45/12—Folding articles or webs with application of pressure to define or form crease lines

- B65H45/22—Longitudinal folders, i.e. for folding moving sheet material parallel to the direction of movement

- B65H45/221—Longitudinal folders, i.e. for folding moving sheet material parallel to the direction of movement incorporating folding triangles

- B65H45/223—Details of folding triangles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2406/00—Means using fluid

- B65H2406/10—Means using fluid made only for exhausting gaseous medium

- B65H2406/11—Means using fluid made only for exhausting gaseous medium producing fluidised bed

- B65H2406/113—Details of the part distributing the air cushion

- B65H2406/1132—Multiple nozzles arrangement

Definitions

- the present invention relates to a former in a folder Rotary printing machine according to the preamble of claims 1 and 2.

- the former For folding oneself continuously through a web-fed rotary press moving formers are used.

- the former usually have them The shape of an inverted triangle over which the moving path is passed.

- air is drawn into the space between the web and the former, blown through radial openings located on the Edges or in bars of the former arranged along the edges, over which the train moves.

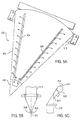

- Fig. 1 and Fig. 2 show different forms of formers according to the prior art Technology.

- a web moves from a wide section of the former to a lower section of the former, at which point the Web has a folded shape, d. H. that the train at or near it previous center line was folded.

- the conical former of Fig. 2 points along its former bars trained openings through which air is blown and an air cushion between the Side surfaces and the moving web is created.

- the low pressure areas can not only be between the air openings on the Forming formers, but also in the openings themselves when the airflow is not is properly regulated.

- the through the individual openings in the funnel rods of the 1 and 2 flowing air flow is not controlled individually.

- the flow of air through the different openings of the funnel rods is controlled collectively, for example by a measuring valve.

- the measuring valve only allows a very rough one Regulation of the air cushion installed between the web and the former. This Low pressure problems can cause the air vents to paint or Paper dust become clogged and the flow of air is blocked. This in turn leads to premature wear of the former and damage to the Train.

- DE 44 35 528 C2 describes a former which is similar to that in FIG. 2 has individual air outlet openings shown, through the air from the interior of the The former into the space between the former surface and the one above it guided paper web is blown. Trench-shaped can form between the openings Wells are located on the surface of the former, one of which is the spread of the Compressed air is supported on the surface. The exiting amount of air is however from the individual air outlet openings.

- EP 0 019 708 A1 describes a method for producing a former. in which the air outlet openings can be punched out in a slot shape. Between However, no air escapes from these slotted holes, so that the problem of Low pressure areas between the air openings results.

- the present invention relates to the introduction of air into a space between the former and the web without the use of air openings or internal Airways in the funnel rods. Achieve the embodiments of the invention an even air distribution on the surface of the former, so that the required air gap or air space between the former surface and the moving path is minimal. So it can be the former for the production of a Fold can be used in the web without any significant contact between the former and the web. Damage to the web and the Wear of the former is thus minimized and / or eliminated.

- the exemplary embodiments of the present invention show a web transporting former with a first surface over which the web moves is, and with a device that air in a space between the web and the first surface in order to let the web float freely, the Air supply device comprises at least one slot which is in the first surface is formed and extends over a substantial part of the length of the first surface extends.

- Fig. 3 shows a former 300 as part of a rotary printing machine 302.

- Die Printing machine 302 comprises at least one roller 304 which forms a web 326 over a web first surface 306 of a front plate 308, which is part of the former 300, feeds.

- the former 300 includes means that extend into the space between the web 326 and supplies air to the first surface 306.

- the air is fed into this intermediate space through at least one slot 310 (FIG. 4), along a substantial portion of the length of the first surface 306 is formed so that the web moves over the first surface on an air cushion.

- the reference to a substantial part of the length means a length sufficient to an adequate air cushion between moving web 326 and the first Generate surface 306 where the size (e.g., width), weight, and The running speed of the web must be taken into account.

- the preferred Embodiment of the invention is at least one slot 310 between one Slot surface 312 and a respective one of the two funnel rods 314 and 316 are formed, however, there is also the possibility of several slots in a row to be provided if desired.

- the front plate 308 is opposite one another the funnel rods 314, 316 in the lowered position. It was on individual air openings in the circumferential areas of the funnel rods (i.e. in Areas of the funnel rods in which these on both sides of the front plate 308th exposed) waived. Instead of these individual air openings in the extensive Areas of the exposed parts of the funnel rods are shown in the embodiment of FIG Fig. 3 is a layered construction in which at least one slot 310 air exit. An equal slot can be on the other side of the front panel 308, namely be formed between the front plate 308 and the funnel rod 316.

- the two funnel rods 314, 316 shown in Fig. 3 are as two cylindrical Poles constructed and assembled so that the center lines of the cylindrical The rods meet at one point and form a funnel nose 318.

- any of the features of the present invention may be implemented Constructions are used.

- the cylindrical rods can also be conical or the like.

- the front panel 308 is immediately below the tangent plane of the two Hopper bars are mounted on the former structure so that the slots 310 are formed between the front plate 308 and the funnel rods 314, 316.

- a Backplate 320 having a lower edge 328 and an upper edge 332 may be attached to one side of the funnel rods 314, 316 that side opposite, on which the front plate 308 is arranged. In Fig. 3 the moves Web 326 non-contact on an air cushion over the front panel 308.

- the front panel 308 and the rear panel 320 form a layered construction, in a desired amount of compressed air through one or more air inlet openings 322 can be initiated.

- the air volumes can be chosen in any way you want be measured.

- the can in the interior Airflow conducted between the front panel 308 and the rear panel 320 with a conventional air valve 324 can be regulated. This let in air fulfills the Interior that of the front panel 308, the rear panel 320 and the two Funnel rods 314, 316 is determined.

- FIG. 3 also shows a stationary Support plate 330, which holds the lower part 318 of the funnel rods 314, 316 together and a portion of the interior between the front panel 308, the rear panel 320 and the funnel rods 314, 316 forms.

- a stationary upper one Support plate 334 is provided on an upper part of the former 300, which is connected to the upper Edge 332 of the rear plate 320 is adjacent. Air from the interior can only pass through Slots such as slot 310 shown in FIG. 3 escape. So the air moves under the web 326 and over the front panel in such a way that the web 326 is free floats.

- the web running over the former into a well to set the defined floating state and the compressed air supplied by the Controlling slots 310 has the advantage of creating folds in the web takes place without increased wear of the former and no danger of Lubrication of the printed web 326 due to clogged air openings consists.

- Fig. 4 shows a partial cross section of the former of Fig. 3 can be seen that the air supply to create an air cushion between the moving web and surface 306 of front panel 308 by changing the Dimension of the slots 310 can be regulated.

- the slots 310 can for example, wider or narrower to allow the airflow to any Adjust web width.

- the air flow is controlled so that the air escapes from the interior of the former only below the web 326, as it moves over the front panel 308.

- Through slots 310 amount of air supplied is controlled by moving the effective width of the slots 310 along their length is varied.

- At least one adjusting button 402 is provided, which is rotatable about an axis 404 and how a screw can be rotated around one to laterally move the air flow control slit closure 406.

- the Slit closure 406 may be responsive to one triggered by the set knob 402 Rotary movement of an eccentric 408 can be shifted.

- a slot closure 406, the has been moved to narrow the slot 310 is in the right part of the Fig. 4 shown in broken lines.

- FIG. 4 is also the use of an air lock 410 between the Rear plate 320 and the funnel rods 314, 316 shown.

- an air seal 410 may be provided between the upper edge 332 of the rear plate 320 and the upper support plate 334.

- the shafts 412 of the adjusting buttons 402 serve to faceplate 308 spaced apart from hopper rods 314, 316 hold and form the slots 310.

- FIG lateral movement of the slot closures also by a vertical movement of the Front panel 308 done, d. H. by changing the distance between Front panel 308 and rear panel 320 to allow air to enter the space between the first surface 306 and the web 326.

- Front plate 308 to move in the tangential direction, or the slots 310, which in Fig. 3 along an essential part of the former as continuous slots are formed, in alternative embodiments also by several slots of to replace any desired length along the former. Additional slots may also be provided in the front panel 308 parallel to the slots 310.

- FIG. 5A to 5C illustrate an alternative embodiment of a former 500 according to the present invention.

- the funnel rods and a faceplate used to form the slots 310 a single hopper plate 502 with preferably conical side walls replaced.

- the funnel plate 502 represents a first surface which is used to form the Gap between the moving web 512 and the former 500 is used.

- the slots 504 and 506 extend substantially along one Part of the length of the funnel plate 502.

- the former nose 508 of the former 500 can be removed with the former plate 502 be connected (z. B. by means of screws or the like), so that this nose, which is to form a fold in the running web 512 is used in a simple manner by a other nose 508 can be replaced.

- An upper part of the former can be on a stationary support 510 can be mounted.

- airflow control may be similar Way, as described in relation to the embodiment of FIG. 3, take place. That is, it can be in the interior between the hopper plate 502 and one Airflow regulation takes place behind the backplate (not shown in FIG. 5A).

- the Airflow regulation can be done in the same manner as in the embodiment of FIG. 3 and 4 by controlling the width of the slots in the hopper plate 502 using an or several slot closures 406. Closing the interior can be done in the same way as described with reference to FIG. 3.

- FIG. 5B shows a front view of the former of FIG. 5A, with the web 512 in moving in a vertically downward direction.

- the edges of the web are pulled down over the conical sides of the funnel plate 502, so to form a fold 514 in the moving web.

- the fold as such will be there by rollers 516, 518, which with the tapering, conically shaped side walls of the funnel plate 502 cooperate.

- FIG. 5C shows a side view of the process shown in FIG. 5B. How in it as can be seen, the web 512 moves over a hopper inlet roller 520 of FIG Printing machine and further over the former 500 and is folded; then the leaves Web 512 the lower, reduced width part of the former 500.

- the embodiments shown in Figs. 3-5 are only Examples are and that there are a number of variations.

- the in slots shown in these figures can be designed in any manner a uniform air flow in the space between the web and the To achieve the surface of the former, over which the web moves.

- the air flow control slits 406 may alternatively Embodiments can be designed differently.

- the Slot fasteners extend the length of the slots.

- Number of individual airflow control closures along the length of the Slots are either adjacent or spaced apart.

Landscapes

- Folding Of Thin Sheet-Like Materials, Special Discharging Devices, And Others (AREA)

Description

Die vorliegende Erfindung betrifft einen Falztrichter in einem Falzapparat einer

Rotationsdruckmaschine gemäß dem Oberbegriff von Anspruch 1 und 2.The present invention relates to a former in a folder

Rotary printing machine according to the preamble of

Für das Falzen einer sich kontinuierlich durch eine Rollenrotationsdruckmaschine bewegenden Bahn werden Falztrichter verwendet. Falztrichter besitzen gewöhnlich die Form eines umgekehrten Dreiecks, über das die sich bewegende Bahn geführt wird. Bei einem herkömmlicher Falztrichter wird Luft in den Zwischenraum zwischen der Bahn und dem Falztrichter geblasen, und zwar durch radiale Öffnungen, die sich an den Rändern oder in entlang der Ränder angeordneten Stangen des Falztrichters befinden, über welche sich die Bahn bewegt.For folding oneself continuously through a web-fed rotary press moving formers are used. The former usually have them The shape of an inverted triangle over which the moving path is passed. at In a conventional former, air is drawn into the space between the web and the former, blown through radial openings located on the Edges or in bars of the former arranged along the edges, over which the train moves.

Fig. 1 und Fig. 2 zeigen verschiedene Formen von Falztrichtern nach dem Stand der Technik.Fig. 1 and Fig. 2 show different forms of formers according to the prior art Technology.

In der Ausführungsform der Fig. 1 bewegt sich eine Bahn von einem breiten Abschnitt des Falztrichters zu einem unteren Abschnitt des Falztrichters, an welcher Stelle die Bahn eine gefalzte Form angenommen hat, d. h. daß die Bahn an oder nahe ihrer vorherigen Mittellinie gefalzt wurde. Durch die sich in einem Abstand entlang der Längen der Trichterstangen befindlichen Öffnungen wird Luft geblasen, um ein Luftkissen zwischen den Seitenflächen des Falztrichters und der Bahn zu erzeugen. Gleichermaßen weist der konische Falztrichter der Fig. 2 entlang seiner Trichterstangen ausgebildete Öffnungen auf, durch welche Luft geblasen und ein Luftkissen zwischen den Seitenflächen und der sich bewegenden Bahn geschaffen wird.In the embodiment of Fig. 1, a web moves from a wide section of the former to a lower section of the former, at which point the Web has a folded shape, d. H. that the train at or near it previous center line was folded. By being at a distance along the Openings are blown to lengths along the funnel rods To create air cushions between the side surfaces of the former and the web. Likewise, the conical former of Fig. 2 points along its former bars trained openings through which air is blown and an air cushion between the Side surfaces and the moving web is created.

Jedoch ist bei den in den Fig. 1 und 2 dargestellten Falztrichtern keine gleichmäßige Druckverteilung in den Bereichen zwischen den Öffnungen gegeben. Es entstehen sogar Niederdruckbereiche, so daß die bedruckte Papierbahn die stationären Trichterstangen kontaktieren kann. Dieser Kontakt hinterläßt dann oft Schmierstellen auf der Bahn. Eine weitere Konsequenz beim Kontakt der Bahn mit den Trichterstangen ist der allmähliche Verschleiß der Stangen.However, the former in Figures 1 and 2 is not uniform Pressure distribution in the areas between the openings. It even arises Low pressure areas so that the printed paper web the stationary hopper rods can contact. This contact often leaves lubrication points on the web. A Another consequence of the contact of the web with the funnel rods is the gradual one Wear on the bars.

Die Niederdruckbereiche können sich nicht nur zwischen den Luftöffnungen auf dem Falztrichter bilden, sondern auch in den Öffnungen selbst, wenn der Luftstrom nicht richtig reguliert wird. Der durch die individuellen Öffnungen in den Trichterstangen der Fig. 1 und 2 fließende Luftstrom wird nicht individuell gesteuert. Das Strömen der Luft durch die verschiedenen Öffnungen der Trichterstangen wird kollektiv gesteuert, beispielsweise durch ein Meßventil. Jedoch erlaubt das Meßventil nur eine sehr grobe Regulierung des zwischen der Bahn und dem Falztrichter aufgebauten Luftkissens. Diese Niederdruckprobleme können dazu führen, daß die Luftöffnungen mit Farbe oder Papierstaub verstopft werden und somit das Durchströmen der Luft blockiert ist. Dies führt wiederum zu vorzeitiger Abnutzung des Falztrichters und zu Beschädigungen der Bahn.The low pressure areas can not only be between the air openings on the Forming formers, but also in the openings themselves when the airflow is not is properly regulated. The through the individual openings in the funnel rods of the 1 and 2 flowing air flow is not controlled individually. The flow of air through the different openings of the funnel rods is controlled collectively, for example by a measuring valve. However, the measuring valve only allows a very rough one Regulation of the air cushion installed between the web and the former. This Low pressure problems can cause the air vents to paint or Paper dust become clogged and the flow of air is blocked. This in turn leads to premature wear of the former and damage to the Train.

Die Anwendung eines Luftstromes ist weiterhin von den in Rollenrotationsdruckmaschinen zum Wenden oder Umlenken der bedruckten Papierbahn eingesetzten Wendestangen her bekannt, wobei ein Luftkissen erzeugt wird, um die Bewegungsrichtung der Bahn ohne Kontakt mit der Bahn zu ändern. Diese Art von Einrichtung wird verwendet, wenn die auf die Bahn gedruckte Farbe noch feucht ist, denn jeglicher Kontakt zwischen der Bahn und einer Wendestange würde zu Beschädigungen der Bahn führen und wahrscheinlich den Druckprozeß unterbrechen. Die mit Druckluft beaufschlagten Wendestangen erfordern einen relativ großen Luftspalt zwischen der Bahn und der Oberfläche der Wendestange. Bei einem Falztrichter ist jedoch ein minimaler Luftspalt erforderlich, um ein möglichst konstantes und genaues Schnittregister und damit eine hohe Qualität der Druckprodukte zu erzielen.The use of an air flow is still from the in Web-fed rotary printing machines for turning or redirecting the printed paper web used turning rods ago known, wherein an air cushion is generated to the Change the direction of movement of the web without contact with the web. This kind of Device is used when the ink printed on the web is still damp, because any contact between the train and a turning bar would be too Damage to the web and probably interrupt the printing process. The Turning rods loaded with compressed air require a relatively large air gap between the web and the surface of the turning bar. With a former however, a minimal air gap is required in order to be as constant and accurate as possible To achieve cutting registers and thus a high quality of the printed products.

Es wurde versucht, die oben erwähnten Mängel bei Falztrichtern zu beseitigen, indem die Positionen der Luftöffnungen in den Trichterstangen neu angeordnet und verändert wurden und die Anzahl der Luftöffnungen erhöht wurde. Außerdem wurde ein Band mit einem niedrigen Reibungskoeffizienten auf der Oberfläche der Trichterstangen angebracht. Jedoch konnten durch diese Maßnahmen die zuvor erwähnten Mängel nicht beseitigt werden.Attempts have been made to remedy the above-mentioned shortcomings in the former the positions of the air openings in the funnel rods rearranged and changed and the number of air openings has been increased. A tape was also included a low coefficient of friction on the surface of the funnel rods appropriate. However, these measures did not solve the aforementioned shortcomings be eliminated.

In der DE 44 35 528 C2 ist ein Falztrichter beschrieben, der ähnlich dem in Fig. 2 dargestellten individuelle Luftauslassöffnungen besitzt, durch die Luft vom Innenraum des Falztrichters in den Zwischenraum zwischen der Falztrichteroberfläche und der darüber geführten Papierbahn geblasen wird. Zwischen den Öffnungen können sich grabenförmige Vertiefungen an der Oberfläche des Falztrichters befinden, von denen die Ausbreitung der Druckluft auf der Oberfläche unterstützt wird. Die austretende Luftmenge wird jedoch von den individuellen Luftaustrittsöffnungen bestimmt.DE 44 35 528 C2 describes a former which is similar to that in FIG. 2 has individual air outlet openings shown, through the air from the interior of the The former into the space between the former surface and the one above it guided paper web is blown. Trench-shaped can form between the openings Wells are located on the surface of the former, one of which is the spread of the Compressed air is supported on the surface. The exiting amount of air is however from the individual air outlet openings.

In der EP 0 019 708 A1 ist ein Verfahren zum Herstellen eines Falztrichters beschrieben, bei dem die Luftaustrittsöffnungen schlitzförmig ausgestanzt werden können. Zwischen diesen Schlitzlöchern tritt allerdings keine Luft aus, sodass sich auch hier das Problem von Niederdruckbereichen zwischen den Luftöffnungen ergibt.EP 0 019 708 A1 describes a method for producing a former. in which the air outlet openings can be punched out in a slot shape. Between However, no air escapes from these slotted holes, so that the problem of Low pressure areas between the air openings results.

Demgemäß ist es die Aufgabe der Erfindung, einen Falztrichter zu schaffen, der eine

stets abschmierfreie Führung der Bahn gewährleistet. Die Aufgabe wird

erfindungsgemäß durch den Anspruch 1 gelöst.Accordingly, it is the object of the invention to provide a former, which is a

lubrication-free guidance of the web is guaranteed at all times. The task is

solved according to the invention by

Die vorliegende Erfindung betrifft das Einleiten von Luft in einen Zwischenraum zwischen Falztrichter und Bahn, ohne die Benutzung von Luftöffnungen oder internen Luftwegen in den Trichterstangen. Die erfindungsgemäßen Ausführungsbeispiele erzielen eine gleichmäßige Luftverteilung auf der Oberfläche des Falztrichters, so daß der benötigte Luftspalt bzw.Luftraum zwischen der Falztrichteroberfläche und der sich bewegenden Bahn minimal ist. Es kann also der Falztrichter für die Erzeugung eines Falzes in der Bahn verwendet werden, ohne daß ein nennenswerter Kontakt zwischen dem Falztrichter und der Bahn stattfindet. Eine Beschädigung der Bahn und die Abnutzung des Falztrichters sind somit minimiert und/oder beseitigt.The present invention relates to the introduction of air into a space between the former and the web without the use of air openings or internal Airways in the funnel rods. Achieve the embodiments of the invention an even air distribution on the surface of the former, so that the required air gap or air space between the former surface and the moving path is minimal. So it can be the former for the production of a Fold can be used in the web without any significant contact between the former and the web. Damage to the web and the Wear of the former is thus minimized and / or eliminated.

Die Ausführungsbeispiele der vorliegenden Erfindung zeigen einen eine Bahn transportierenden Falztrichter mit einer ersten Oberfläche, über die die Bahn bewegt wird, und mit einer Einrichtung, die Luft in einen Zwischenraum zwischen der Bahn und der ersten Oberfläche zuführt, um die Bahn frei schweben zu lassen, wobei die Luftzuführeinrichtung mindestens einen Schlitz umfaßt, der in der ersten Oberfläche gebildet ist und sich über einen wesentlichen Teil der Länge der ersten Oberfläche erstreckt.The exemplary embodiments of the present invention show a web transporting former with a first surface over which the web moves is, and with a device that air in a space between the web and the first surface in order to let the web float freely, the Air supply device comprises at least one slot which is in the first surface is formed and extends over a substantial part of the length of the first surface extends.

Die Merkmale der vorliegenden Erfindung werden in der folgenden Beschreibung bevorzugter Ausführungsbeispiele im Zusammenhang mit den beigefügten, nachstehend aufgeführten Zeichnungen näher erläutert.The features of the present invention will become apparent in the following description preferred embodiments in connection with the accompanying, below listed drawings explained in more detail.

Es zeigen: <

- Fig. 1

- einen Falztrichter nach dem Stand der Technik;

- Fig. 2

- einen weiteren Falztrichter nach dem Stand der Technik;

- Fig. 3

- ein Ausführungsbeispiel eines Falztrichters gemäß vorliegenden Erfindung;

- Fig. 4

- eine teilweise Querschnittansicht des Falztrichters der Fig. 3; und

- Fig. 5A - 5C

- ein alternatives Ausführungsbeispiel eines Falztrichters gemäß vorliegender Erfindung.

- Fig. 1

- a folding former according to the prior art;

- Fig. 2

- a further former according to the prior art;

- Fig. 3

- an embodiment of a former in accordance with the present invention;

- Fig. 4

- a partial cross-sectional view of the former of Fig. 3; and

- 5A-5C

- an alternative embodiment of a former in accordance with the present invention.

Fig. 3 zeigt einen Falztrichter 300 als Teil einer Rotationsdruckmaschine 302. Die

Druckmaschine 302 umfaßt mindestens eine Walze 304, die eine Bahn 326 über eine

erste Oberfläche 306 einer Frontplatte 308, die Teil des Falztrichters 300 ist, zuführt.Fig. 3 shows a former 300 as part of a

Der Falztrichter 300 umfaßt eine Einrichtung, die in den Raum zwischen der Bahn 326

und der ersten Oberfläche 306 Luft zuführt. In einem Ausführungsbeispiel der Erfindung

erfolgt die Luftzufuhr in diesen Zwischenraum durch mindestens einen Schlitz 310

(Fig. 4), der entlang eines wesentlichen Teils der Länge der ersten Oberfläche 306

gebildet ist, so daß sich die Bahn über die erste Oberfläche auf einem Luftkissen bewegt.

Der Bezug auf einen wesentlichen Teil der Länge bedeutet eine Länge, die ausreicht, um

ein angemessenes Luftkissen zwischen der sich bewegenden Bahn 326 und der ersten

Oberfläche 306 zu erzeugen, wobei die Größe (z. B. die Breite), das Gewicht und die

Laufgeschwindigkeit der Bahn zu berücksichtigen sind. Bei der bevorzugten

Ausführungsform der Erfindung ist mindestens ein Schlitz 310 zwischen einer

Schlitzfläche 312 und einer jeweiligen der beiden Trichterstangen 314 und 316 gebildet,

wobei jedoch ebenfalls die Möglichkeit besteht, mehrere Schlitze hintereinander

vorzusehen, sofern dies gewünscht ist. The former 300 includes means that extend into the space between the

In dem in Fig. 3 gezeigten Ausführungsbeispiel ist die Frontplatte 308 in einer gegenüber

den Trichterstangen 314, 316 abgesenkten Position angeordnet. Es wurde auf

individuelle Luftöffnungen in den umfänglichen Bereichen der Trichterstangen (d. h. in

Bereichen der Trichterstangen, in denen diese auf beiden Seiten der Frontplatte 308

freiliegen) verzichtet. Anstelle dieser individuellen Luftöffnungen in den umfänglichen

Bereichen der freiliegenden Teile der Trichterstangen zeigt die Ausführungsform der

Fig. 3 eine geschichtete Konstruktion, bei der von mindestens einem Schlitz 310 Luft

austritt. Ein gleicher Schlitz kann auf der anderen Seite der Frontplatte 308, nämlich

zwischen der Frontplatte 308 und der Trichterstange 316 gebildet sein.In the exemplary embodiment shown in FIG. 3, the

Auf diese Weise werden auf herkömmlichen Falztrichtern Niederdruckbereiche zwischen den Luftlöchern und an den Luftlöchern entstandene Niedrigdruckbereiche beseitigt. Somit kann eine gleichmäßigere Luftverteilung erzielt und ein Luftkissen über den gesamten Zwischenraum gemäß den Ausführungsbeispielen der vorliegenden Erfindung erstellt werden.In this way, low-pressure areas between eliminates the low pressure areas created in the air holes and in the air holes. This allows a more even air distribution and an air cushion over the total gap according to the embodiments of the present invention to be created.

Die in Fig. 3 gezeigten beiden Trichterstangen 314, 316 sind als zwei zylindrische

Stangen konstruiert und derart zusammengesetzt, daß die Mittellinien der zylindrischen

Stangen an einem Punkt zusammentreffen und eine Trichternase 318 bilden. Für die

Verwirklichung der Merkmale der vorliegenden Erfindung können jedoch beliebige

Konstruktionen verwendet werden. Beispielsweise können die zylindrischen Stangen auch

konisch o. ä. ausgebildet sein.The two

Die Frontplatte 308 ist unmittelbar unterhalb der Tangentialebene der beiden

Trichterstangen auf die Falztrichterkonstruktion montiert, so daß die Schlitze 310

zwischen der Frontplatte 308 und den Trichterstangen 314, 316 gebildet sind. Eine

Hinterplatte 320, die eine untere Kante 328 und eine obere Kante 332 (Fig. 3)aufweist,

kann an einer Seite der Trichterstangen 314, 316 angebracht sein, die der Seite

gegenüberliegt, an der die Frontplatte 308 angeordnet ist. In Fig. 3 bewegt sich die

Bahn 326 berührungslos auf einem Luftpolster über die Frontplatte 308. The

Die Frontplatte 308 und die Hinterplatte 320 bilden eine geschichtete Konstruktion, in

die über einen oder mehrere Lufteinlaßöffnungen 322 eine gewünschte Menge Druckluft

eingeleitet werden kann. Die Luftmengen können nach Wunsch in beliebiger Weise

gemessen werden. Wie in Fig. 3 weiterhin gezeigt ist, kann der in den Innenraum

zwischen der Frontplatte 308 und der Hinterplatte 320 geleitete Luftstrom mit einem

herkömmlichen Luftventil 324 reguliert werden. Diese eingelassene Luft erfüllt den

Innenraum, der von der Frontplatte 308, der Hinterplatte 320 und den beiden

Trichterstangen 314, 316 bestimmt wird. Fig. 3 zeigt ferner eine stationäre

Stützplatte 330, die den unteren Teil 318 der Trichterstangen 314, 316 zusammenhält

und einen Teil des Innenraums zwischen der Frontplatte 308, der Hinterplatte 320 und

den Trichterstangen 314, 316 bildet. Gleichermaßen ist eine stationäre obere

Stützplatte 334 an einem oberen Teil des Falztrichters 300 vorgesehen, die an die obere

Kante 332 der Hinterplatte 320 angrenzt. Luft aus dem Innenraum kann nur durch

Schlitze wie den in Fig. 3 gezeigten Schlitz 310, entweichen. Somit bewegt sich die Luft

unter die Bahn 326 und über die Frontplatte in der Weise, daß die Bahn 326 frei

schwebt.The

Wie in den Ausführungsbeispielen der Erfindung gezeigt ist, besteht die Möglichkeit, den

Luftstrom durch die Schlitze 310 entlang der Länge der Schlitze zu regulieren. Bei einer

solchen Regulierung des Luftstroms können Faktoren, wie eine Änderung der Bahnbreite

oder Bahngeschwindigkeit, berücksichtigt werden. Außerdem kann durch solch eine

Regulierung der durch die Schlitze 310 fließende Luftstrom ausgeglichen und somit in

dem Zwischenraum zwischen Bahn und Falztrichter-Frontplatte 308 gleichmäßig verteilt

werden. Eine solche Luftstromregulierung kann auch durch Steuerung der Breite der

Schlitze 310 mittels eines oder mehrerer den Luftstrom steuernden Schlitzverschlüsse 406

erfolgen.As shown in the exemplary embodiments of the invention, there is the possibility of

Regulate air flow through the

Die erfindungsgemäße Fähigkeit, die über den Falztrichter laufende Bahn in einen wohl

definierten Schwebezustand zu versetzen und die zugeführte Druckluft durch die

Schlitze 310 zu steuern, bringt den Vorteil mit sich, daß die Falzbildung in der Bahn

ohne eine erhöhte Abnutzung des Falztrichters stattfindet und keine Gefahr des

Abschmierens der bedruckten Bahn 326 aufgrund einer Verstopfung von Luftöffnungen

besteht.The ability according to the invention, the web running over the former into a well

to set the defined floating state and the compressed air supplied by the

Fig. 4 zeigt einen teilweisen Querschnitt des Falztrichters der Fig. 3. Daraus ist

ersichtlich, daß die Luftzufuhr zur Erstellung eines Luftkissens zwischen der sich

bewegenden Bahn und der Oberfläche 306 der Frontplatte 308 durch Änderung der

Dimension der Schlitze 310 reguliert werden kann. Die Schlitze 310 können

beispielsweise breiter oder schmäler gemacht werden, um den Luftstrom an jegliche

Bahnbreite anzupassen. Wie in Fig. 4 gezeigt ist, wird der Luftstrom so gesteuert, daß

die Luft aus dem Innenraum des Falztrichters nur unterhalb der Bahn 326 entweicht,

während sich diese über die Frontplatte 308 bewegt. Die durch die Schlitze 310

zugeführte Luftmenge wird gesteuert, indem die effektive Breite der Schlitze 310 entlang

ihrer Länge variiert wird.Fig. 4 shows a partial cross section of the former of Fig. 3

can be seen that the air supply to create an air cushion between the

moving web and

In dem Ausführungsbeispiel der Fig. 4 ist mindestens ein Stellknopf 402 vorgesehen, der

um eine Achse 404 drehbar ist und wie eine Schraube gedreht werden kann, um einen

den Luftstrom steuernden Schlitzverschluß 406 seitlich zu verschieben. Der

Schlitzverschluß 406 kann in Reaktion auf eine von dem Stellknopf 402 ausgelöste

Drehbewegung eines Exzenters 408 verschoben werden. Ein Schlitzverschluß 406, der

verschoben worden ist, um den Schlitz 310 zu verschmälern, ist im rechten Teil der

Fig. 4 in gebrochenen Linien dargestellt. Somit kann durch eine derartige Steuerung der

Luftzufuhr ein gewünschtes beständiges Schweben der Bahn 326 über der durch die

Frontplatte 308 definierten ersten Oberfläche 306 erzielt werden.In the exemplary embodiment in FIG. 4, at least one

In Fig. 4 ist auch die Verwendung eines Luftverschlußes 410 zwischen der

Hinterplatte 320 und den Trichterstangen 314, 316 gezeigt. Gleichermaßen können

Luftverschlüsse 410 zwischen der unteren Kante 328 der Hinterplatte 320 und der

Stützplatte 330 verwendet werden, um das untere Teil 318 der in Fig. 3 gezeigten

Trichterstangen zusammenzuhalten. Zusätzlich kann ein Luftverschluß 410 zwischen der

oberen Kante 332 der Hinterplatte 320 und der oberen Stützplatte 334 angebracht sein. In Fig. 4 is also the use of an

Wie in Fig. 4 ebenfalls ersichtlich ist, dienen die Schäfte 412 der Stellknöpfe 402 dazu,

die Frontplatte 308 in einem Abstandsverhältnis zu den Trichterstangen 314, 316 zu

halten und die Schlitze 310 zu bilden. Selbstverständlich kann die in Fig. 4 gezeigte

seitliche Bewegung der Schlitzverschlüsse auch durch eine senkrechte Bewegung der

Frontplatte 308 erfolgen, d. h. durch eine Veränderung des Abstands zwischen

Frontplatte 308 und Hinterplatte 320, um die Luftzufuhr in den Zwischenraum zwischen

der ersten Oberfläche 306 und der Bahn 326 zu steuern. Ferner ist es denkbar, die

Frontplatte 308 in tangentialer Richtung zu verschieben, oder die Schlitze 310, die in

Fig. 3 entlang eines wesentlichen Teils des Falztrichters als kontinuierliche Schlitze

ausgebildet sind, in alternativen Ausführungsformen auch durch mehrere Schlitze von

beliebiger gewünschter Länge entlang des Falztrichters zu ersetzen. Zusätzliche Schlitze

können auch in der Frontplatte 308 parallel zu den Schlitzen 310 vorgesehen sein.As can also be seen in FIG. 4, the

Die Fig. 5A bis 5C stellen ein alternatives Ausführungsbeispiel eines Falztrichters 500

gemäß vorliegender Erfindung dar. Bei der in Fig. 5A gezeigten Ausführung wurden die

für die Bildung der Schlitze 310 verwendeten Trichterstangen und eine Frontplatte durch

eine einzige Trichterplatte 502 mit vorzugsweise konisch geformten Seitenwänden

ersetzt. Die Trichterplatte 502 stellt eine erste Oberfläche dar, die zur Bildung des

Zwischenraums zwischen der sich bewegenden Bahn 512 und dem Falztrichter 500

verwendet wird. Die Schlitze 504 und 506 erstrecken sich entlang eines wesentlichen

Teils der Länge der Trichterplatte 502. Wie bei dem Ausführungsbeispiel der Fig. 3

kann die Trichternase 508 des Falztrichters 500 mit der Trichterplatte 502 abnehmbar

verbunden werden (z. B. mittels Schrauben o. ä.), so daß diese Nase, die zur Bildung

eines Falzes in der laufenden Bahn 512 verwendet wird, auf einfache Weise durch eine

andere Nase 508 ersetzt werden kann. Ein oberer Teil des Falztrichters kann auf eine

stationäre Stütze 510 montiert werden.5A to 5C illustrate an alternative embodiment of a former 500

according to the present invention. In the embodiment shown in FIG. 5A, the

funnel rods and a faceplate used to form the slots 310

a

Bei dem Ausführungsbeispiel der Fig. 5A kann eine Luftstromsteuerung in ähnlicher

Weise, wie dies in bezug auf die Ausführungsform der Fig. 3 beschrieben ist, erfolgen.

Das heißt, es kann in dem Innenraum zwischen der Trichterplatte 502 und einer

Hinterplatte (in Fig. 5A nicht gezeigt) eine Luftstromregulierung stattfinden. Die

Luftstromregulierung kann in gleicher Weise wie bei der Ausführungsform von Fig. 3

und 4 durch Steuerung der Breite der Schlitze in der Trichterplatte 502 mittels eines oder

mehrerer Schlitzverschlüsse 406 erfolgen. Das Verschließen des Innenraums kann in

gleicher Weise, wie dies mit Bezug auf Fig. 3 beschrieben ist, vorgenommen werden.In the embodiment of FIG. 5A, airflow control may be similar

Way, as described in relation to the embodiment of FIG. 3, take place.

That is, it can be in the interior between the

Fig. 5B zeigt eine Vorderansicht des Falztrichters der Fig. 5A, bei der die Bahn 512 in

eine senkrecht nach unten verlaufende Richtung bewegt wird. Die Kanten der Bahn

werden über die konischen Seiten der Trichterplatte 502 nach unten gezogen, um so

einen Falz 514 in der sich bewegenden Bahn zu bilden. Der Falz als solcher wird dabei

durch Walzen 516, 518, die mit den sich zuspitzenden, konisch geformten Seitenwänden

der Trichterplatte 502 zusammenwirken, geformt.FIG. 5B shows a front view of the former of FIG. 5A, with the

Fig. 5C zeigt eine Seitenansicht des in Fig. 5B dargestellten Vorgangs. Wie darin

ersichtlich ist, bewegt sich die Bahn 512 über eine Trichtereinlaufwalze 520 der

Druckmaschine und weiter über den Falztrichter 500 und wird gefalzt; dann verläßt die

Bahn 512 den unteren, eine verminderte Breite aufweisenden Teil des Falztrichters 500.FIG. 5C shows a side view of the process shown in FIG. 5B. How in it

as can be seen, the

Es soll verstanden sein, daß die in den Fig. 3-5 darstellten Ausführungsformen nur Beispiele sind und daß es eine Reihe von Variationen gibt. Beispielsweise können die in diesen Figuren dargestellten Schlitze in jeder beliebigen Art und Weise gestaltet sein, um einen gleichmäßigen Luftstrom in dem Zwischenraum zwischen der Bahn und der Oberfläche des Falztrichters, über die sich die Bahn bewegt, zu erzielen. Zusätzlich können die den Luftstrom steuernden Schlitzverschlüsse 406 in alternativen Ausführungsbeispielen anders gestaltet sein. Beispielsweise können sich die Schlitzverschlüsse entlang der Länge der Schlitze erstrecken. Alternativ kann in Abhängigkeit des vom Anwender gewünschten Ausmaßes der Luftstromsteuerung eine Anzahl von individuellen Luftstromsteuerungsverschlüssen entlang der Länge der Schlitze entweder aneinandergrenzend oder voneinander beabstandet angeordnet sein. It should be understood that the embodiments shown in Figs. 3-5 are only Examples are and that there are a number of variations. For example, the in slots shown in these figures can be designed in any manner a uniform air flow in the space between the web and the To achieve the surface of the former, over which the web moves. additionally the air flow control slits 406 may alternatively Embodiments can be designed differently. For example, the Slot fasteners extend the length of the slots. Alternatively, in Depending on the extent of air flow control desired by the user Number of individual airflow control closures along the length of the Slots are either adjacent or spaced apart.

- 100100

- Falztrichter (Fig. 1)Folder (Fig. 1)

- 102102

- Bahntrain

- 104104

- breiter Teil des Falztrichters 100wide part of the former 100

- 106106

- unterer Teil des Falztrichters 100lower part of the former 100

- 108108

-

Luftlöcher der Trichterstangen 110, 111Air holes in the

funnel rods - 110110

- Trichterstangehopper bar

- 111111

- Trichterstangehopper bar

- 112112

- Seitenfläche des Falztrichters 100Side surface of the former 100

- 114114

- Seitenfläche des Falztrichters 100Side surface of the former 100

- 200200

- Falztrichter (Fig. 2)Folder (Fig. 2)

- 202202

- Trichterstangehopper bar

- 204204

- Trichterstangehopper bar

- 300300

- Falztrichter (Fig. 3)Folder (Fig. 3)

- 302302

- RotationsdruckmaschineRotary press

- 304304

- Walzeroller

- 306306

-

erste Oberfläche der Frontplatte 308first surface of

front panel 308 - 308308

- Frontplattefront panel

- 310310

- Schlitzslot

- 312312

- Schlitzflächeslot surface

- 314314

- Trichterstangehopper bar

- 316316

- Trichterstangehopper bar

- 318318

- Trichternaseformer nose

- 320320

- Hinterplatterear plate

- 322322

- LufteinlaßöffnungAir inlet opening

- 324324

- Luftventilair valve

- 326326

- Bahntrain

- 328328

-

untere Kante der Hinterplatte 320lower edge of

rear plate 320 - 330330

- stationäre Stützplatte stationary support plate

- 332332

-

obere Kante der Hinterplatte 320top edge of

backplate 320 - 334334

- stationäre Stützplattestationary support plate

- 402402

- Stellknopf (Fig. 4)Adjustment button (Fig. 4)

- 404404

- Achse des StellknopfesAxis of the control knob

- 406406

- Schlitzverschlüsseslot closures

- 408408

- Exzentereccentric

- 410410

- Luftverschlußair lock

- 412412

-

Schaft des Stellknopfes 402Shaft of the adjusting

knob 402 - 500500

- Falztrichter (Fig. 5A-5C)Folder (Fig. 5A-5C)

- 502502

- Trichterplatteformer board

- 504504

- Schlitzslot

- 506506

- Schlitzslot

- 508508

- Trichternaseformer nose

- 510510

- stationäre Stützestationary support

- 512512

- Bahntrain

- 514514

- Falz in der BahnFold in the web

- 516516

- Walzeroller

- 518518

- Walzeroller

- 520520

- TrichtereinlaufwalzeFormer inlet roller

Claims (11)

- Folding former for folding a moving paper web in a web-fed rotary printing machine, having a first surface (306; 502), over which the web (326; 512) is transported, an air-filled internal space in the folding former (3, 300, 500) and a device for supplying air from the internal space into an intermediate space formed by the first surface (306; 502) and the web (326; 512), characterized in that at least one slot (310; 504, 506) is formed in the first surface, through which the air escapes from the internal space into the intermediate space, the slot extending over a substantial part of the length of the first surface.

- Folding former according to Claim 1, characterized in that this additionally comprises at least two rods (314, 316) for folding the web and a first plate (308) and a second plate (320), which are fitted to mutually opposite sides of the two rods (314, 316), the at least one slot (310) being formed between the first plate (308) and at least one of the two rods (314, 316).

- Folding former according to Claim 1 or 2, characterized in that this also comprises at least one additional slot (310) between the other of the at least two rods (314, 316) and the first plate (308), in order to let air into the intermediate space.

- Folding former according to either of Claims 2 and 3, characterized in that, between the first plate (308), the second plate (320) and the two rods (314, 316), an internal space is defined into which the air is introduced as a predefined air flow.

- Folding former according to one of the preceding claims, characterized in that this also comprises a device for regulating the width of the at least one slot (310), in order to control the air flow introduced into the intermediate space.

- Folding former according to Claim 5, characterized in that the device for regulating the width also comprises at least one moveable slot closure (406) for controlling the air flow and a device (402) for regulating the position of the at least one slot closure (406) within the at least one slot (310).

- Folding former according to Claim 6, characterized in that the device (402) for regulating the position of the at least one slot closure (406) also comprises at least one eccentric (408), which his operatively connected to the at least one slot closure (406) and comprises a rotatable setting knob (402) for regulating the position of the eccentric (408).

- Folding former according to Claim 5, characterized in that the device for regulating the slot width changes the distance between a front plate (308) and the parts (314, 316) of the folding former which define the internal space.

- Folding former according to Claim 1, characterized in that the first surface (306) is formed as a former plate (502) which is matched to the shape of the folding former (500) and into which the at least one slot (504, 506) is directly introduced.

- Folding former according to Claim 9, characterized in that a total of two slots (504, 506) are introduced into the former plate (502) in the region of the side edges of the latter.

- Folding former according to either of Claims 9 and 10, characterized in that at the tapering end of the former plate (502), a former nose (508) is provided, which is detachably connected to the former plate (502).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US09/048,011 US5947411A (en) | 1998-03-26 | 1998-03-26 | Method and apparatus for air flotation |

| US48011 | 1998-03-26 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0945385A2 EP0945385A2 (en) | 1999-09-29 |

| EP0945385A3 EP0945385A3 (en) | 1999-12-22 |

| EP0945385B1 true EP0945385B1 (en) | 2002-10-02 |

Family

ID=21952278

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99101732A Expired - Lifetime EP0945385B1 (en) | 1998-03-26 | 1999-02-10 | Folding triangle of a folding apparatus of a rotary printing press |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US5947411A (en) |

| EP (1) | EP0945385B1 (en) |

| JP (1) | JP4195143B2 (en) |

| DE (2) | DE19905387A1 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10031814A1 (en) | 2000-06-30 | 2002-01-10 | Heidelberger Druckmasch Ag | Device for contact-free guiding of material web over surface has facility whereby volume of gaseous medium flowing beneath web from air cushion is variable by means of adjustable closing element regardless of web format |

| DE10057886A1 (en) * | 2000-11-22 | 2002-05-23 | Heidelberger Druckmasch Ag | Turning bar arrangement for strip-processing rotation printing machine has closure elements movable within casing on rails and moved independently of each other by drives |

| WO2004037537A2 (en) * | 2002-10-19 | 2004-05-06 | Koenig & Bauer Aktiengesellschaft | Guiding elements for a printing unit |

| US20110064509A1 (en) * | 2009-09-17 | 2011-03-17 | Goss International Americas, Inc. | Air delivery apparatus for delivering air to a moving substrate in a printing press |

| DE102012201238B3 (en) * | 2012-01-30 | 2012-12-27 | Koenig & Bauer Aktiengesellschaft | Device of a web-fed rotary printing machine for processing one or more printed webs and method for forming a longitudinally folded web |

| US9336466B2 (en) | 2014-09-08 | 2016-05-10 | Fuji Xerox Co., Ltd. | Printing apparatus including a moving guiding portion |

| DE102021103766A1 (en) | 2021-02-17 | 2022-08-18 | Manroland Goss Web Systems Gmbh | Funnel nose and fold former |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2619057A (en) * | 1951-02-15 | 1952-11-25 | Dwight W Ellis Jr | Web folder and stitcher apparatus |

| DE1142878B (en) * | 1961-01-28 | 1963-01-31 | Maschf Augsburg Nuernberg Ag | Fold former for longitudinal folding of paper webs processed in rotary printing machines |

| US3191926A (en) * | 1963-02-06 | 1965-06-29 | Avisun Corp | Web folding apparatus |

| BE680532A (en) * | 1966-05-04 | 1966-10-17 | ||

| US4043495A (en) * | 1975-03-03 | 1977-08-23 | Frank Sander | Air cushioned turn bar |

| DE2657789A1 (en) * | 1976-12-21 | 1978-06-29 | Maschf Augsburg Nuernberg Ag | DEVICE FOR PULLING A PAPER TRAIL INTO THE FOLDER OF A ROTARY PRINTING MACHINE |

| US4308984A (en) * | 1978-05-11 | 1982-01-05 | Vits Maschinenbau Gmbh | Jet-conveyor box for floatingly guiding a conveyed strip or sheet material |

| DE2921757A1 (en) * | 1979-05-29 | 1980-12-04 | Maschf Augsburg Nuernberg Ag | METHOD FOR PRODUCING A FUNNEL SHEET FOR A FOLDING HOPPER OF A ROTARY PRINTING MACHINE, AND A FUNNEL SHEET PRODUCED THEREFORE |

| FI60261C (en) * | 1980-03-28 | 1981-12-10 | Valmet Oy | OEVERTRYCKSMUNSTYCKE FOER BEHANDLING AV BANOR |

| DE3215472C2 (en) * | 1982-04-24 | 1984-02-23 | M.A.N.- Roland Druckmaschinen AG, 6050 Offenbach | Reversing bar surrounded by air |

| US4848633A (en) * | 1986-02-28 | 1989-07-18 | Thermo Electron Web Systems, Inc. | Non-contact web turning and drying apparatus |

| US4698914A (en) * | 1986-05-29 | 1987-10-13 | E. I. Du Pont De Nemours And Company | Setting/drying process for flexible web coating |

| US4726502A (en) * | 1986-07-07 | 1988-02-23 | Cryderman Gary G | Apparatus for entraining and directing a wet paper web |

| FI77708C (en) * | 1987-09-28 | 1989-04-10 | Valmet Paper Machinery Inc | ARRANGEMANG AV OEVERTRYCKSMUNSTYCKEN AVSETT FOER BEHANDLING AV BANOR. |

| US5233919A (en) * | 1992-06-18 | 1993-08-10 | Heidelberg Harris Gmbh | Angle bar air regulating device for turning a web |

| DE4428593A1 (en) * | 1993-11-04 | 1995-05-11 | Heidelberger Druckmasch Ag | Apparatus and method for measuring and regulating the tension of a web in the former area of a folder for a printing press |

| DE4435528C2 (en) * | 1994-10-05 | 1997-09-04 | Roland Man Druckmasch | Folder for a printing press |

| DE19607397A1 (en) * | 1996-02-28 | 1997-09-04 | Heidelberger Druckmasch Ag | Device and method for guiding sheet material in a printing press, in particular in a sheet-fed offset printing press |

| DE19619547A1 (en) * | 1996-05-15 | 1997-11-27 | Vits Maschinenbau Gmbh | Air cushion nozzle and device for heat treatment of a continuously moving web with air cushion nozzles |

-

1998

- 1998-03-26 US US09/048,011 patent/US5947411A/en not_active Expired - Lifetime

-

1999

- 1999-02-10 DE DE19905387A patent/DE19905387A1/en not_active Withdrawn

- 1999-02-10 EP EP99101732A patent/EP0945385B1/en not_active Expired - Lifetime

- 1999-02-10 DE DE59902899T patent/DE59902899D1/en not_active Expired - Lifetime

- 1999-03-26 JP JP08438899A patent/JP4195143B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP0945385A3 (en) | 1999-12-22 |

| DE59902899D1 (en) | 2002-11-07 |

| JPH11314837A (en) | 1999-11-16 |

| EP0945385A2 (en) | 1999-09-29 |

| US5947411A (en) | 1999-09-07 |

| JP4195143B2 (en) | 2008-12-10 |

| DE19905387A1 (en) | 1999-09-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69923544T2 (en) | Paper web feed device in a web-fed rotary printing press with a web tension regulator | |

| DE2857473C2 (en) | ||

| DE2708390B2 (en) | Method and device for controlling the thickness of webs | |

| DE69308064T2 (en) | Air guiding device with a drain plate for turning a moving web | |

| EP0945385B1 (en) | Folding triangle of a folding apparatus of a rotary printing press | |

| EP0071769B1 (en) | Device for preventing the curling-up of the front edges of sheets in a delivery apparatus for a rotary sheet-printing machine | |

| DE19651739A1 (en) | Web coating applicator | |

| DD159142A5 (en) | DEVICE FOR PRODUCING TWO CONTINUOUS CIGARETTE TRACKS AT THE SAME TIME | |

| DE69004704T2 (en) | Lid for a card. | |

| DE2549726B2 (en) | Machine for the production of fiber webs | |

| EP0406529B1 (en) | Coating device | |

| DE4024229C1 (en) | ||

| DE3229402C2 (en) | DEVICE ON A CARD OR CRAWLE FOR FLEECE PRODUCTION | |

| DE2736644B1 (en) | Headbox | |

| DE1511218B2 (en) | PAPER MASH FEEDING DEVICE FOR PAPER MACHINES | |

| DE4409415C5 (en) | Metering device for a headbox of a paper machine | |

| DE69530679T2 (en) | DEVICE FOR CONTROLLING THE ROLLS OF THE ROLLS IN A MACHINE FOR CURVING GOODS | |

| DE4328997C2 (en) | Wet section of a twin wire GAP former | |

| DE2800547B2 (en) | Headbox for paper machines | |

| DE3940357A1 (en) | MACHINE FOR THE SIMULTANEOUS PRODUCTION OF TWO CONTINUOUS CIGARETTE STRIPS | |

| EP0570733A1 (en) | Coating apparatus for applying a coating colour onto a paper web | |

| DE4237310C2 (en) | Headbox with device for adjusting the fiber orientation | |

| EP0887462A2 (en) | Machine to manufacture a material web | |

| DE9206750U1 (en) | Application unit for applying coating colour to a paper web | |

| DE10324711A1 (en) | headbox |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): CH DE FR GB IT LI |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19991126 |

|

| AKX | Designation fees paid |

Free format text: CH DE FR GB IT LI |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: BURKE, DAVID CHARLES Inventor name: ALBERT, KEVIN FRANCIS |

|

| 17Q | First examination report despatched |

Effective date: 20010913 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE FR GB IT LI |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20021002 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59902899 Country of ref document: DE Date of ref document: 20021107 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20021127 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030703 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20110223 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20110223 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20120306 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20120228 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120229 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120210 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20131031 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59902899 Country of ref document: DE Effective date: 20130903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130903 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130228 |